Mixed bacteria system, method for decomposing hemicellulose using same and method for producing alcohol

A technology of hemicellulose and alcohol, applied in the fields of biochemical equipment and methods, enzymes, hydrolase, etc., to achieve the best production efficiency and the effect of improving the biomass alcohol production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

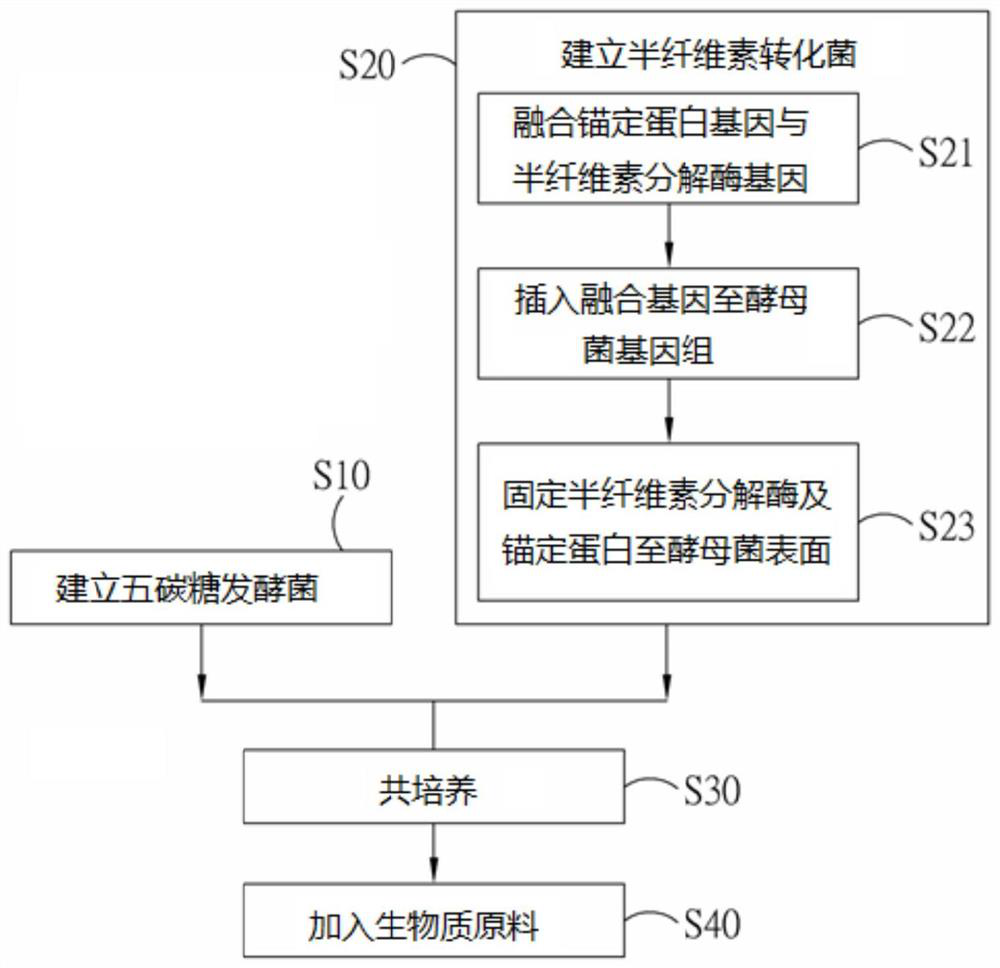

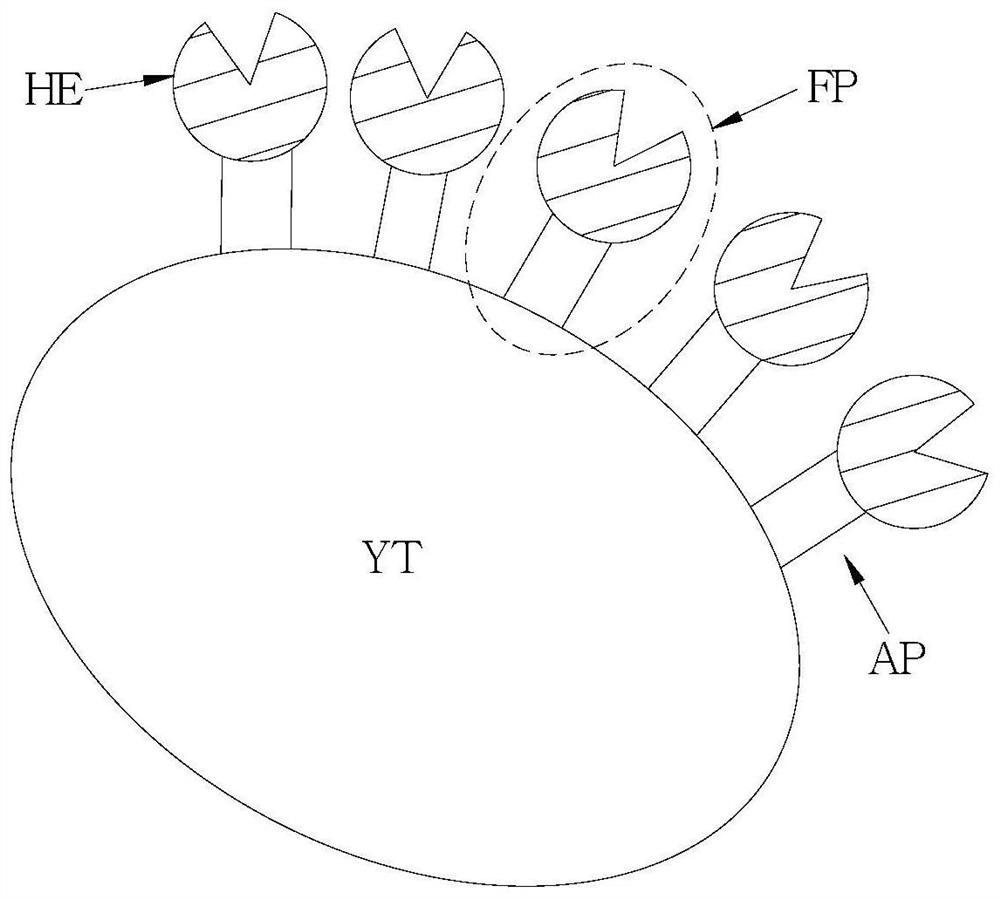

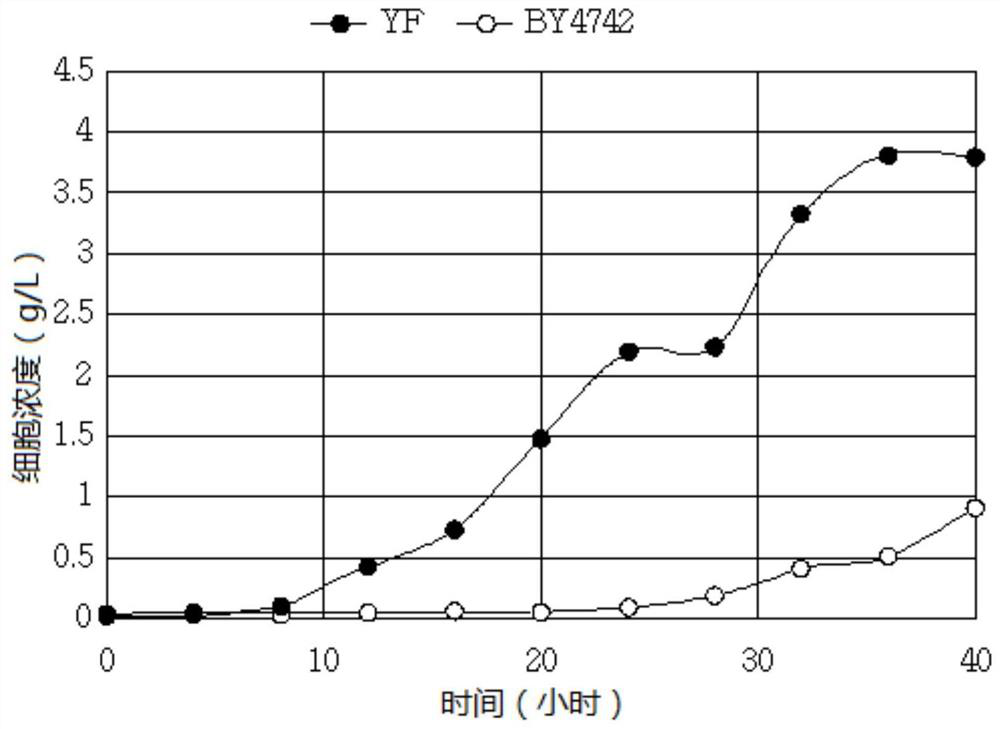

[0025] The main method of the hemicellulolytic method provided by the present invention is to divide the yeast into several groups, wherein genes of different hemicellulolytic enzymes and anchor proteins can be fused and inserted into the genome of the yeast respectively, so that these groups Secretory expression of fusion proteins with different hemicellulolytic enzymes. The expressed fusion protein has an anchor protein part, which will be inserted into the surface of the yeast when it contacts the surface of the yeast, so that the hemicellulolytic enzyme is also fixed on the surface of the yeast. On the other hand, the remaining group can insert exogenous genes to express enzymes with five-carbon sugar fermentation function. Next, yeasts of all the above groups were co-cultured to form a mixed bacteria system. When the biomass material containing hemicellulose is added to the mixed bacteria system, the hemicellulose can be decomposed into five-carbon sugar by hemicelluloly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com