Three-phase asynchronous motor for explosion-proof fan

A three-phase asynchronous, explosion-proof fan technology, applied in the direction of machines/engines, manufacturing motor generators, electromechanical devices, etc., can solve the problems of shortening the service life of the motor, breakdown of the insulation of the motor coil, and the reduction of the insulation resistance of the motor, so as to avoid The effect of motor burnout accident, accelerated evaporation speed, and accelerated discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

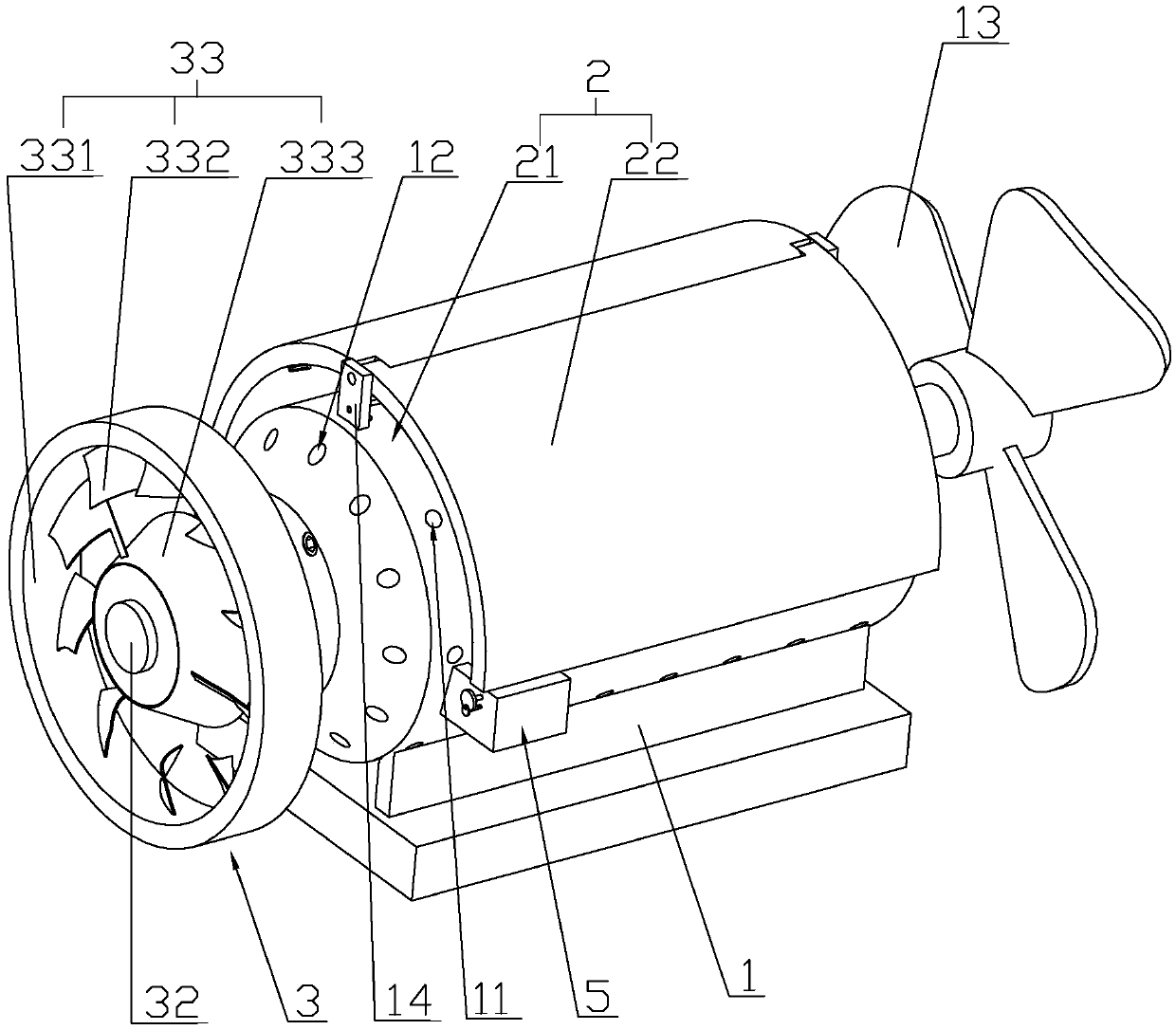

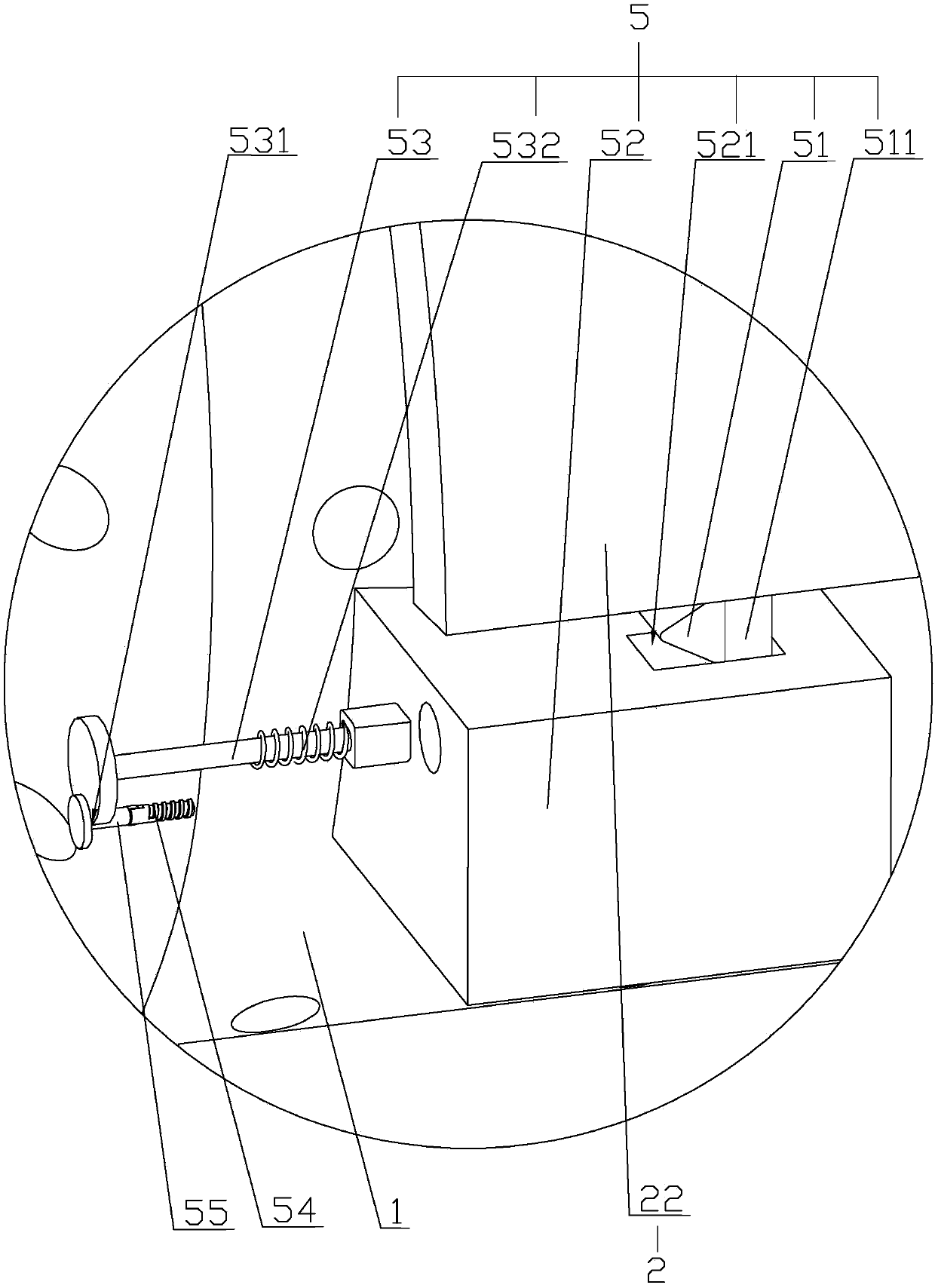

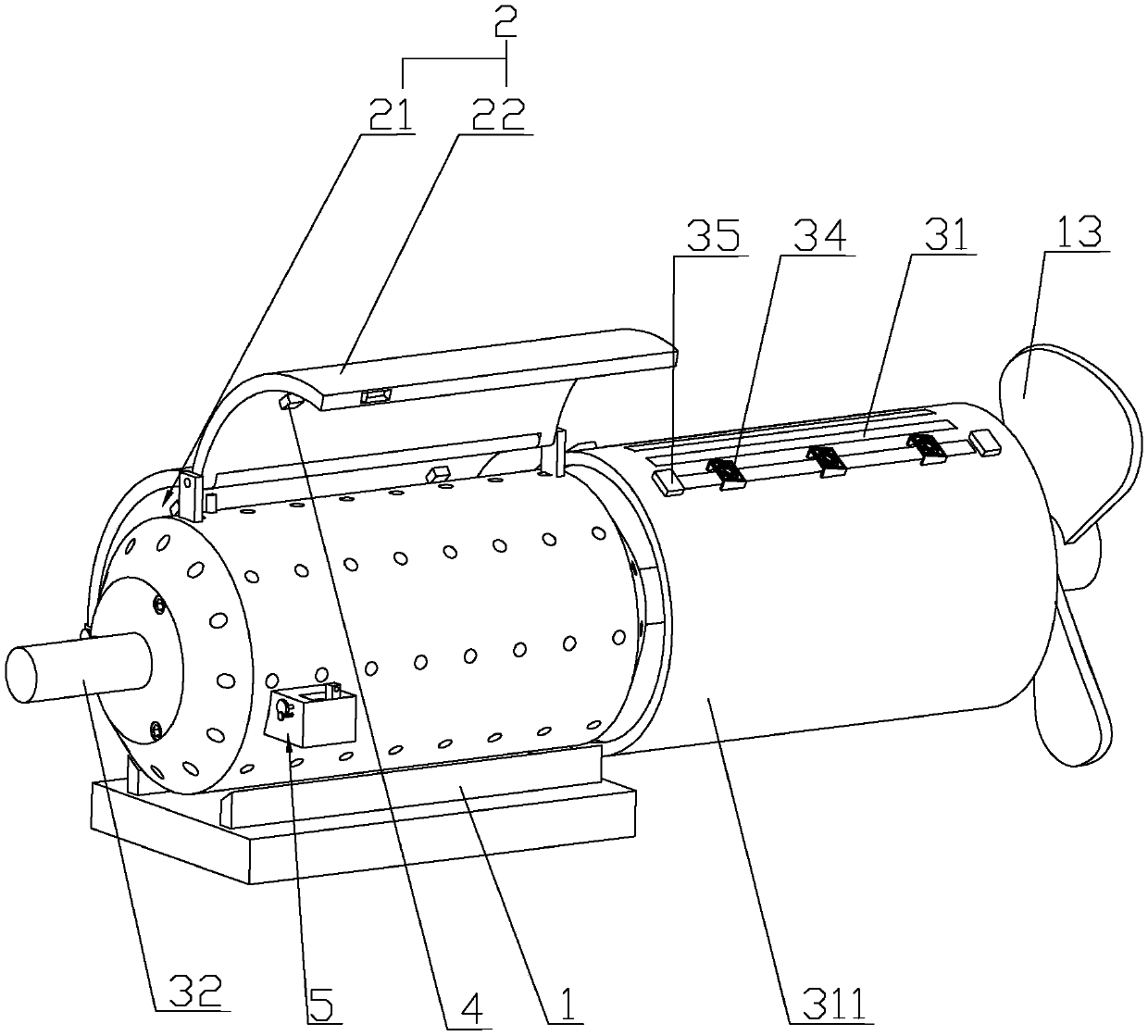

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0036] refer to figure 1 , is a three-phase asynchronous motor for an explosion-proof fan disclosed in the present invention, including a motor body 1, a casing 2 sleeved outside the motor body 1, a fan blade 13 fixed coaxially with the output shaft of the motor body 1, and a set A dehumidification mechanism 3 on the motor body 1 for dehumidification. There are three fan blades 13 and they are distributed at equiangular intervals around the output shaft of the motor body 1. When the motor body 1 rotates, the fan blades 13 are driven to rotate, so as to play the role of ventilation and realize the effect of a fan.

[0037] The casing 2 includes a base 14 welded and fixed on the top of the motor body 1 , and two ventilation covers 22 hinged to the base 14 . Two ventilation covers 22 are symmetrically distributed along the base 14 and rotate in opposite direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com