Integrated plug-in head

A plug-in head and component technology, which is applied in the direction of electrical components, electrical components, electrical components to assemble printed circuits, etc., can solve the problems of small application range, low plug-in efficiency, inconvenient control, etc., and achieve convenient and reliable control, simple structure, Easy to control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

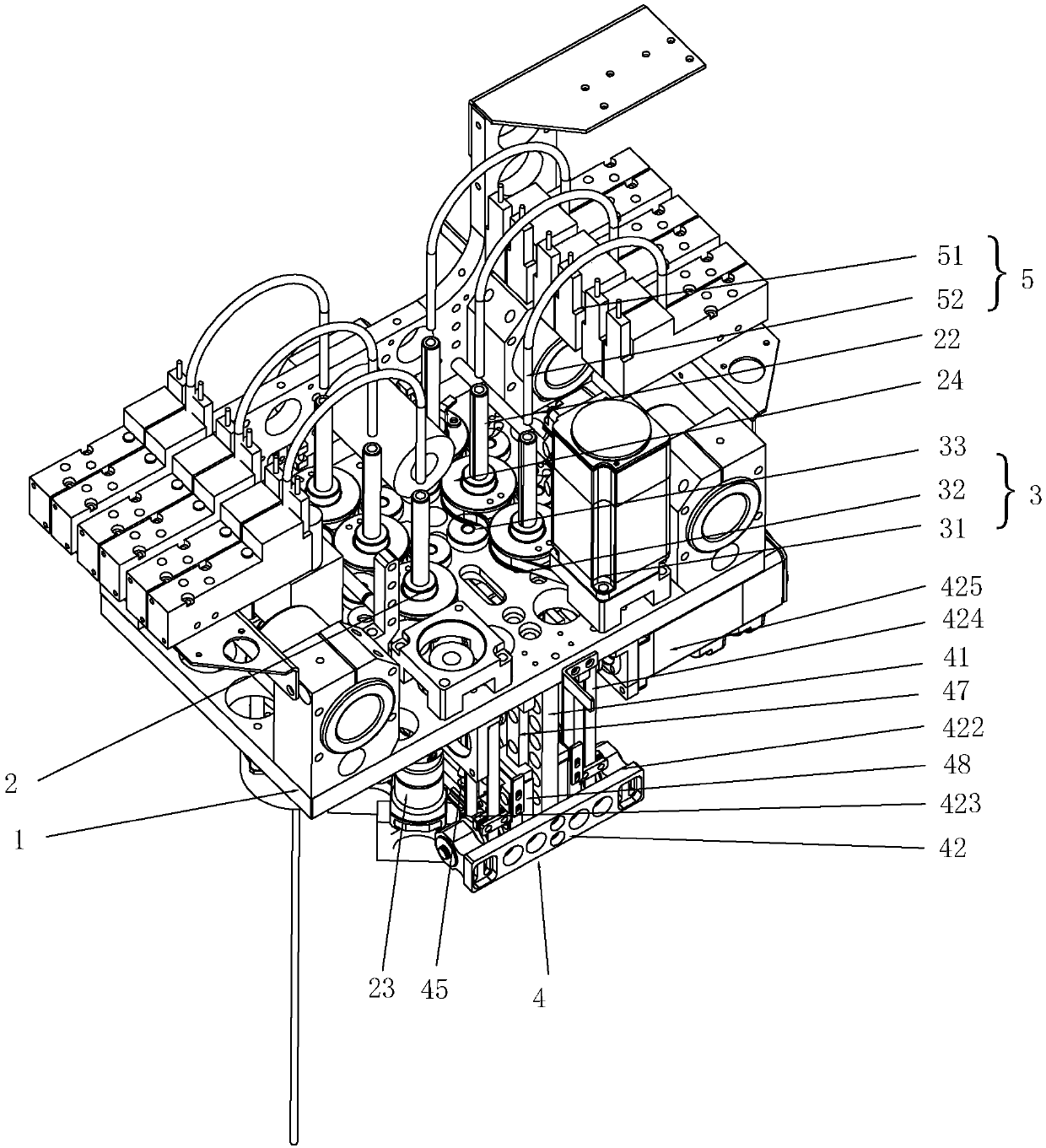

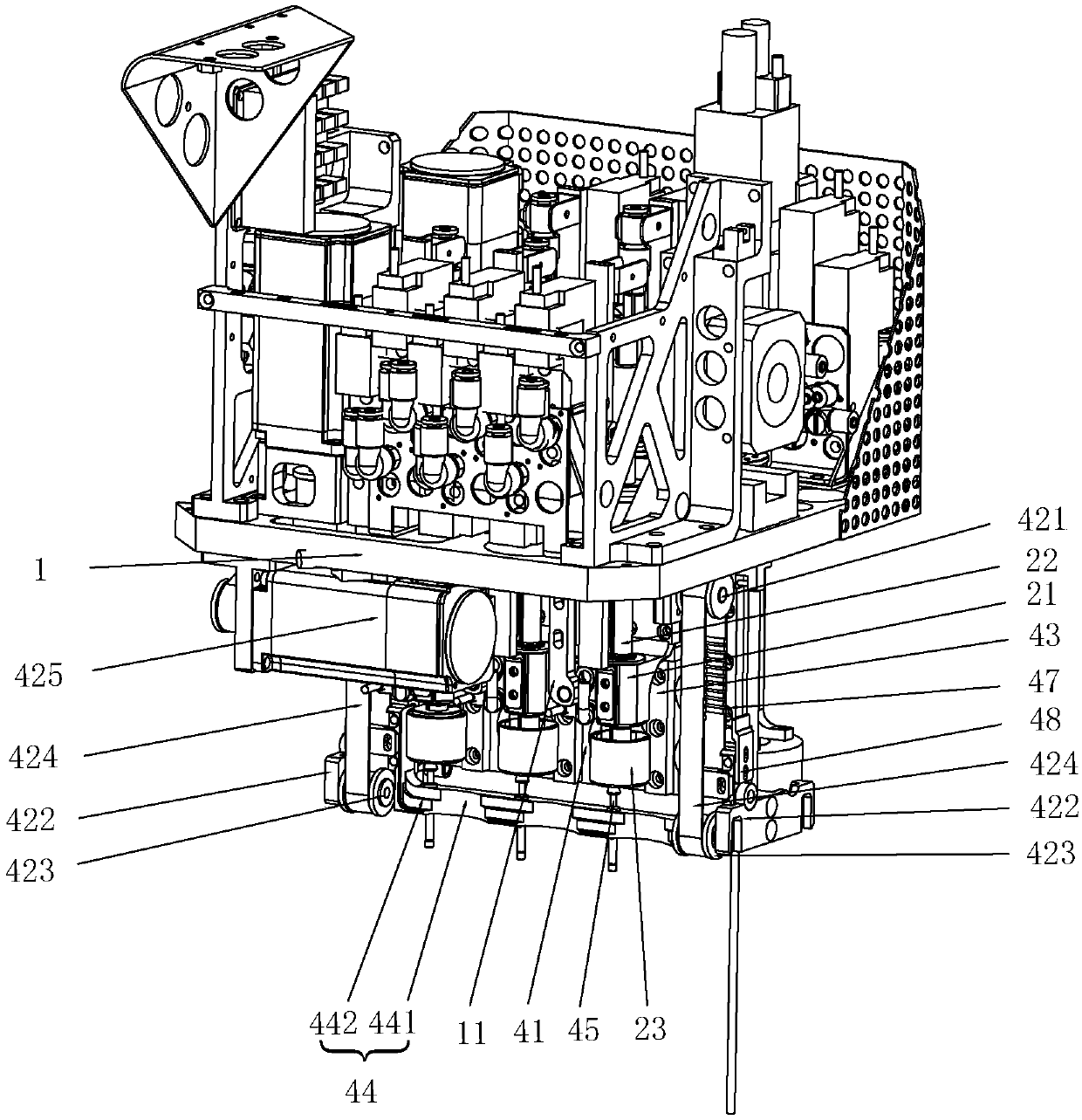

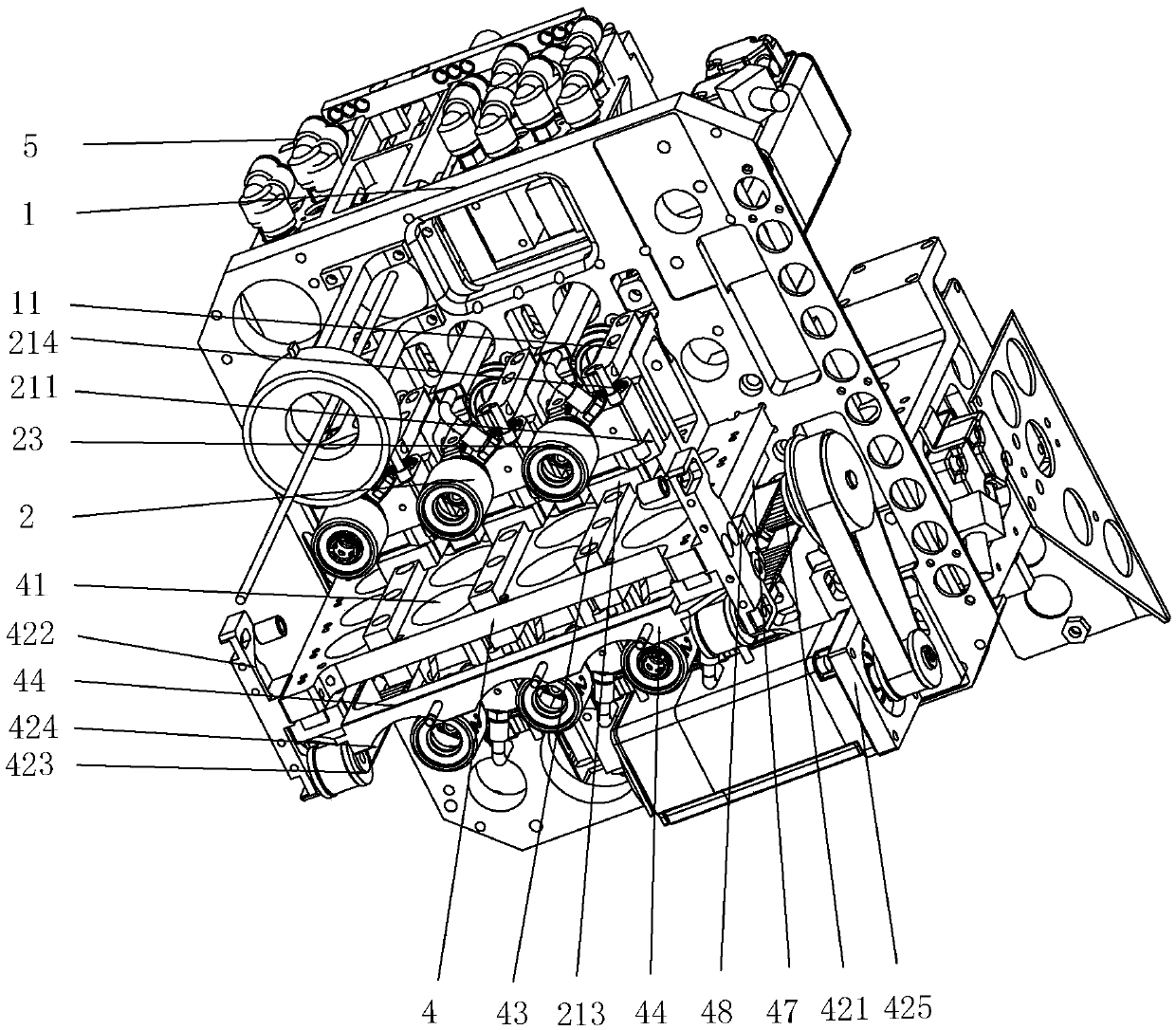

[0028] see Figure 1 to Figure 9 , an integrated plug-in head of the present invention, including a mounting base 1, a clamping assembly 2 movably mounted on the mounting base 1, a rotating group 3, and a lifting group 4 for controlling the lifting of the clamping assembly 2, said The lifting group 4 includes a lifting frame 41 installed on the bottom of the installation base 1, a cross bar 44 that can slide vertically on the lifting frame 41, and a lifting member 42 for driving the cross bar 44 to move. The clamping assembly 2 is set There are several groups, and they are arranged side by side on the front side and / or the rear side of the lifting frame 41. The rotating group 3 can drive all the clamping components 2 on the same side to rotate synchronously. The lifting frame 41 corresponds to each group of clamping components 2 Each set of clamping components 2 is slidably mounted on the corresponding vertical rail 43 through the locking member 21, and the cross bar 44 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com