Vacuum cleaner

A dust collector and vacuum technology, which is applied in the direction of vacuum cleaners, vacuum cleaner storage devices, suction filters, etc., and can solve problems such as interference and disturbance of vacuum cleaner curtain displays or paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

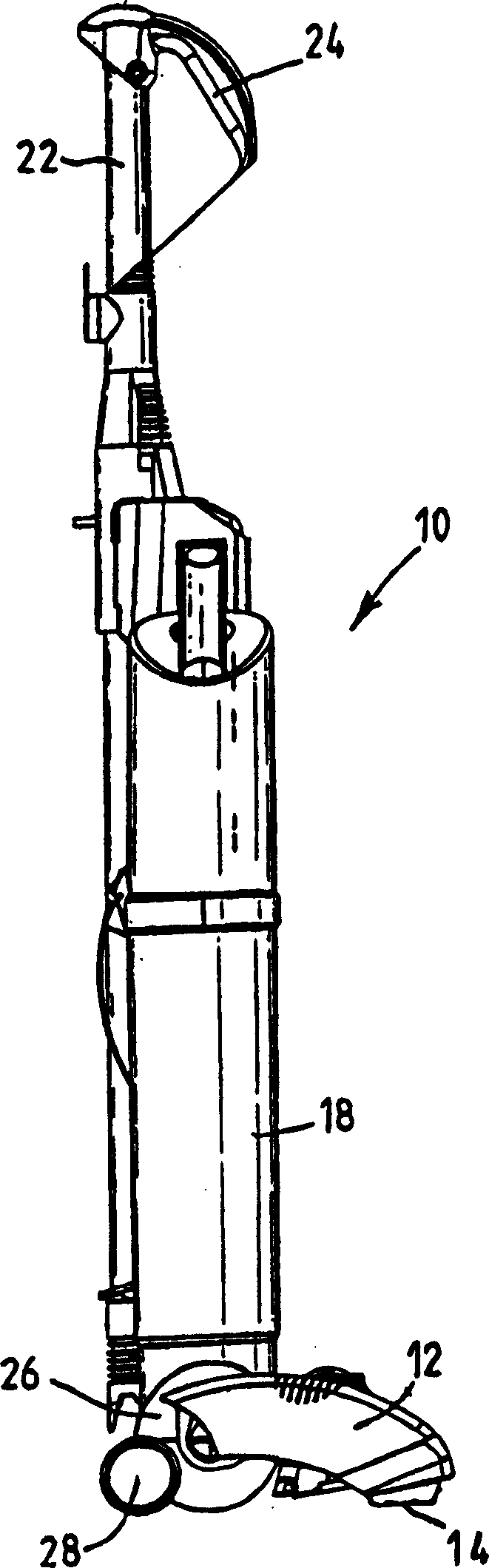

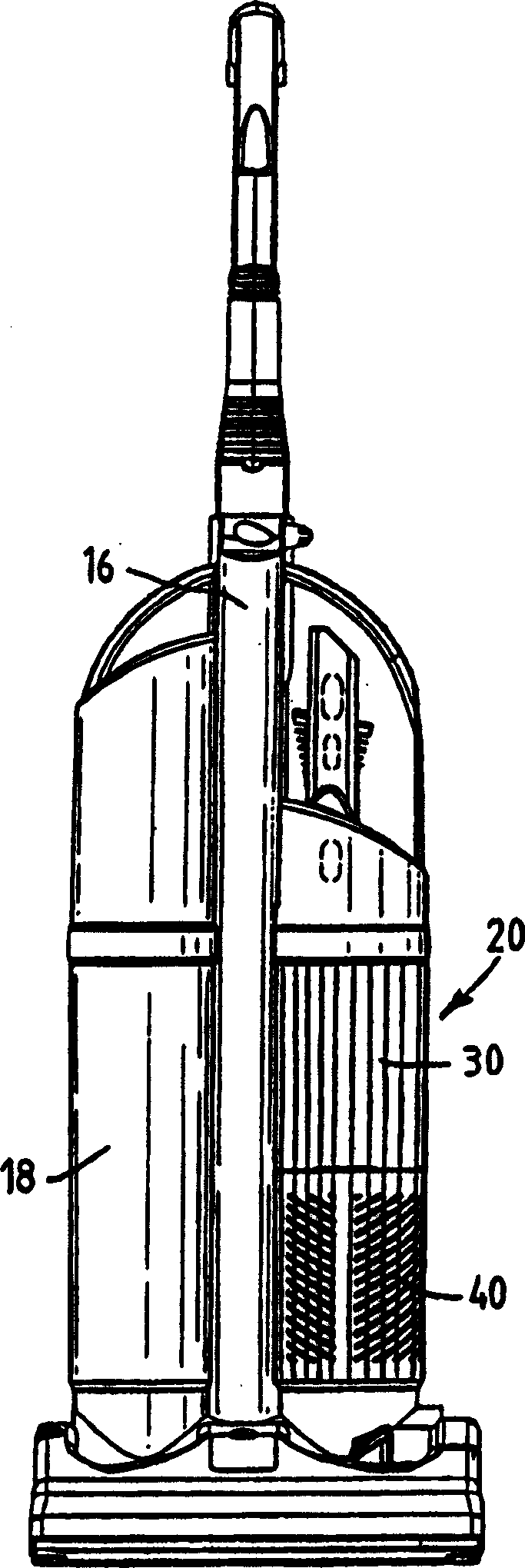

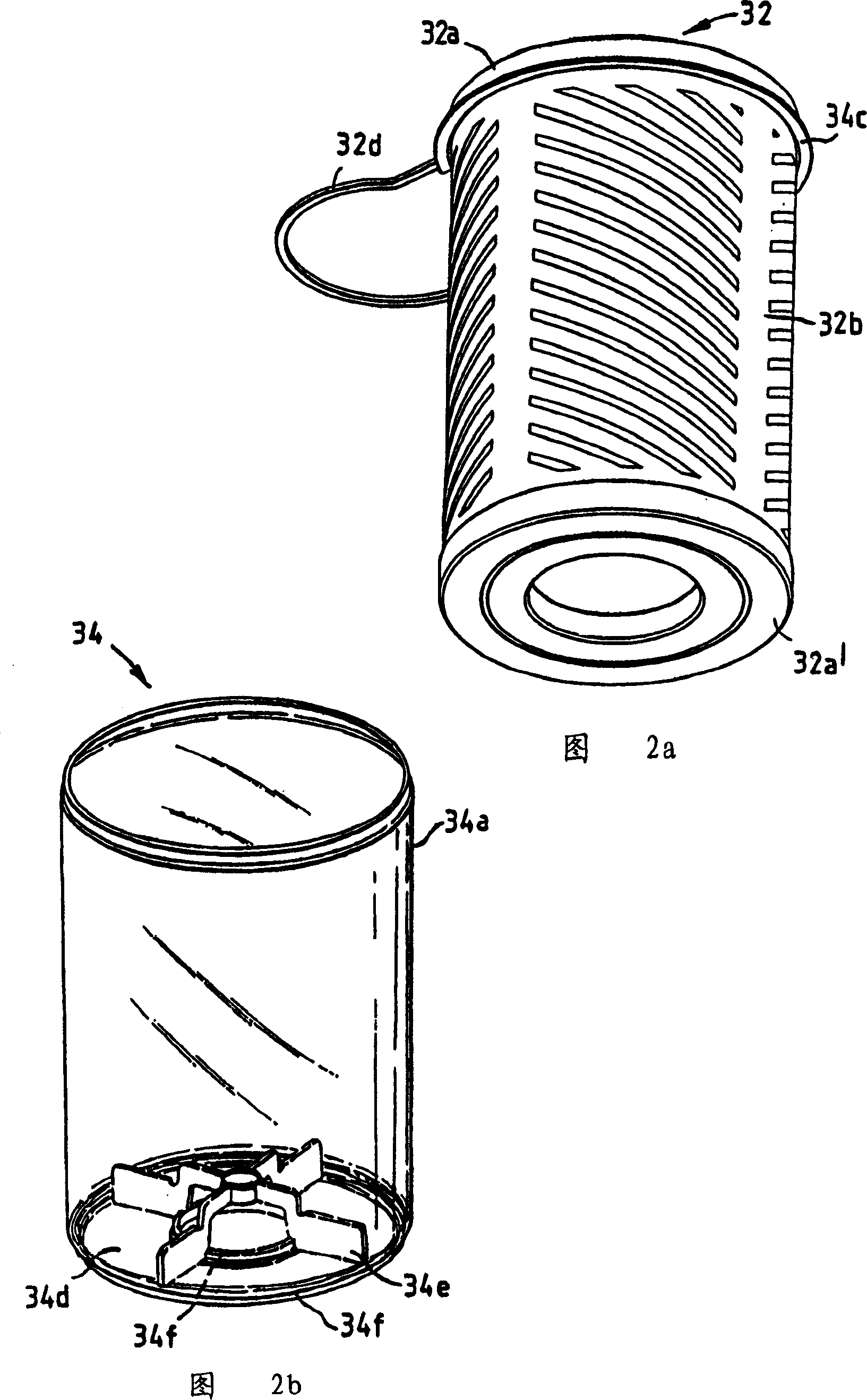

[0012] The vacuum cleaner of the present invention is shown in Figure 1a and Figure 1b middle. As can be seen, the vacuum cleaner 10 is an upright dust collector having a dust extraction head 12 which cooperates with an inlet 14 for dusty air. The central support 16 supports the dust separator 18 on one side and the filter element 20 on the other side. An upwardly extending handle 22 is located at the rear of the central support 16 and is in the form of a lever that is free to release when the vacuum cleaner is being used in cylinder mode. An upwardly extending handle 22 is connected to a handle 24 and has features other than those of the present invention. The dedusting head 12 is rotatably connected on the motor housing 26 , a motor is housed in the motor housing 26 and a pair of support wheels 28 are also connected on the motor housing 26 . In use, the motor draws dusty air into the vacuum cleaner 10 through the dusty air inlet 14 , or through the shaft 22 . The air t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com