Solvent desorption apparatus and process method for silica gel refining and regenerating base oil

A technology of regenerated base oil and process method, which is applied in the field of solvent desorption devices for refining and regenerated base oil with silica gel, which can solve the problems of inability to continue adsorption, inability to remove oil, and low regeneration efficiency of adsorbents, and achieve simple structure and promote blow-off and degreasing, easy to achieve results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

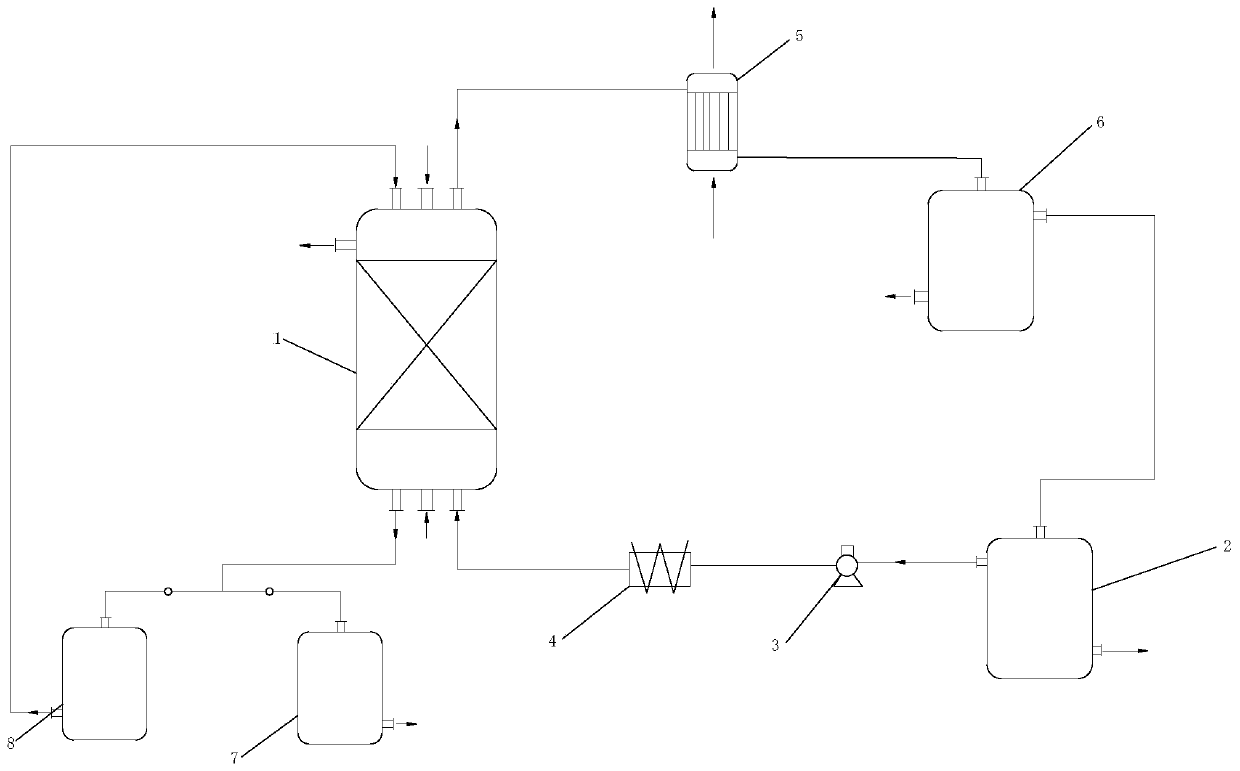

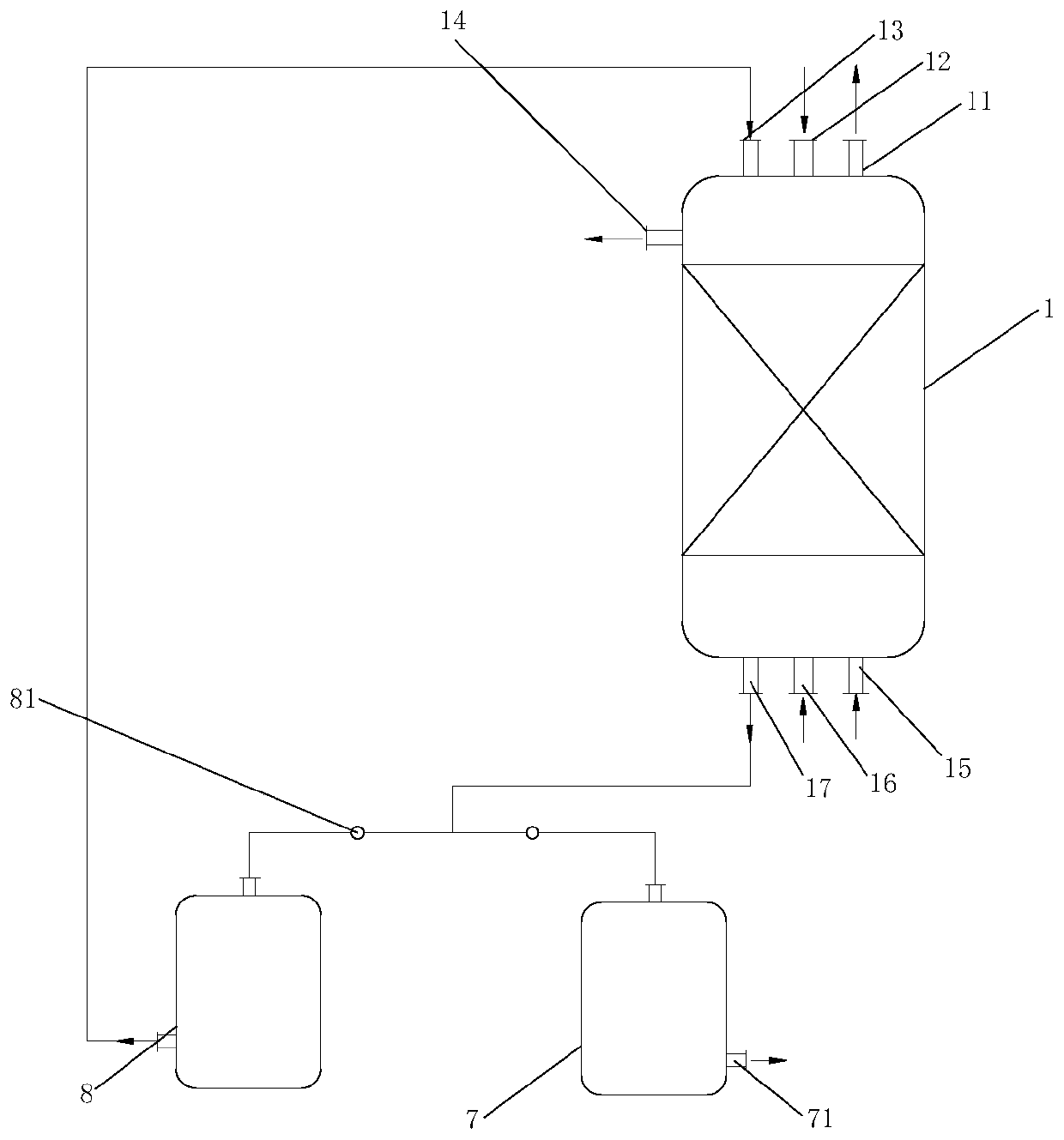

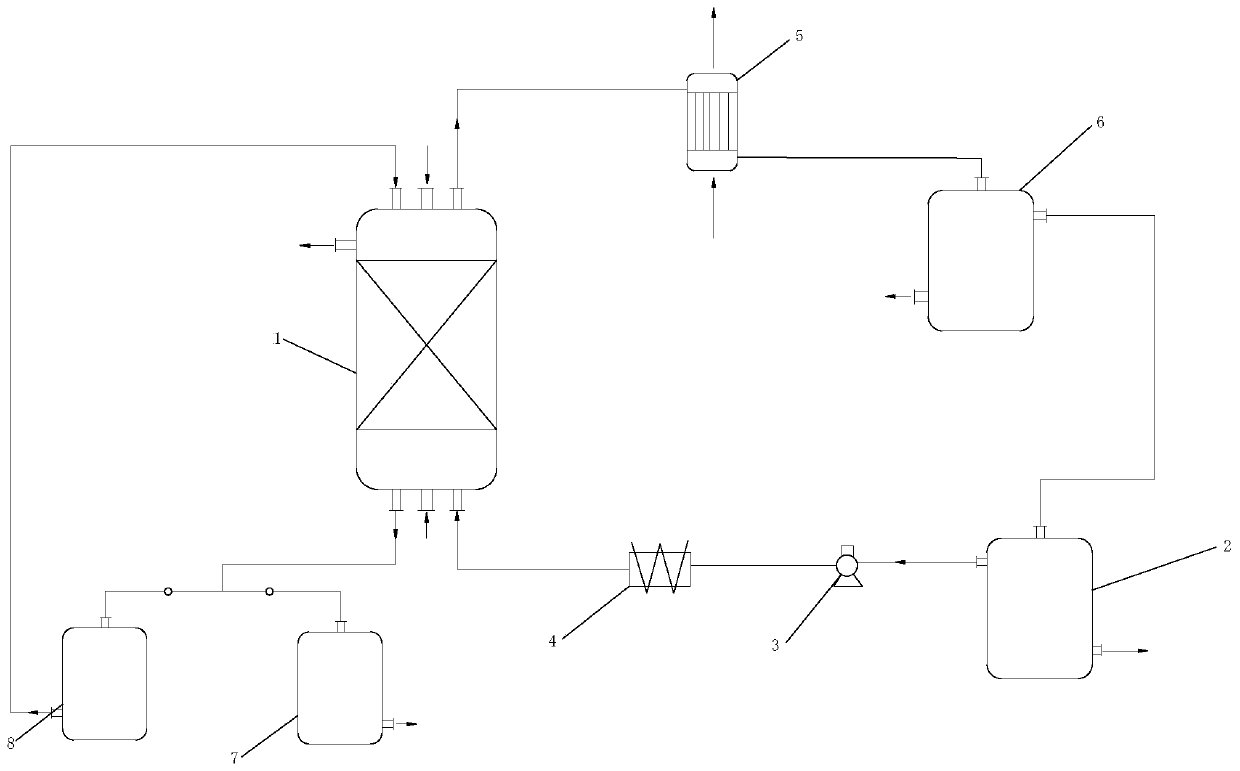

[0035] Such as Figure 1-2 As shown, a solvent desorption device for refining and regenerated base oil with silica gel includes a reaction tower 1, a gas circulation device and a solvent circulation device. The reaction tower 1 is vertically arranged on a fixed surface, and the interior of the reaction tower 1 is a cavity structure, the reaction tower 1 is provided with several inlets and outlets, including a solvent inlet 13, a silica gel inlet 12 and a gas outlet 11 arranged horizontally at the top of the reaction tower 1 in sequence, and the upper end of the side surface of the reaction tower 1 is provided with a No. 2 outlet. The oil port 14, the bottom of the reaction tower 1 is provided with a No. 1 oil outlet 17, an oil inlet 16 and an air inlet 15 in sequence.

[0036] The gas circulation device includes a gas storage tank 2 arranged on one side of the reaction tower 1. The surface of the gas storage tank 2 is provided with several gas outlet ports and gas inlet ports....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com