Auxiliary rotor core and end ring welding device

A rotor core and auxiliary device technology, applied in auxiliary devices, welding/cutting auxiliary equipment, welding equipment, etc., can solve problems such as poor positioning means, difficult end ring and rotor core concentricity, position and set position deviation, etc. , to achieve the effect of easy welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below according to the accompanying drawings and specific embodiments.

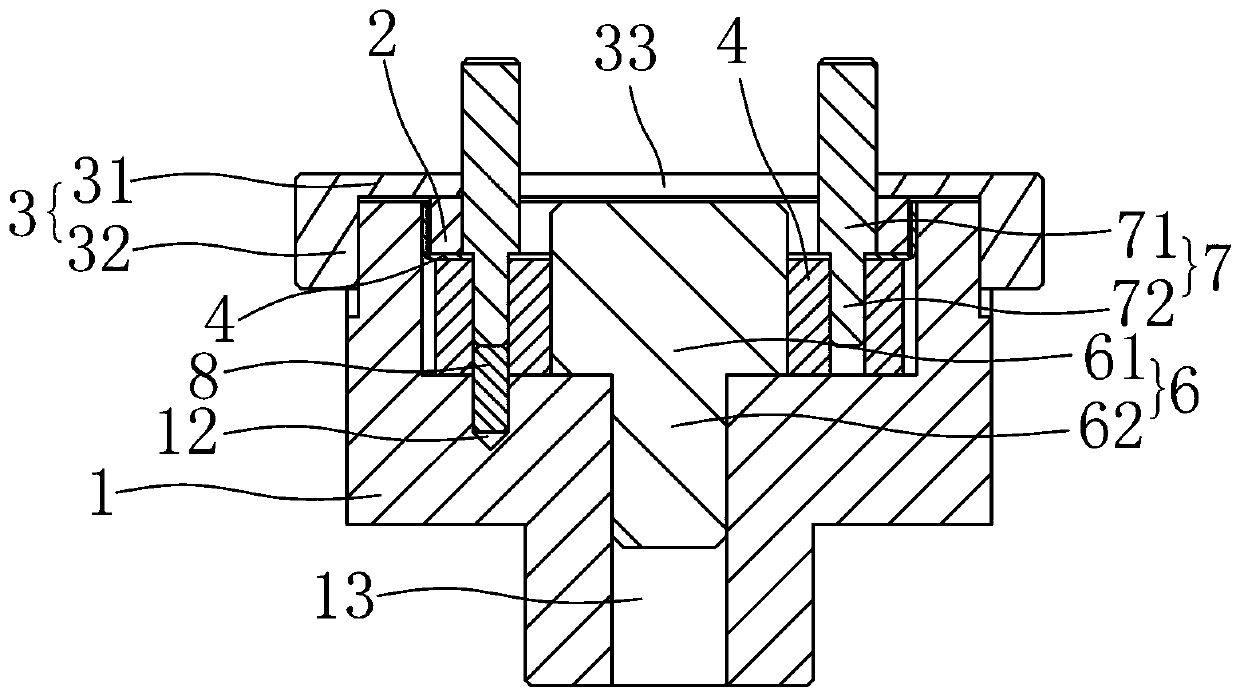

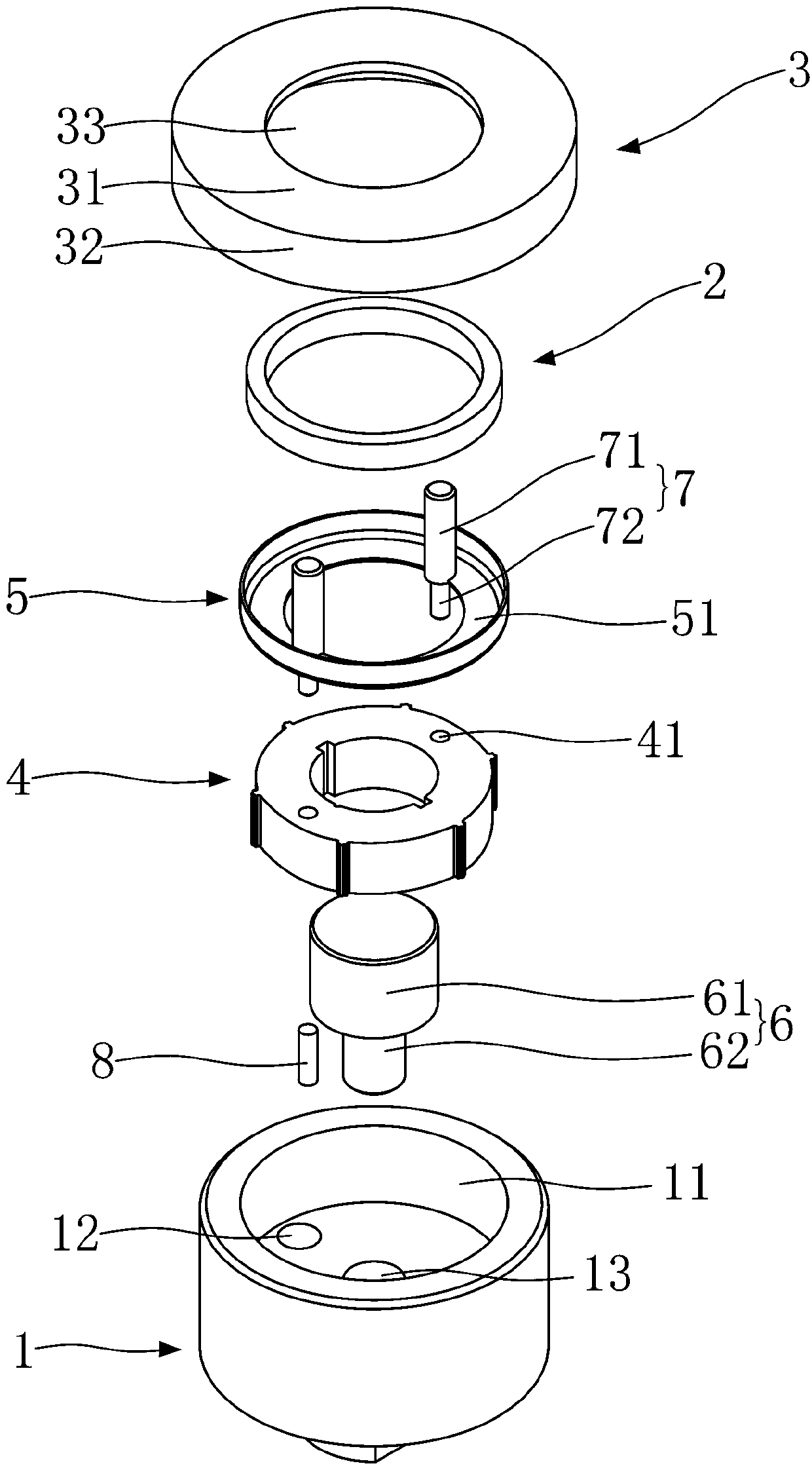

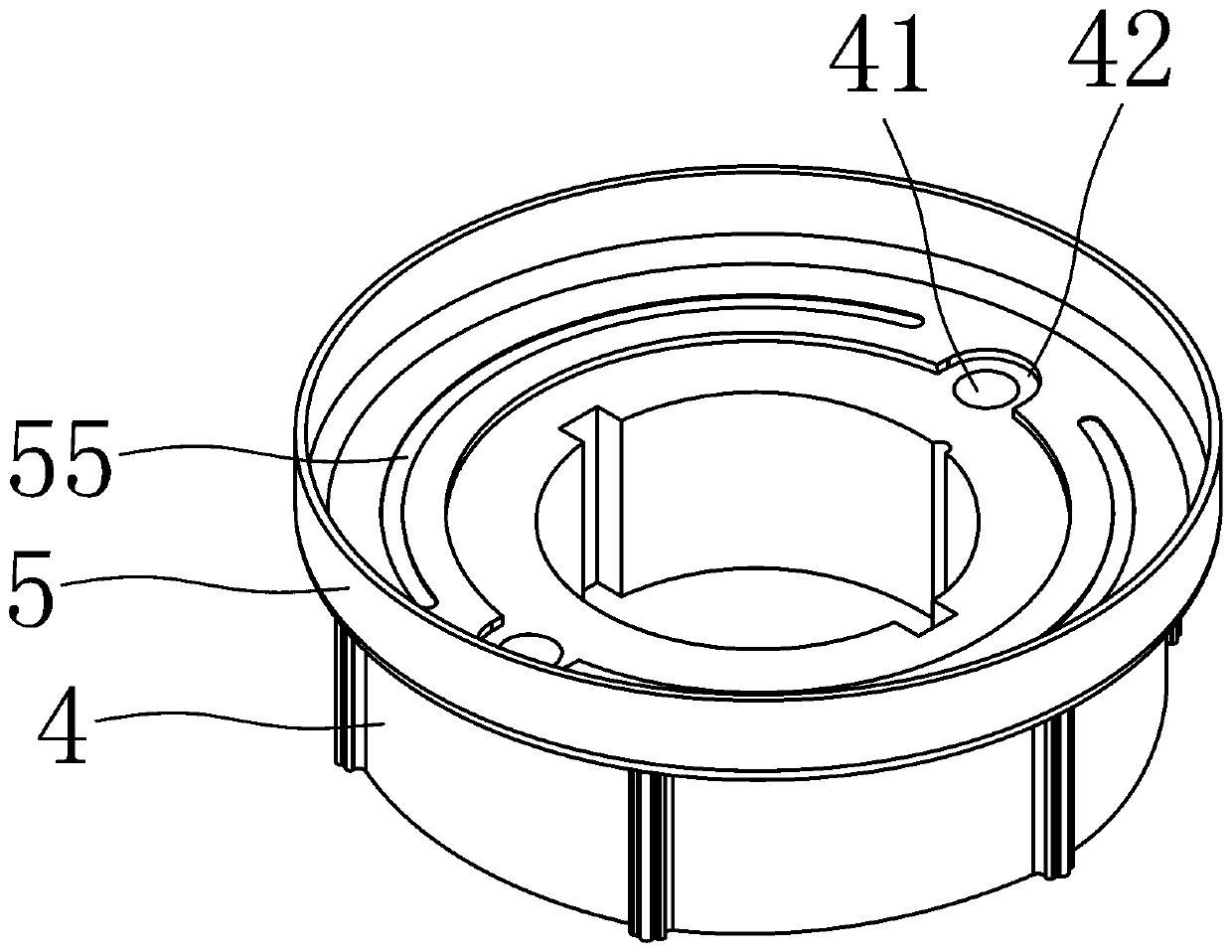

[0020] Depend on Figure 1 to Figure 3 As shown, the auxiliary device of the present invention is used for the positioning of the rotor core 4 and the end ring 5 , and for the positioning and fixing between the rotor core 4 and the end ring 5 , so as to facilitate subsequent welding to form weld marks 55 . A rotor iron core and end ring welding auxiliary device of the present invention includes a positioning sleeve 1, an annular pressure block 2, and a fixed cover 3. The positioning sleeve 1 is formed with a ring for accommodating the annular pressure block 2, the rotor core 4 and the end ring 5. The accommodation groove 11, the center of the accommodation groove 11 is provided with a positioning column 6 for positioning the circumferential position of the rotor core 4, the fixed cover 3 includes a cover top 31, and a ring-shaped fixing part 32 extend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com