Farming box for industrial insect farming and cleaning method thereof

A culture frame, factory-like technology, applied in the direction of cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc. The effect of improving the sealing effect and improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

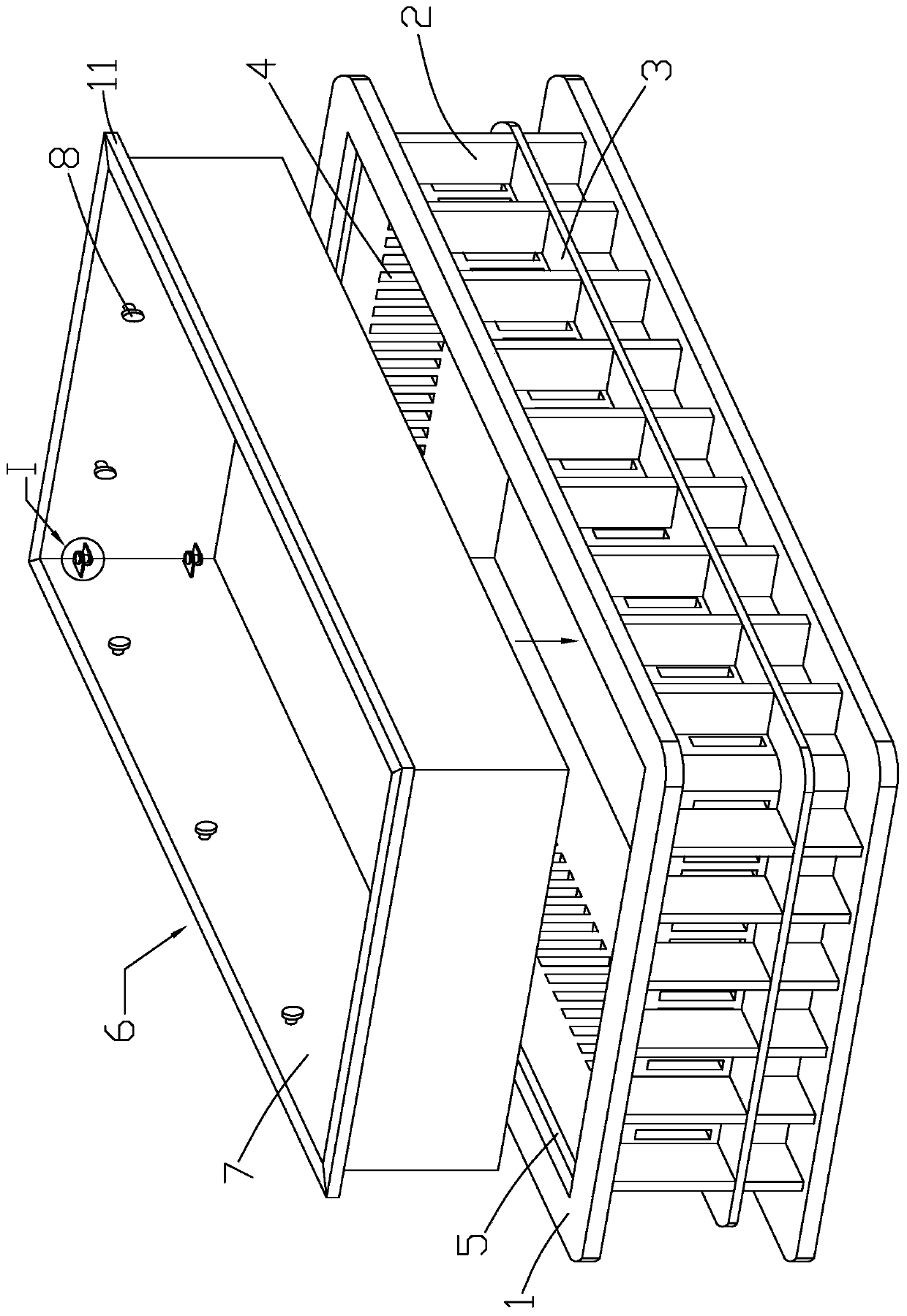

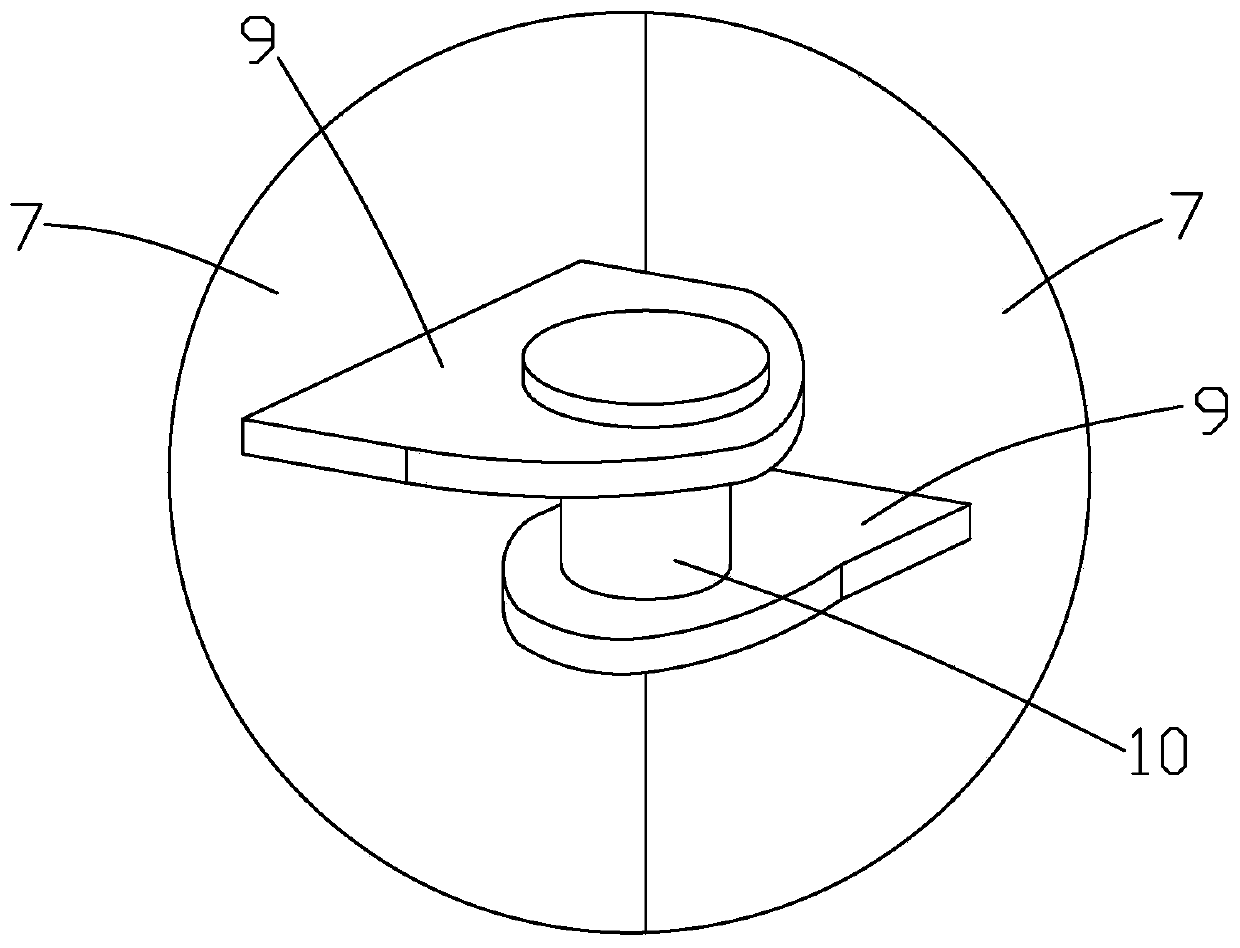

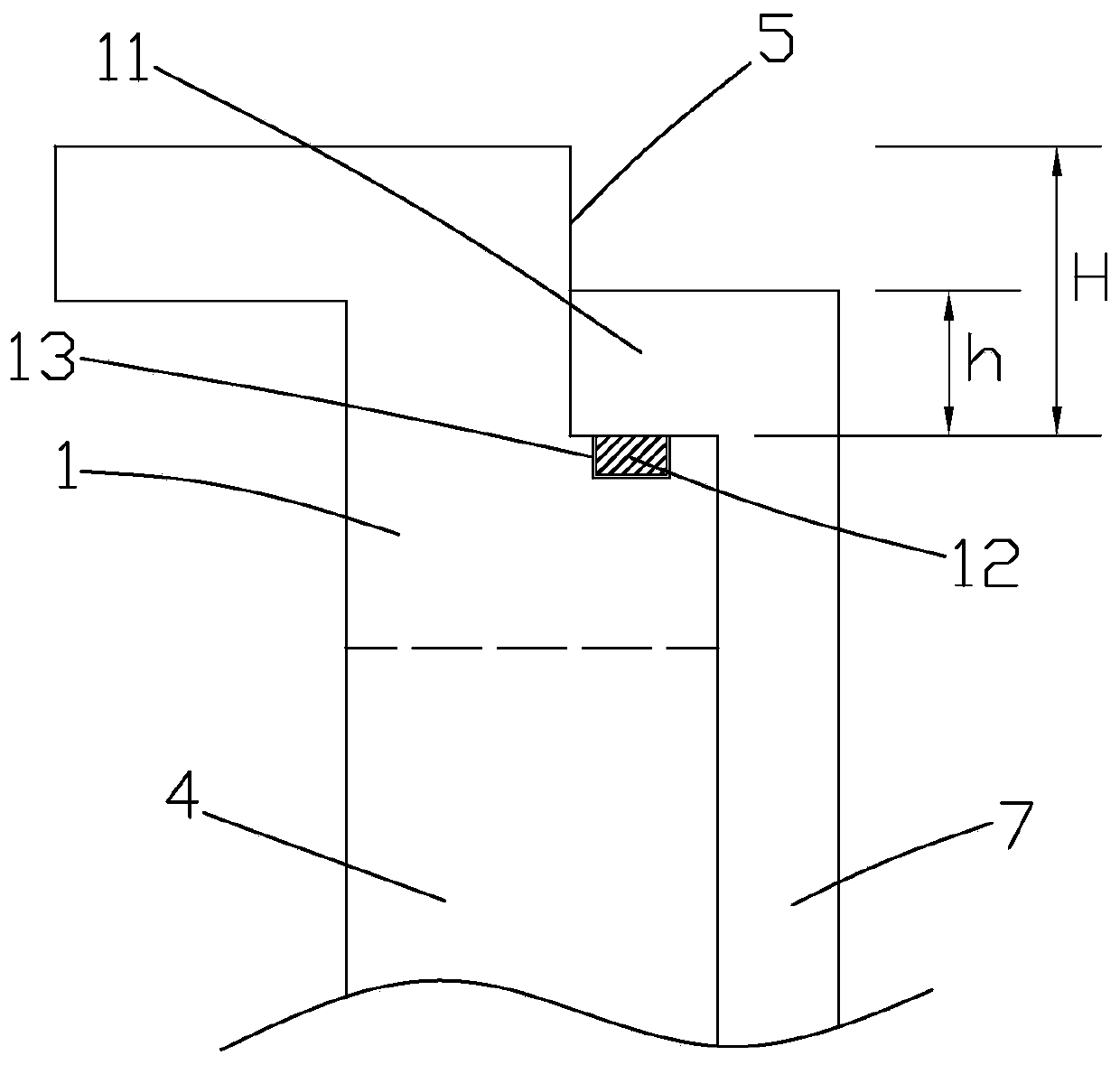

[0050] Such as Figure 1 to Figure 4 As shown, it is a breeding frame for industrialized insect breeding of the present invention, including a frame body 1, a vertical reinforcement rib 2 and a transverse reinforcement rib 3 are arranged on the outer surface of the frame body 1, and two adjacent vertical reinforcement ribs 2 There are cooling grooves 4 evenly arranged between them, and a sealing mechanism 6 is also included. The sealing mechanism 6 includes four baffles 7, and the four baffles 7 are connected end to end to form a rectangular structure. The left and right sides of the baffles 7 are respectively provided with second limiters. The hole 14 and the second stopper 15, the second stopper 15 matches the second stopper hole 14, the second stopper hole 14 and the second stopper 15 improve the distance between the two adjacent baffle plates 7 The connection strength and stability of the baffle plate 7 are arranged on the inner surface of the baffle plate 7, and the lifti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com