Patents

Literature

95results about How to "Reduce dissatisfaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

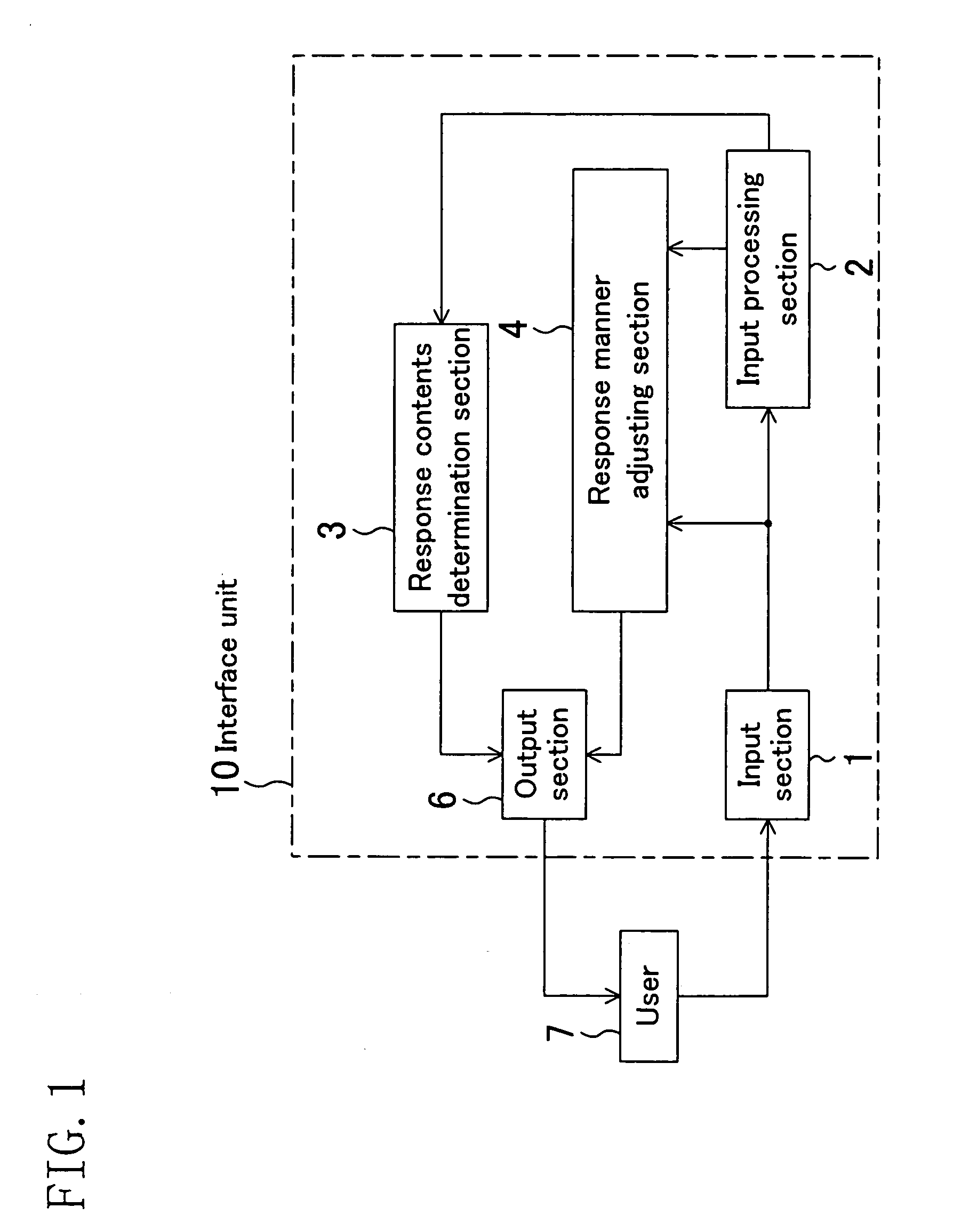

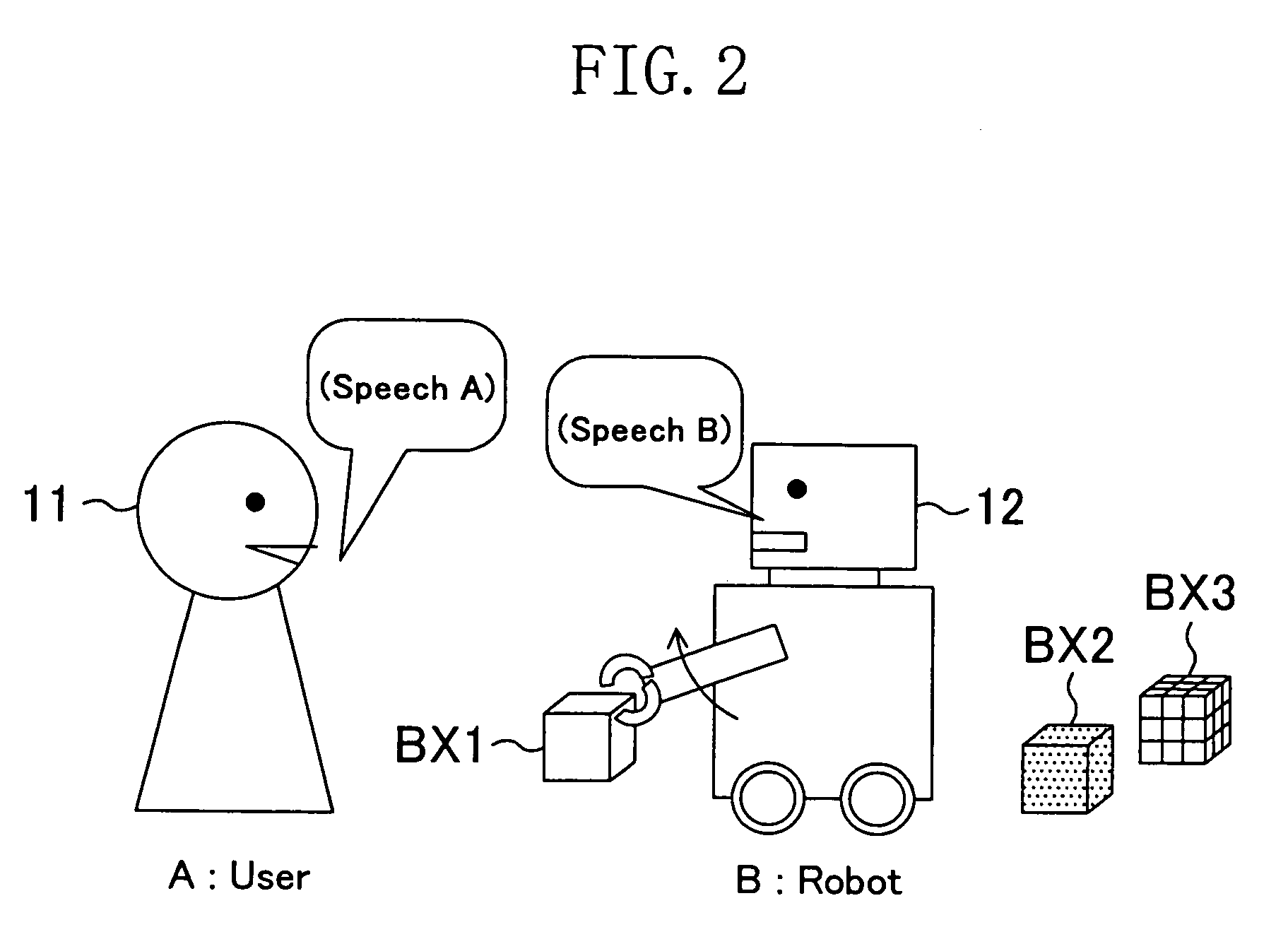

User adaptive system and control method thereof

InactiveUS7684977B2Strong interactionSmoother interactionSpeech recognitionSpeech synthesisContent determinationSpeech sound

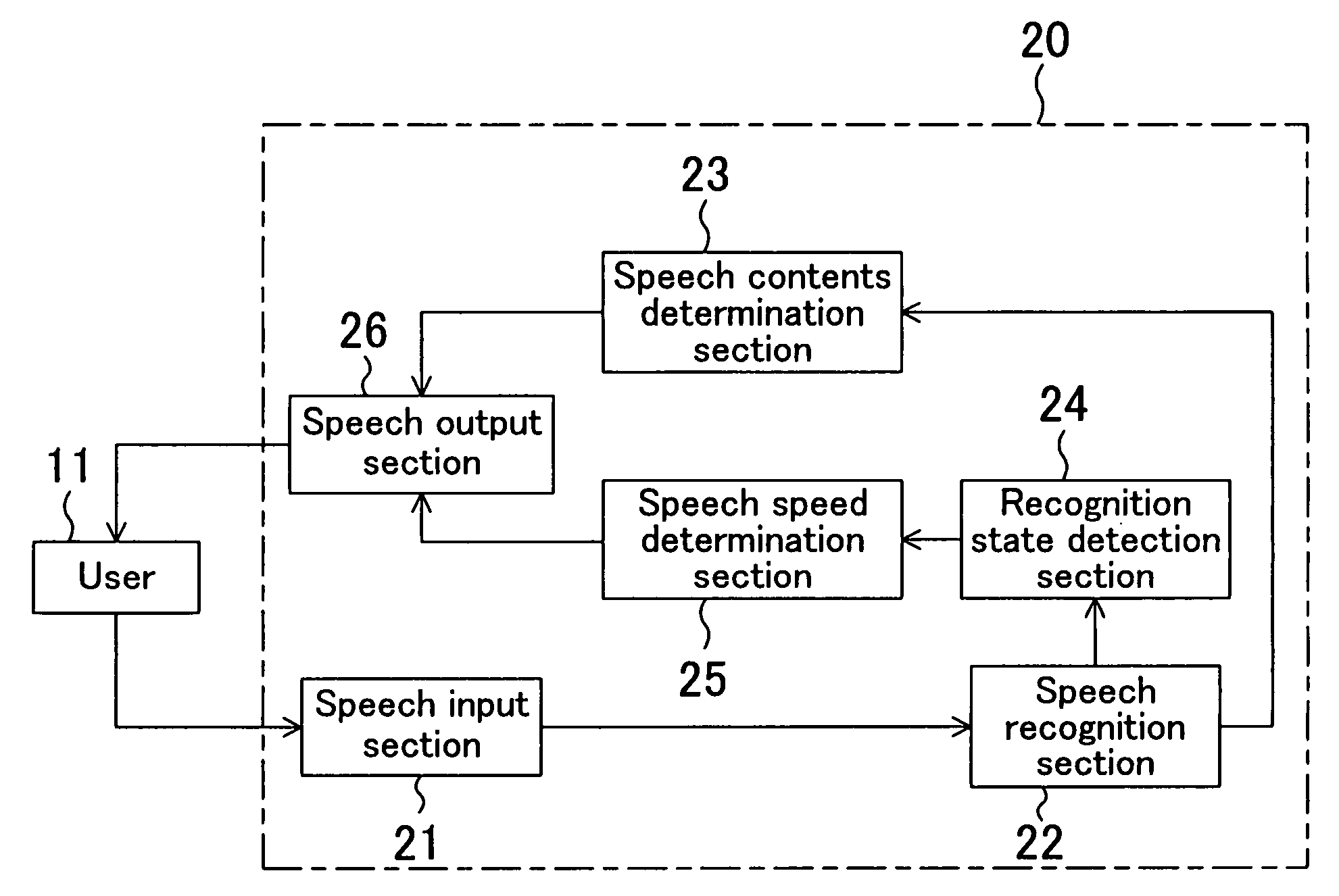

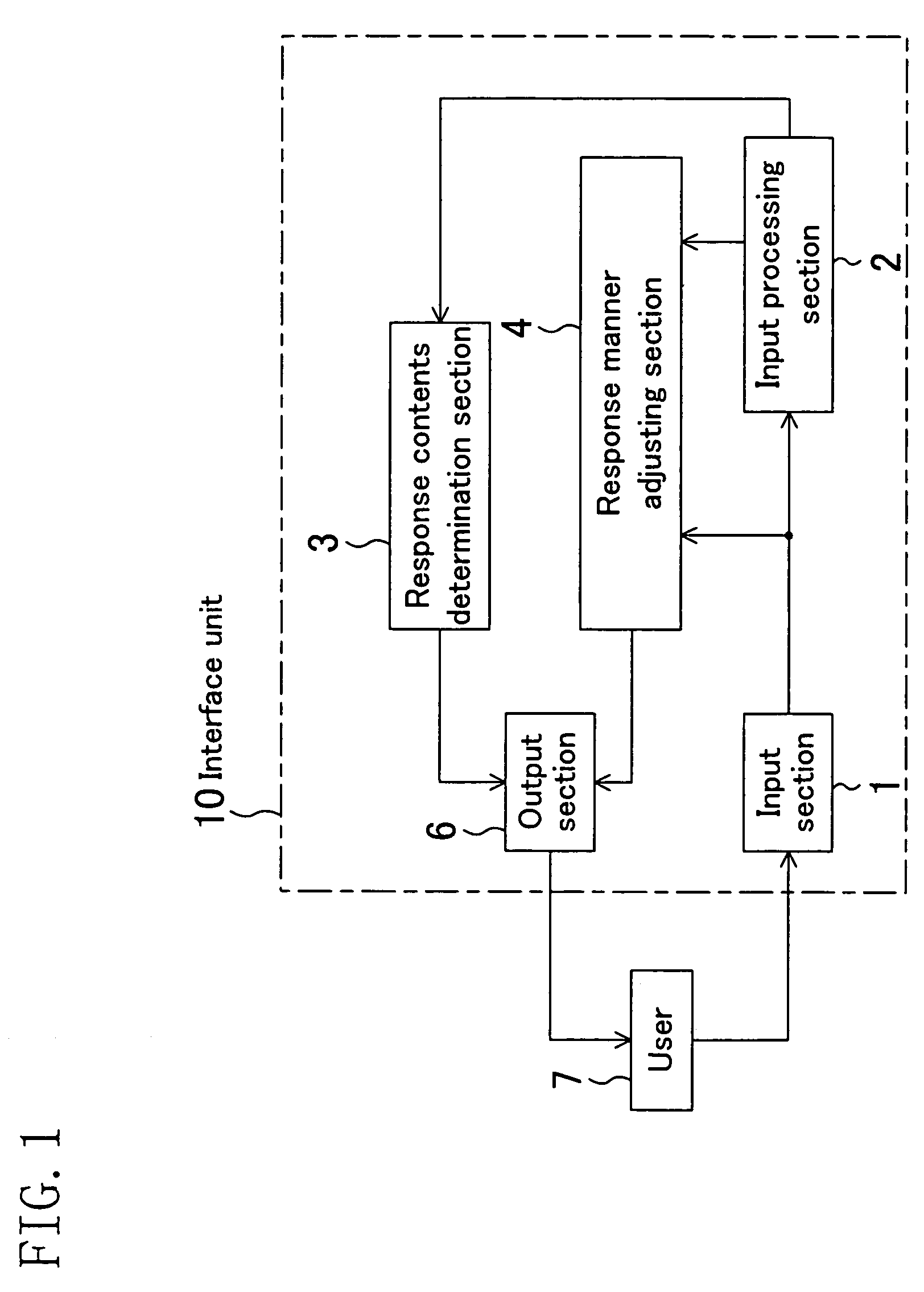

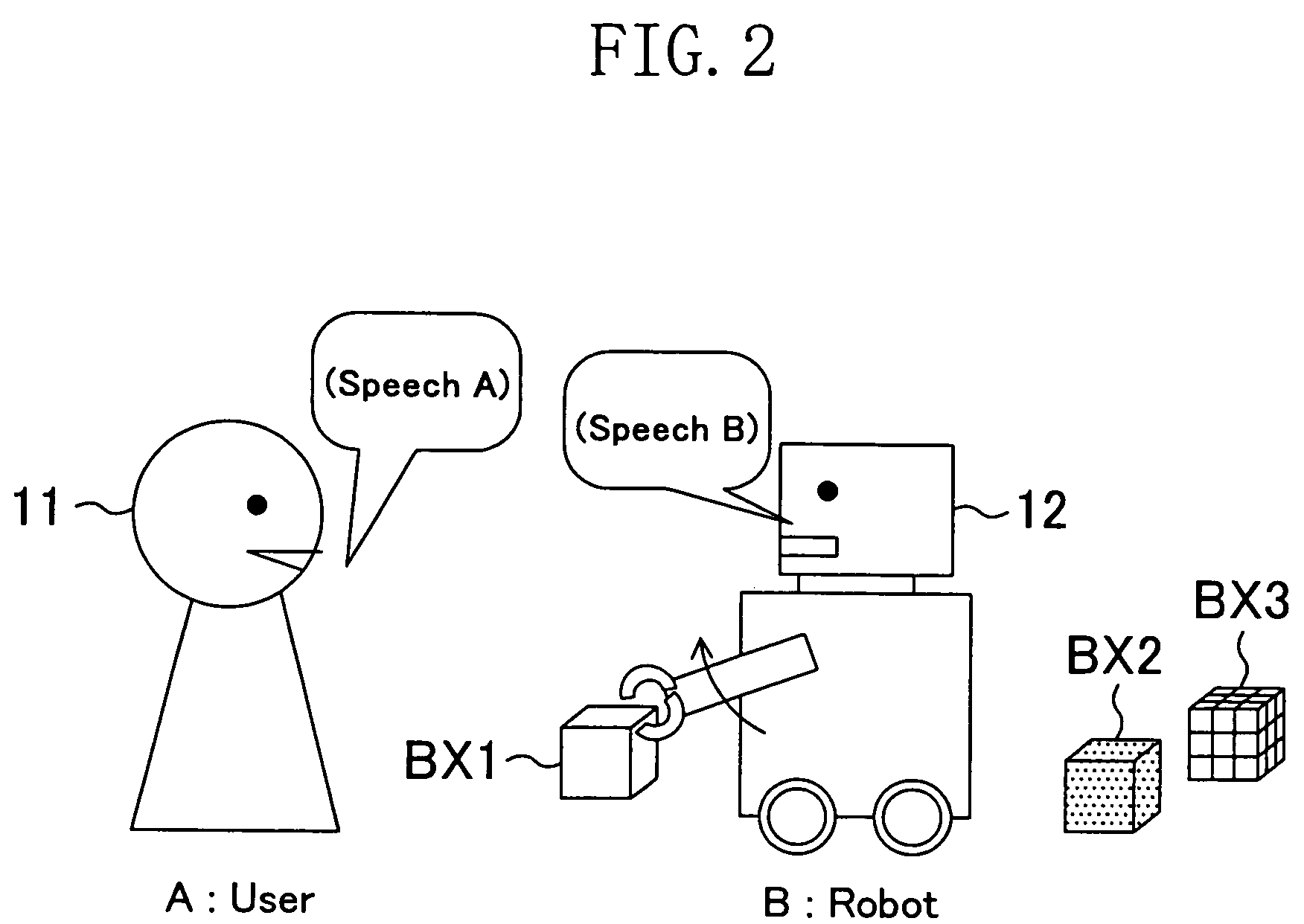

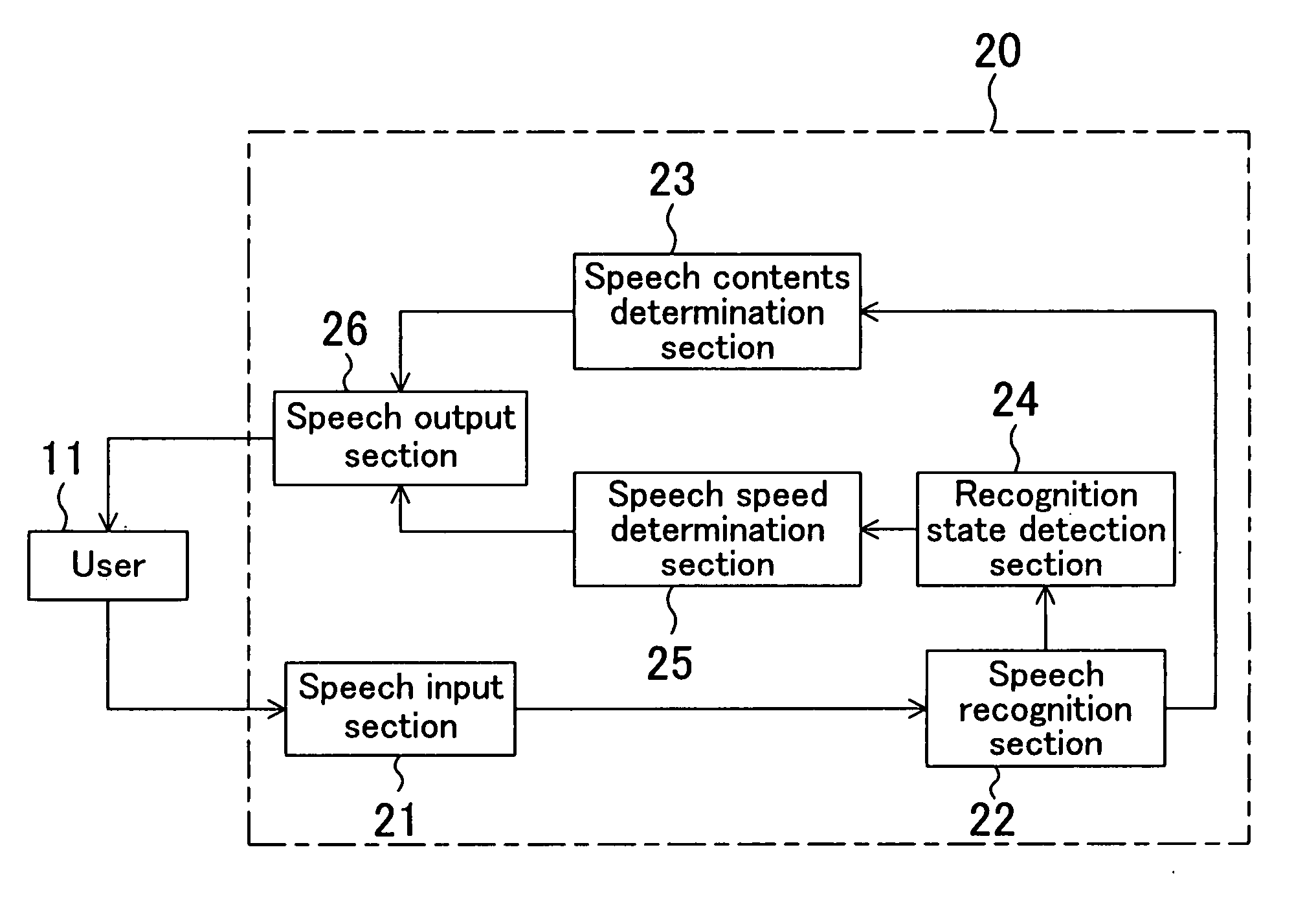

In an interface unit, an input section obtains an input signal of user's speech or the like and an input processing section processes the input signal and detects information relating to the user. On the basis of the detection result, a response contents determination section determines response contents to the user. While, a response manner adjusting section adjusts a response manner to the user, such as speech speed and the like, on the basis of the processing state of the input signal, the information relating to the user detected from the input signal, and the like.

Owner:SOVEREIGN PEAK VENTURES LLC

User adaptive system and control method thereof

InactiveUS20060287850A1Smooth communicationStrong interactionDigital computer detailsSound input/outputContent determinationSpeech sound

In an interface unit, an input section obtains an input signal of user's speech or the like and an input processing section processes the input signal and detects information relating to the user. On the basis of the detection result, a response contents determination section determines response contents to the user. While, a response manner adjusting section adjusts a response manner to the user, such as speech speed and the like, on the basis of the processing state of the input signal, the information relating to the user detected from the input signal, and the like.

Owner:SOVEREIGN PEAK VENTURES LLC

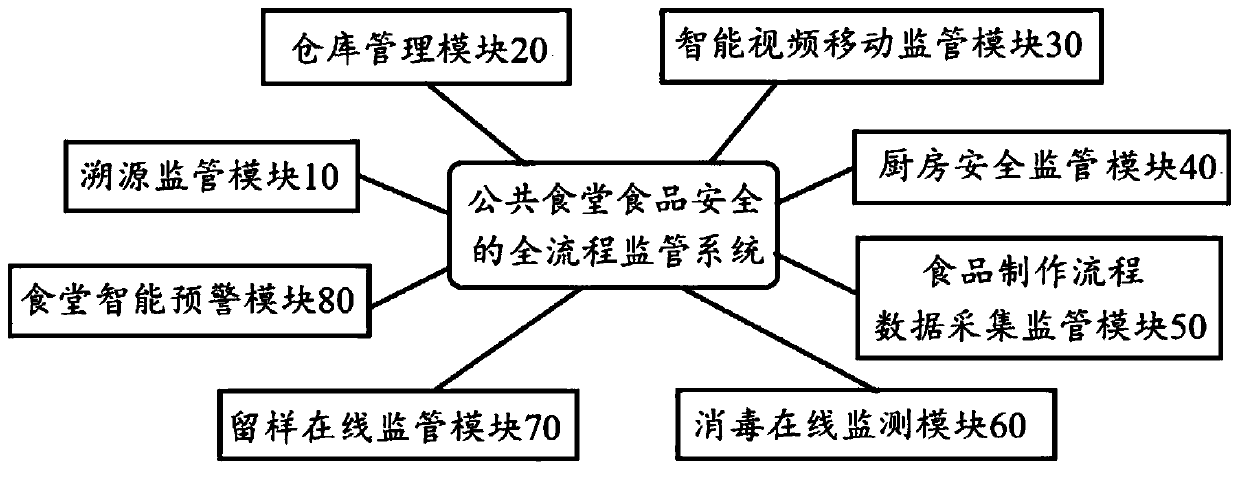

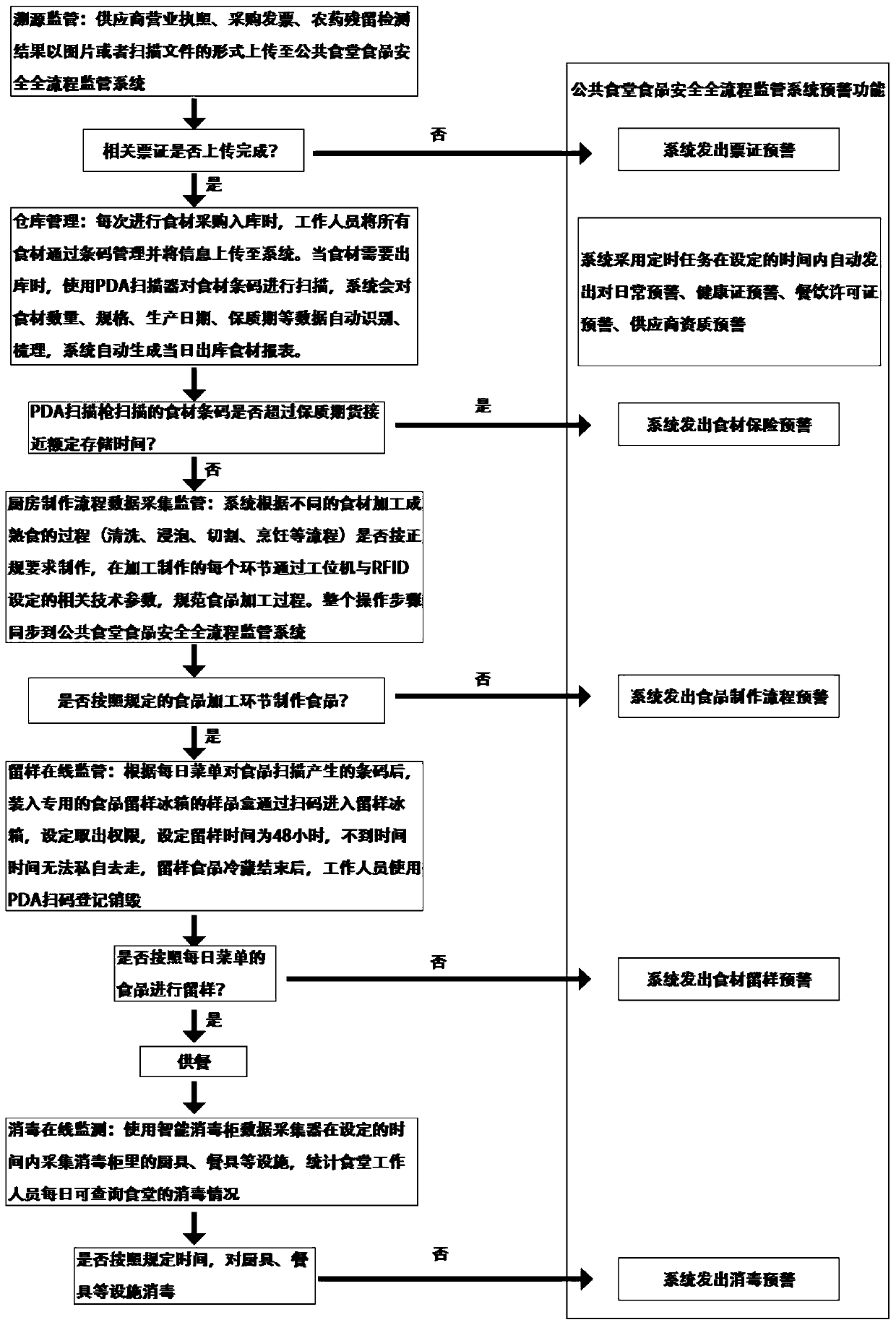

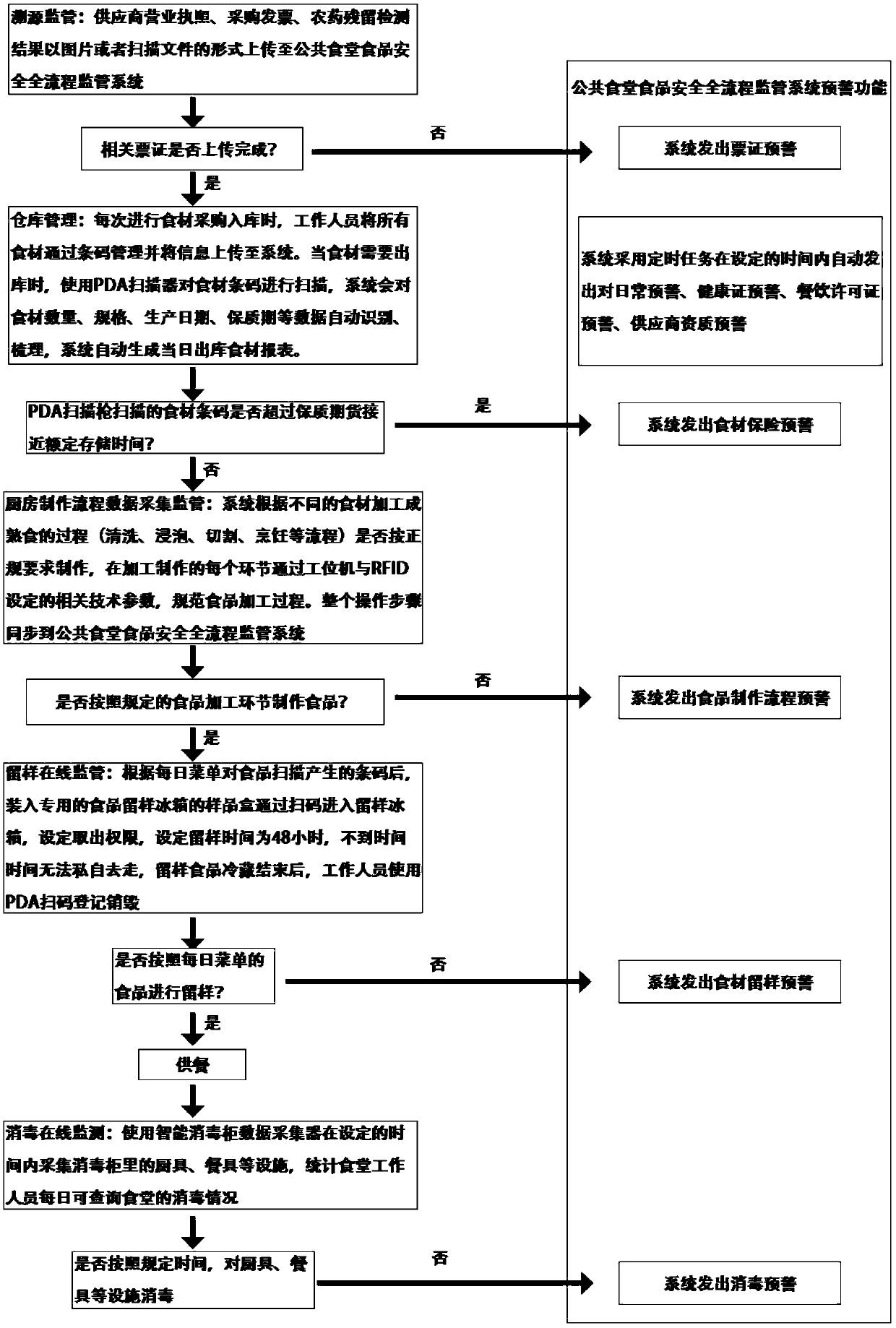

A whole-process supervision system for food safety of a public canteen

PendingCN109697685AImprove food safety regulationAdvance modernizationCo-operative working arrangementsResourcesStorage garageMeal preparation

The invention relates to the technical field of food safety monitoring. The whole-process supervision system comprises a traceability supervision module, a warehouse management module, an intelligentvideo mobile supervision module, a kitchen safety supervision module, a food making process data acquisition supervision module, a disinfection online monitoring module, a reserved sample online supervision module and a canteen intelligent early warning module. According to the invention, the Internet of Things is fully utilized; big data, cloud computing, techniques for intelligent analysis of video and the like, supervision for comprehensively improving food safety, propelling food safety management modernization, procurement and acceptance from food raw materials, operation processes of processing and cooking, meal preparation, cleaning and disinfection of meal appliances, sample reservation and the like can be standardized, refined, efficient, informationized and standardized in supervision, food safety consciousness of schools and kindergarten canteens is enhanced, food safety management systems are perfected, food safety responsibility is put into practice, processing and manufacturing behaviors are standardized, and food poisoning events are prevented and controlled.

Owner:惠州市格讯信息产业有限公司 +1

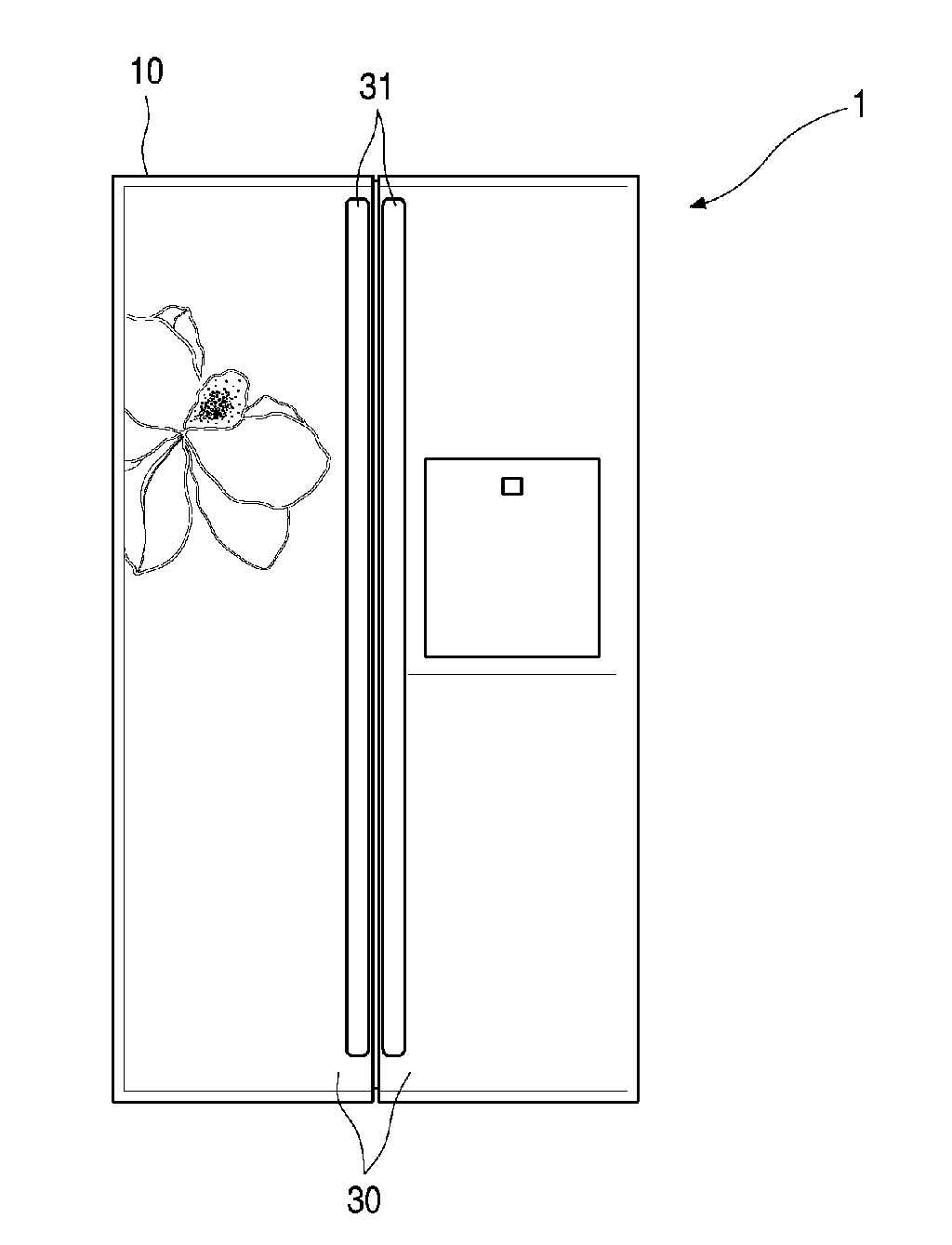

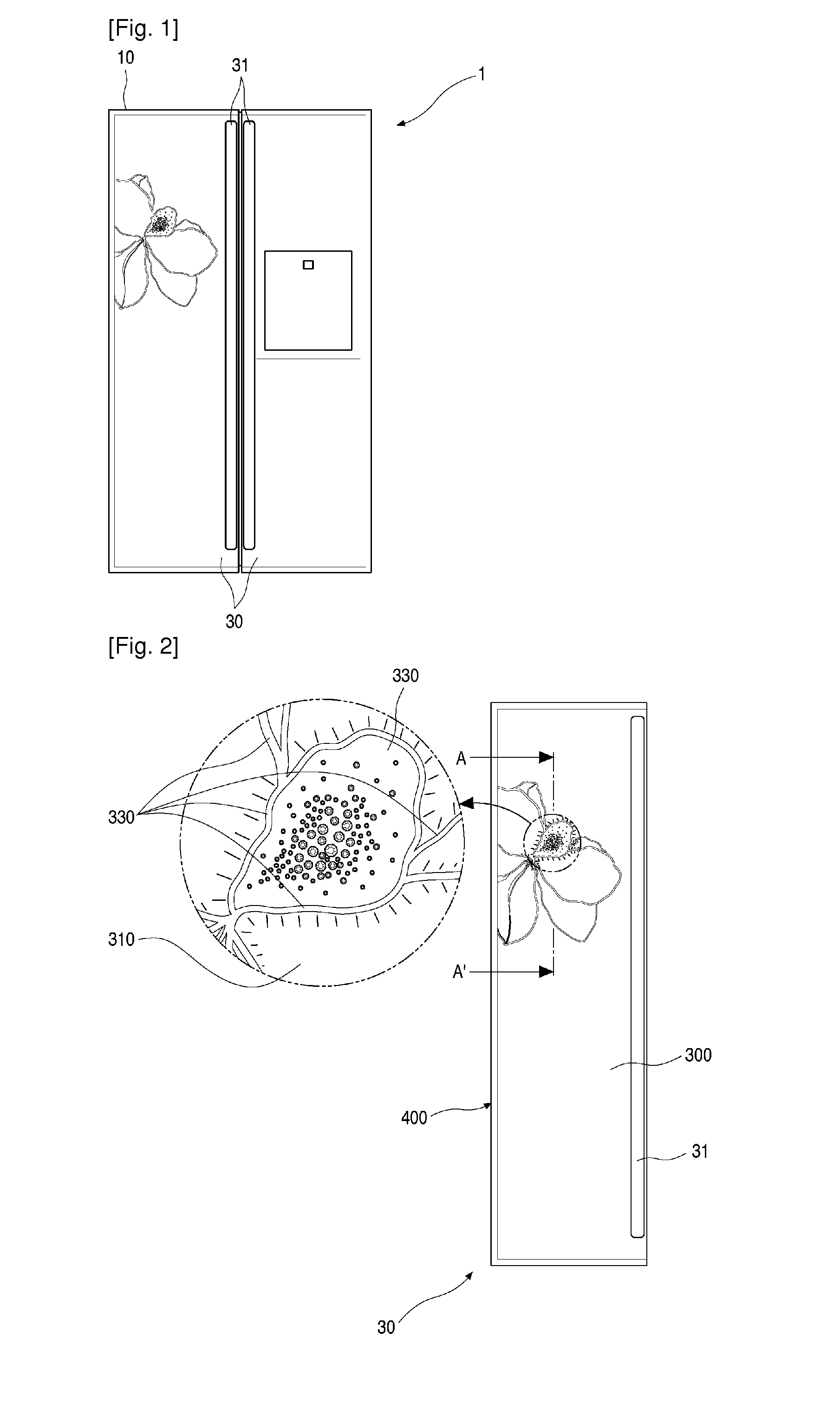

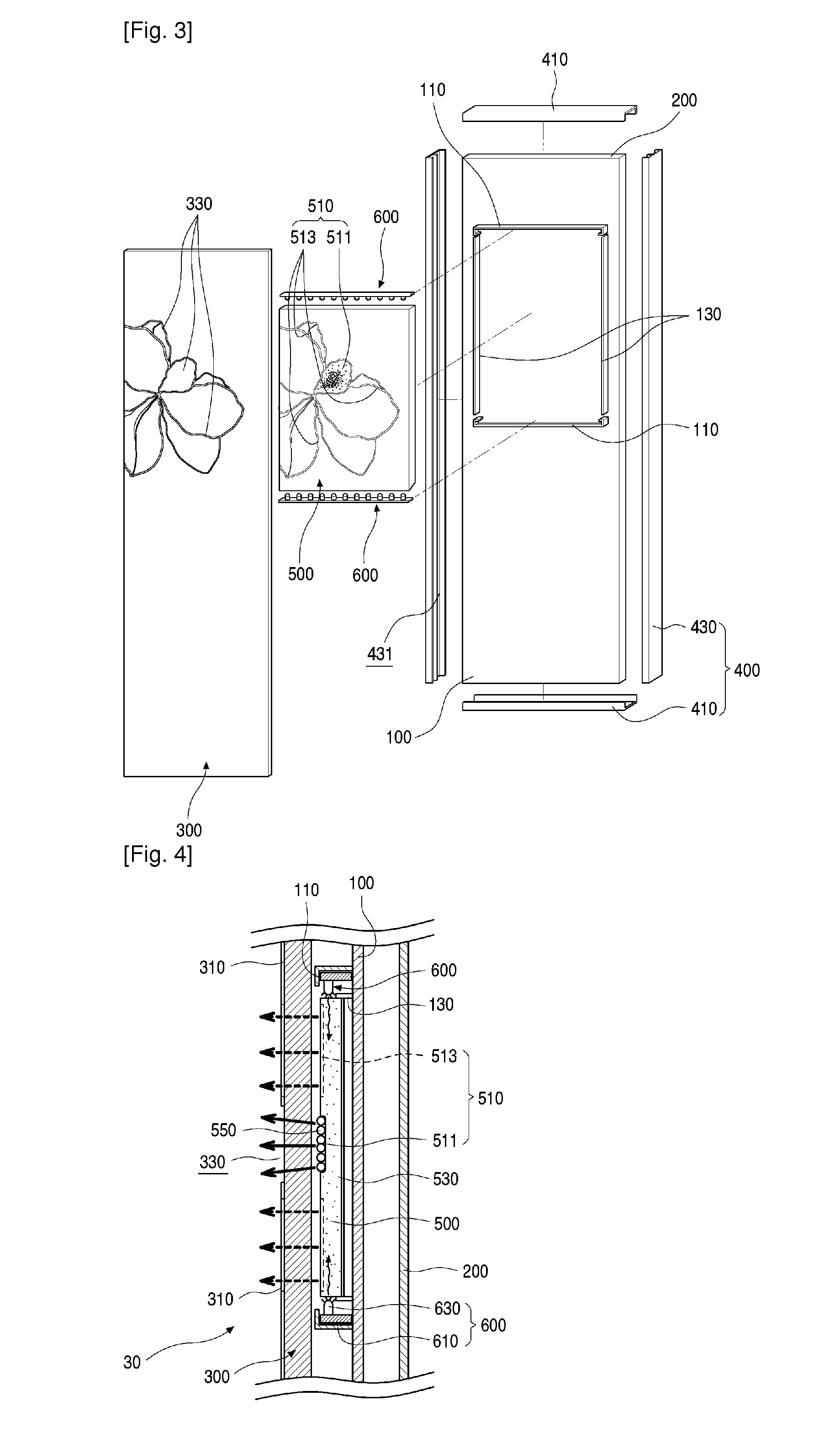

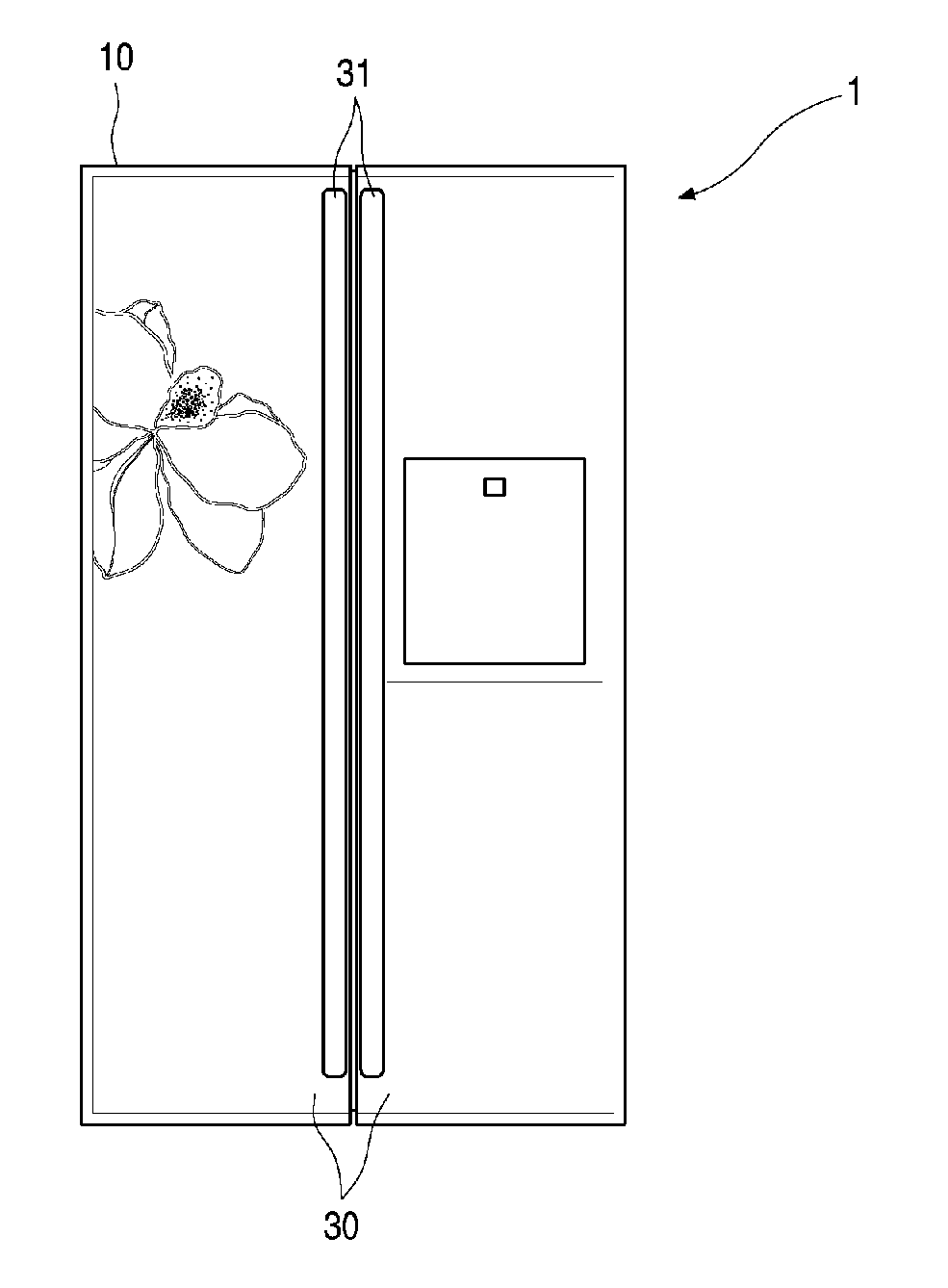

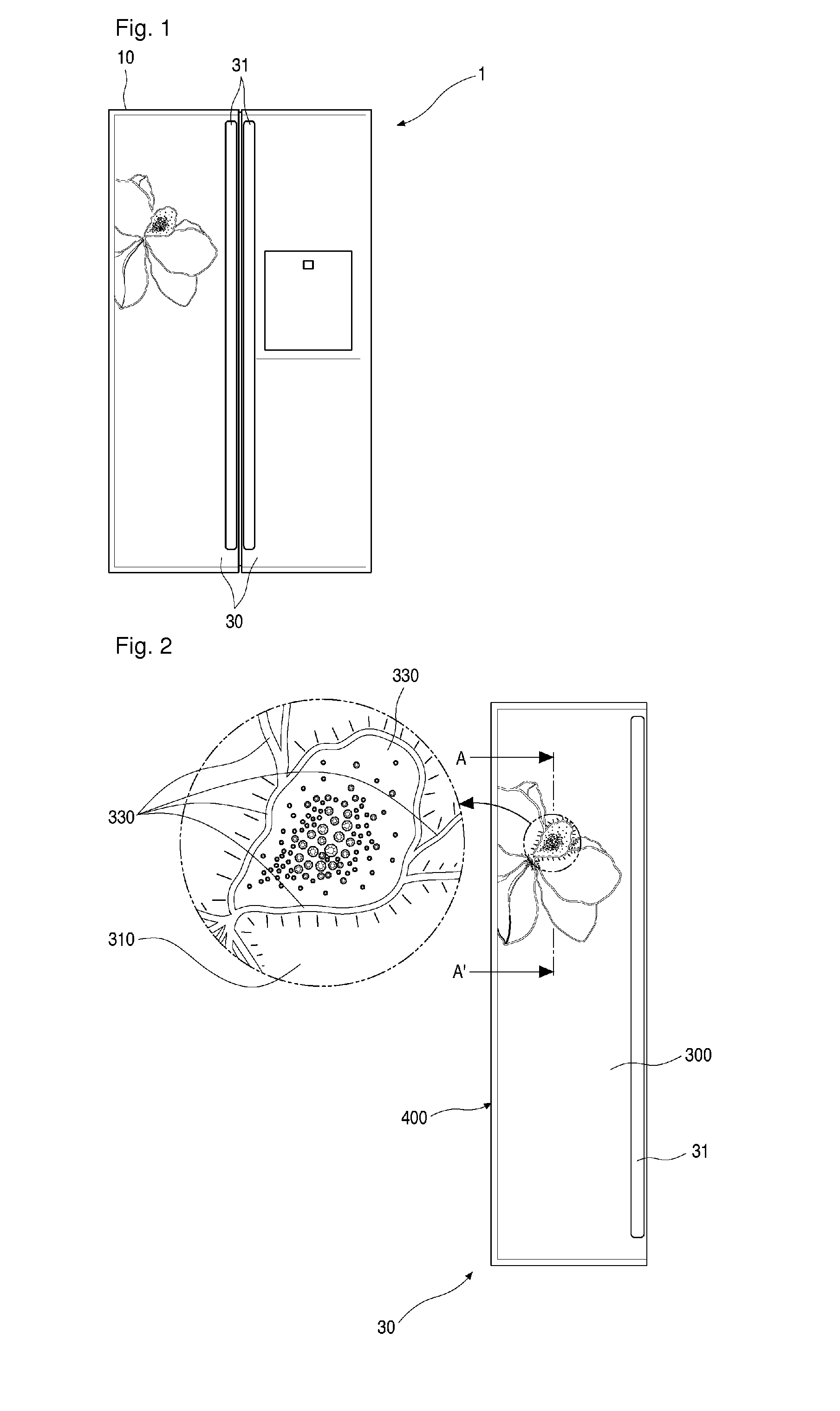

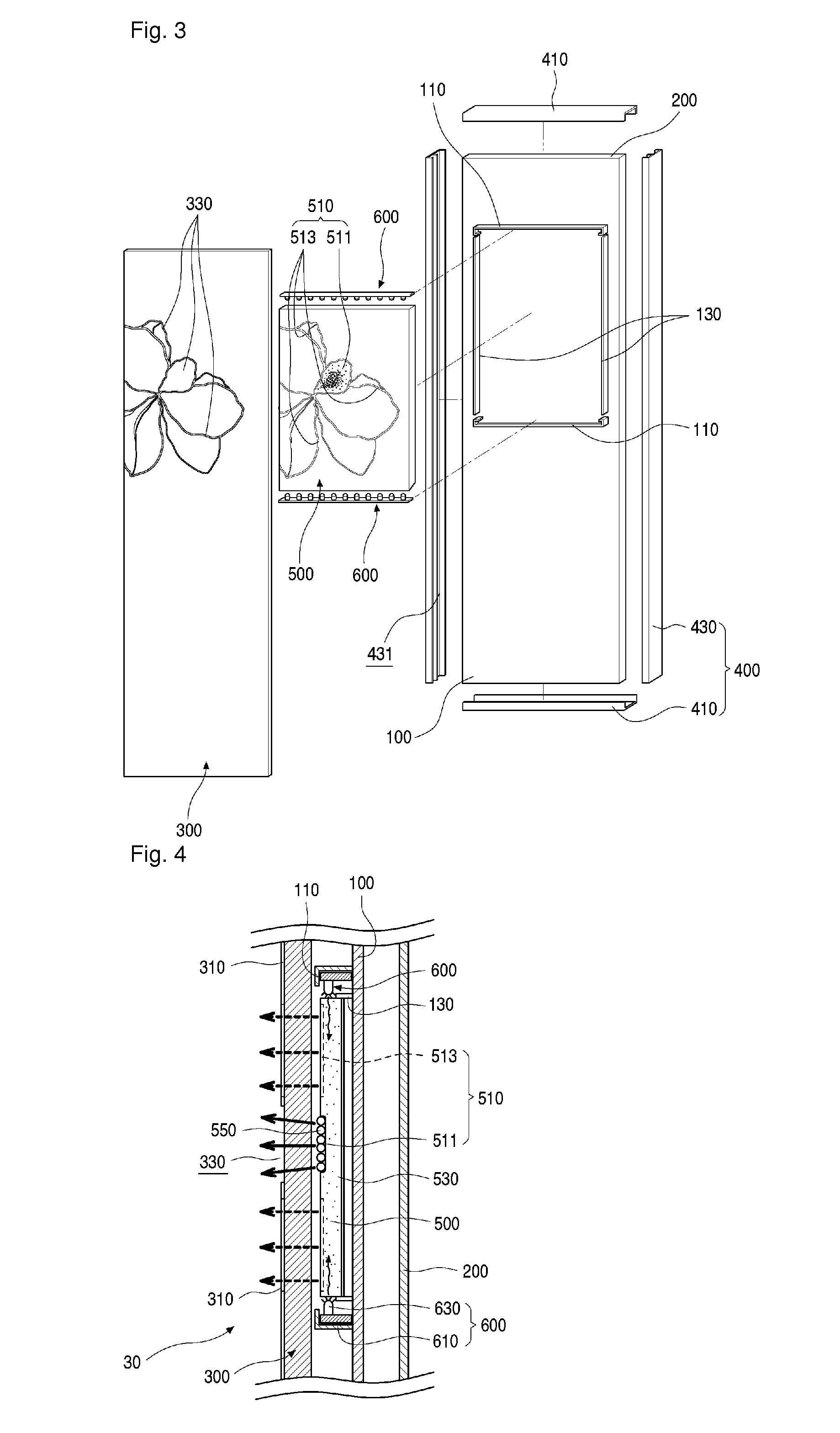

Refrigerator and refrigerator door

ActiveUS20100319383A1Reduce lightNew levelFurnace componentsLighting elementsEngineeringRefrigerated temperature

Owner:LG ELECTRONICS INC

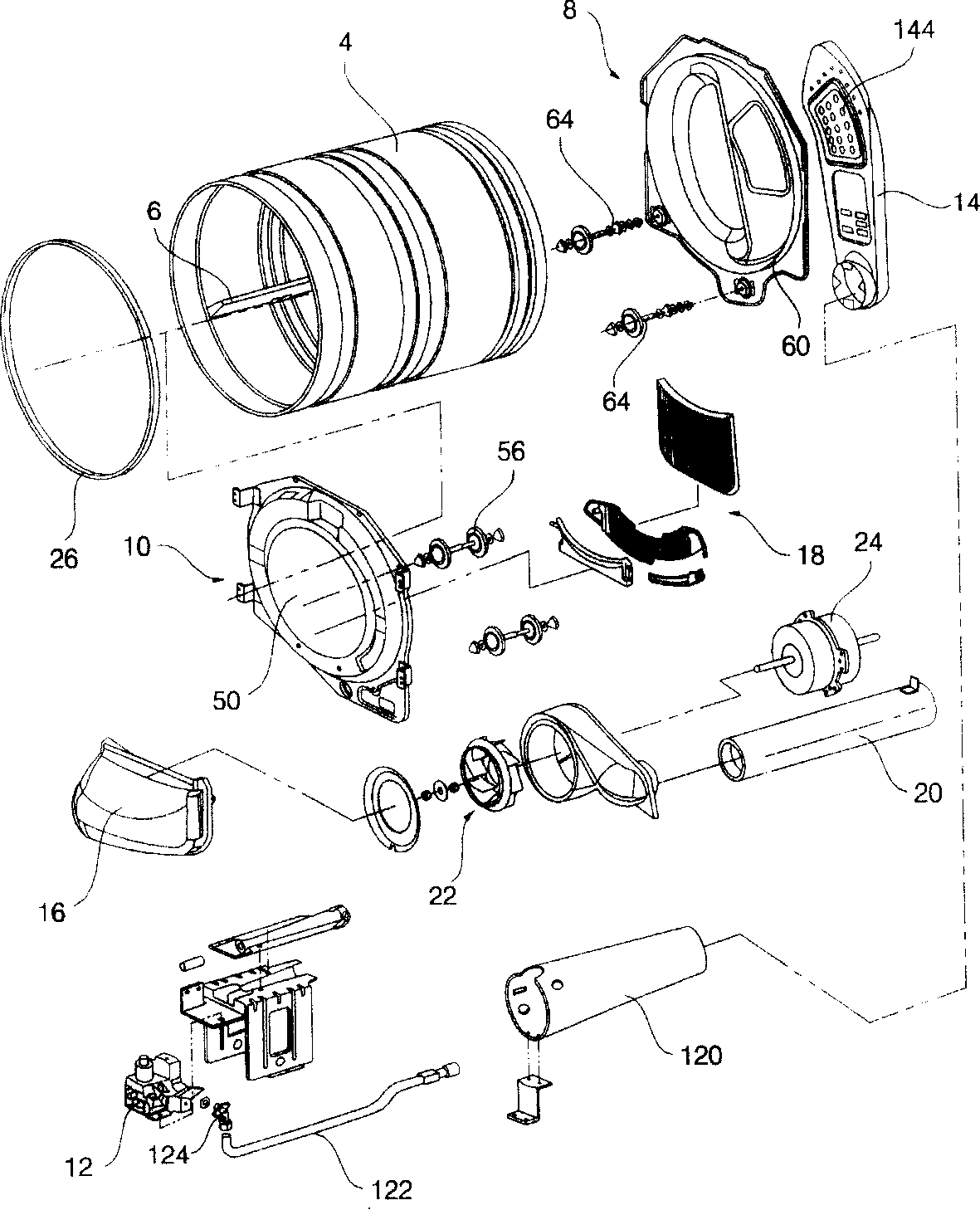

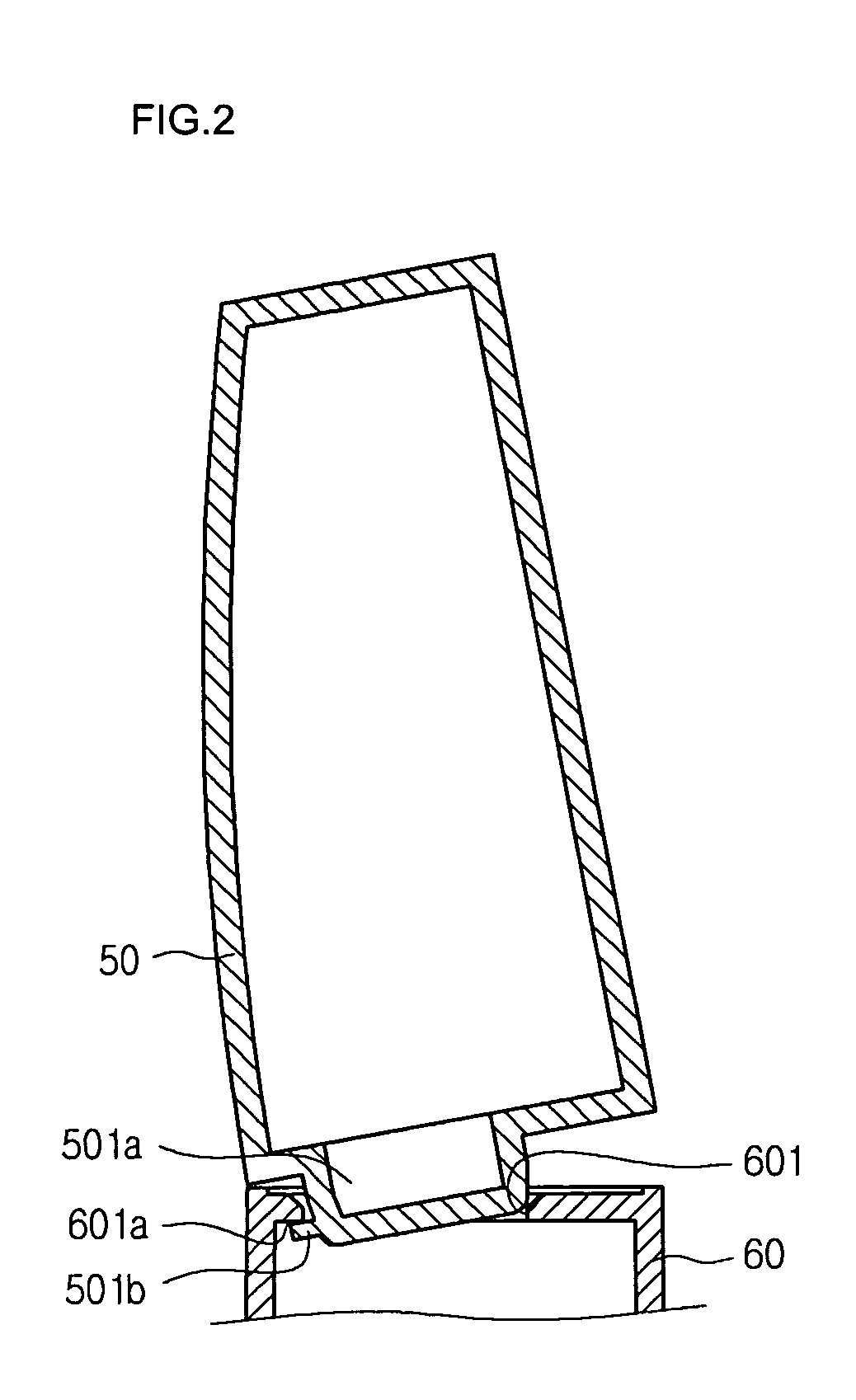

Scouring agent feeding mechanism of scouring apparatus

InactiveCN101177896APrevent random dischargePromote formationOther washing machinesTextiles and paperSiphonAtmospheric pressure

The invention discloses a detergent supplying device of a washing device, comprising a detergent box that is arranged on an opening hole of the washing device in a drawable way and is provided with a detergent accommodating part with an opening at the back, a bleaching agent accommodating part and a softener accommodating part that are arranged inside the detergent accommodating part and are formed by separating from a baseplate and the bottom surface of which is provided with siphon pipes in a bulgy way, a detergent box cover arranged on the detergent accommodating part and is provided with siphon pipe covers that can fit the siphon pipes and a shielding device arranged in front of the lower side of the siphon pipes for keeping certain air pressure to the lower part of the siphon pipes when being pushed into the detergent box. When the detergent box is inserted and installed, the invention can prevent bleaching agent and softener accommodated in the bleaching agent accommodating part and the softener accommodating part from moving and the phenomenon of being discharged through the siphon pipes and the siphon pipe covers.

Owner:NANJING LG PANDA APPLIANCES

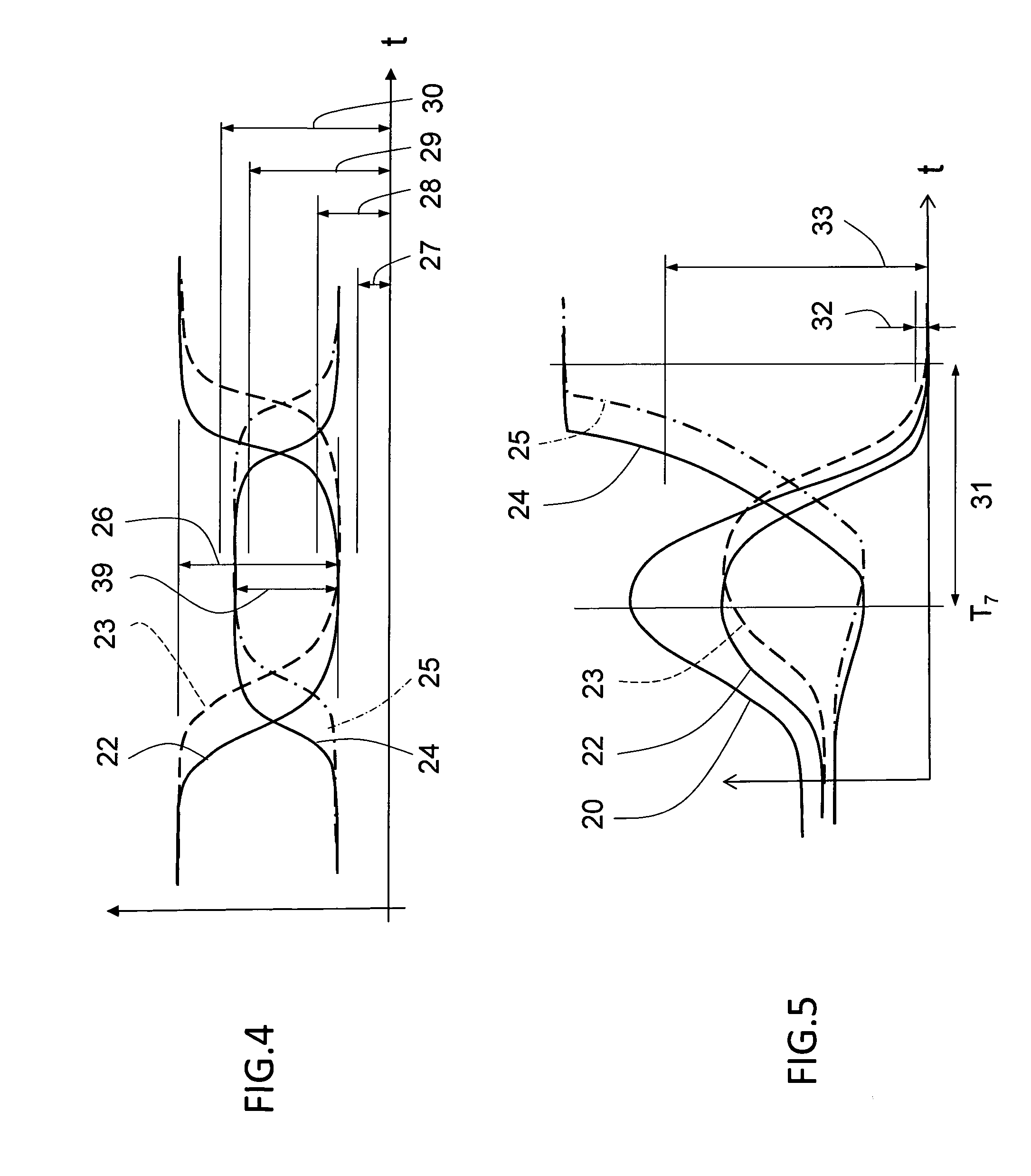

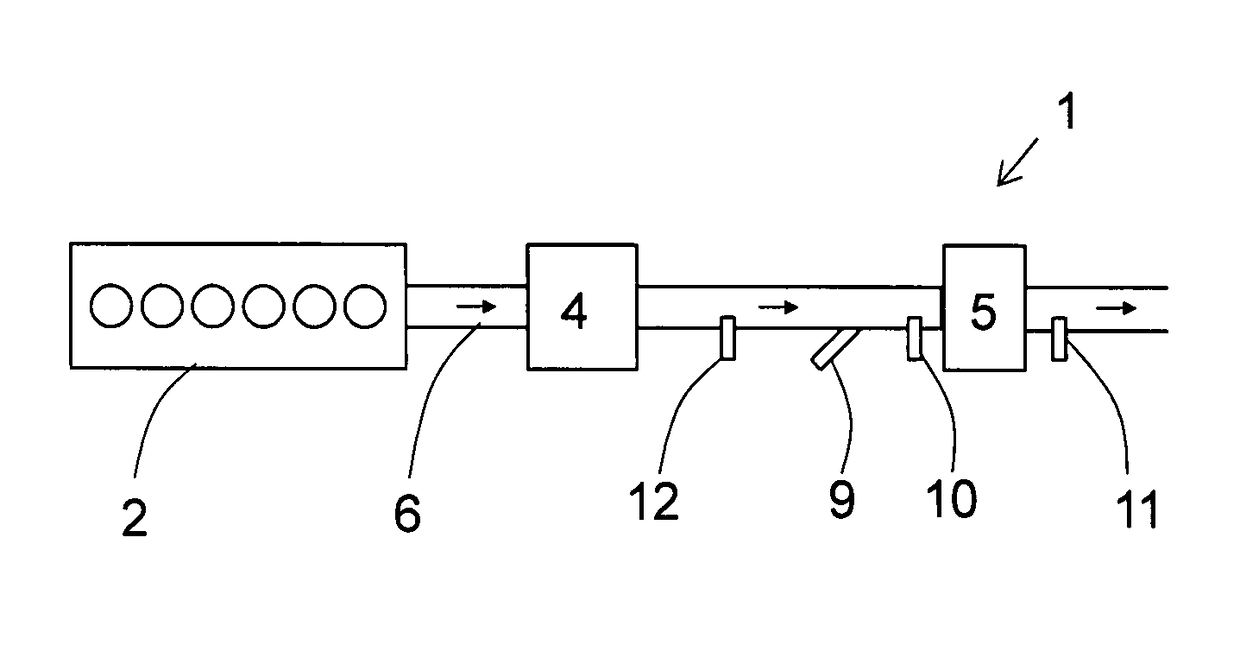

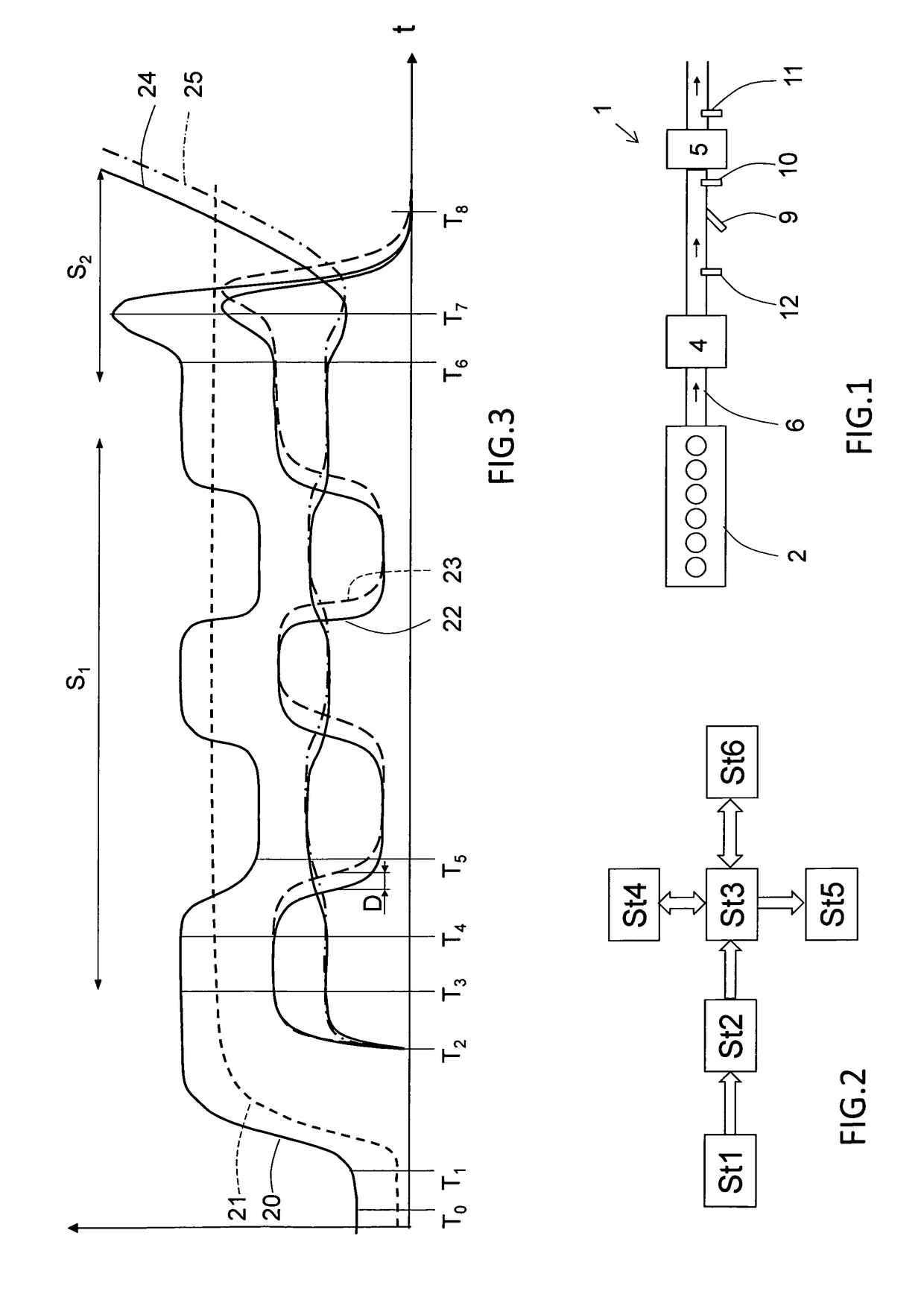

Self-diagnosing method for diagnosing a scr system

ActiveUS20150113953A1Improve accuracyLower Reliability RequirementsElectrical controlInternal combustion piston enginesNitrogen oxideExhaust gas sensor

A self-diagnosing method for diagnosing a selective catalytic reduction (SCR) system of a vehicle that includes an internal combustion engine. An SCR system is arranged downstream of the engine, and the SCR system includes at least one exhaust gas sensor that is sensitive to nitrogen oxides (NOx) gas. The method includes a first diagnosing sequence (S1) of ensuring that the vehicle is in a stationary state, controlling the engine to operate in a high NOx output engine operating state and in a low NOx output engine operating state, registering an output signal of the at least one exhaust gas sensor when the engine operates in each of the high NOx output engine operating state and low NOx output engine operating state, and diagnosing NOx measurement performance of the at least one exhaust gas sensor on the basis of the registered sensor output.

Owner:VOLVO LASTVAGNAR AB

Refrigerator and refrigerator door

ActiveUS8608330B2Reduce lightReduce direct lightFurnace componentsLighting elementsEngineeringRefrigerated temperature

Owner:LG ELECTRONICS INC

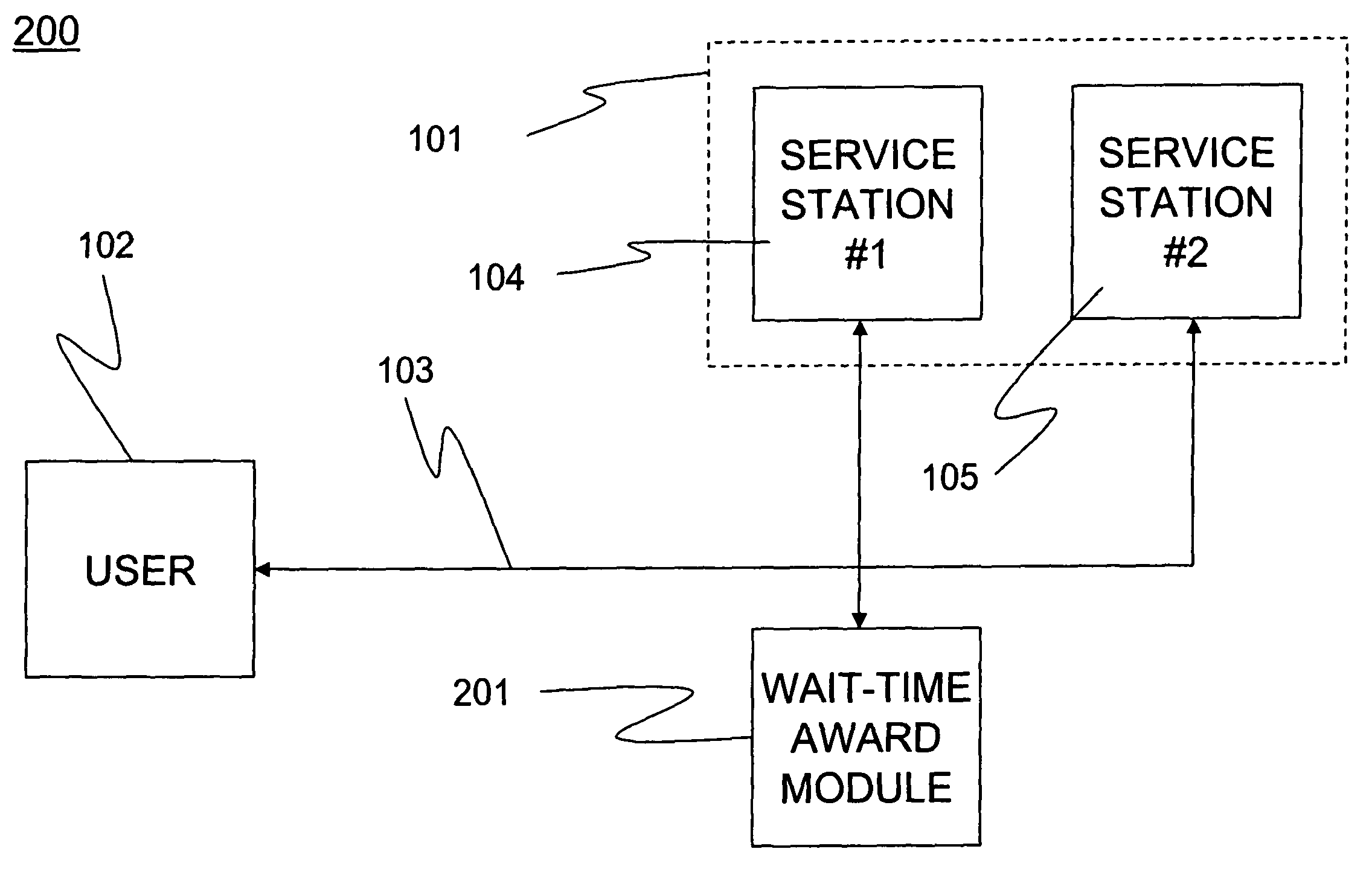

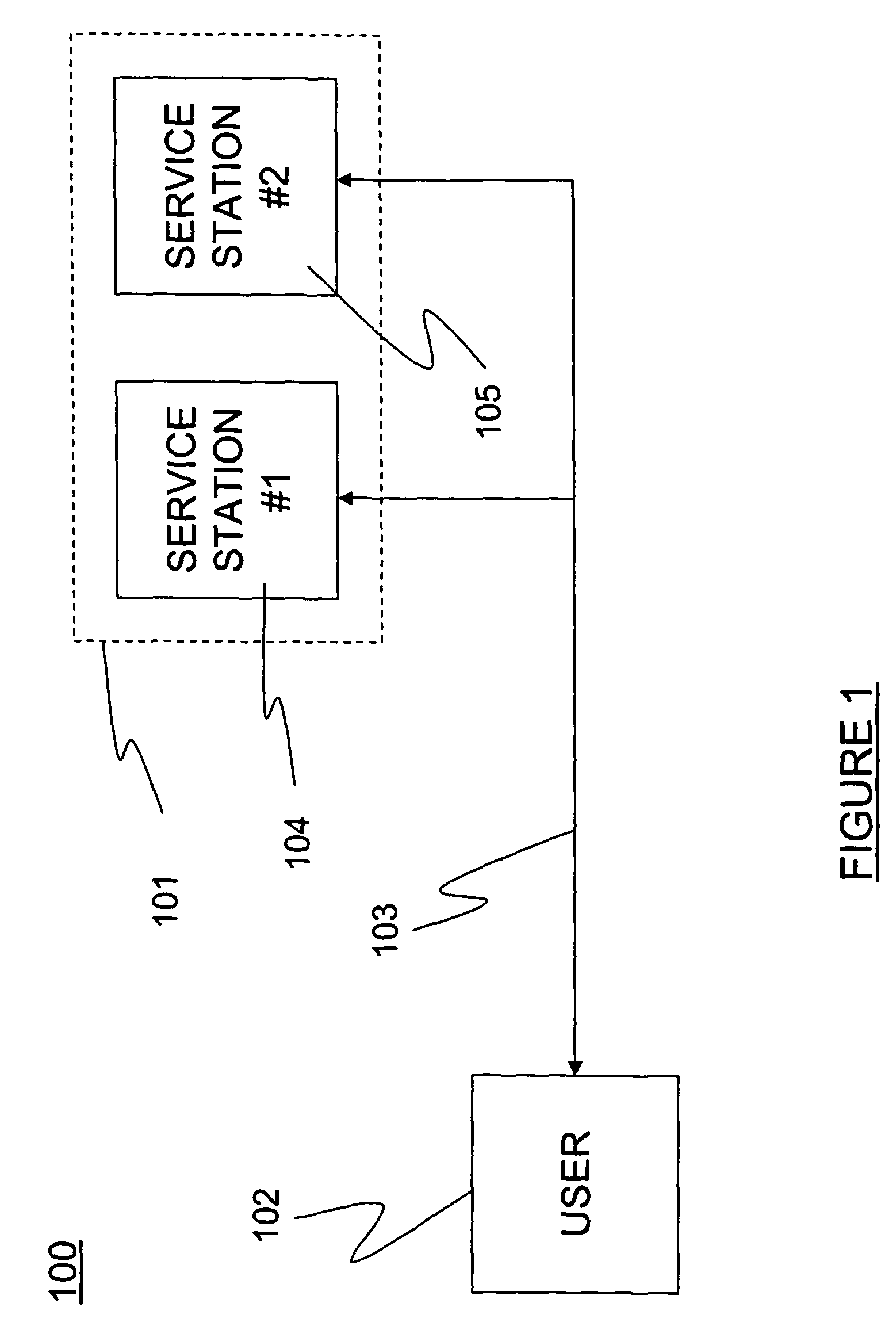

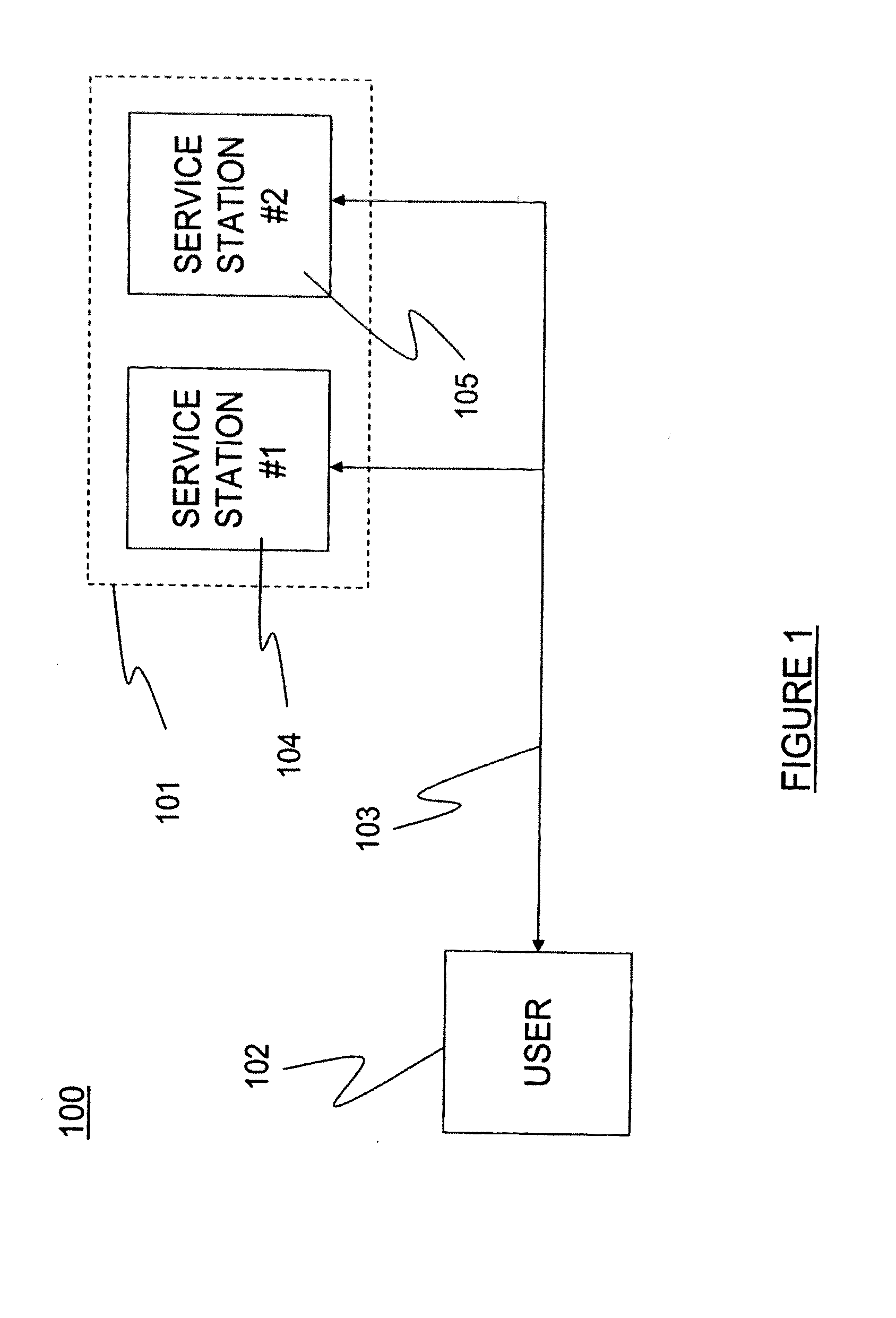

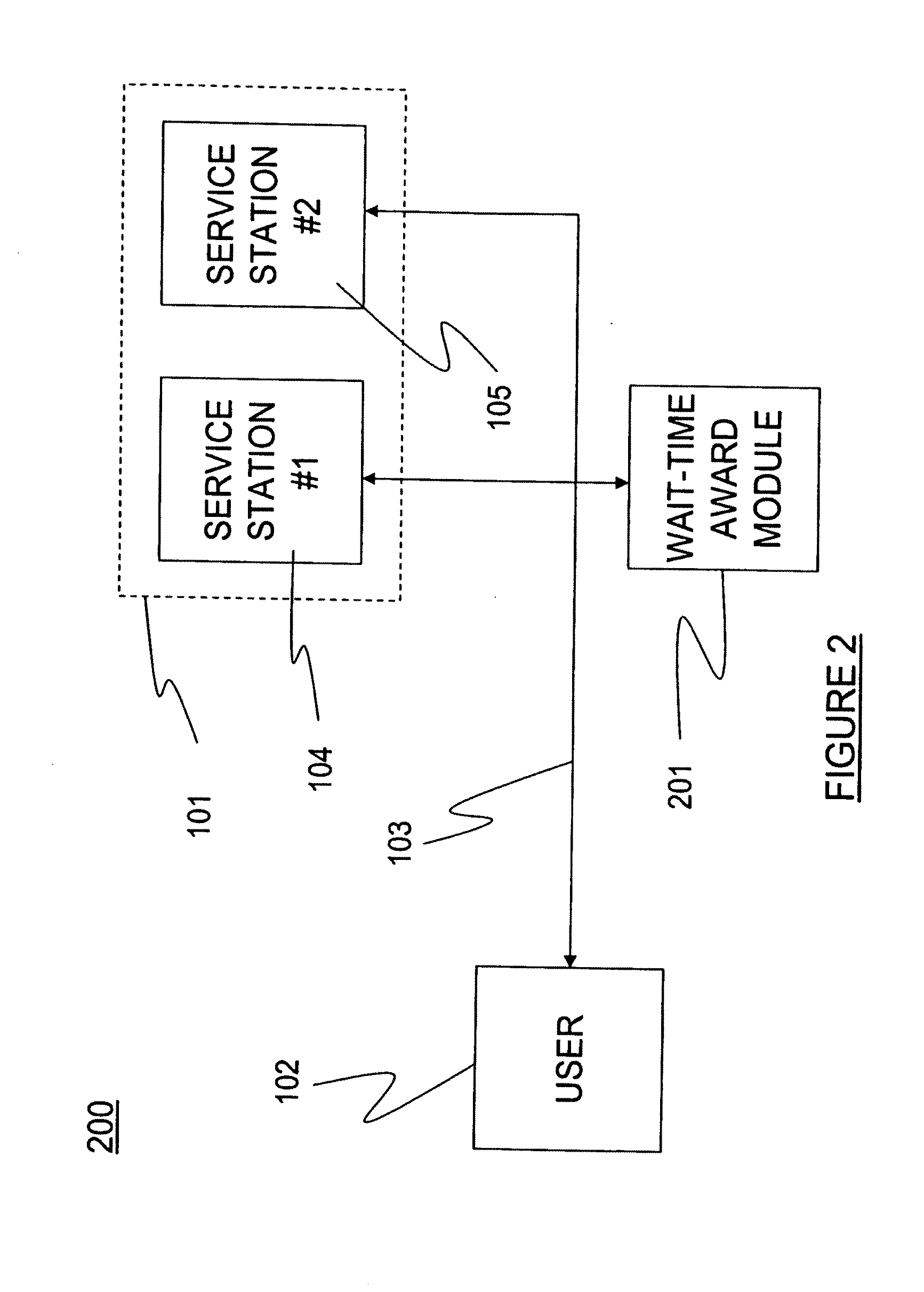

Method and structure for automated crediting to customers for waiting

InactiveUS8284924B2Reduce likelihoodImprove customer satisfactionManual exchangesFranking apparatusReal-time computingComputer science

A method and structure for reducing customer dissatisfaction for waiting includes a queue monitoring subsystem which detects an entry of a customer into a waiting queue. A reward computing subsystem calculates a reward for the customer for being in the waiting queue, and a communication subsystem communicates the reward to the customer. At least one of subsystems is automated.

Owner:IBM CORP

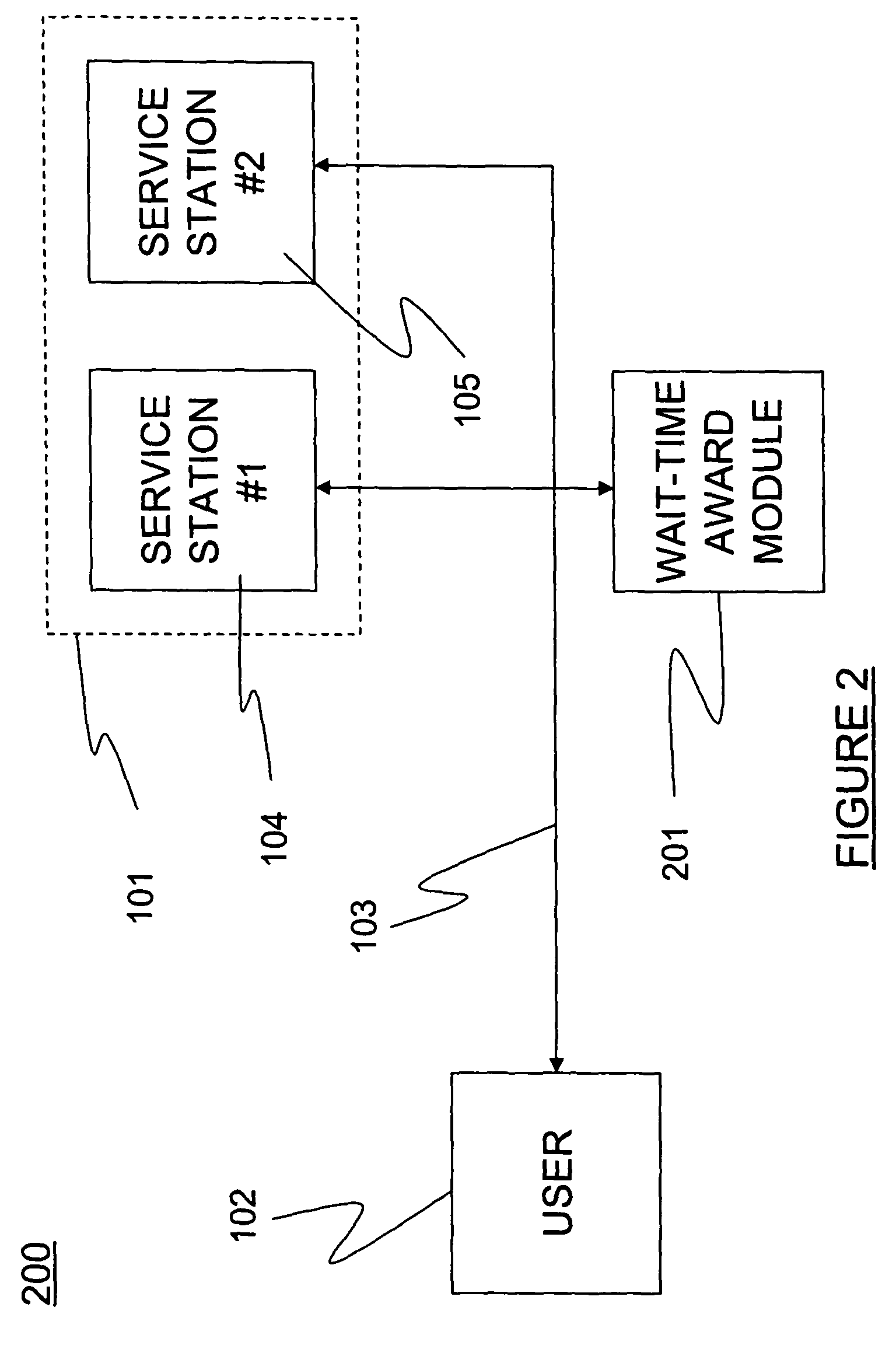

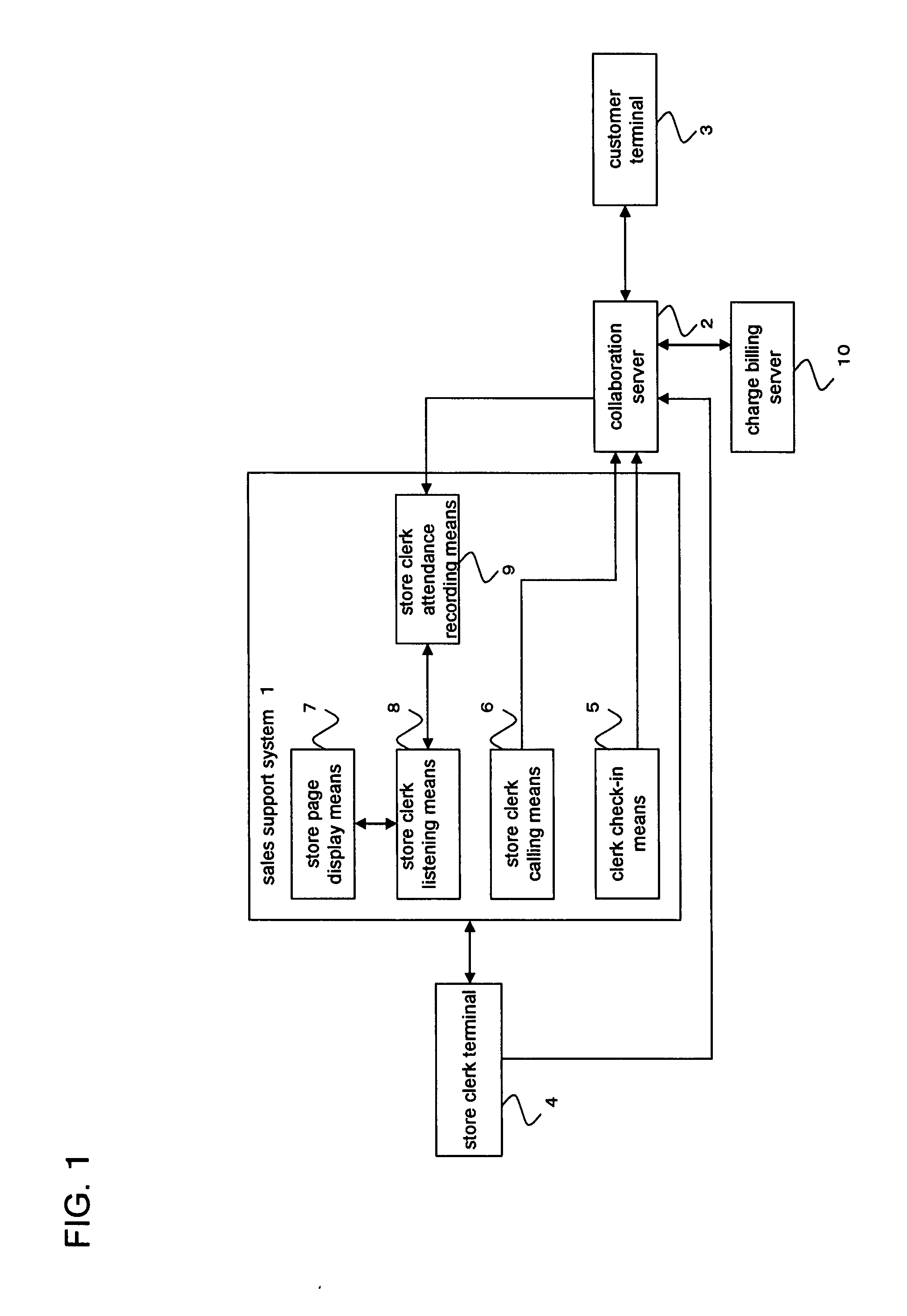

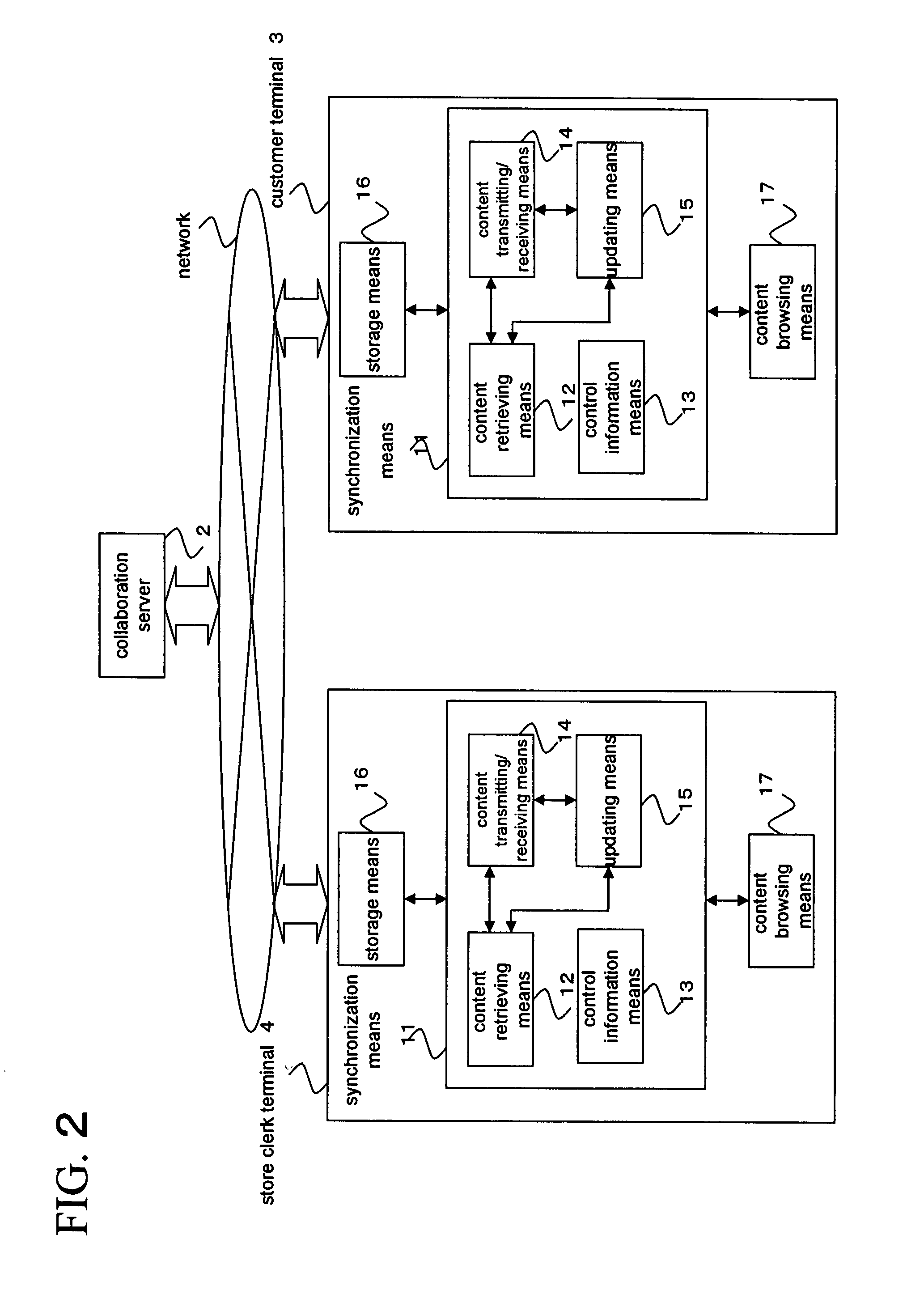

Sales Support System

InactiveUS20080046333A1Avoid opportunitiesWide rangeVisual presentationOffice automationSupporting systemComputer science

There is provided a sales support system enabling a user to purchase a product in a store on a network while communicating with a store clerk. The sales support system comprises store page display means for storing content associated with the store site and transmitting the content to a customer terminal, and store clerk call means for receiving information on a consultation instruction from a customer terminal, selecting one port which can be used in a collaboration server, transmitting to the collaboration server or the customer terminal an instruction for connecting the customer terminal to the collaboration server via the port, and transmitting the selected port number and a contact number to the customer terminal.

Owner:SYNCPLUS

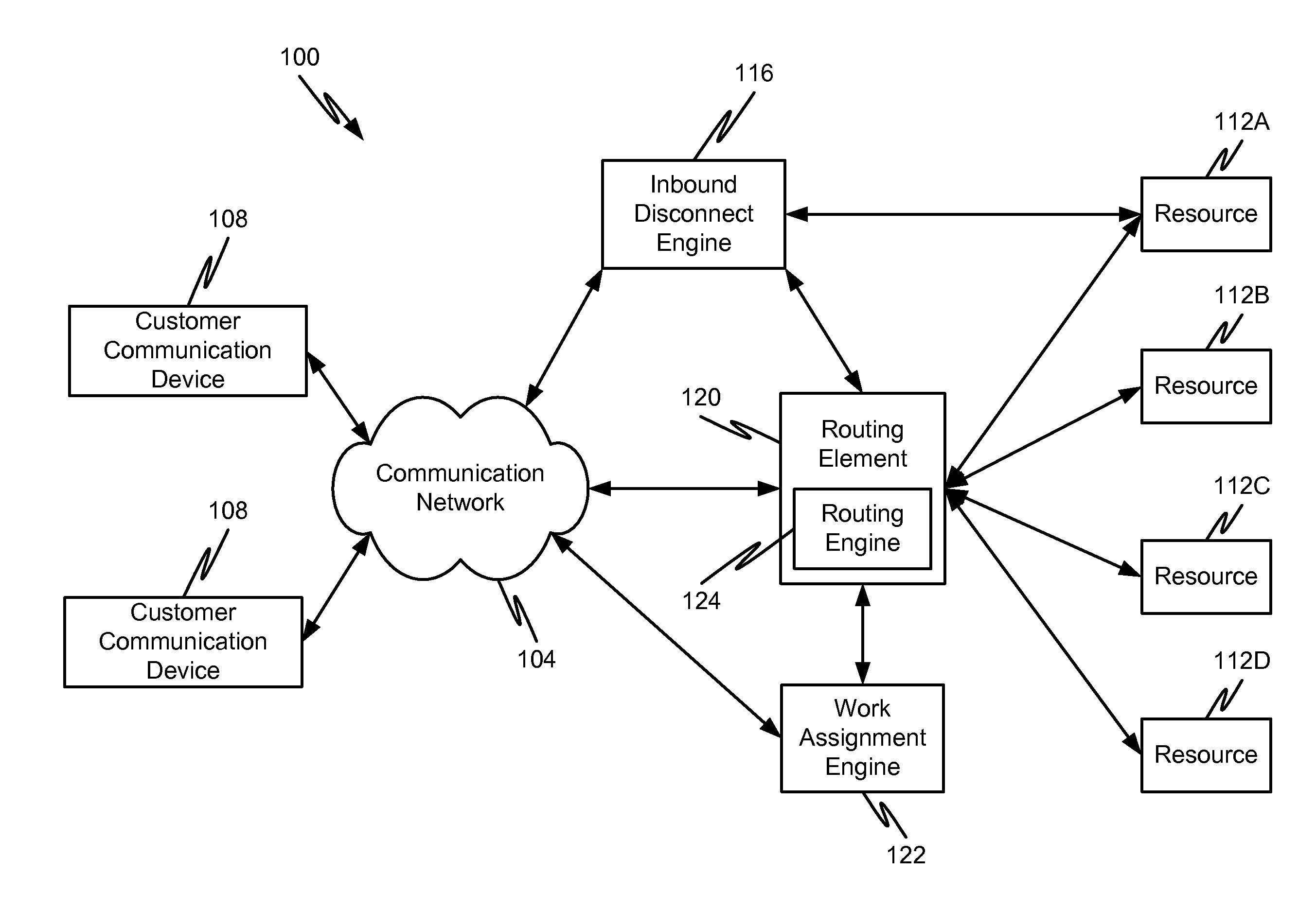

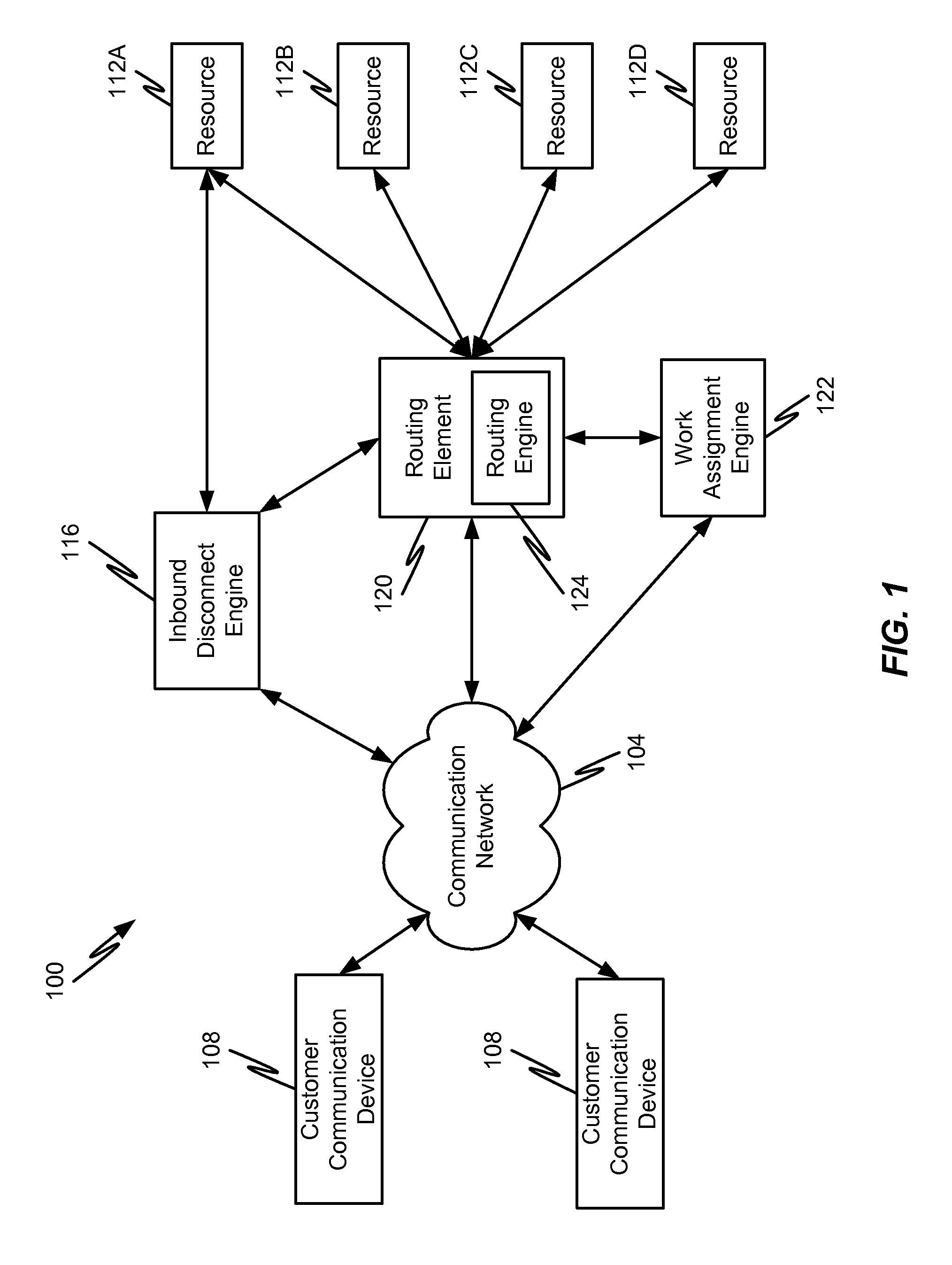

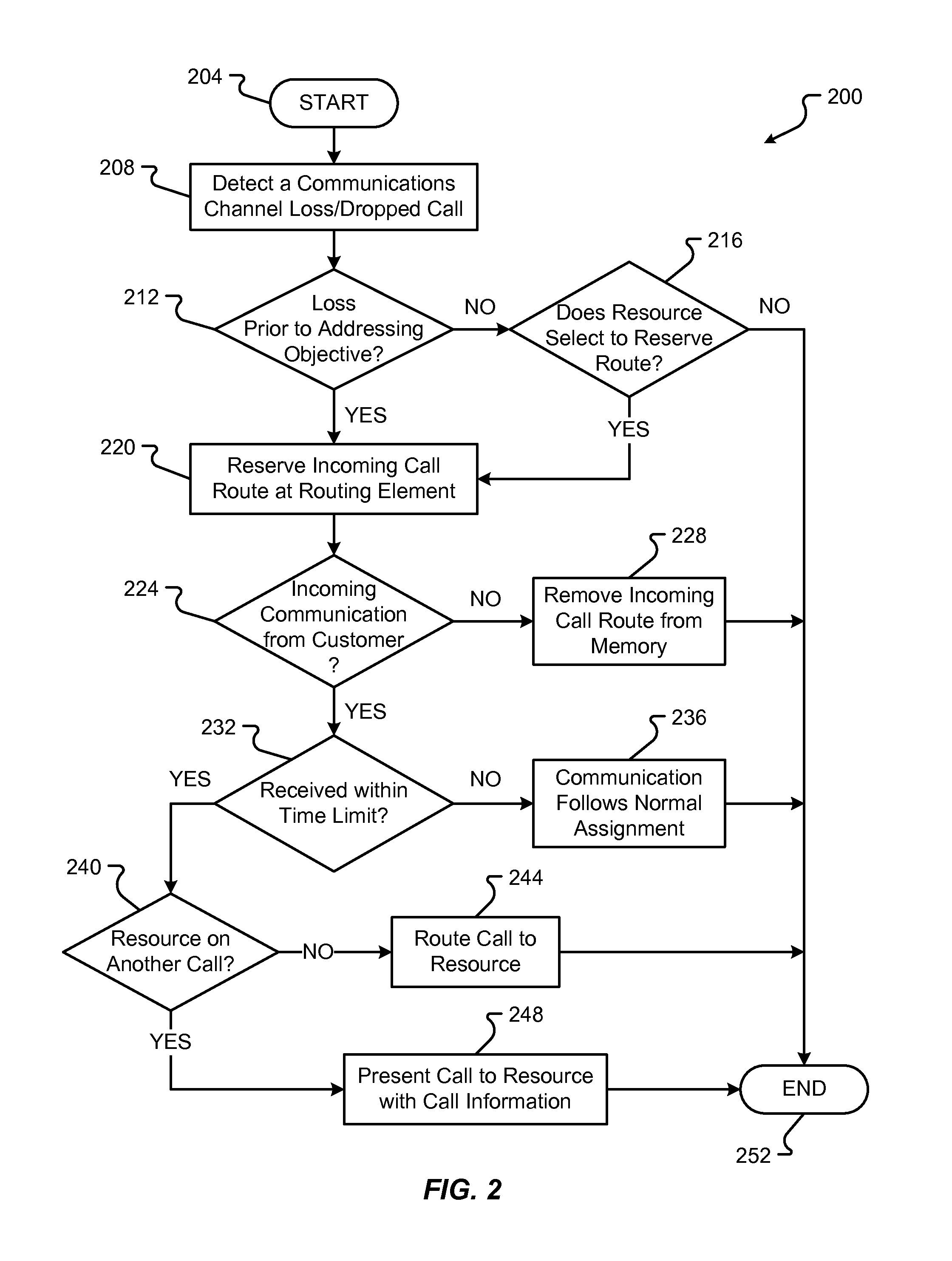

Inbound contact center call disconnect buffer

ActiveUS20150163361A1Improve customer satisfactionOperation efficiency can be improvedManual exchangesAutomatic exchangesContact centerReal-time computing

A contact center is described along with various methods and mechanisms for administering the same. Methods are provided that detect a communications channel loss in a communication between a customer and a resource of a contact center. The method determines when the communications channel loss occurred. When the communications loss occurs prior to an objective of the customer being resolved the method reserves an incoming communication route for the customer to call back and reach the same resource when the call back is made in a predetermined and limited amount of time.

Owner:AVAYA INC

Forging method for automotive eccentric shaft

InactiveCN103846378AReduce consumptionReduce consumption costMetal-working apparatusFurnace typesChemical compositionRoom temperature

The invention discloses a forging method for an automotive eccentric shaft. The forging method comprises the following steps that a cylindrical blank is poured, wherein the cylindrical blank contains the following chemical compositions in percentage by weight: 0.35-0.45% of C, 1.2-2.6% of Mn, 0.6-1.5% of Si, 0.2-2.0% of Cr, 0.22-0.37% of W, 0.14-0.32% of Cu, P being greater than or equal to 0.043%, S being greater than or equal to 0.030%, and the residual amount of Fe and inevitable impurities; the poured blank body is cooled to the temperature of 150 DEG C and then heated to 500-660 DEG C, the blank body is subjected to heat insulation for 3-5 hours and undergoes furnace cooling to reach 100 DEG C, then the blank body is subjected to heat insulation for 4 hours and heated to 550-660 DEG C, and the blank body is subjected to heat insulation for 3-5 hours and is cooled to 300 DEG C at the speed of 25 DEG C per hour and is cooled to the room temperature at the speed of 20 DEG C per hour. With the forging method, the automotive eccentric shaft is suitable for large batch industrial production, the phenomena of containing impurities and insufficient filling in the forging process are reduced, the mechanical performance of products is further improved, the material consumption is saved, and the mold life of the products is prolonged.

Owner:MAANSHAN HENGYI MACHINERY MFG

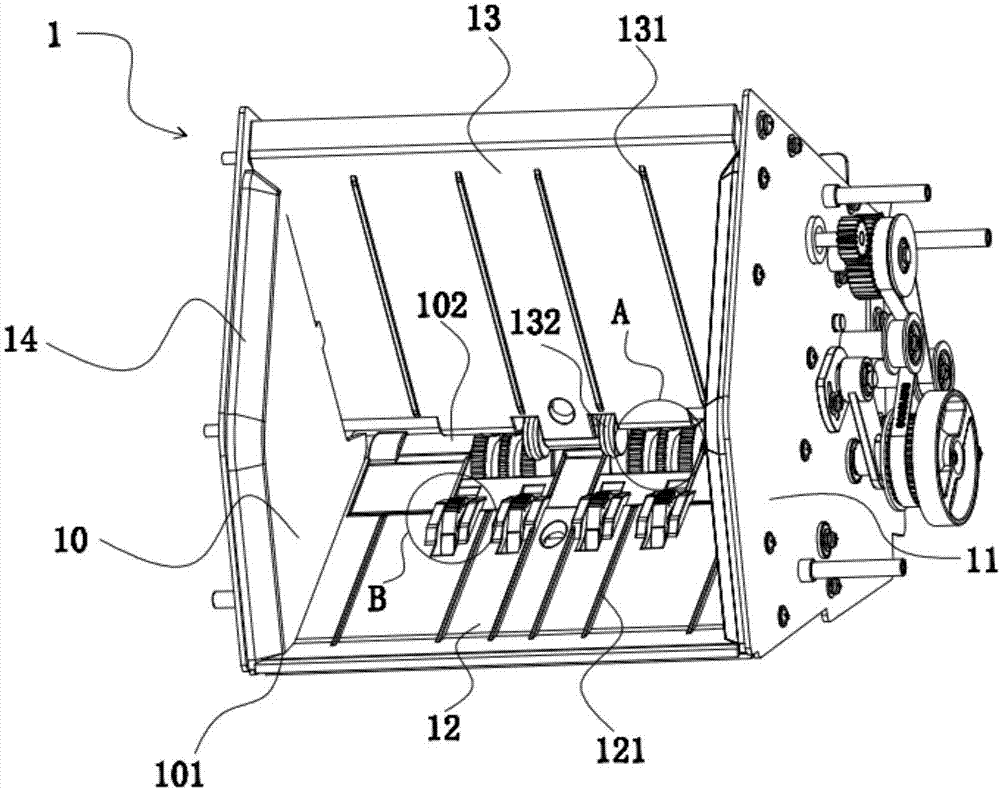

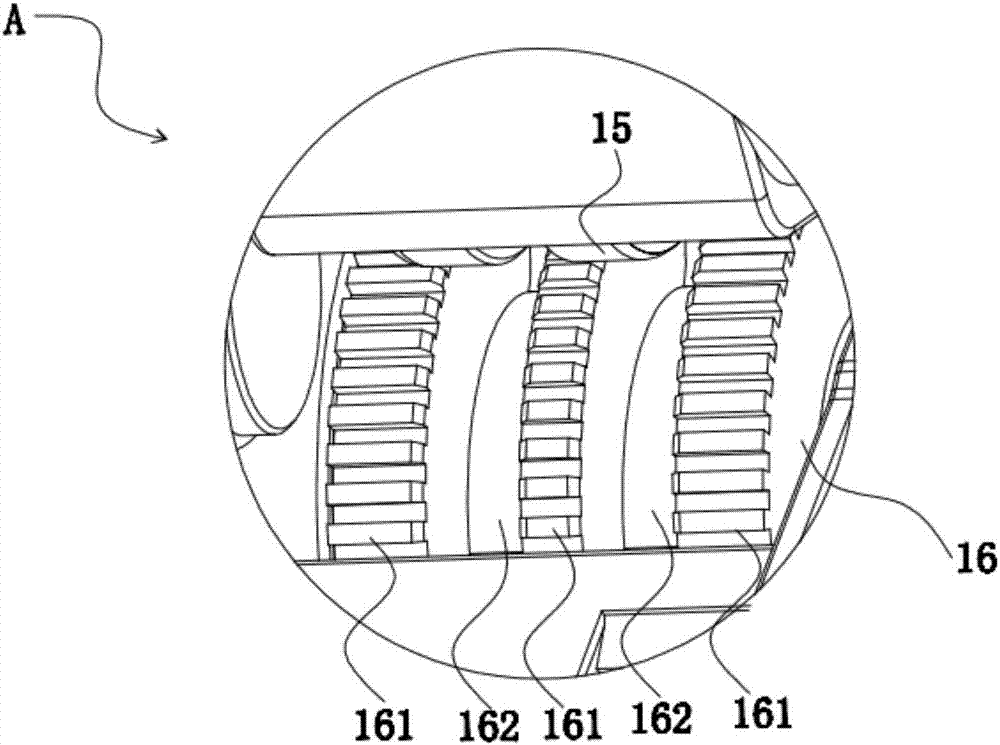

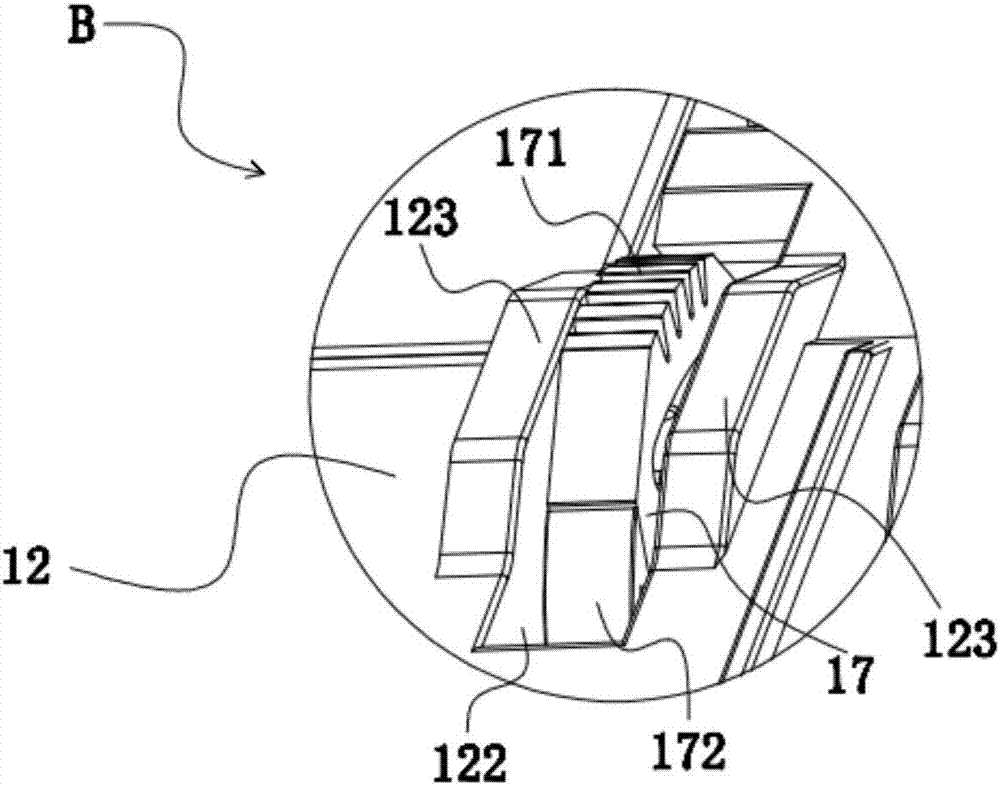

Deposit terminal and deposit and withdrawal system

InactiveCN107004325AReduce dissatisfactionImprove trustComplete banking machinesCoin/currency accepting devicesTransmission channelEngineering

In order to overcome a problem of time-consuming storage of a large amount of cash in a conventional cash recycling system, there is provided a deposit terminal which includes an open banknote cavity (10) and a banknote transmission channel for transferring the banknotes. The banknote cavity (10) has a banknote gap (102) and an opening (101) for feeding the banknotes. The banknote transmission channel is connected to the banknote gap (102), extends along the direction opposite to the banknote cavity (10), is provided with a separating module for separating the banknotes and located at a position adjacent to banknote gap (102) of the banknote transmission channel. Further, a deposit and withdrawal system is also disclosed for customers to deposit large amount of cash and to achieve a function of non-stop money addition. The open deposit model can monitor the process of money addition and avoid a danger that the customer may be clamped by a cash door.

Owner:SHENZHEN YIHUA COMP +2

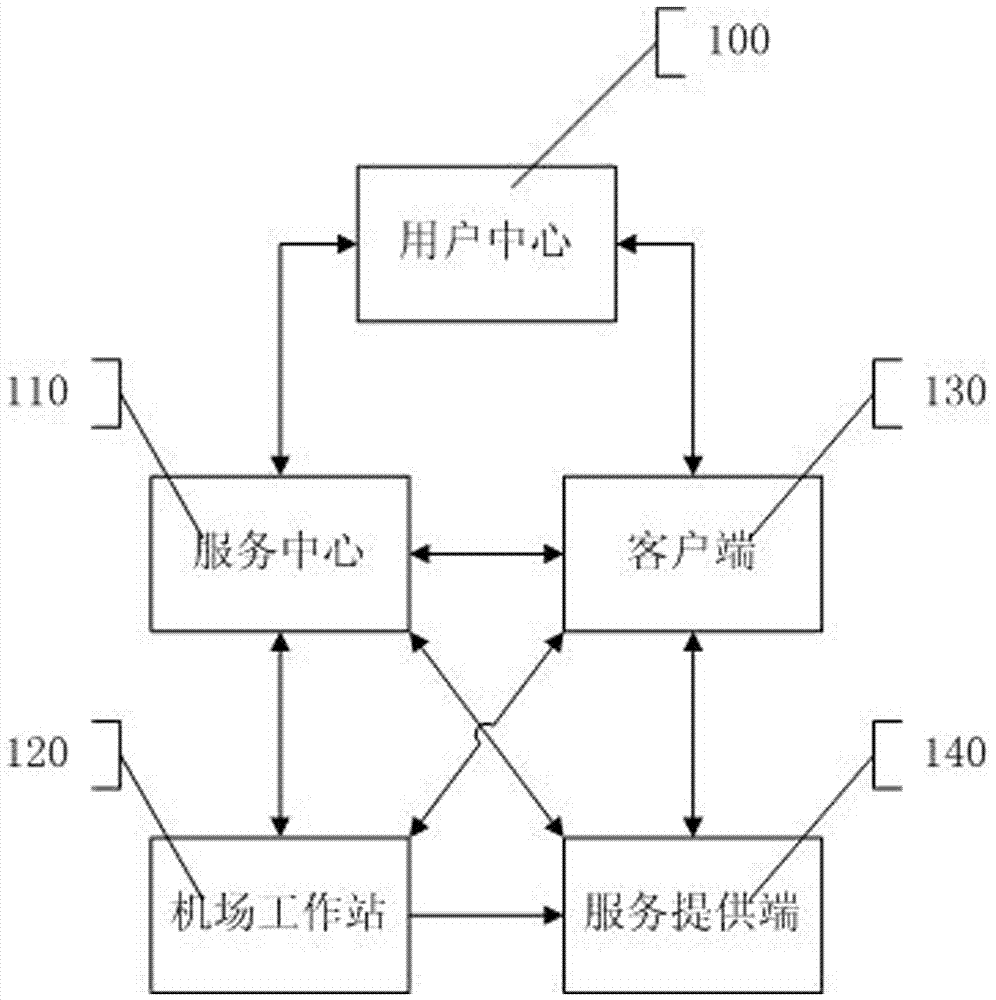

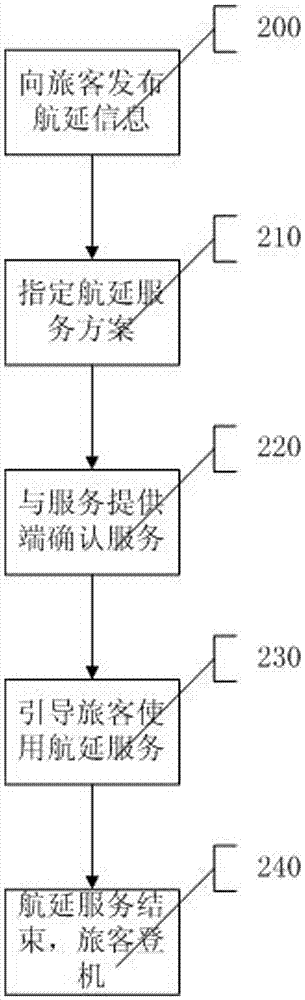

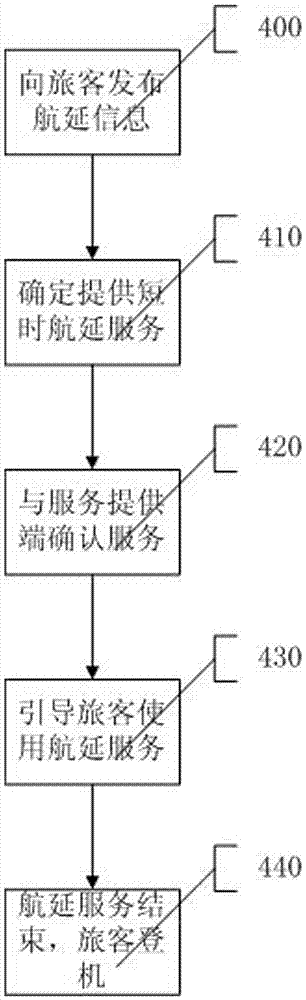

Unified service platform for flight delay of civil aviation

ActiveCN106910154AReduce dissatisfactionImprove socializationData processing applicationsClient-sideService provision

The invention provides a unified service platform for flight delay of civil aviation. The platform comprises a client used by a user, a user center for examining and recording personal data and flight taking information of a traveler, a service center for receiving flight and flight delay information sent by an airport or an airline and issuing the flight delay information to the client and performing the service, an airport work station for providing an airport services for a traveler, and a service providing terminal for providing a terminal service for a traveler. Therefore, when the flight delay occurs, a ground service taking mechanism can issue dynamic flight information and service information to travelers timely and provide individualized, high-quality and timely flight delay services for travelers, so that the trip experience of the traveler can be improved and the traveler service quality of the airline company can be improved. Meanwhile, the traveler service information is issued and is open to public, so that social resources participate in the travel service process in a unified manner; and close combination with the traveler services of the airline company can be realized.

Owner:杜雪 +1

Method and structure for automated crediting to customers for waiting

InactiveUS20120323646A1Reduce the possibilityImprove customer satisfactionMarketingComputer scienceReal-time computing

Owner:INT BUSINESS MASCH CORP

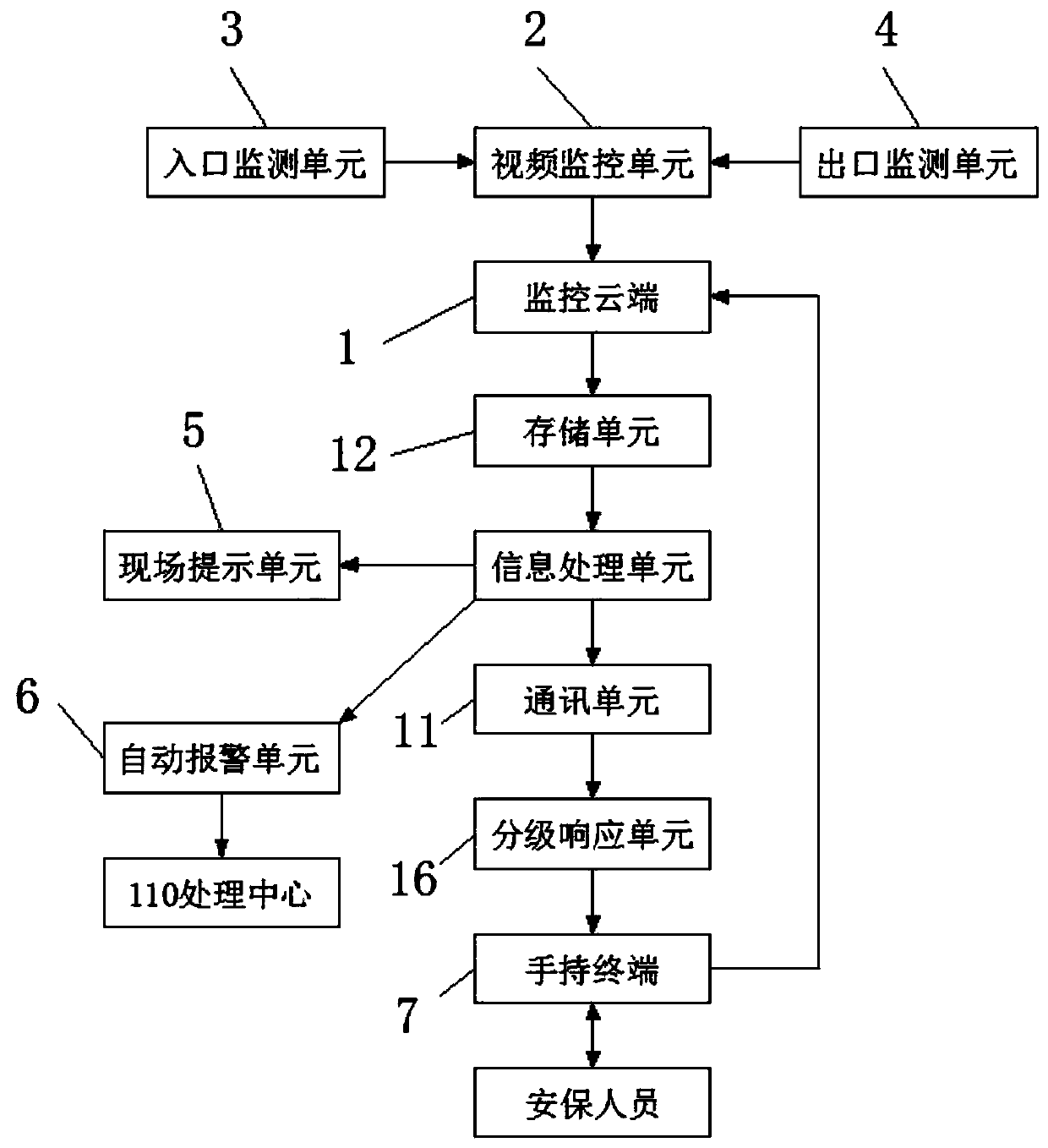

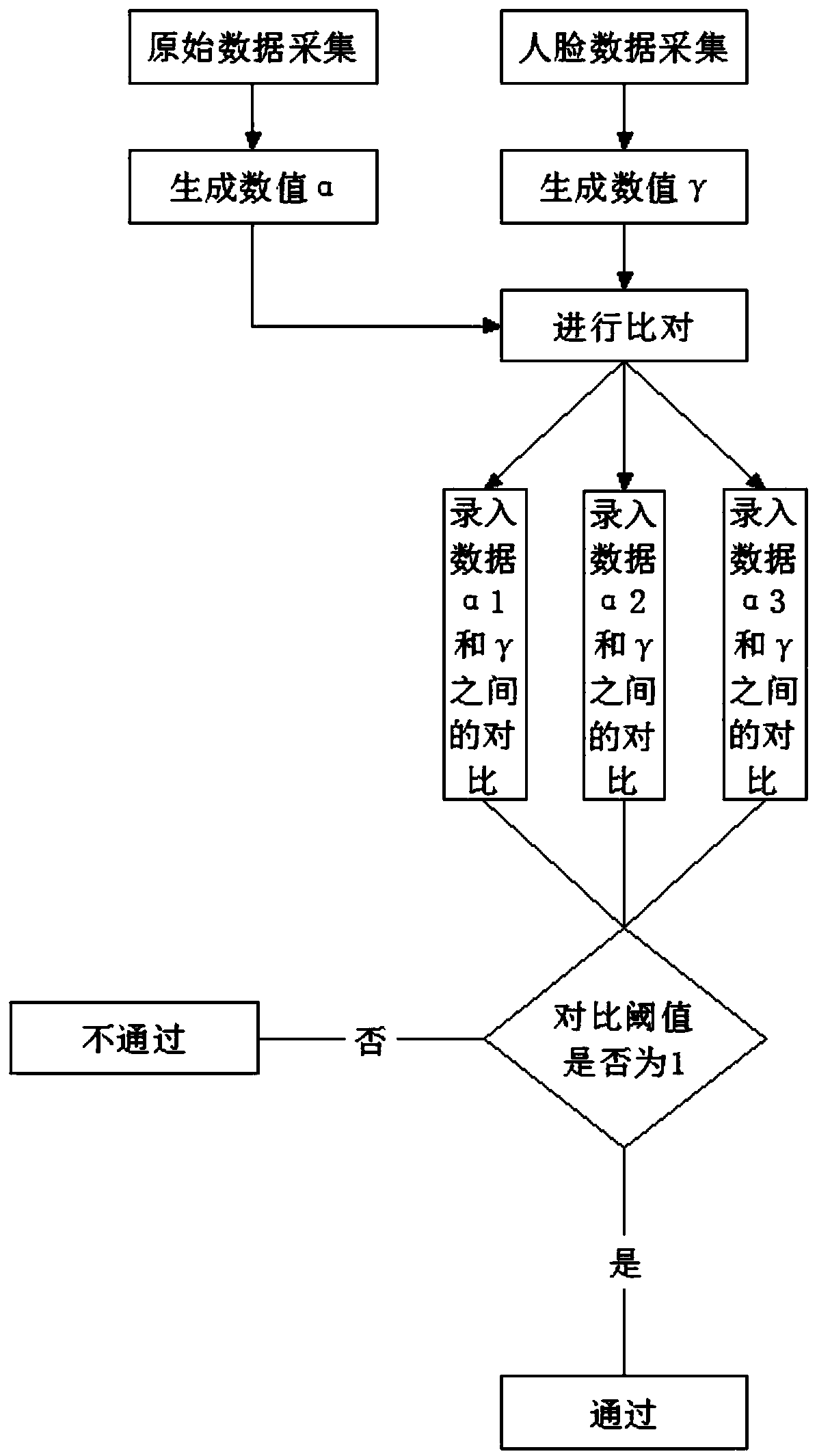

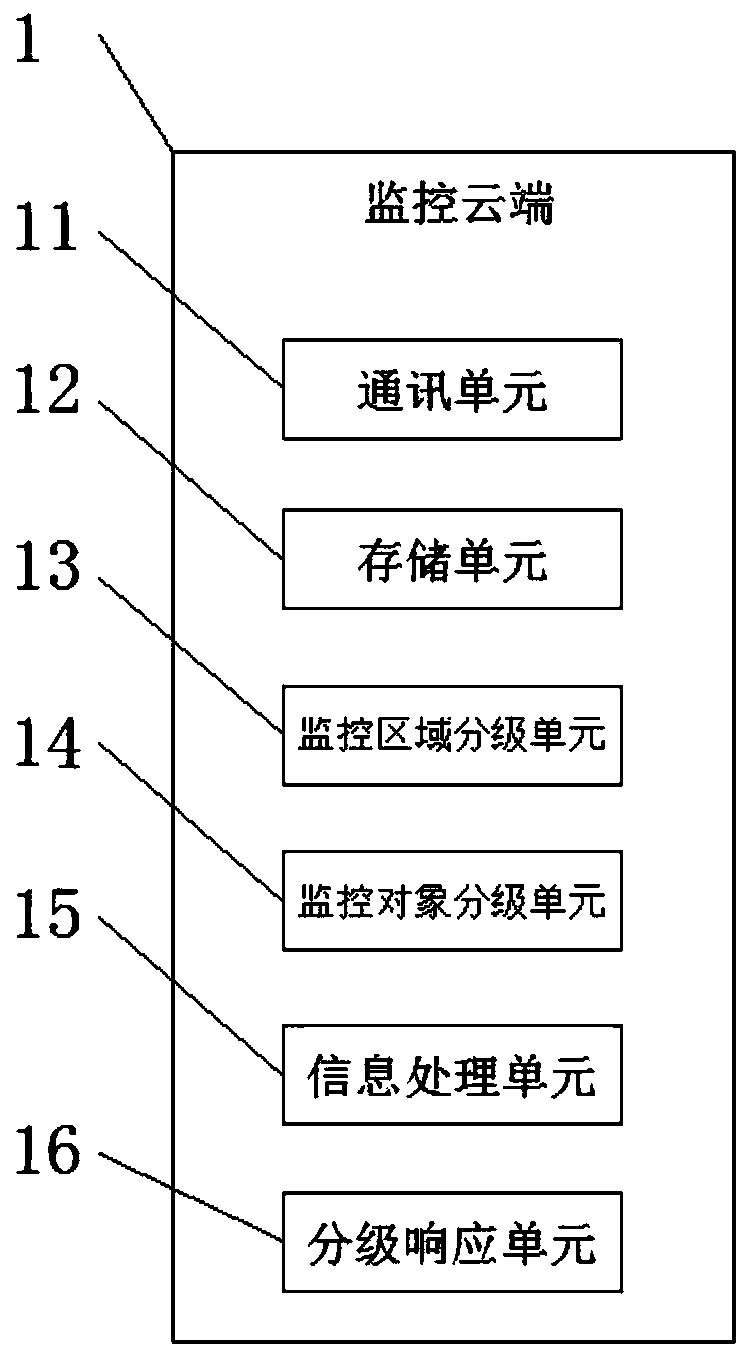

An intelligent community safety monitoring system and a safety monitoring method

InactiveCN109671001AEasy accessImprove monitoringTelevision system detailsData processing applicationsVideo monitoringMonitoring system

The invention discloses an intelligent community safety monitoring system and a safety monitoring method. The system comprises a monitoring cloud, a video monitoring unit, an entrance monitoring unit, an outlet monitoring unit, a field prompting unit, an automatic alarm unit and a hand-held terminal. The monitoring cloud is arranged in an equipment operation room; the video monitoring unit is connected with the monitoring cloud through an electric signal transmitted in the electronic connecting line; the entrance monitoring unit is installed at an entrance of a community and is connected withthe video monitoring unit via an electric signal transmitted in the electronic connecting line; the exit monitoring unit is installed at a community exit and is connected with the video monitoring unit through an electric signal transmitted in the electronic connecting line, the on-site prompting unit is installed on the community monitoring device, and the automatic alarm unit is connected withthe monitoring cloud through an electric signal transmitted in the electronic connecting line. According to the smart community safety monitoring system and the safety monitoring method, the identities of people entering and exiting the community can be identified in time, and the community comfort level index is improved.

Owner:上海东冠通信建设有限公司

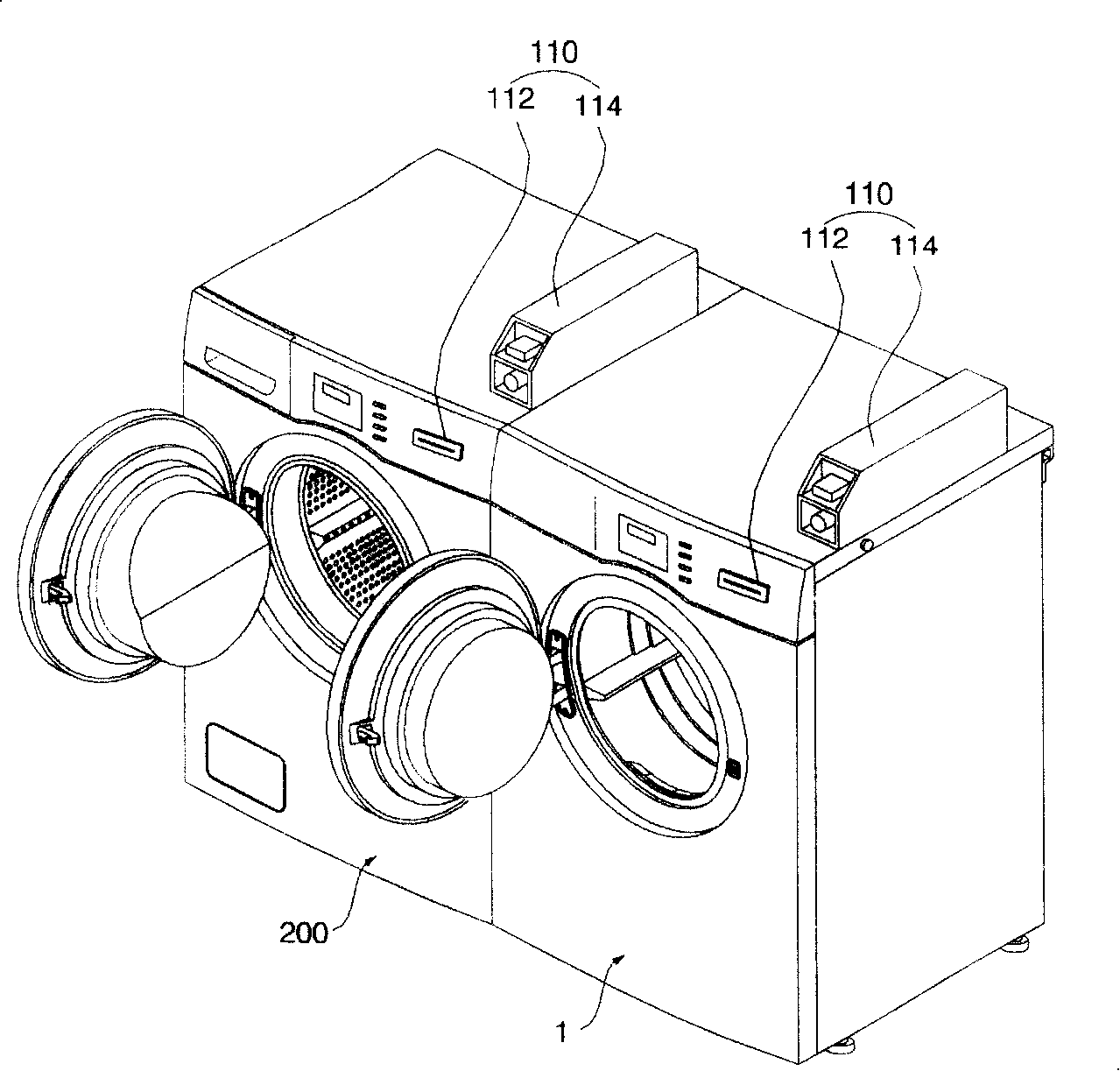

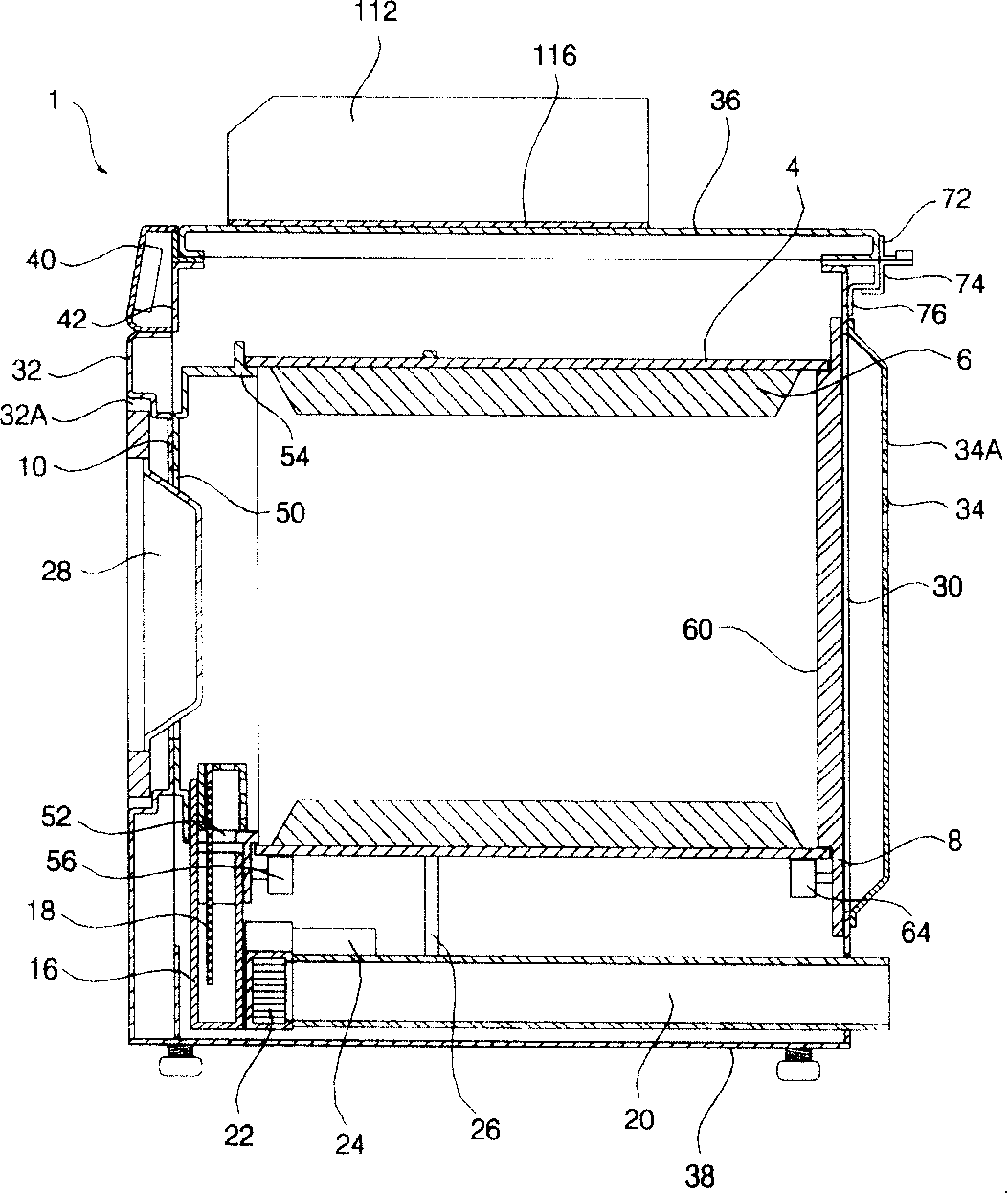

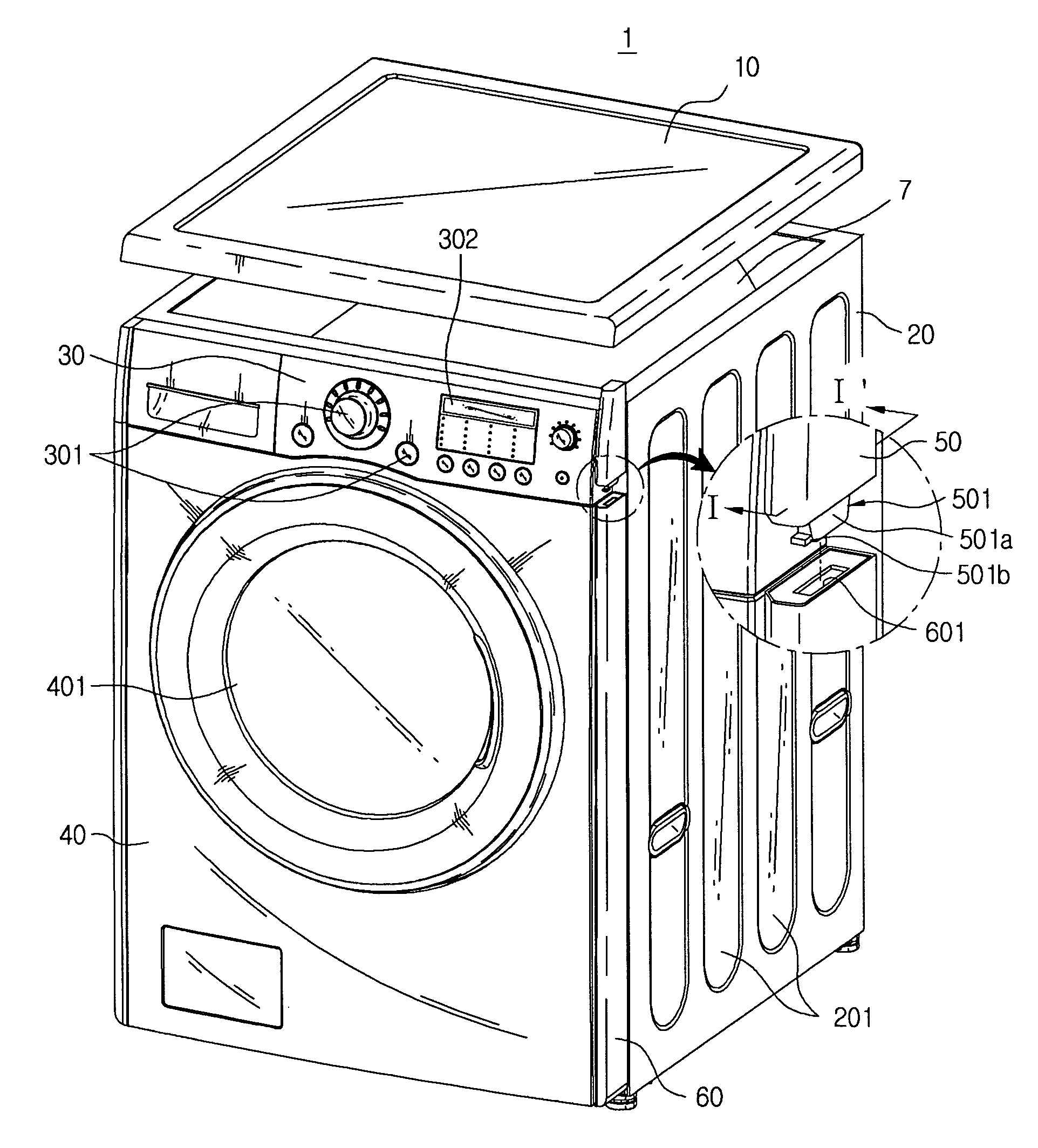

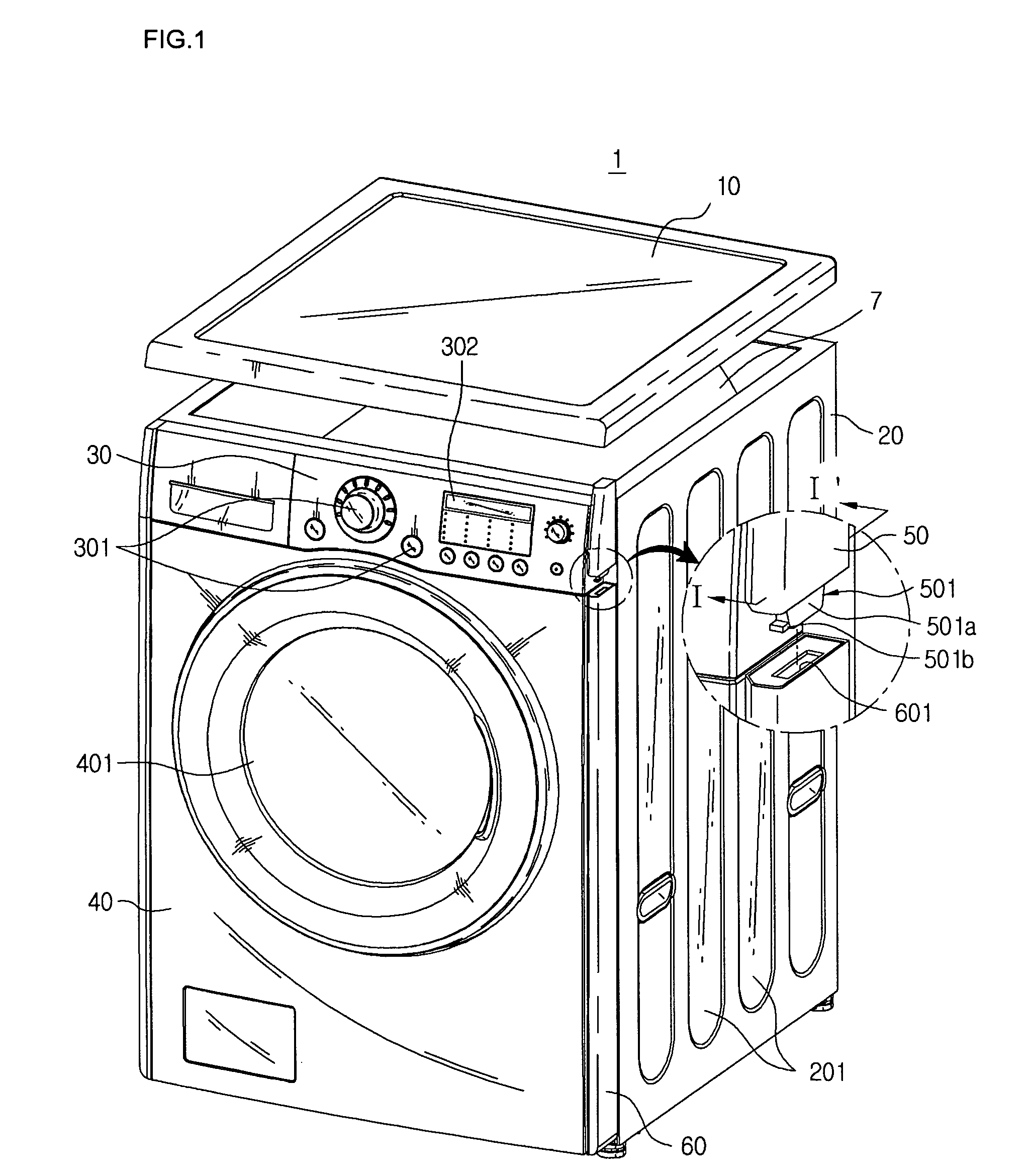

Washing machine

InactiveUS20070180867A1Enhance alignmentNoise and vibration be preventOther washing machinesControl devices for washing apparatusSurface plateFront panel

A washing machine is provided. The washing machine includes a cabinet defining a contour of the washing machine, a front panel coupled to a front portion of the cabinet, a control panel coupled to an upper portion of the front panel, upper panels coupled on both sides of the control panel, and side panels coupled on both sides of the front panel. Each upper panel is provided at a lower end with a hook portion. Each side panel is provided at an upper end with a hook hole in which the hook portion is inserted.

Owner:LG ELECTRONICS INC

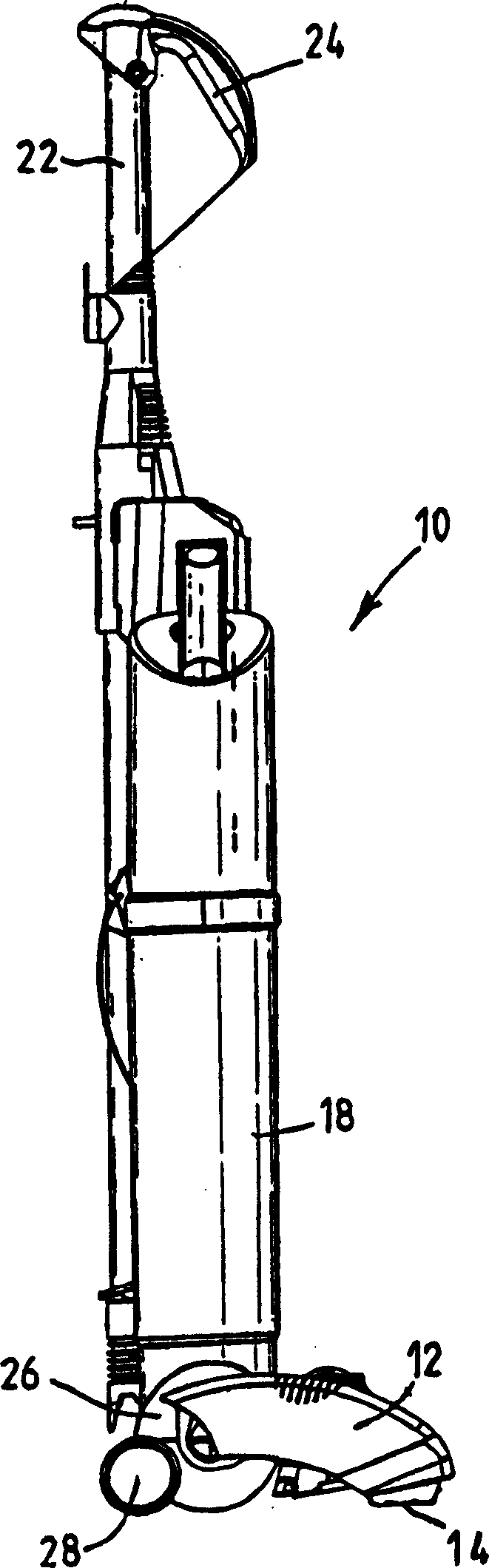

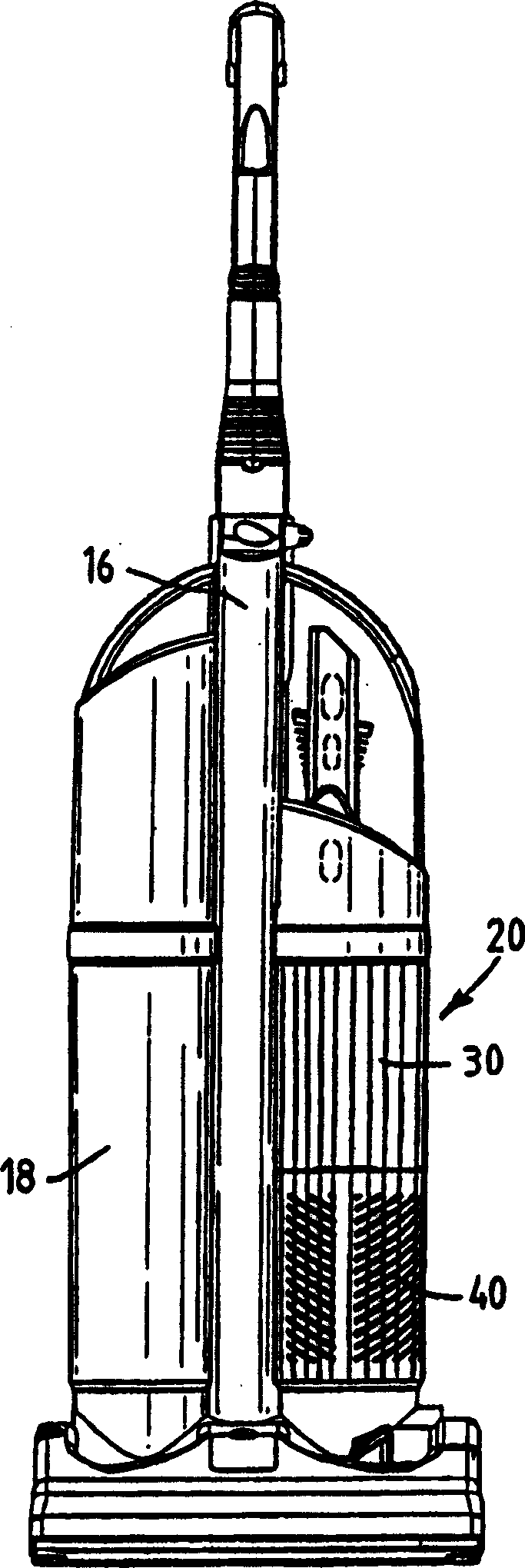

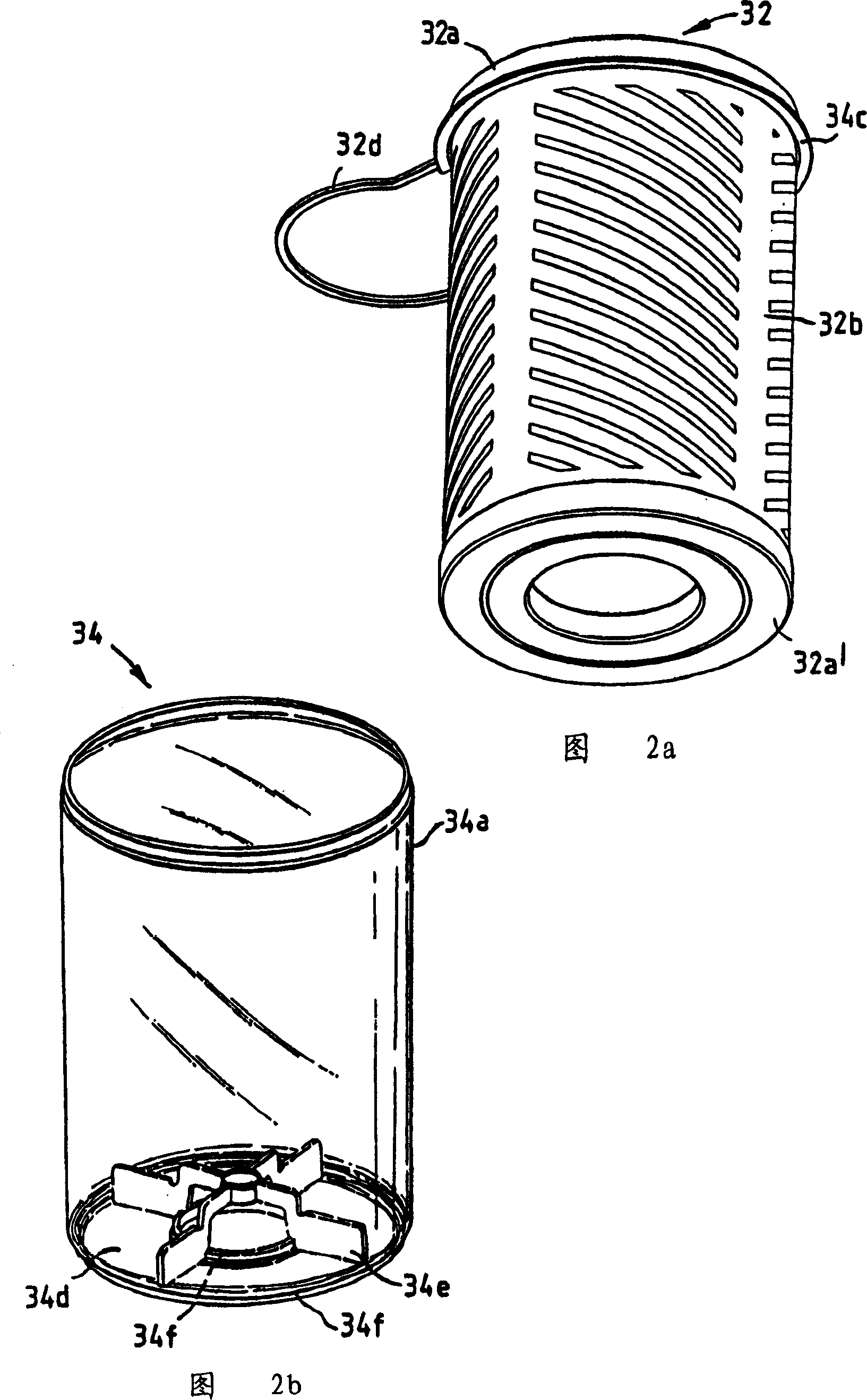

Vacuum cleaner

InactiveCN1593319AReduce intensityReduce dissatisfactionSuction filtersSuction cleaner storing devicesVacuum cleanerWaste management

The invention provides a vacuum cleaner comprising an airflow path having a dirty air inlet (14) and a clean air outlet (44e), a fan (48) for drawing an airflow along the airflow path from the dirty air inlet (14) to the clean air outlet (44e), a motor (50) for driving the fan (48), separating apparatus (18) for separating dirt and dust from the airflow, a pre-motor filter (32) arranged upstream of the motor (50) and a post-motor filter (42) arranged downstream of the motor (50), wherein both the pre-motor filter (32) and the post-motor filter (42) are cylindrical filters. The invention further provides a vacuum cleaner comprising an airflow path having a dirty air inlet (14) and a clean air outlet (44e), a fan (48) for drawing an airflow along the airflow path from the dirty air inlet (14) to the clean air outlet (44e), a motor (48) for driving the fan (50), separating apparatus (18) for separating dirt and dust from the airflow, a pre-motor filter (32) arranged upstream of the motor (50) and a post-motor filter (42) arranged downstream of the motor (50), wherein the post-motor filter (42) is housed in a casing (44) containing a plurality of slots or apertures (44e), the slots or apertures (44e) forming the clean air outlet and being arranged such that, in use, the aiflow is diffused as it leaves the clean air outlet.

Owner:DYSON TECH LTD

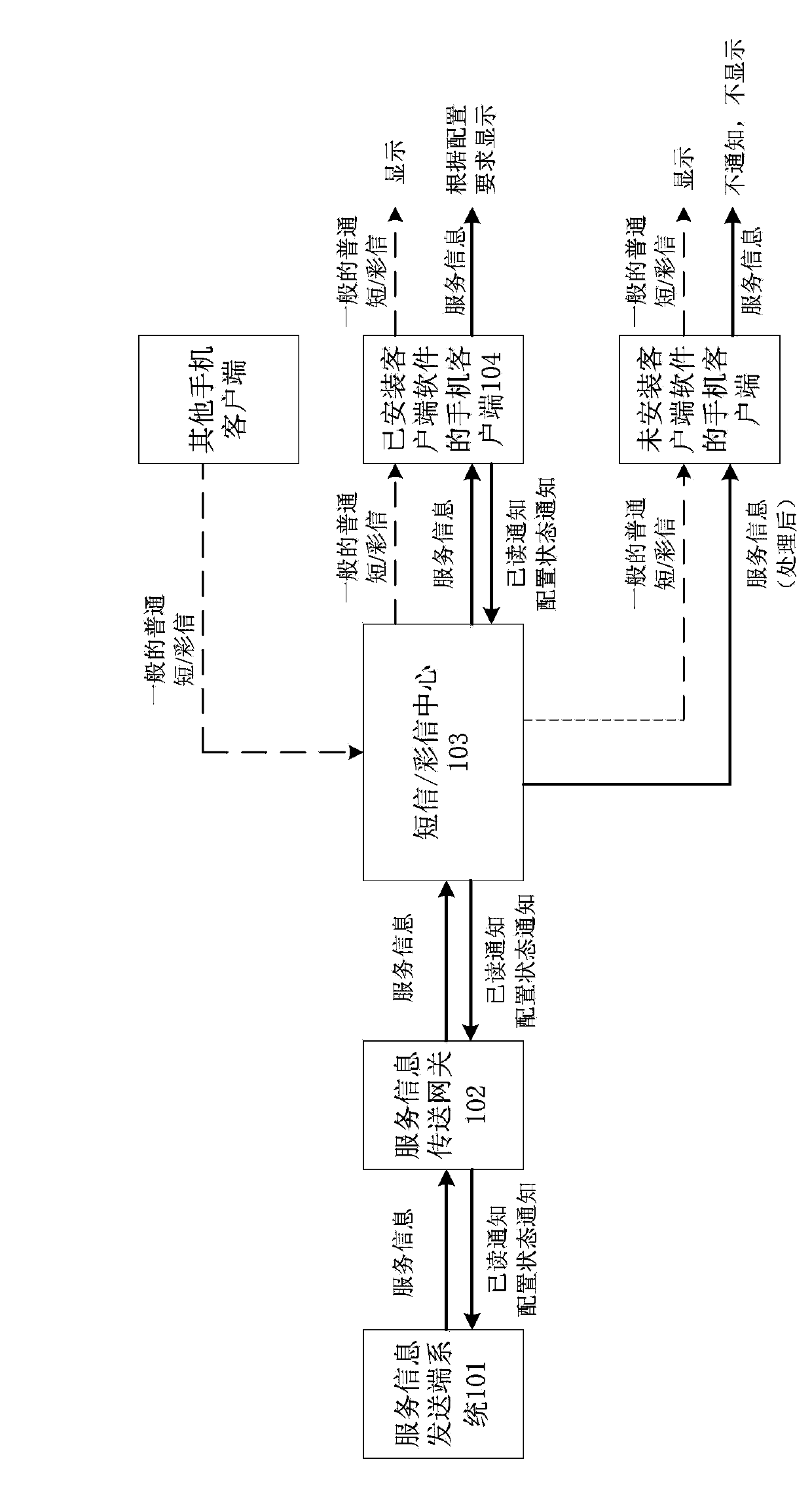

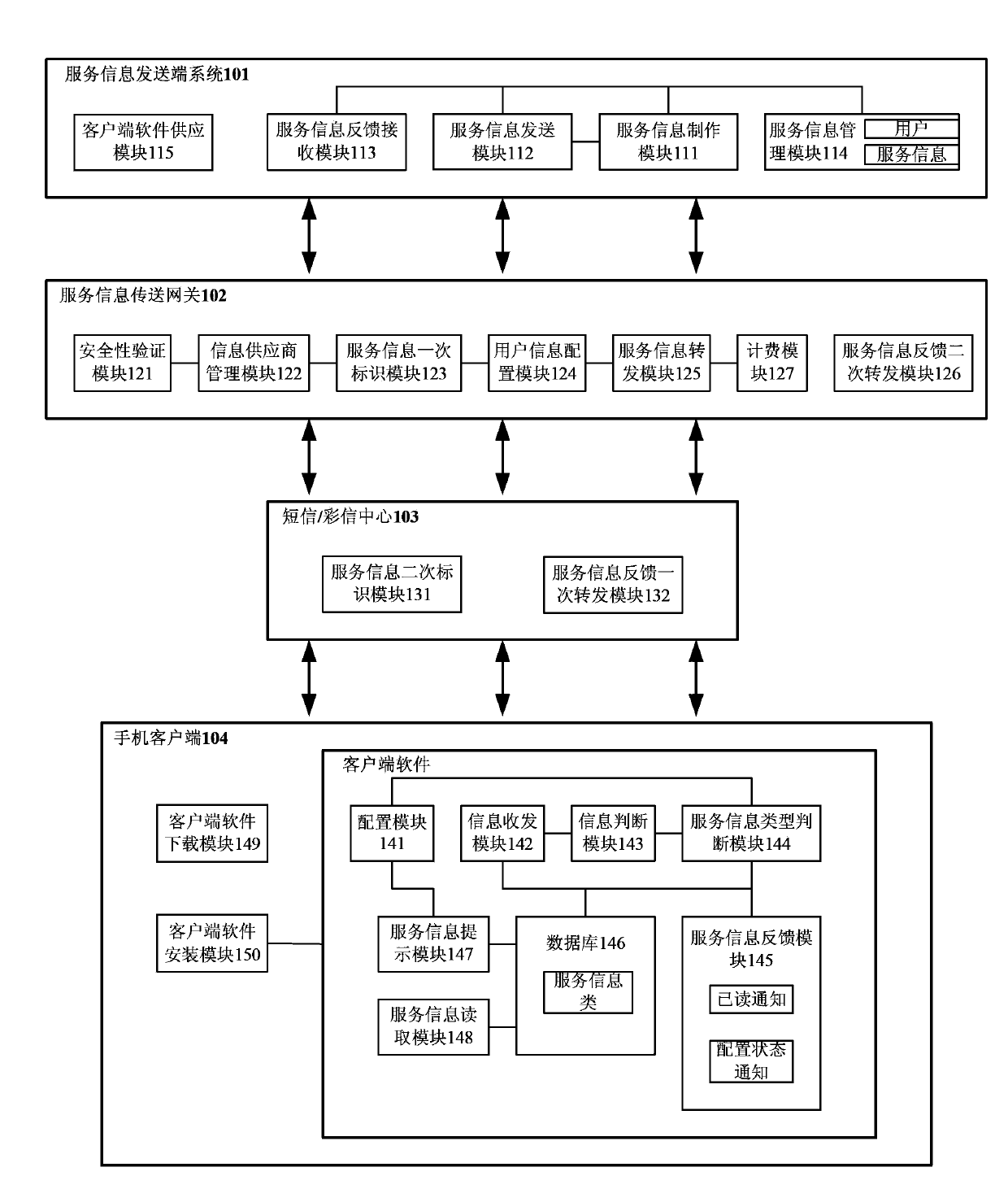

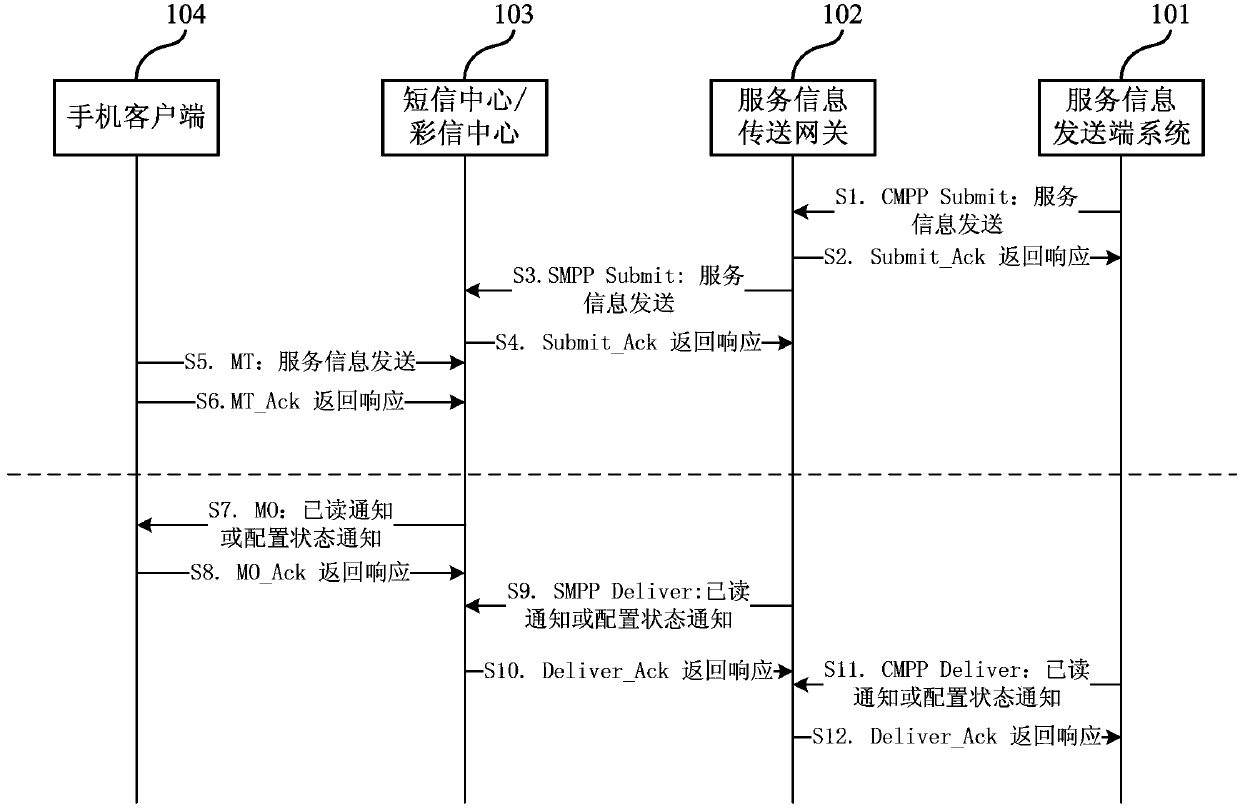

User perception-based service information push system and push method

InactiveCN103634751AReduce dissatisfactionReduce complaintsMessaging/mailboxes/announcementsSecurity arrangementUser perceptionUsers perceptions

The invention provides a user perception-based service information push system and a push method. The push system comprises a service information sending terminal system, a service information transmission gateway, a short message / multimedia message center and a mobile phone client terminal. The service information sending terminal system is used for providing and sending service information. The service information transmission gateway is connected with the service information sending terminal system and receives the service information, and the verified and processed service information is forwarded after security verification, authentication verification, and bit-message bit primary identification processing and subscription verification are performed on the service information. The short message / multimedia message center is connected with the service information transmission gateway and used for performing bit-message bit primary identification processing on the service information and sending out the processed service information. The mobile phone client terminal is connected with the short message / multimedia message center and used for receiving the service information which is processed according to the preset process of the service information after confirmation. The push information is classified in a refining way so that a user can actively select the received the service information, disturbance of spam information on the user is reduced, occupation rate of communication resource is reduced and information issuing efficiency is enhanced.

Owner:SHANGHAI ZHONGYI COMM TECH ENG

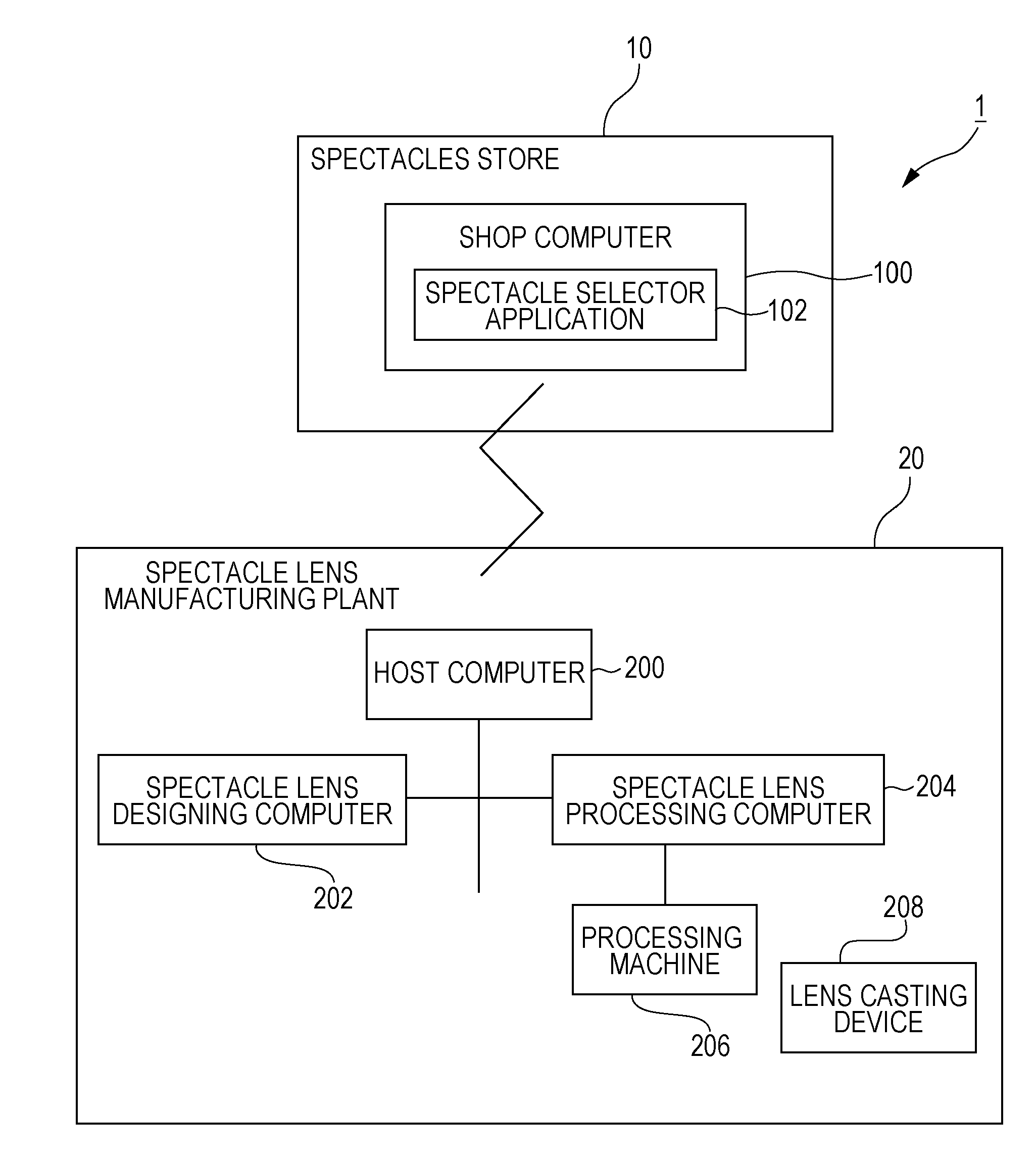

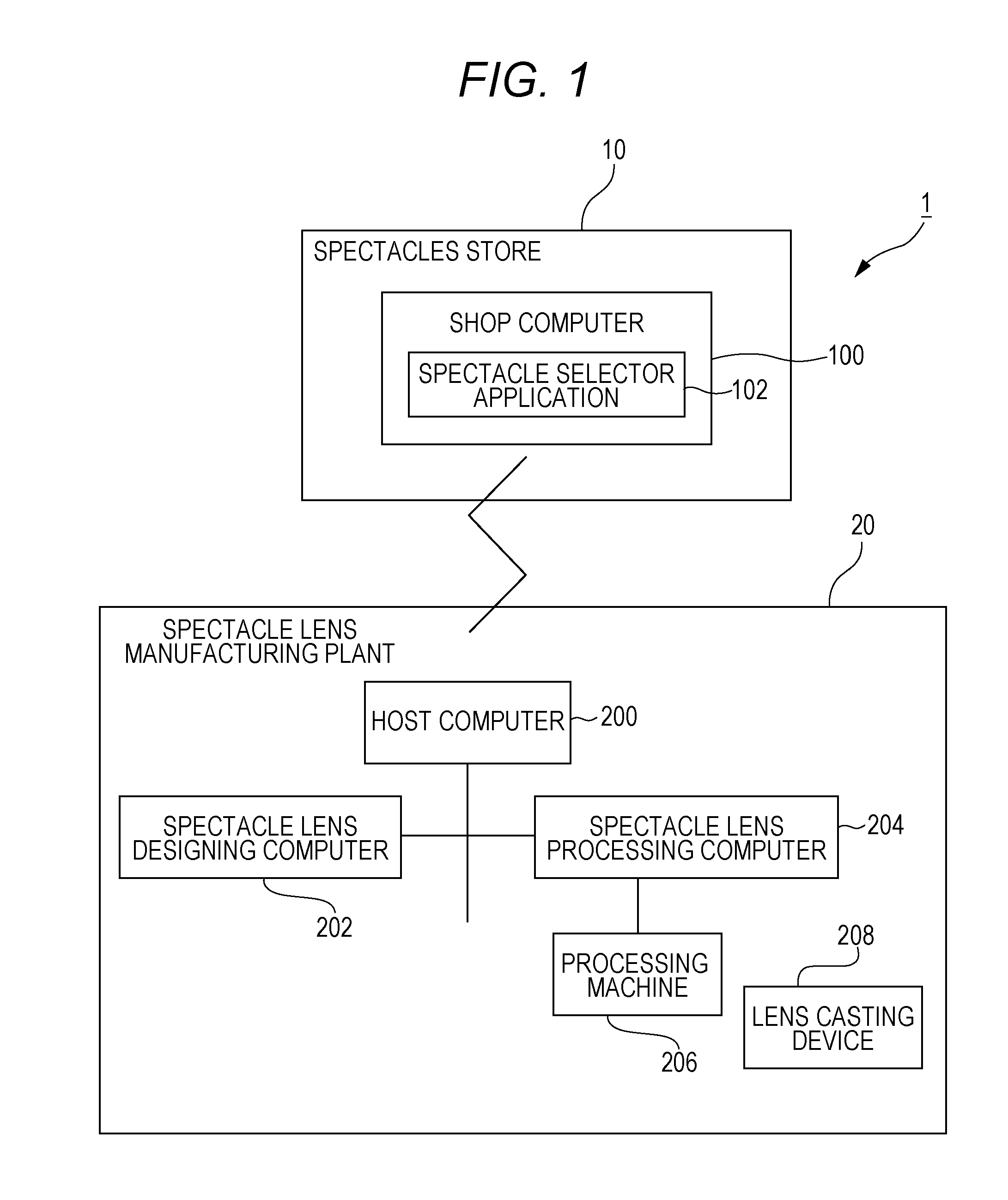

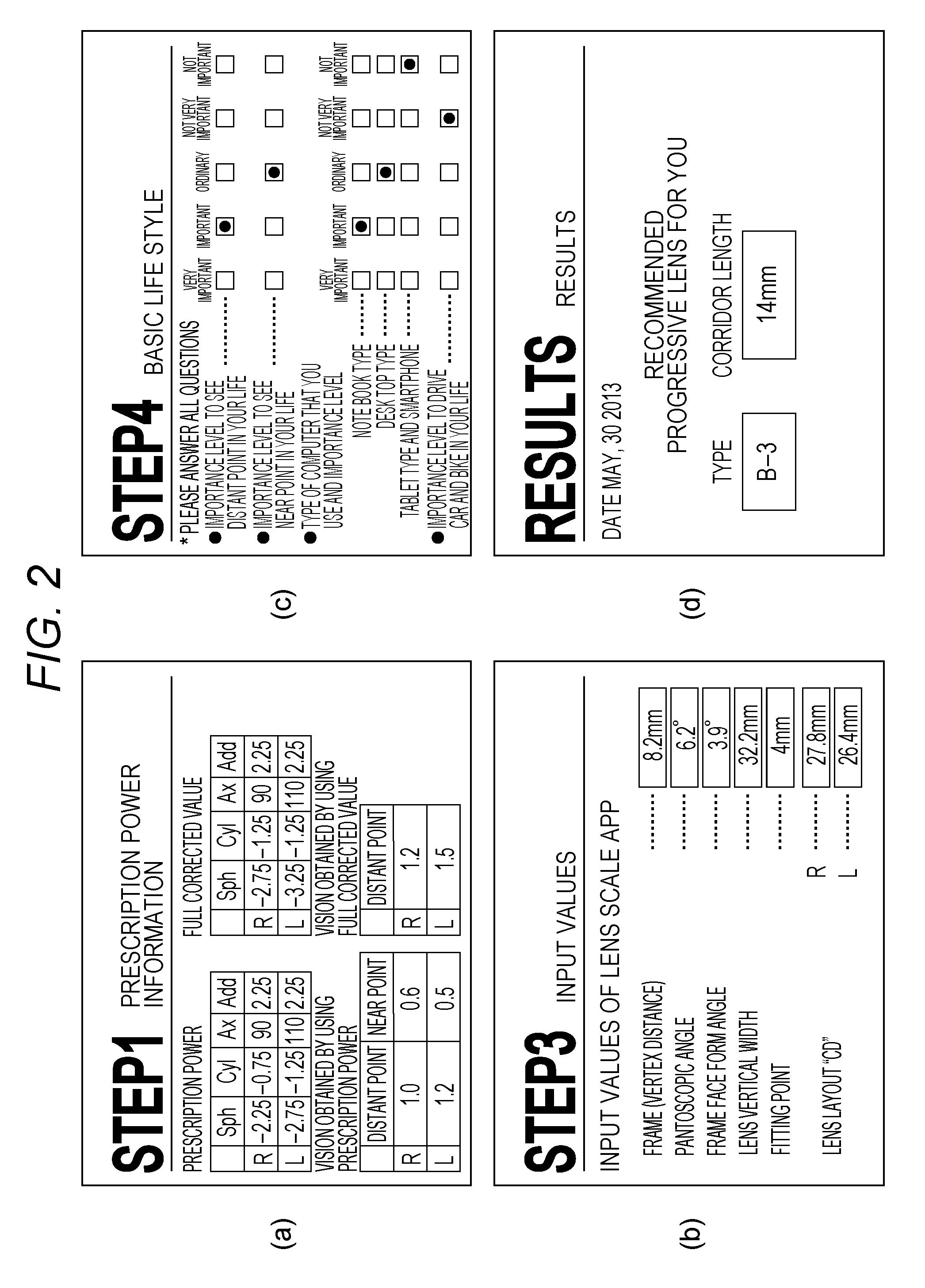

Method, program, and device for manufacturing progressive refractive power lens, manufacturing method for progressive refractive power lens, and lens supply system

InactiveUS20160327808A1Reduce dissatisfactionSpectales/gogglesEye diagnosticsUses eyeglassesMultifocal lenses

Owner:HOYA LENS THAILAND LTD

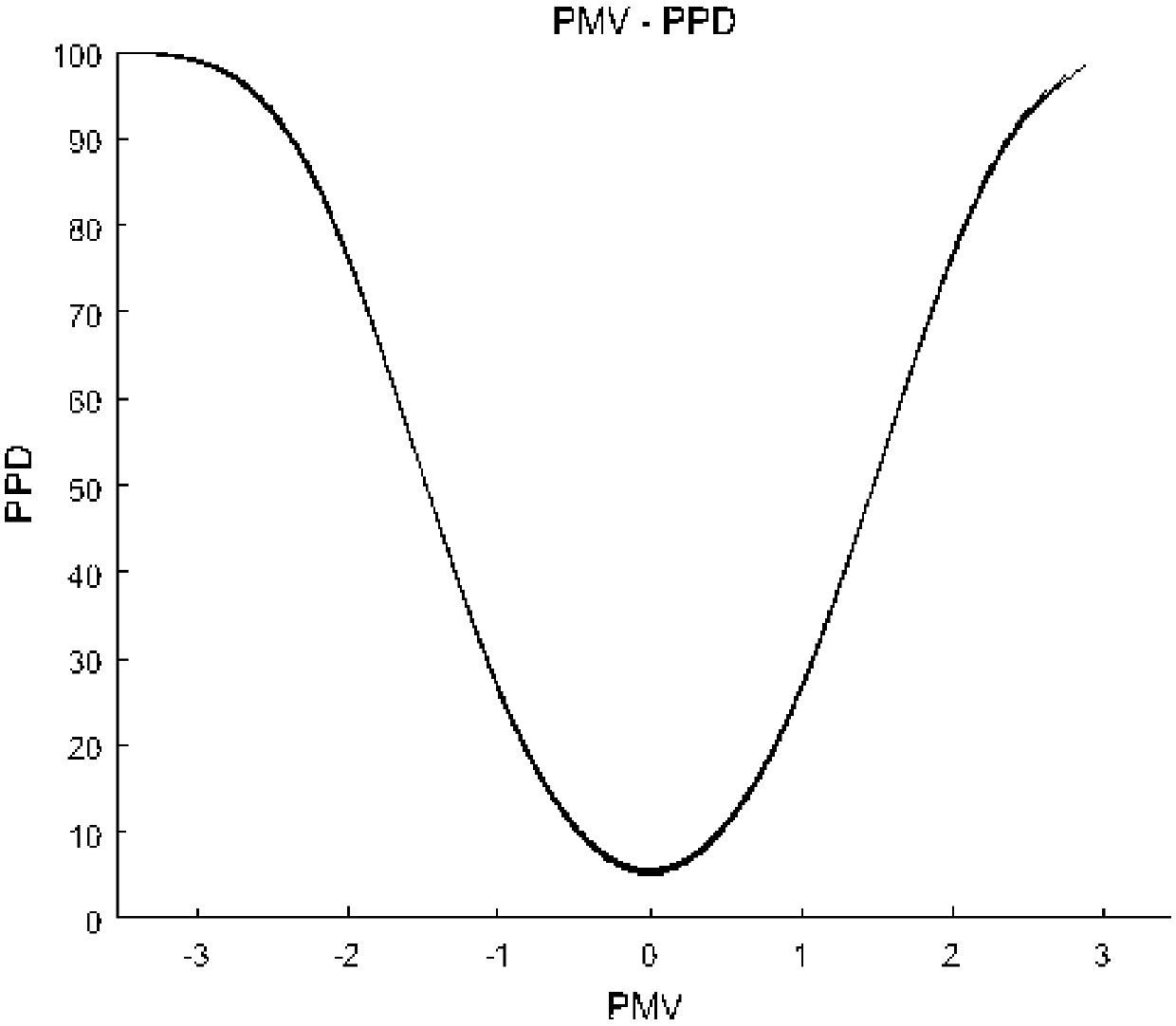

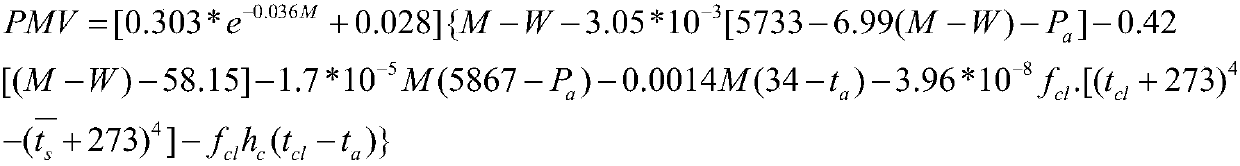

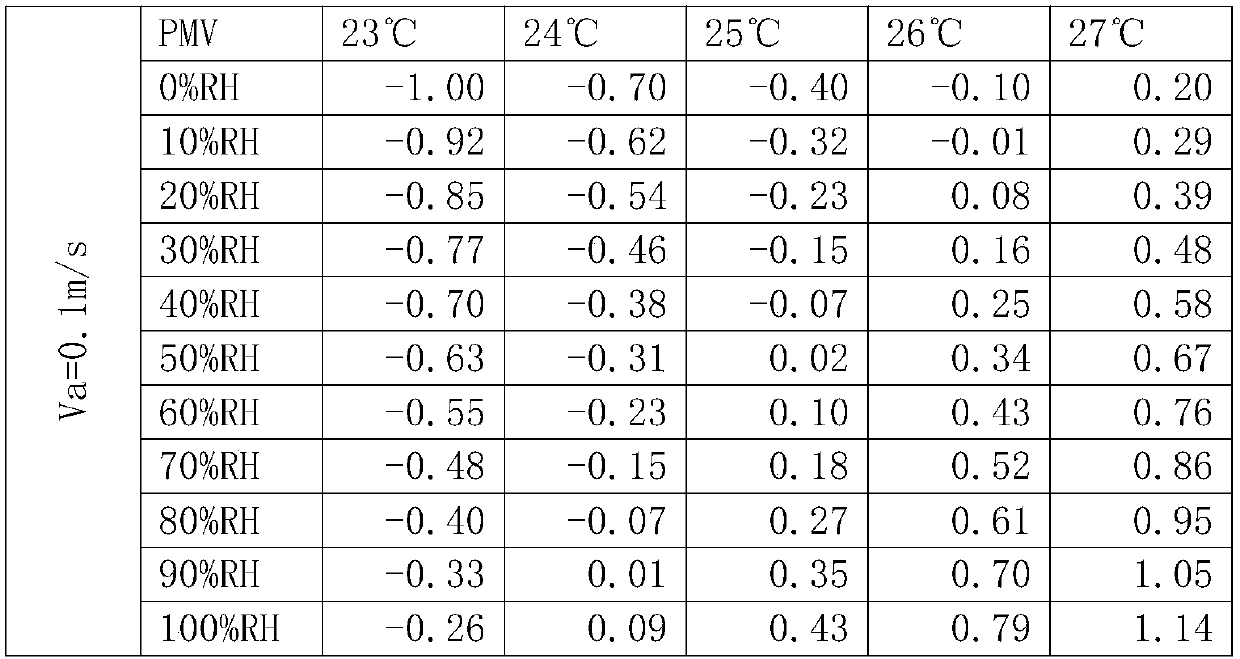

Method and system for improving comfort control precision of direct-current variable-frequency air conditioner

InactiveCN108361936AImprove fine-tuningReduce dissatisfactionMechanical apparatusSpace heating and ventilation safety systemsElectrical resistance and conductanceEngineering

The invention relates to the field of air conditioners, and discloses a method and a system for improving comfort control precision of a direct-current variable-frequency air conditioner. According tothe method and the system, under the condition that the cost of a hardware control scheme is not increased, the calculation and control precision of the PMV can be greatly improved, and the comfort level of a user for using the air conditioner is improved to the largest extent. The method comprises the following steps that firstly, a temperature-AD sampling value relation table is obtained by utilizing an air conditioner temperature-resistance relation table, and the indoor temperature resolution is improved through the temperature-AD sampling value relation table; then by adopting the mode of using the frequency being integer multiples of 0.1Hz for controlling the operation of a compressor in an increment / decrement mode, the fine adjustment capacity of the compressor is improved; and finally, under the condition that the cost of the hardware control scheme is not increased, the calculation and control precision of the PMV can be greatly improved, and the comfort level of the user forusing the air conditioner can be improved to the largest extent. The method and the system are suitable for controlling the comfort of the direct-current variable-frequency air conditioner.

Owner:四川长虹空调有限公司

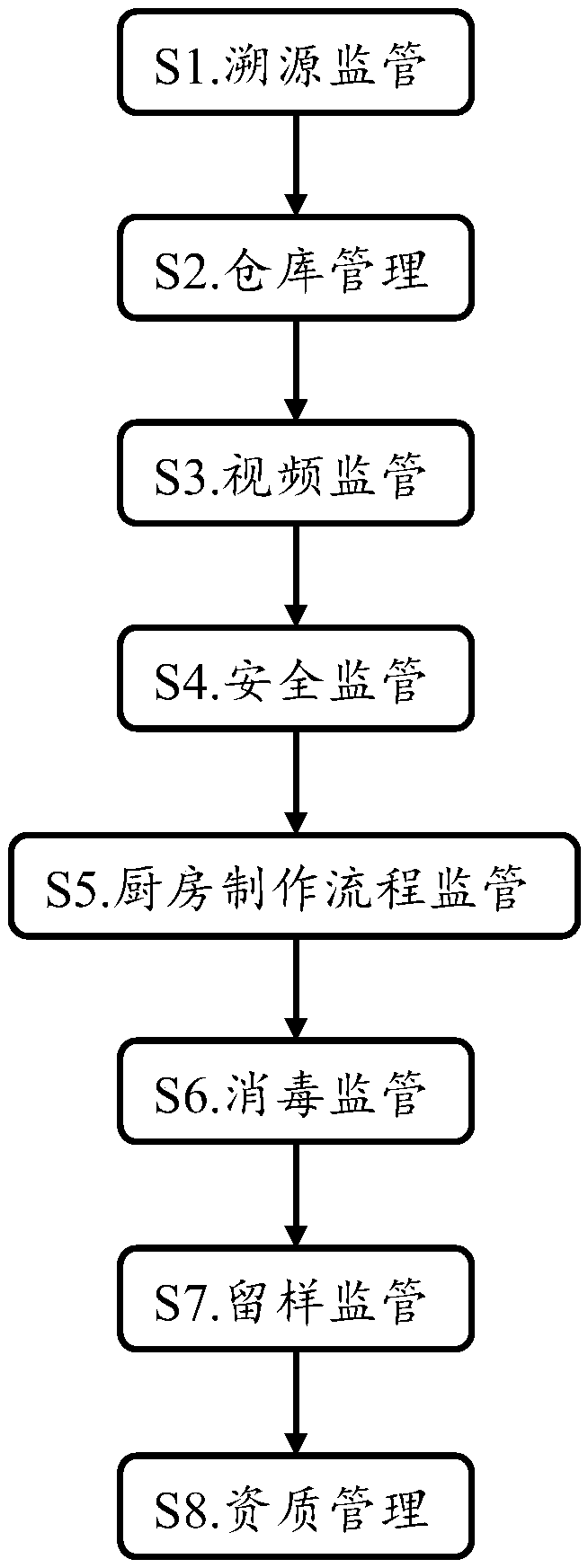

A whole-process supervision method for food safety of a public canteen

PendingCN109685306AImprove the safety management systemGuarantee the healthy growth of mind and bodyResourcesInformatizationFood poisoning

The invention relates to the technical field of food safety monitoring, and particularly discloses a whole-process supervision method for public canteen food safety, which comprises the following steps: traceability supervision; Warehouse management; Video supervision; Carrying out safety supervision; Supervising a food making process; Disinfecting and supervising; Carrying out reserved sample supervision; Qualification management. Technologies such as Internet of Things, big data, cloud computing, video intelligent analysis and the like are fully utilized, food safety supervision is comprehensively improved, food safety management modernization is promoted, and standardized, refined, efficient, informationized and standardized supervision can be realized from operation processes such as food raw material purchase and acceptance inspection, processing and cooking, meal preparation, tableware cleaning and disinfection and sample reserving. According to the invention, a canteen food environment can be created for students; Governments and supervision departments are helped to effectively supervise schools and kindergartens; Food safety awareness of schools and kindergarten canteens is enhanced, a food safety management system is perfected, food safety responsibilities are put into practice, and food poisoning events are prevented and controlled.

Owner:惠州市格讯信息产业有限公司 +1

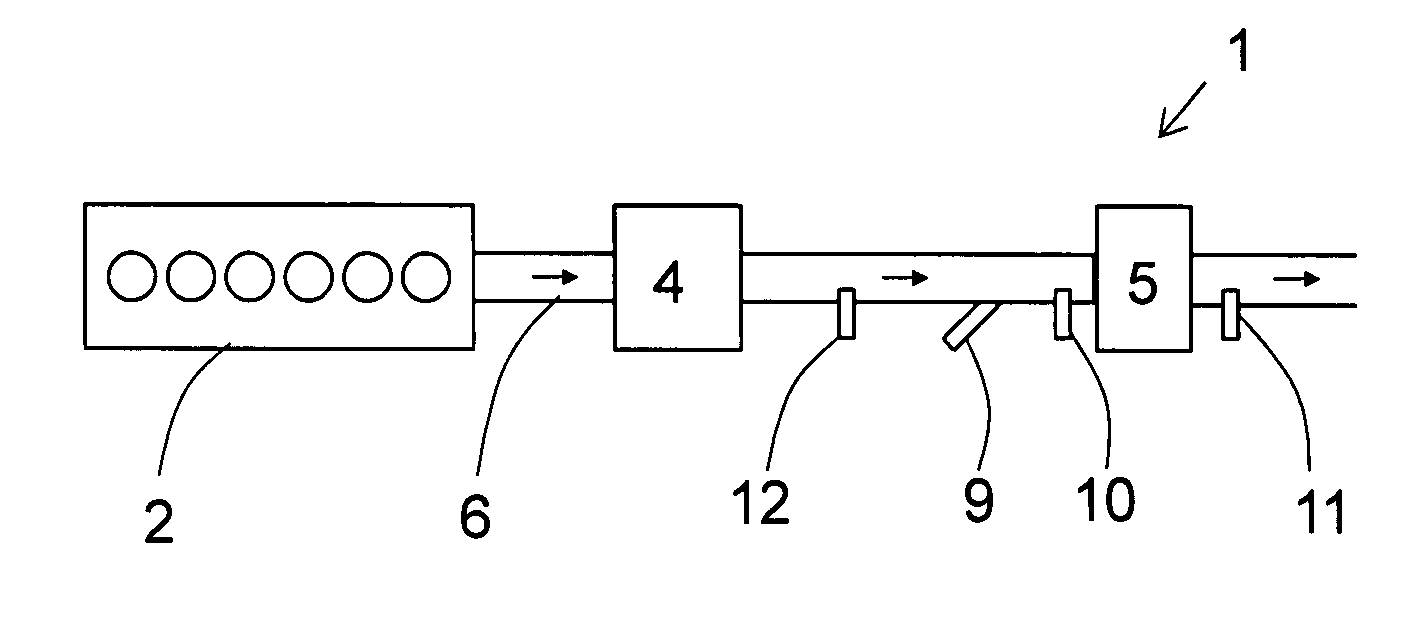

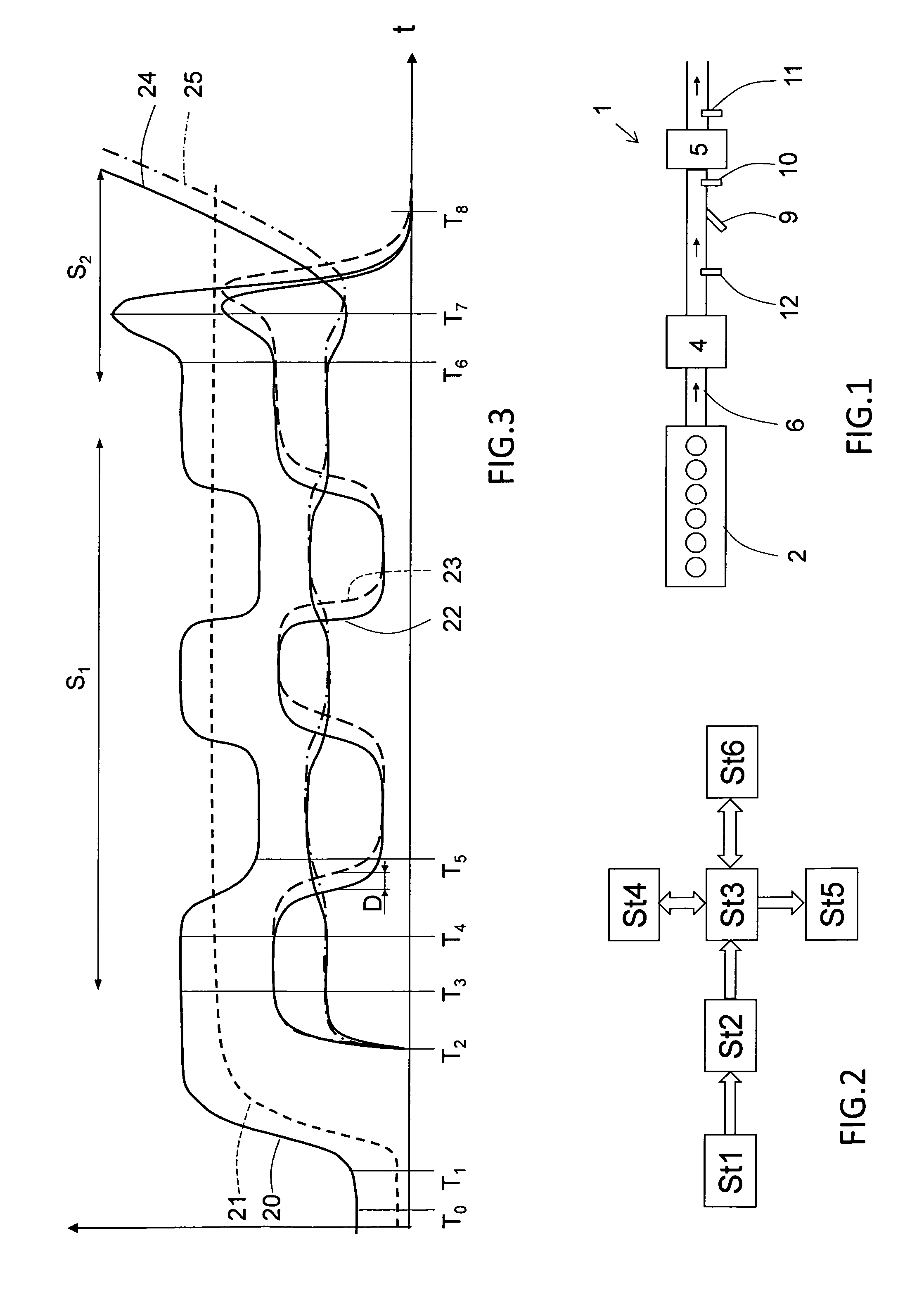

Self-diagnosing method for diagnosing a SCR system

ActiveUS9677488B2Reduce dissatisfactionReduce riskElectrical controlInternal combustion piston enginesNitrogen oxideExhaust gas sensor

A self-diagnosing method for diagnosing a selective catalytic reduction (SCR) system of a vehicle that includes an internal combustion engine. An SCR system is arranged downstream of the engine, and the SCR system includes at least one exhaust gas sensor that is sensitive to nitrogen oxides (NOx) gas. The method includes a first diagnosing sequence (S1) of ensuring that the vehicle is in a stationary state, controlling the engine to operate in a high NOx output engine operating state and in a low NOx output engine operating state, registering an output signal of the at least one exhaust gas sensor when the engine operates in each of the high NOx output engine operating state and low NOx output engine operating state, and diagnosing NOx measurement performance of the at least one exhaust gas sensor on the basis of the registered sensor output.

Owner:VOLVO LASTVAGNAR AB

Machining method for automotive front axle half shaft

InactiveCN103071971AExtend your lifeReduce contaminationMetal rollingChemical compositionMaterial consumption

The invention discloses a machining method for an automotive front axle half shaft, comprising the following steps that a steel ingot is poured, and the steel ingot comprises the chemical compositions in percentage by weight that C is more than or equal to 0.180 percent and is less than or equal to 0.250 percent, Si is more than or equal to 0.79 percent and is less than or equal to 1.00 percent, Mn is more than or equal to 0.78 percent and is less than or equal to 1.00 percent, P is more than or equal to trace amount and is less than or equal to 0.030 percent, S is more than or equal to trace amount and is less than or equal to 0.030 percent, Cr is more than or equal to 11.50 percent and is less than or equal to 13.50 percent, and inevitable impurities account for the rest amount. The machining method for the automotive front axle half shaft facilitates large-batch industrialized production, the phenomena of dirt containing and insufficient filling in the forging process are reduced, the mechanical performance of products is further improved, the material consumption of the products is saved, and the service life of a mold of the products is improved.

Owner:CHANGLI FORGING

Online car-hailing order sending method

InactiveCN111178659AReduce waiting timeEasy to matchBuying/selling/leasing transactionsResourcesData scienceOperations research

The invention relates to the technical field of the Internet, and discloses an online car-hailing order sending method, which realizes bidirectional selection by utilizing asymmetric evaluation of a driver and a passenger and improves the satisfaction of the driver and the passenger. The online car-hailing order sending method is characterized in that behaviors of a passenger party and a driver party are divided more meticulously, multi-dimensional scoring is carried out; certain rewards and punishment are applied; on one hand, the probability of civilized passengers to civilized drivers is improved; the probability of rejecting good coins by inferior coins is effectively reduced; another aspect, the guidance of rewards and punishment is beneficial to constraining behaviors of both parties; the development of riding civilization is facilitated; a multi-dimensional evaluation system is used; compared with the prior art, the method has the advantages that the driver party and the passenger party are evaluated more stereoscopically, on one hand, better matching is achieved, the satisfaction degree of the two parties is improved, and on the other hand, the matching degree of the two parties is improved to the maximum extent while the actual transport capacity is not affected due to the fact that points and bearing degrees which cannot be borne by each person are different and additional service fees are supplemented.

Owner:孙群

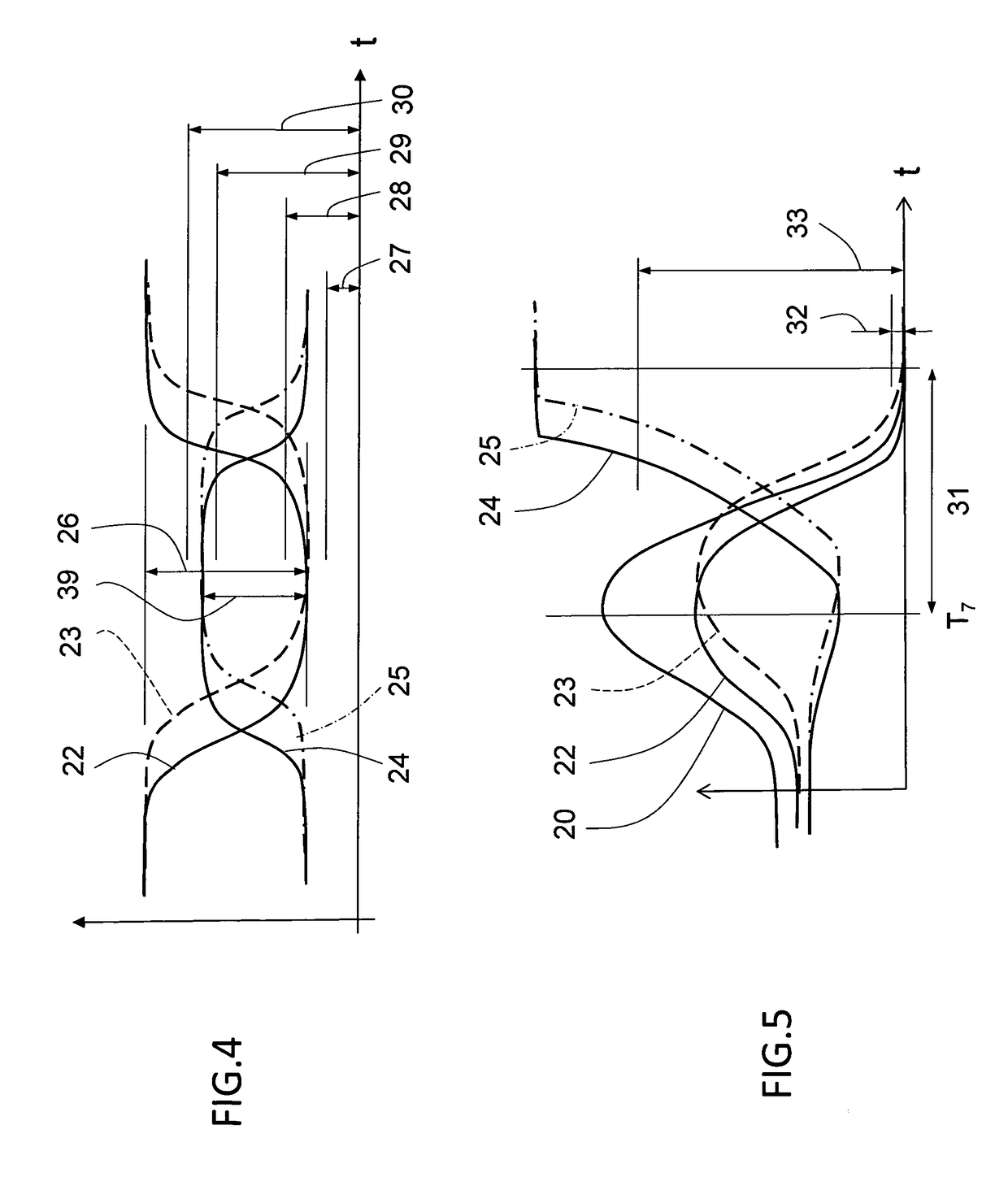

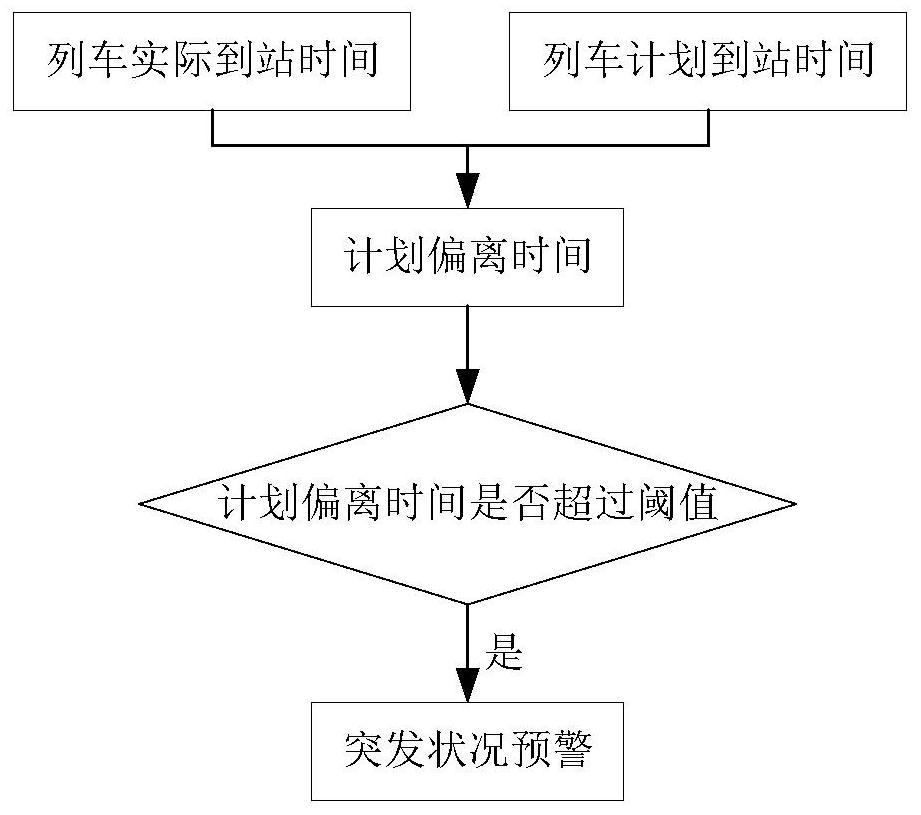

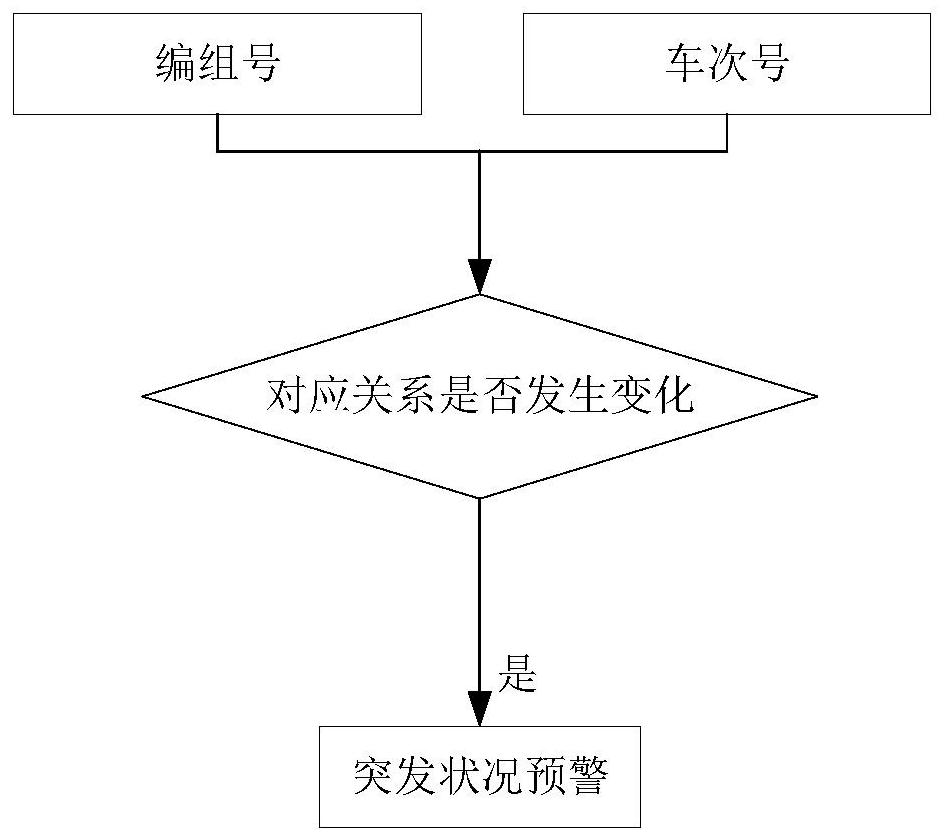

Rapid early warning method and system for rail traffic accidents

PendingCN112465334AReduce dissatisfactionImprove service levelAlarmsResourcesTraffic crashComputer science

The invention belongs to the technical field of urban rail transit management, and particularly relates to a rapid early warning method and system for rail transit accidents. In an existing urban railoperation process, after an emergency occurs, field personnel carry out train operation adjustment and passenger flow control according to experience. However, the mode is lack of scientific and effective data support. The invention provides a rapid early warning method for rail transit accidents, and the method comprises the following steps: 1) identifying the possibility of an emergency according to the real-time running state data of a rail transit line network train, and pushing and displaying possible emergency information; 2) analyzing the influence range of emergencies; 3) realizing dispatcher dispatching simulation according to assumptions of duration of different emergencies, and providing train operation adjustment suggestions; 4) according to assumptions of duration of different emergencies, analyzing the passenger flow conditions, and providing passenger flow control suggestions, so the service level of urban rail transit is improved.

Owner:BEIJING JIAOTONG UNIV

Preparation method of submersible pump shaft

InactiveCN105370615AIncrease profitExtend your lifePump componentsPretreated surfacesMechanical propertyMaterials science

The invention discloses a preparation method of a submersible pump shaft. The method comprises the following technological step of a, casting a pump shaft blank, wherein the pump shaft blank comprises, by weight percent, 2.15%-2.35% of C, 1.3%-2.5% of Mn, 0.8%-1.2% of Si, 0.6%-0.9% of Cr, 0.22%-0.35% of Co, 0.15%-0.25% of B, 0.55%-0.95% of Ti, 0.14%-0.22% of Cu, 0.012%-0.023% of P, 0.006%-0.01% of S and the balance Fe and unavoidable inclusion. Mass industrial production is better achieved, phenomena of dirt clamping and inflation dissatisfaction in the forging process are reduced, the mechanical property of products is further improved, product raw materials are saved, and the rust-proof antioxidant service life of the pump shaft is prolonged.

Owner:高鹏

Processing method of forge piece pump shaft

InactiveCN102989945AExtend your lifeReduce contaminationMetal-working apparatusEngine componentsImpurityIndustrial engineering

The invention discloses a processing method of a forge piece pump shaft. The processing method of the forge piece pump shaft comprises the following steps: a step a of pouring a cylindrical blank material, wherein the cylindrical blank material comprises chemical components, by weight percent: 0.26-0.350% of C, 1.2-2.2% of Mn, 0.6-1.5% of Si, 1.6-2.0% of Cr, 0.42-0.8% of W, 0.4-1.0% of Cd, 0.35-0.50% of Cu, no greater than 0.040% of P, no greater than 0.030% of S, and the balance of Fe and inevitable included impurities; and the step a comprises the following steps: cooling the completely-poured blank material to 150 to 200 DEG C in air, heating the blank material to 750 to 800 DEG C at a temperature rise speed of 50 to 60 DEG C for 3-4h heat preservation, cooling the blank material to the room temperature in a furnace and then heating the blank material to 1020 to 1050 DEG C at a temperature rise speed of 100 to 120 DEG C for 1-2h heat preservation; and a step b of forging. The processing method of the forge piece pump shaft is beneficial to the large-batch industrial production of the forge piece pump shaft; and moreover, the phenomena of dirt inclusion and impossible fullness occurring during the forging process are reduced, the mechanical performance of a product is further improved, the product material is saved and the service life of a die for the product is prolonged.

Owner:CHANGLI FORGING

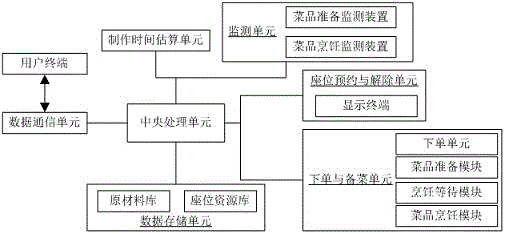

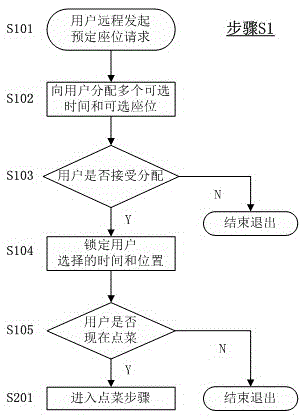

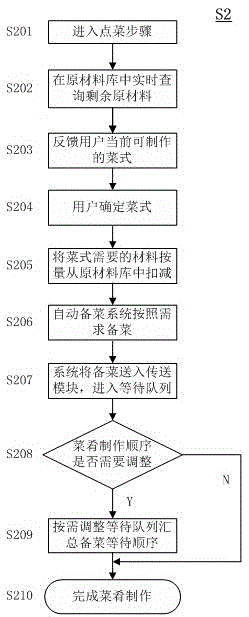

Dinning waiting time calculation method

InactiveCN105469328AExtended waiting timeReduce dissatisfactionData processing applicationsCommunication unitComputer terminal

The invention provides a dinning waiting time calculation method which is applied to a restaurant automation system. The restaurant automation system comprises a user terminal, a data communication unit, a central processing unit, a data storage unit, a seat reserving and cancelling unit, an ordering and dish preparing unit, a making time estimation unit and a monitoring unit. The monitoring unit includes a dish-preparing monitoring device and a dish-cooking monitoring device, and the dish-preparing monitoring device and the dish-cooking monitoring device each include a timing device. The making time estimation unit estimates the waiting time for each link to get the total waiting time, and feeds the total waiting time back to users. Users can easily query and estimate the waiting time. Therefore, user dissatisfaction due to unknown waiting time is reduced, and the user experience is enhanced.

Owner:朱文清

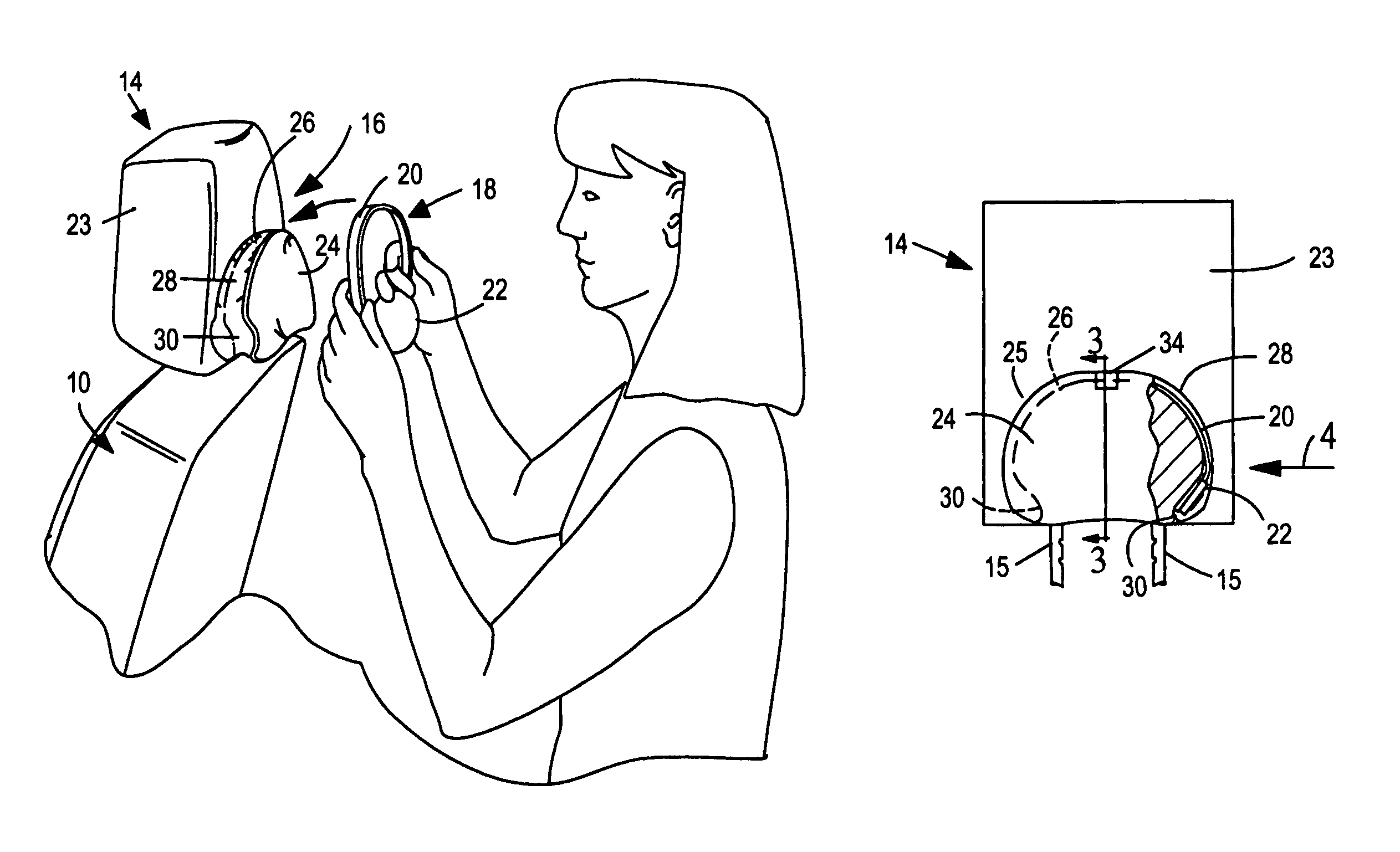

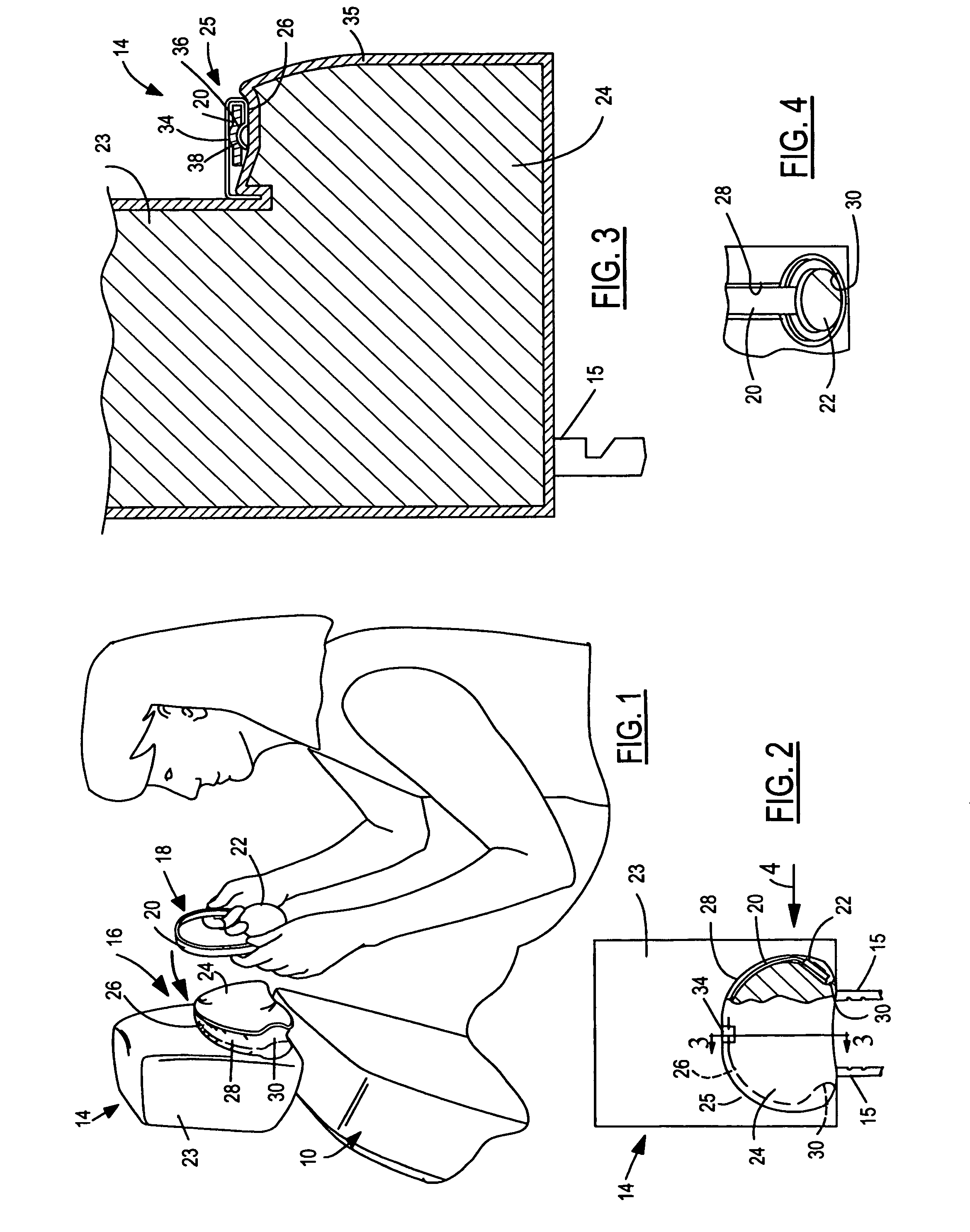

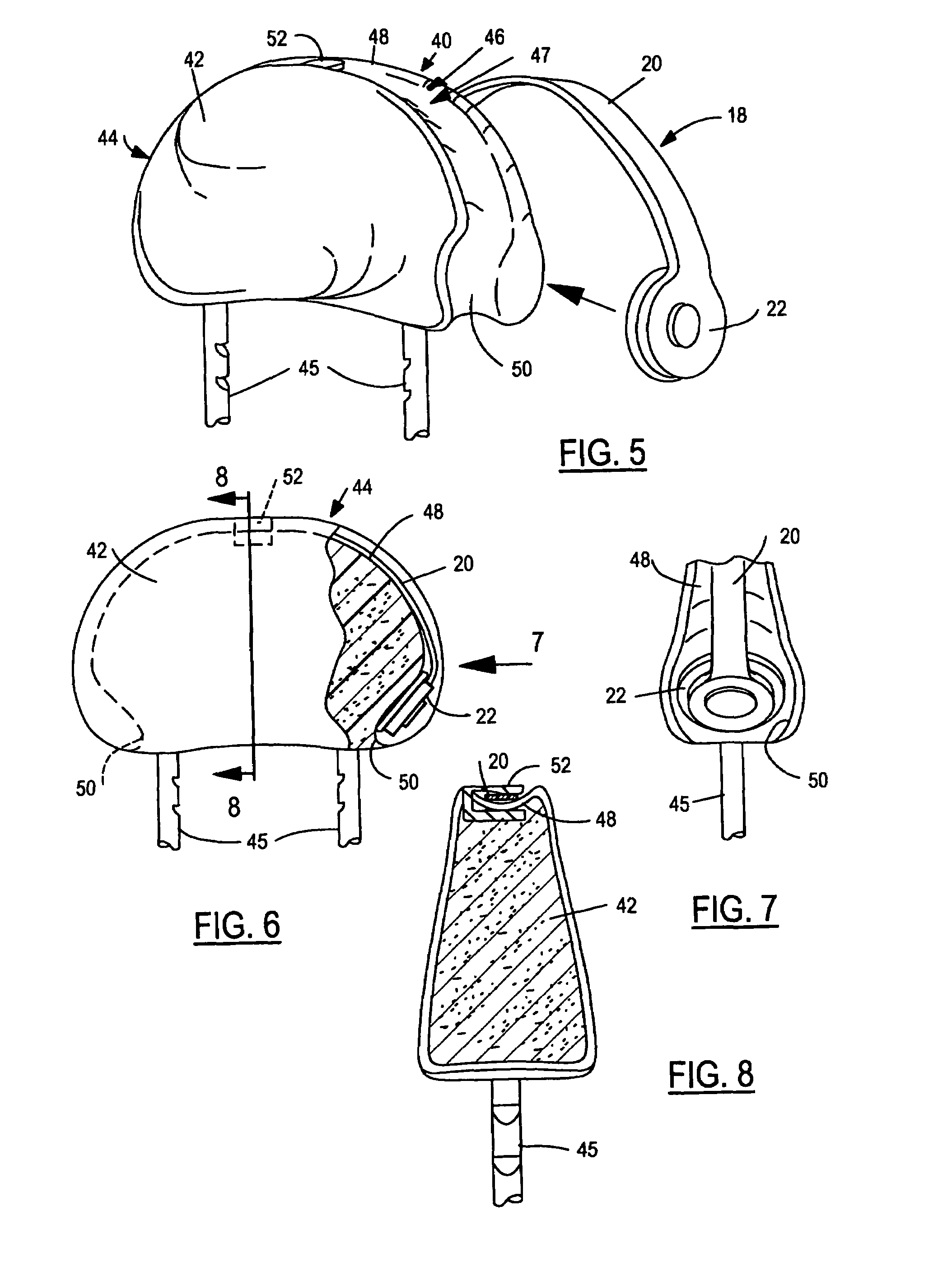

Vehicular packaging system for headphone devices

ActiveUS7643645B2Reduce dissatisfactionAvoid risk of damageTransducer detailsTransmissionEngineeringHeadphones

Owner:FCA US

Forging method of automotive eccentric shaft

InactiveCN102989953AReduce consumptionReduce consumption costMetal-working apparatusFurnace typesChemical compositionSlag

The invention discloses a forging method of an automotive eccentric shaft, which comprises the steps of: a, pouring a cylindrical blank which contains the chemical components of, by weight percent: 0.23-0.40% of C, 1.5-2.0% of Mn, 0.6-0.9% of Si, 0.07-0.15% of Zr, 0.8-2.0% of Cr, 0.42-0.8% of W, 0.4-1.0% of Cd, 0.4-0.50% of Cu, equal to or less than 0.040% of P and equal to or less than 0.030% of S, cooling the poured blank to 300 DEG C, then heating to 650-760 DEG C, thermally insulating for 3-5 hours, furnace cooling to 300 DEG C, thermally insulating for 4 hours, heating again to 650-760 DEG C, thermally insulating for 17 hours, cooling to 400 DEG C at cooling speed of 50 DEG C / hour and then cooling to 140 DEG C at cooling speed of 20 DEG C / hour; b, forging: 1, selecting round bar steel with diameter of 30 and blanking through a shear, with the length of the sheared rough blank is 70.3mm; and 2, heating the rough blank obtained in above step into a medium frequency heating furnace at 1,120-1,180 DEG C for 3.6min. The forging method is good for large scale industrial production of the automotive eccentric shafts, and reduces the problems of slag inclusion and short shot in the forging process. The mechanical property of the automotive eccentric shaft is further improved, material consumption of the eccentric shaft is reduced and the service life of a die for forging the eccentric shaft is prolonged.

Owner:CHANGLI FORGING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com