Method and device for mass production of nanowires

A technology of nano wire material and manufacturing method, applied in the field of mass production manufacturing method of nano wire material and its manufacturing device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] In the following, the present invention will be further described in conjunction with the drawings and specific embodiments, so that those skilled in the art can more easily understand and implement the present invention.

[0069] The main problem to be solved by the present invention is to provide a method for mass production of nanowires and a manufacturing device thereof, especially for manufacturing single crystal nanowires in the field of gas sensing.

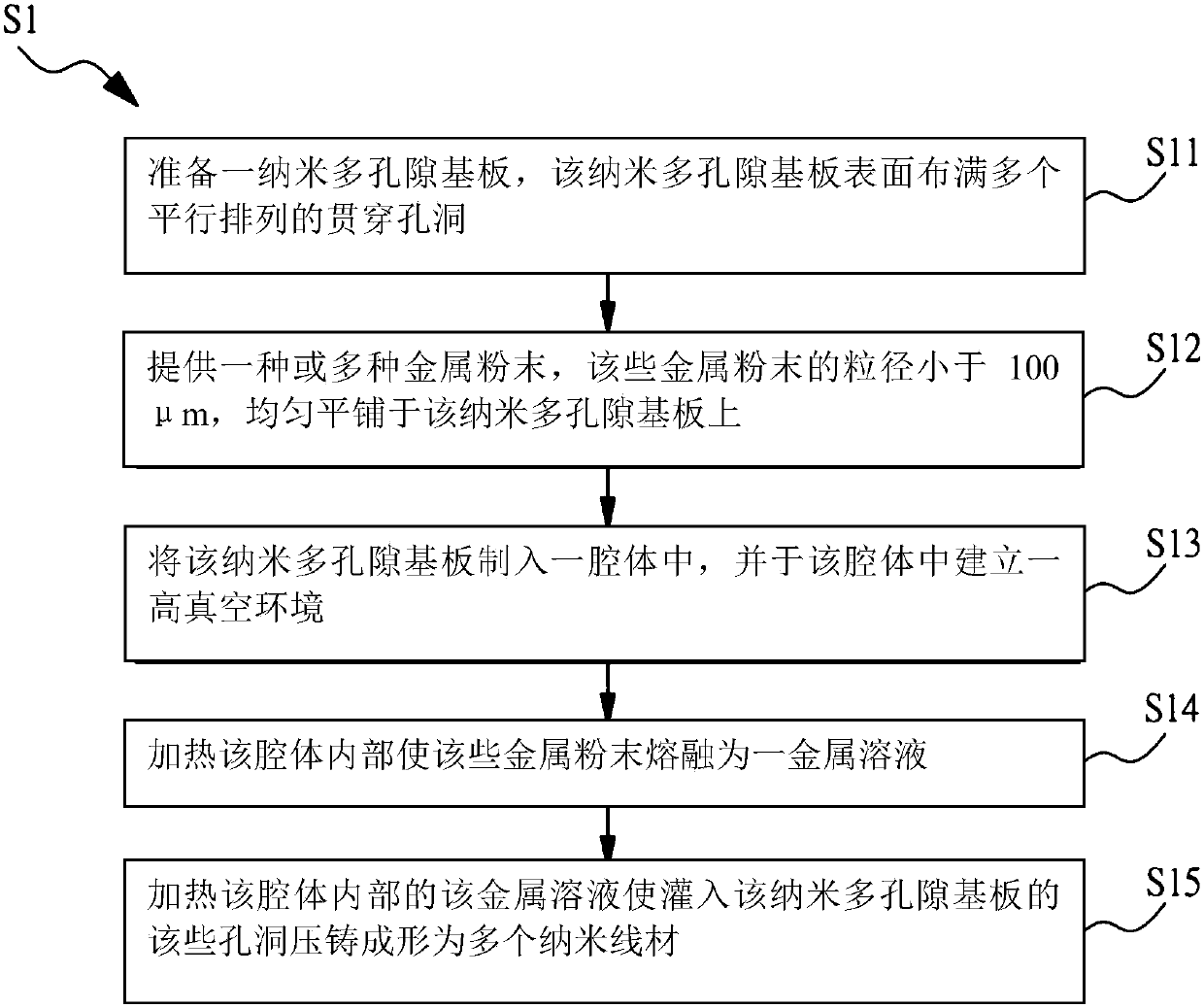

[0070] In order to achieve the above purpose, the present invention discloses a mass production method S1 of nanowires, please refer to Figure 1A ,include:

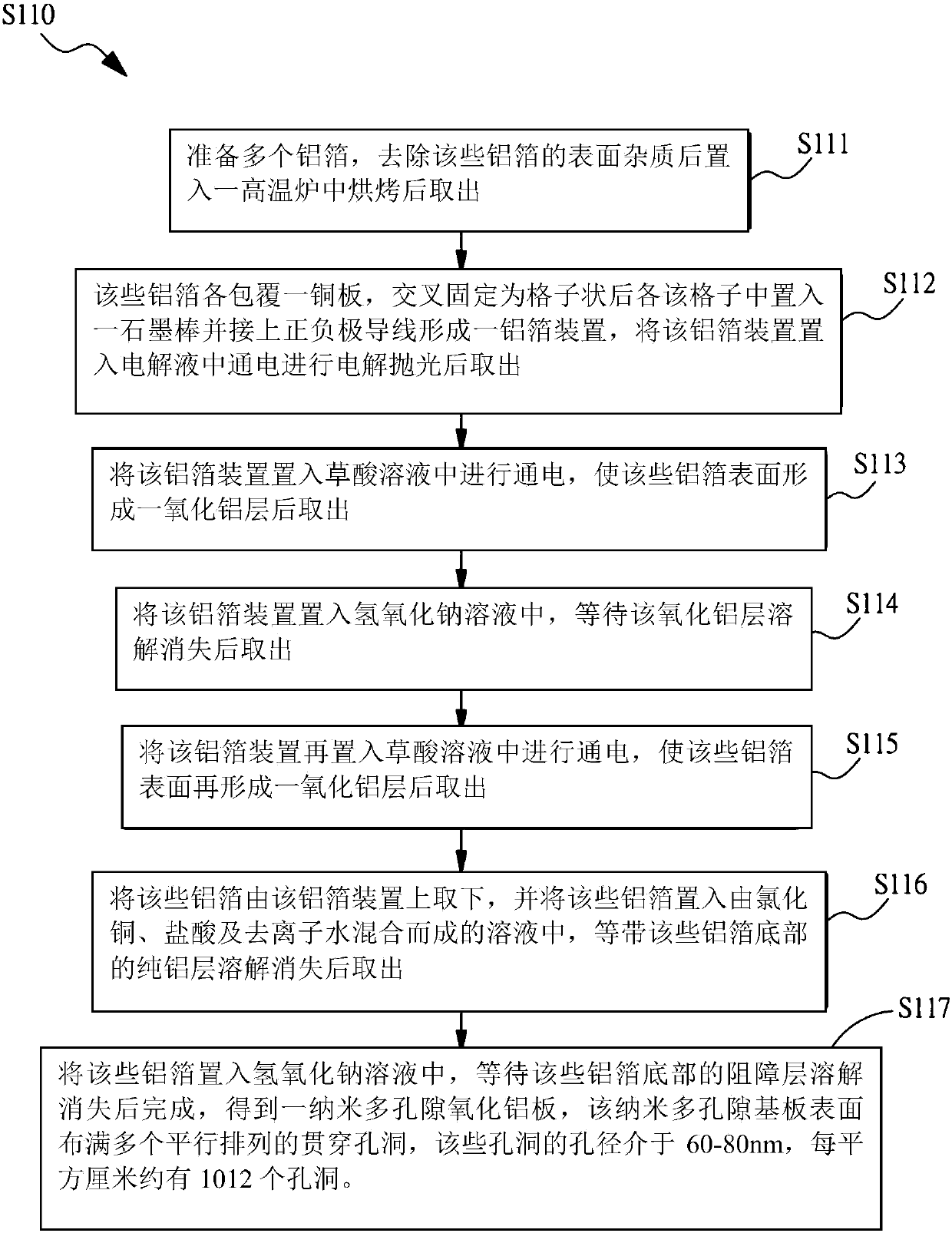

[0071] Step S11: preparing a nanoporous substrate, the surface of the nanoporous substrate is covered with a plurality of through holes arranged in parallel;

[0072] Step S12: providing one or more kinds of metal powders, the particle size of which metal powders is less than 100 μm, uniformly spreading on the nanoporous substrate;

[0073] Step S13: making t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com