Heat-collecting de-icing device and method for ice-coating power transformation device

A technology of substation equipment and ice coating, applied in the direction of switchgear, electrical components, etc., can solve the problems of energy loss, light gathering, large volume, etc., and achieve the effect of real-time electrified ice melting, easy operation, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

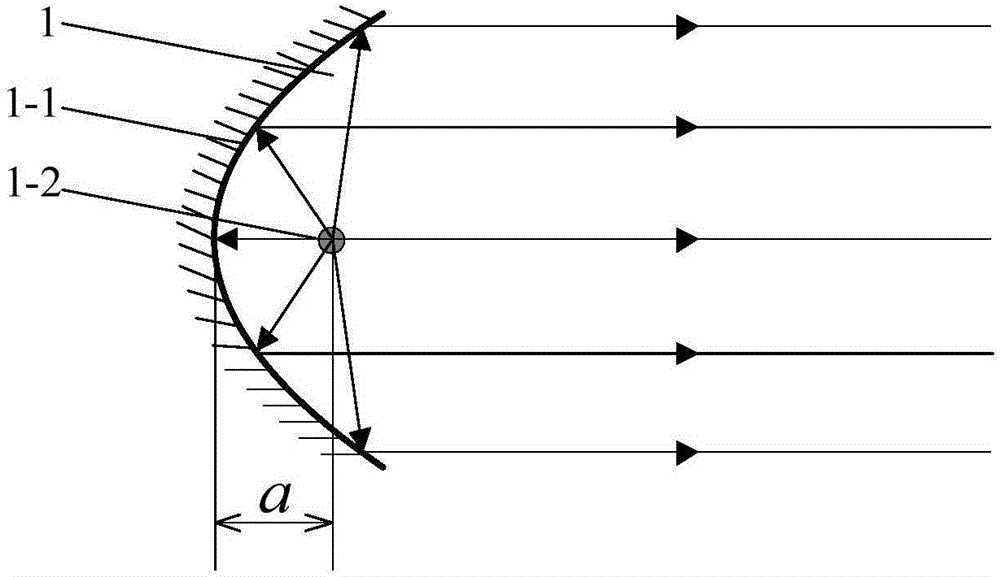

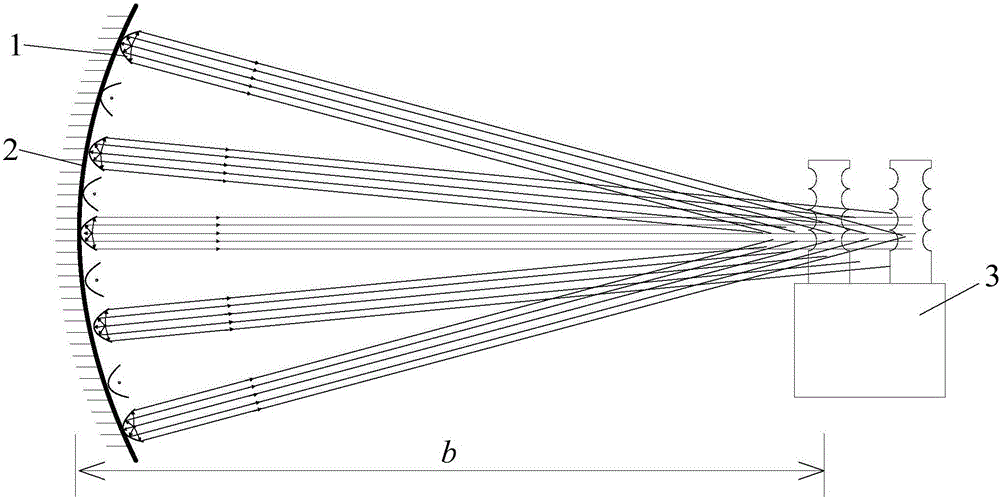

[0045] Embodiment 1: Parabolic focusing type.

[0046] The concentrating unit is composed of an infrared heat lamp with a power of 0.7kW and a parabolic reflector.

[0047] 39 concentrating units 1 are arranged in a circular array on an inner fixed paraboloid 2 with a diameter of 2.5 meters. Adjust the installation angle so that the light beam of each converging unit 1 is perpendicular to the tangent plane of the internal fixed paraboloid 2 at this point, as attached Figure 4 shown. Wherein the focal length of the internal fixed paraboloid 2 is 6 meters, which is greater than the safety distance when melting ice. In this way, the light from the light concentrating unit 1 is gathered to the focal point of the internal fixed paraboloid 2, so that the ice-covered substation equipment 3 located at the focal point can be safely thawed. In this embodiment, the power of the ice-melting generator can reach 27.3kW.

Embodiment 2

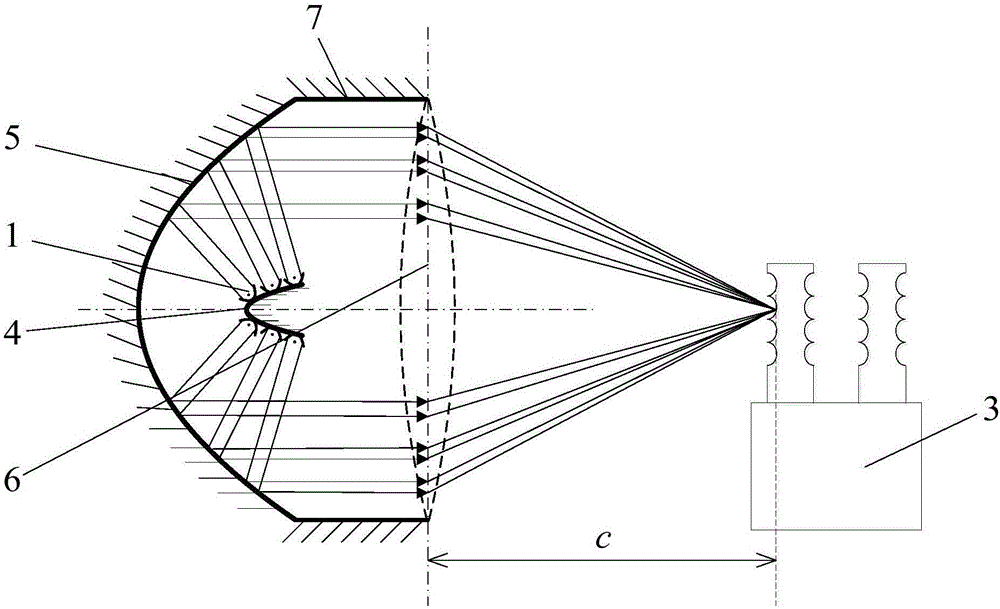

[0048] Embodiment 2: parabolic reflection + lens focus type.

[0049] The concentrating unit is composed of an infrared heat lamp with a power of 1.5kW and a parabolic reflector.

[0050] Because a single infrared lamp is difficult to meet the power demand, 20 concentrating units 1 are installed on the external fixed paraboloid 4, as shown in the attached image 3 shown. The outer fixed paraboloid 4 is located at the focus of the reflecting paraboloid 5 . Adjust the beam angle of the condensing unit 1 so that the beam is reflected by the reflective parabola 5 to become parallel light, and then transmitted by the convex lens 6 and focused to the focal point of the convex lens 6 . The space between the parabolic reflective surface 5 and the convex lens 6 is closed by a lamp wall 7, and the outer layer of the lamp wall 7 is coated with heat insulating material. The diameter of the convex lens 6 is 3 meters, and the focal length is 8 meters, which is greater than the safety dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com