A whole-process supervision method for food safety of a public canteen

A technology for food safety and public canteens, which is applied in the field of food safety monitoring, can solve the problems of fresh food preservation, insufficient supervision of food sample retention, weak canteen management self-discipline, and incomplete work accounts, etc., to achieve a perfect food safety management system , to ensure the healthy growth of mind and body, and to improve the effect of food safety supervision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiment of the present invention will be explained in detail below in conjunction with the accompanying drawings. The examples given are only for the purpose of illustration, and cannot be interpreted as limiting the present invention. The accompanying drawings are only for reference and description, and do not constitute the scope of patent protection of the present invention. limitations, since many changes may be made in the invention without departing from the spirit and scope of the invention.

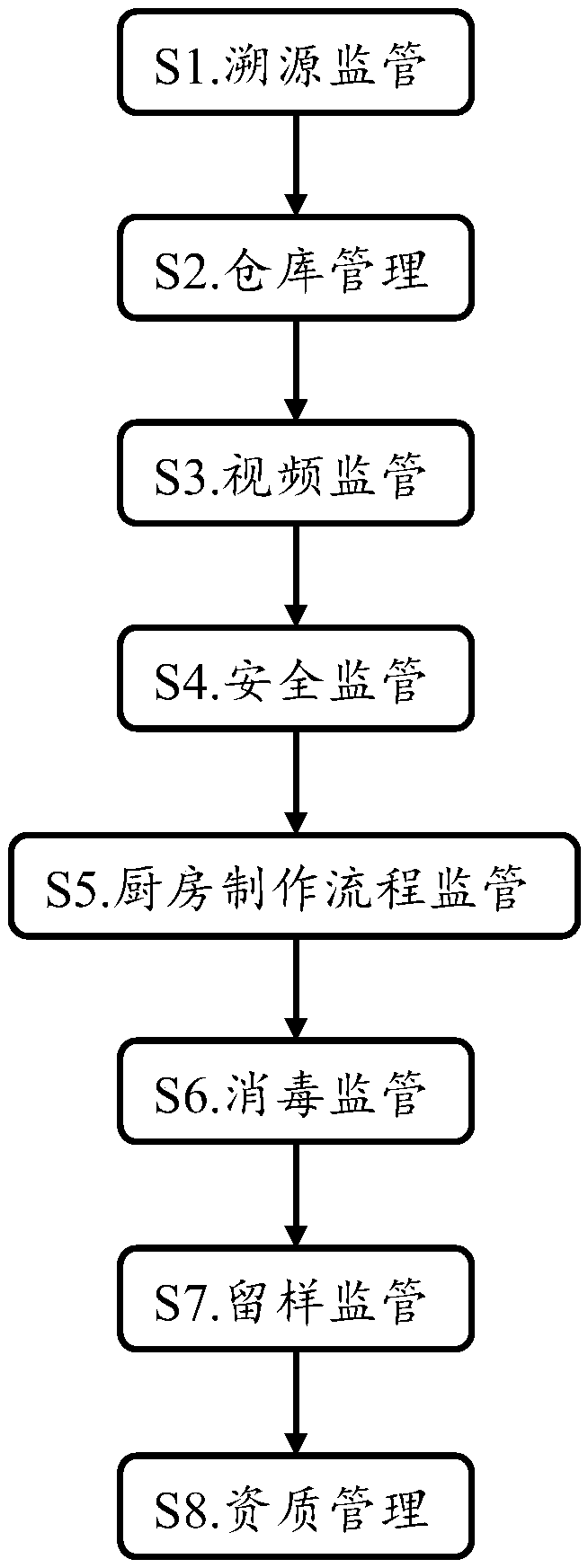

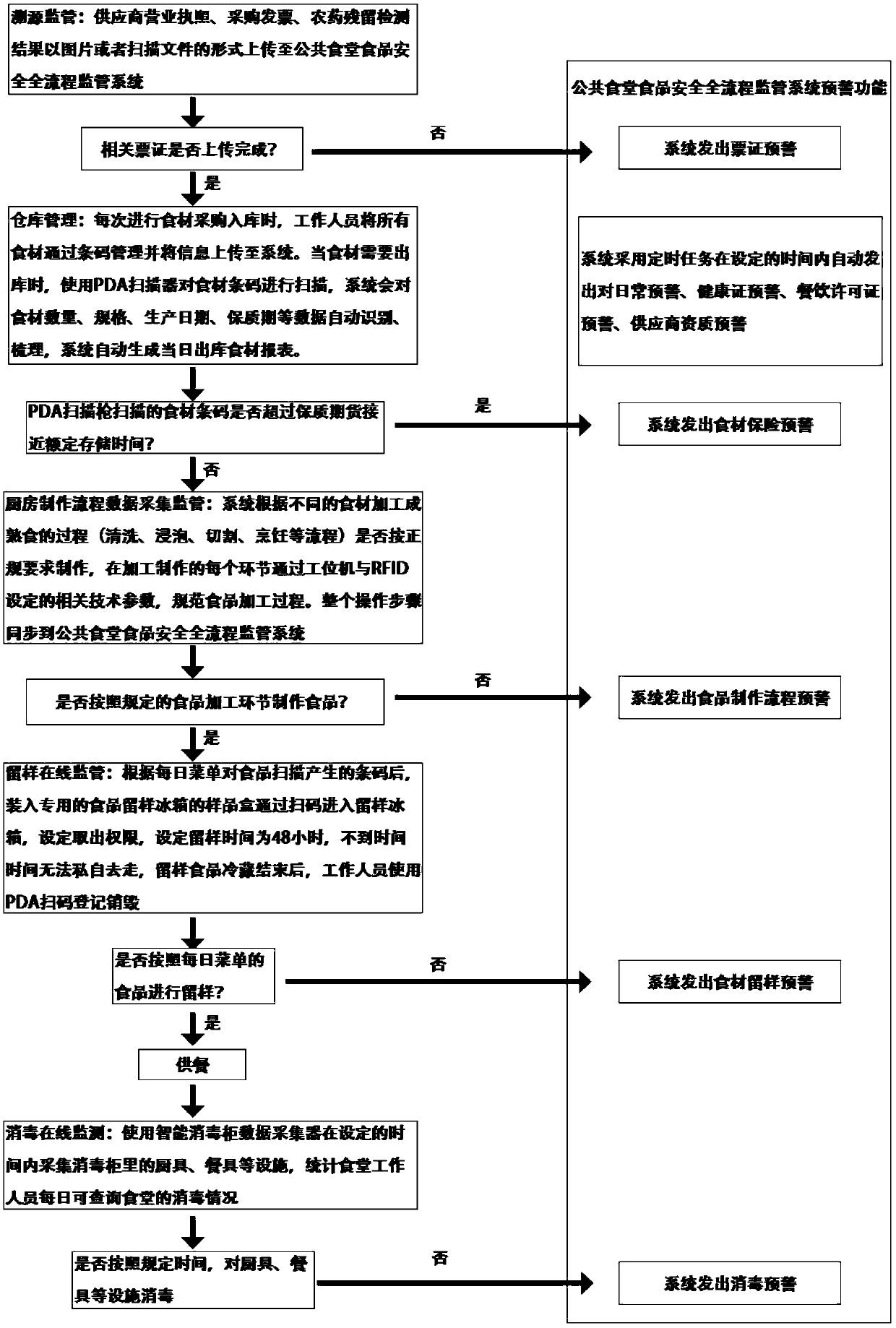

[0034] A full-process supervision method for food safety in public canteens provided by the embodiment of the present invention, the steps of which are as follows: figure 1 As shown, the main operation process of this method can be referred to figure 2 . In this embodiment, the whole-process supervision method for food safety in a public canteen includes the following steps:

[0035] S1. Traceability supervision: perform ticket registration, ticket verification, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com