A kind of braiding method of cable braiding layer

A braiding layer and cable technology, which is applied in the direction of cable/conductor manufacturing, circuits, electrical components, etc., can solve problems such as low work efficiency, unstable wire laying, and manufacturing difficulties, and achieve the effect of realizing automation and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

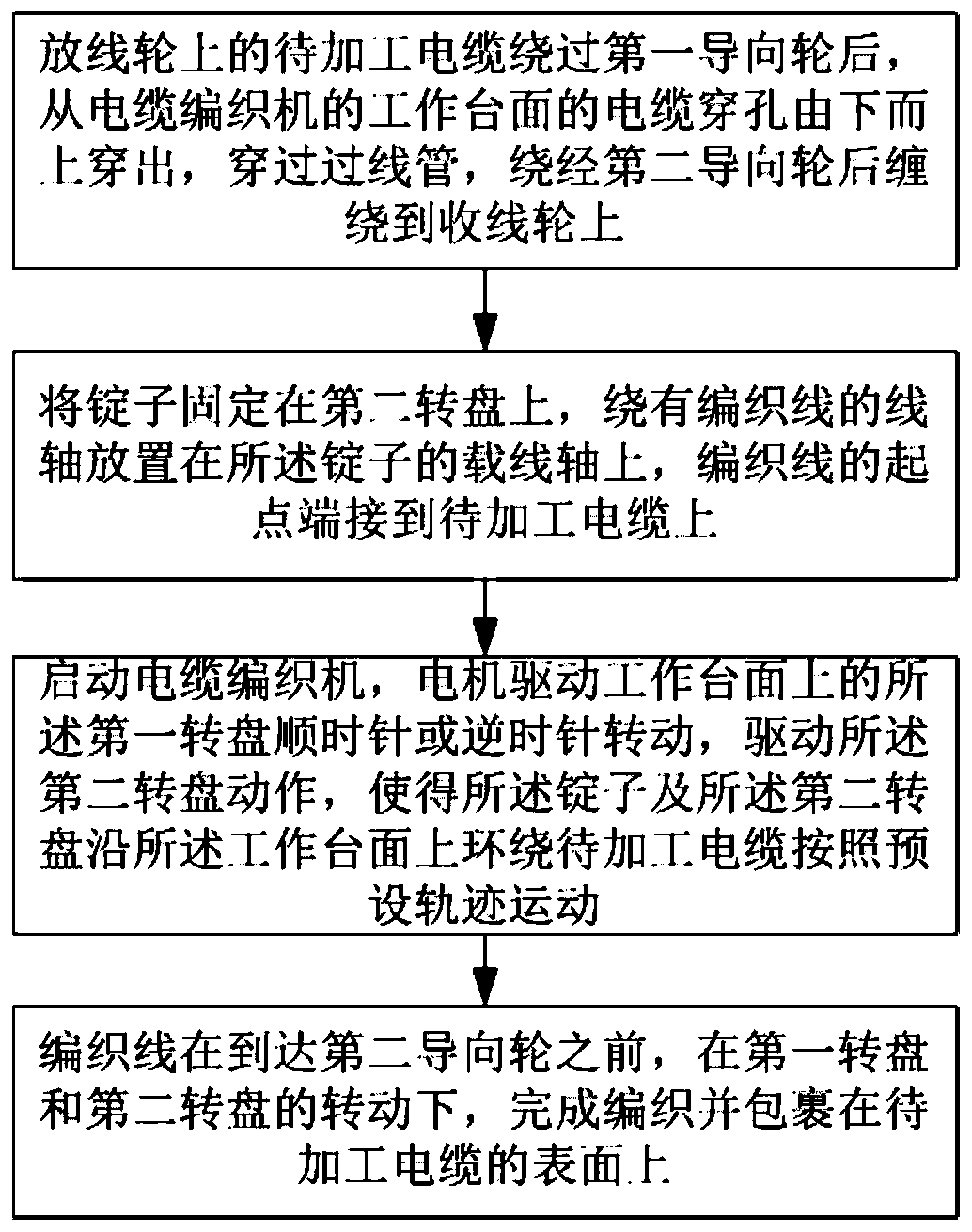

[0048] figure 1 It is a flowchart of a braiding method for a cable braiding layer of the present invention.

[0049] Such as figure 1 Shown, a kind of braiding method of cable braiding layer comprises:

[0050] After the cable to be processed on the pay-off wheel bypasses the first guide wheel, it passes through the cable hole on the working table of the cable braiding machine from bottom to top, passes through the wire tube, winds around the second guide wheel, and then winds up to the take-up wheel;

[0051] Fixing a plurality of spindles on the second turntable, placing a pay-off wheel wound with a braided wire on the wire-carrying shaft of the spindle, and the starting point of the braided wire is terminated on the cable to be processed;

[0052] Start the cable braiding machine, the motor drives the first turntable on the worktable to rotate, the driving force of the spindle is transmitted to the second turntable through the first turntable, that is, the first turntabl...

Embodiment 2

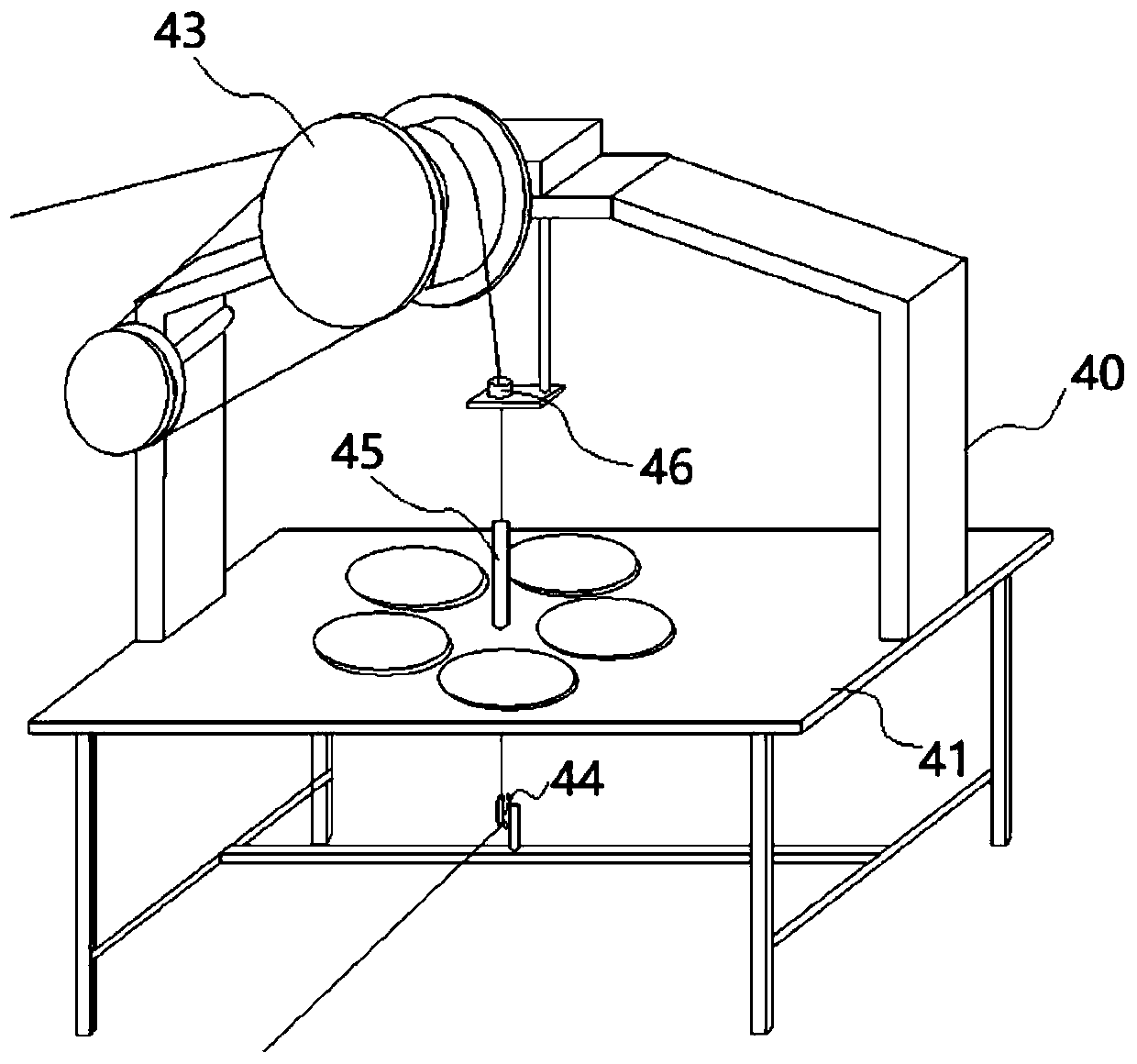

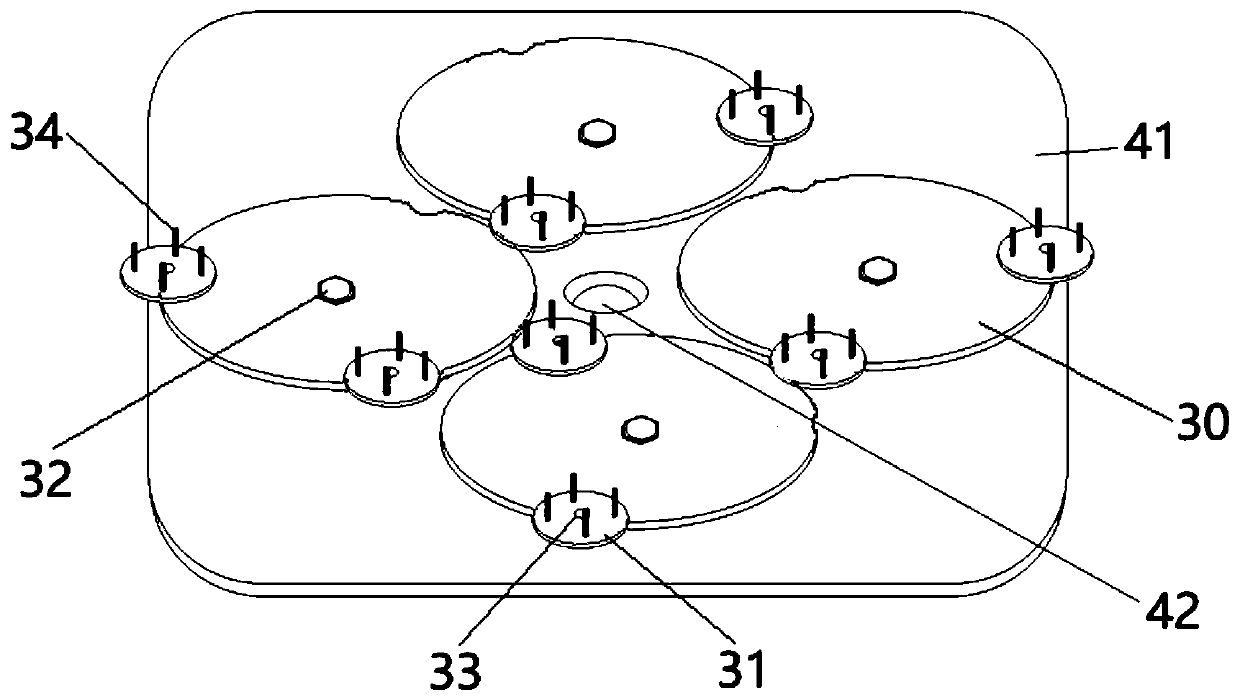

[0066] Such as Figure 2 ~ Figure 4 As shown, a cable braiding machine includes:

[0067] A frame 40, the frame 40 is provided with a working table 41; the working table 41 is provided with a plurality of braiding components. The braiding assembly is rotatably connected to the work surface 41 through the first rotating shaft 32 ; the center of the work surface 41 is provided with a cable through hole 42 . The cable through hole 42 is provided with a wire passing pipe 45 perpendicular to the work surface 41 , and the upper and lower ends of the wire passing pipe 45 respectively form a cable outlet hole and a cable inlet hole. The arrangement of the wire passing tube 45 ensures that the braided wires are naturally straightened before wrapping the outer shielding layer, and will not be deformed under the action of traction, reducing the probability of breakage.

[0068] At least one second guide wheel 43 is arranged above the working surface 41 , and the second guide wheel 43 i...

Embodiment 3

[0084] Such as Figure 5 As shown, the structure of this embodiment is basically the same as that of Embodiment 2, the difference is that:

[0085] There are two connecting shafts 5 of the spindle, which are arranged in parallel between the openings of the two side plates 2 . There is also a polished rod 17 between the two side plates 2, and the polished rod 17 is located below the pay-off wheel 21 and above the connecting shaft 5; the braided wire on the pay-off wheel 21 goes around one of the The third guide wheel 6 on the connecting shaft, the polished rod 17, the third guide wheel 6 on the other connecting shaft, and the fourth guide wheel 22 on the guide rod are output. Two connecting shafts are set, the up and down sliding of the slide block 7 can be made more stable, and it is more conducive to smooth unwinding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com