Multifunctional stirring device for biological pharmacy

A biopharmaceutical and stirring device technology, which is applied in the direction of mixer accessories, transportation and packaging, chemical/physical processes, etc., can solve the problems of affecting the efficiency of pharmaceuticals, increasing the number of processing steps, and the inability to crush raw materials, etc., to achieve the effect of convenient mixing and stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

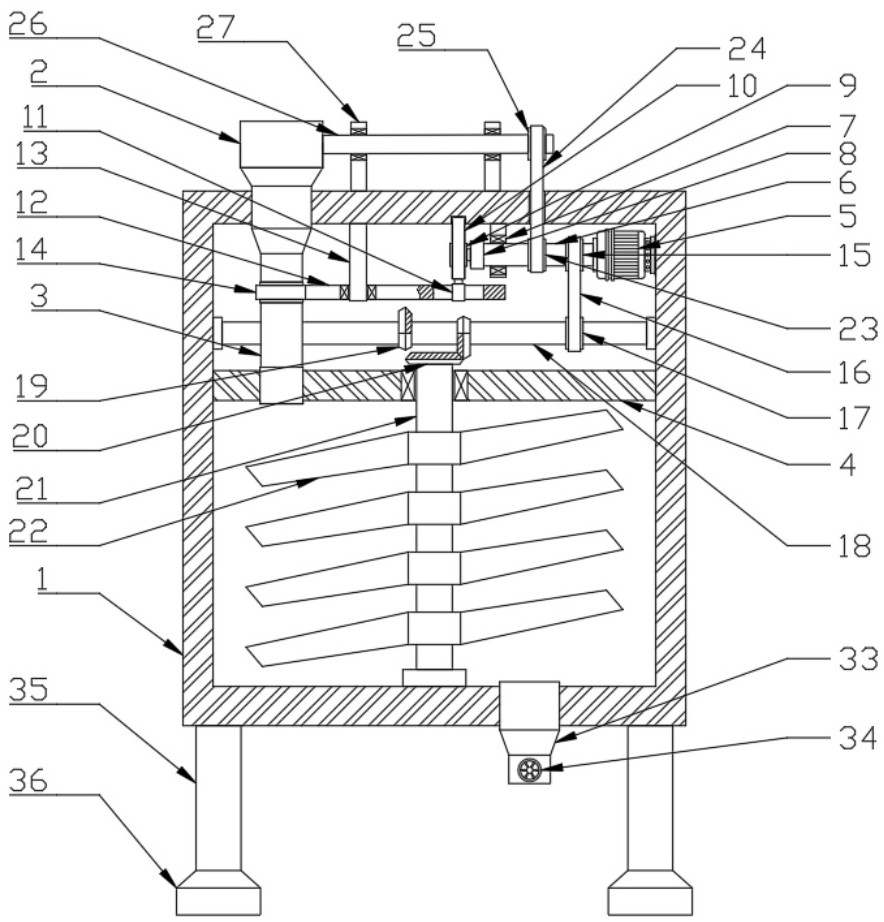

[0025] see Figure 1-Figure 4 , a multifunctional stirring device for biopharmaceuticals, comprising a box body 1, the upper end of the inner cavity of the box body 1 is fixedly connected with a partition 4, and the left side of the top plate of the box body 1 is symmetrically fixedly connected with two feeding hoppers 2 The lower port of the feed hopper 2 runs through the top plate of the box body 1 and extends into the box body 1 to communicate with the upper hole of the feed pipe 3, and the lower port of the feed pipe 3 runs through the partition plate 4 and extends to Below the partition 4, a motor 5 is fixedly connected to the top of the left side wall of the inner cavity of the box body 1, and the output shaft of the motor 5 is fixedly connected to a first rotating shaft 6, and the end of the first rotating shaft 6 away from the motor 5 runs through the second shaft. The bottom end of a fixed rod 7 extends to the left side of the first fixed rod 7 and is fixedly connecte...

Embodiment 2

[0033] The present invention is a further improvement made on the basis of embodiment 1, specifically as follows:

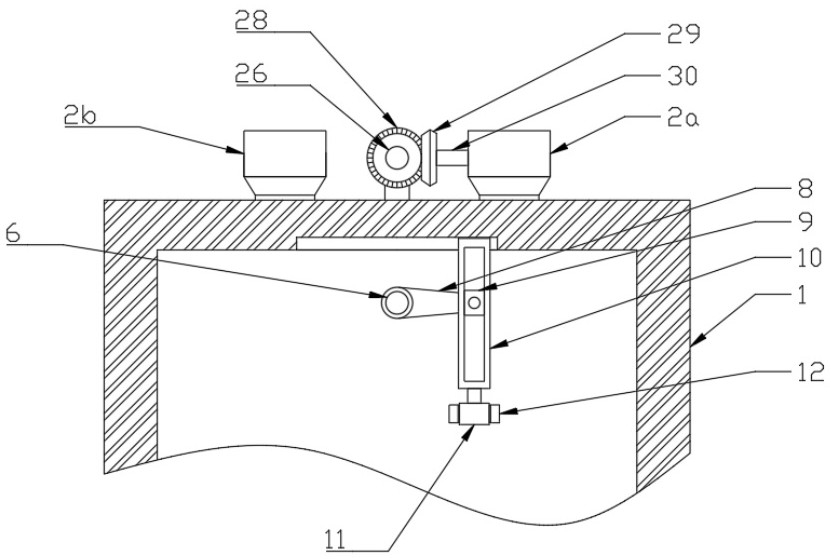

[0034] see Figure 1-4 , the outer surface of the first rotating shaft 6 is also fixedly provided with a second driving pulley 23, and the second driving pulley 23 is connected to the second driven pulley 25 through the second transmission belt 24. The driven pulley 25 is fixedly sleeved on the outer surface of the right end of the third shaft 26, and the top surface of the box body 1 is fixedly connected with two third fixed rods 27 at intervals, and the left end of the third shaft 26 passes through two third fixed rods in turn. The rod 27 extends to the left side of the third fixed rod 27 and is provided with a first bevel gear 28 , and the third shaft 26 is rotatably connected to the third fixed rod 27 through a bearing.

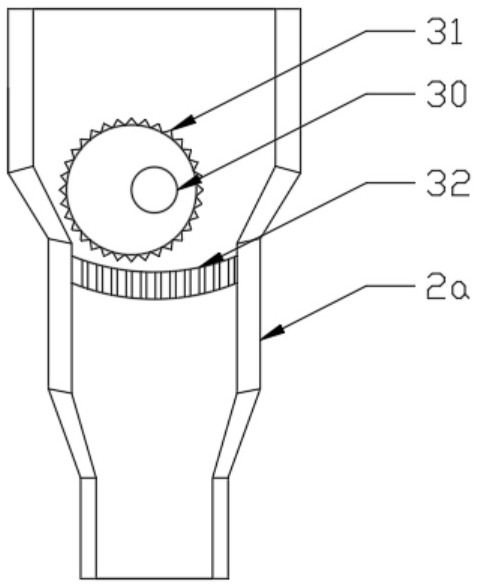

[0035] The two feed hoppers 2 are divided into a solid feed hopper 2a and a liquid feed hopper 2b, and the solid feed hopper 2a is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com