Direct current ice-melting short-circuit control structure

A DC ice-melting and short-circuiting technology, applied in the installation of electrical components, cables, overhead installation, etc., can solve the problems of many human resources, low work efficiency, and large ice-melting power, saving human resources and improving the use efficiency. , the effect of reducing the cost of melting ice time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

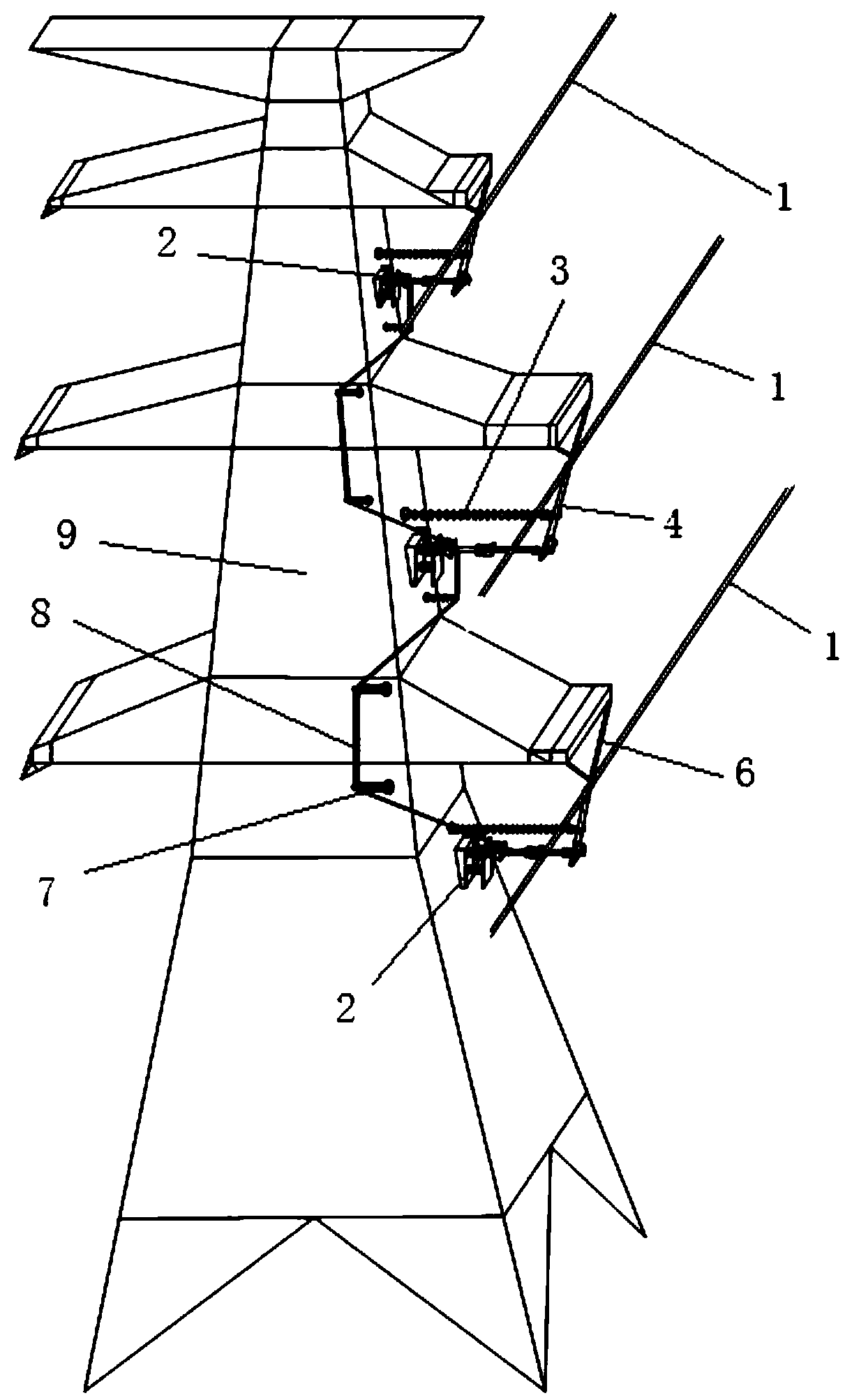

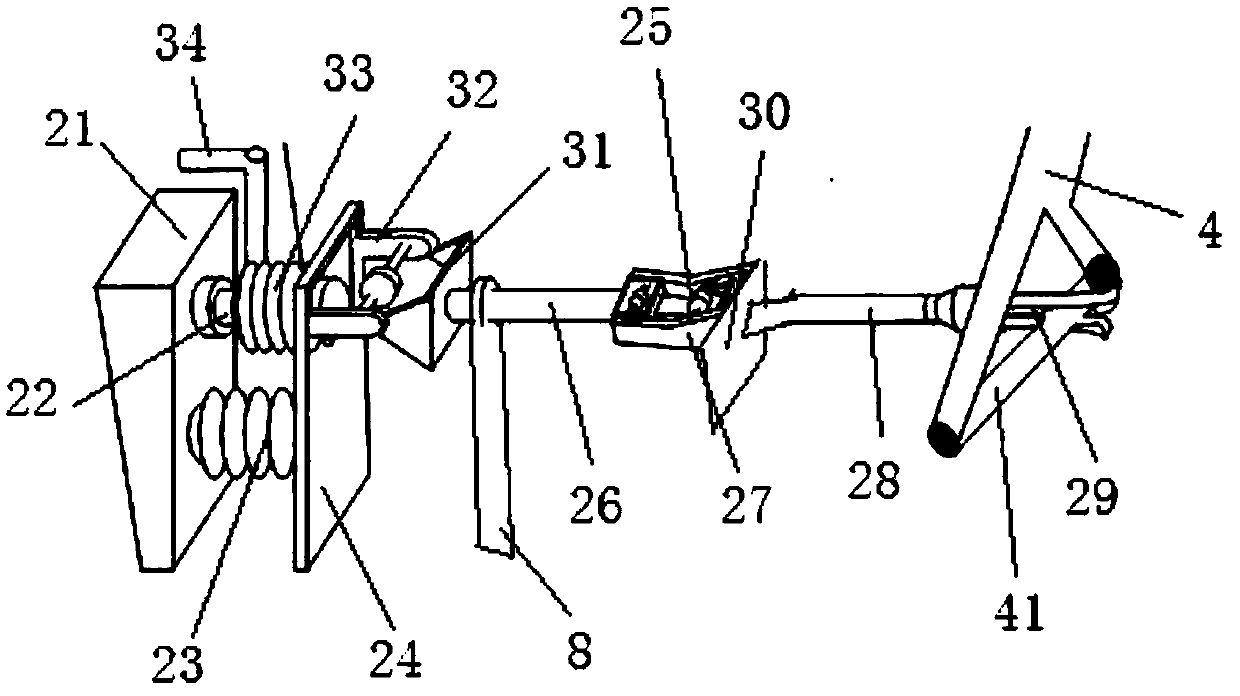

[0021] Example 1: as attached Figures 1 to 5 As shown, a DC ice melting short-circuit control structure includes an iron tower 9 and a power transmission wire 1. Three power transmission wires 1 are suspended on the iron tower 9 through an insulator string 6, and the lower part of the power transmission wire 1 is connected with a cable down Line 4, a horizontal protective insulator 3 is fixedly connected between the cable down conductor 4 and the iron tower 9, and a number of porcelain column insulators 7 are fixed on the side of the iron tower 9, between the iron tower 9 and the bottom end of the cable down conductor 4. A detachable and stackable control rod 2 is movably connected between the three control rods 2 , and a short-circuit wire 8 fixed on the porcelain column insulator 7 is connected between the three control rods 2 . There is a safe distance between the short-circuit wire 8 and the iron tower 9 .

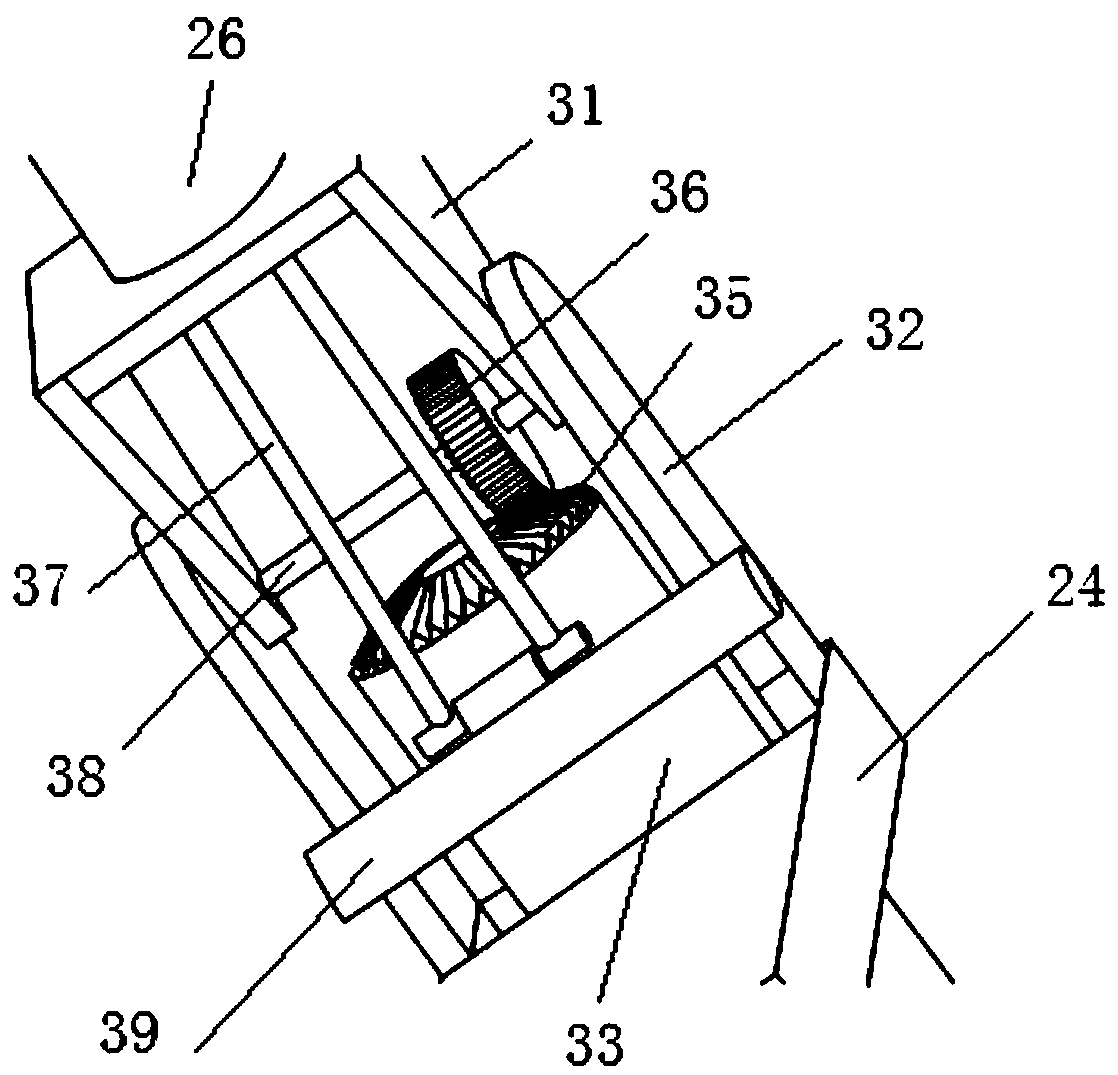

[0022] Further, the joystick 2 includes an insulating base 21 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com