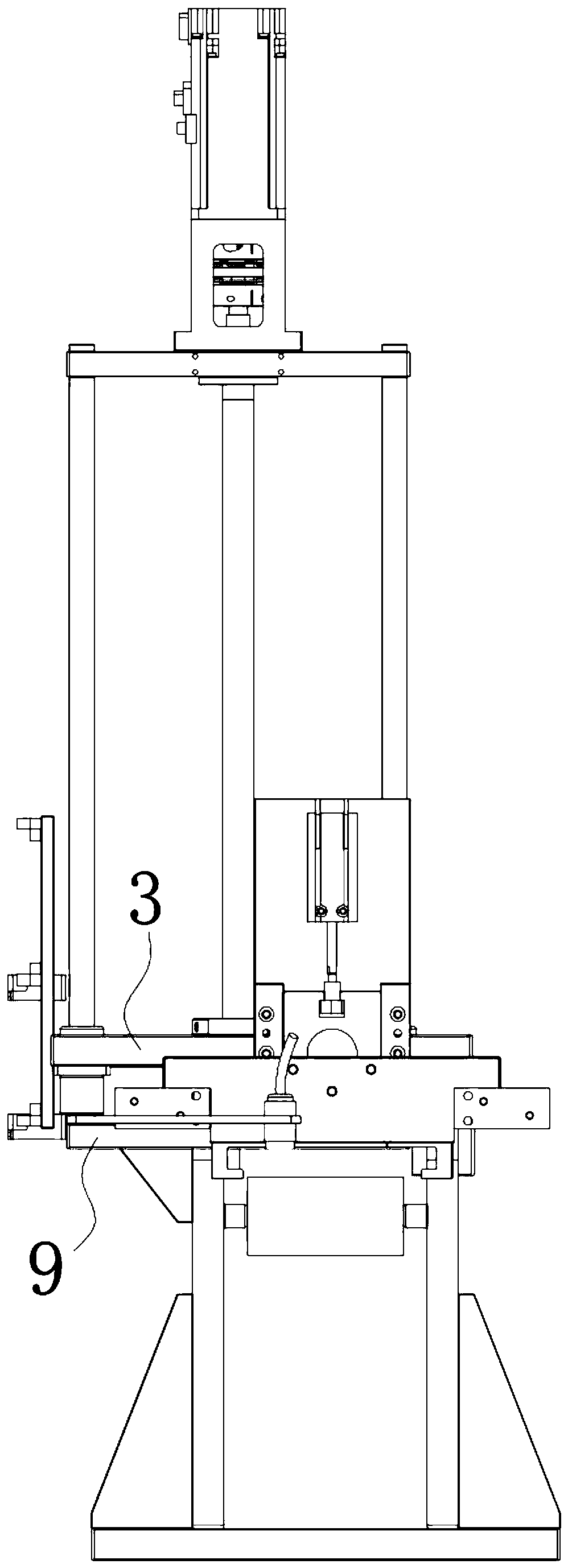

Feeding mechanism of plates

A technology of feeding mechanism and plate, which is applied in the field of assembly line, can solve the problems of operation length cable, difficult plate, etc., and achieve the effect of convenient adsorption and simple and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

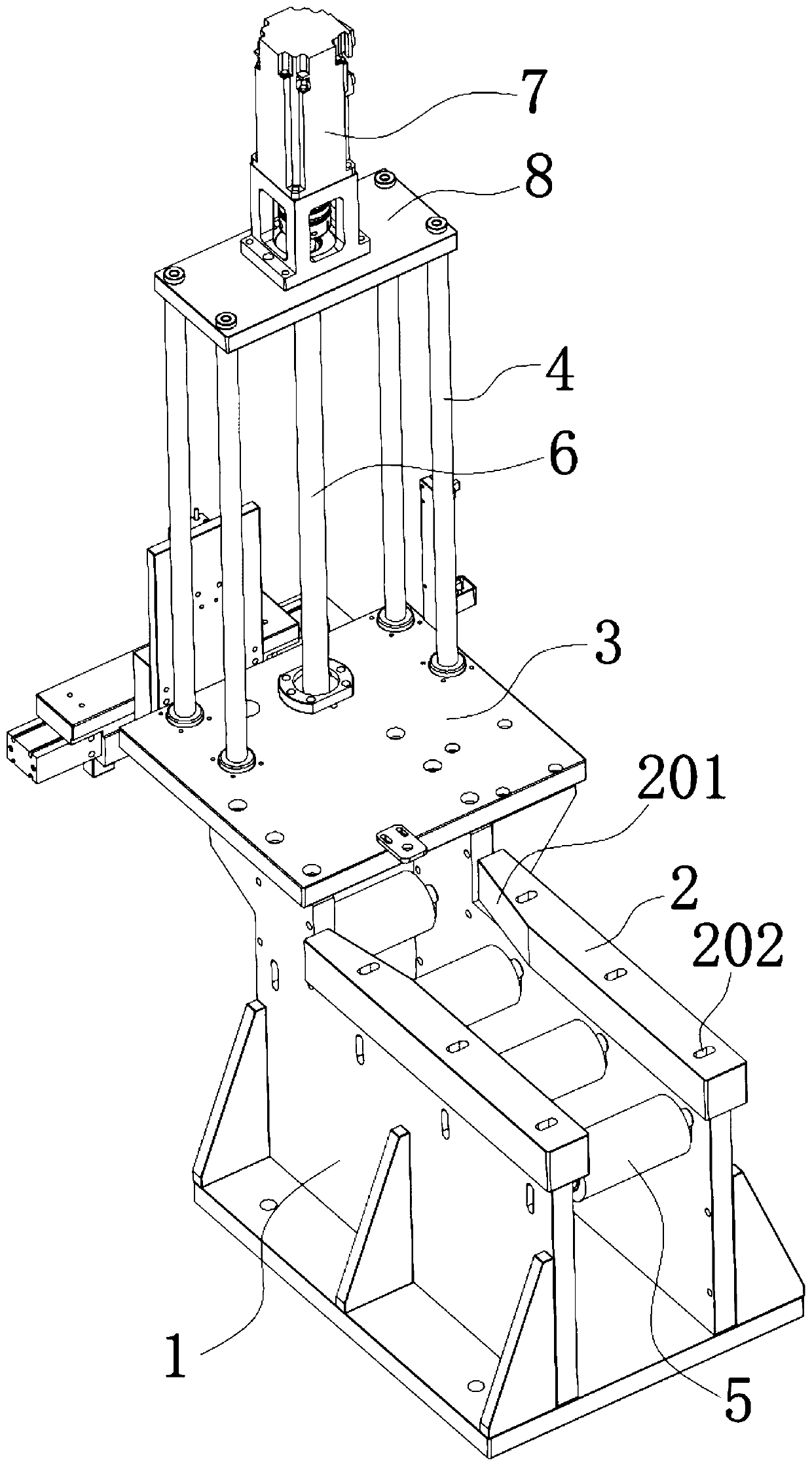

[0030] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

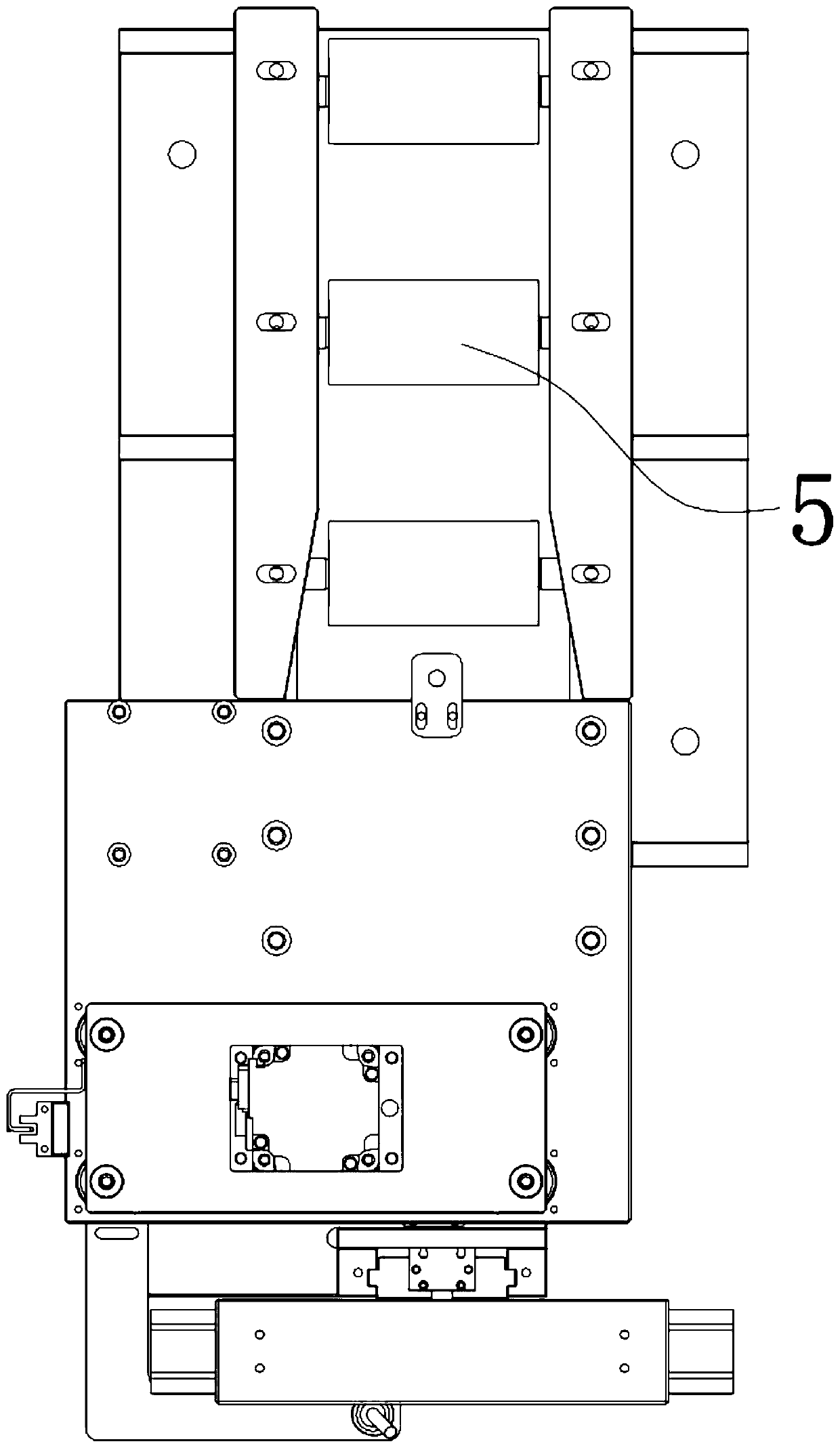

[0031] In order to achieve the purpose of the present invention, a feeding mechanism for a panel includes: a roller group, including several rollers 5 arranged in parallel in the same horizontal plane, and limit strips 2 are arranged on both sides above the rollers 5 to limit The length direction of the bit bar 2 is perpendicular to the self-axis direction of the roller 5; the suction cup 10 is in adsorption contact with the upper surface of the plate; the clamps 17, a pair of clamps 17 are arranged horizontally, and the clamps 17 have translations that move closer or farther away from each other. Degree of freedom, the direction of the line between a pair of clamps 17 is parallel to the self-axis direction of the roller 5; the moving mechanism includes a lifting plate 9 with a vertical lifting degree of freedom, and the suction cup 10, the clamps 17 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com