Side-driving-type all-position automatic welding trolley traveling mechanism for pipeline

A technology of automatic welding and traveling mechanism, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc. Guarantee the effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

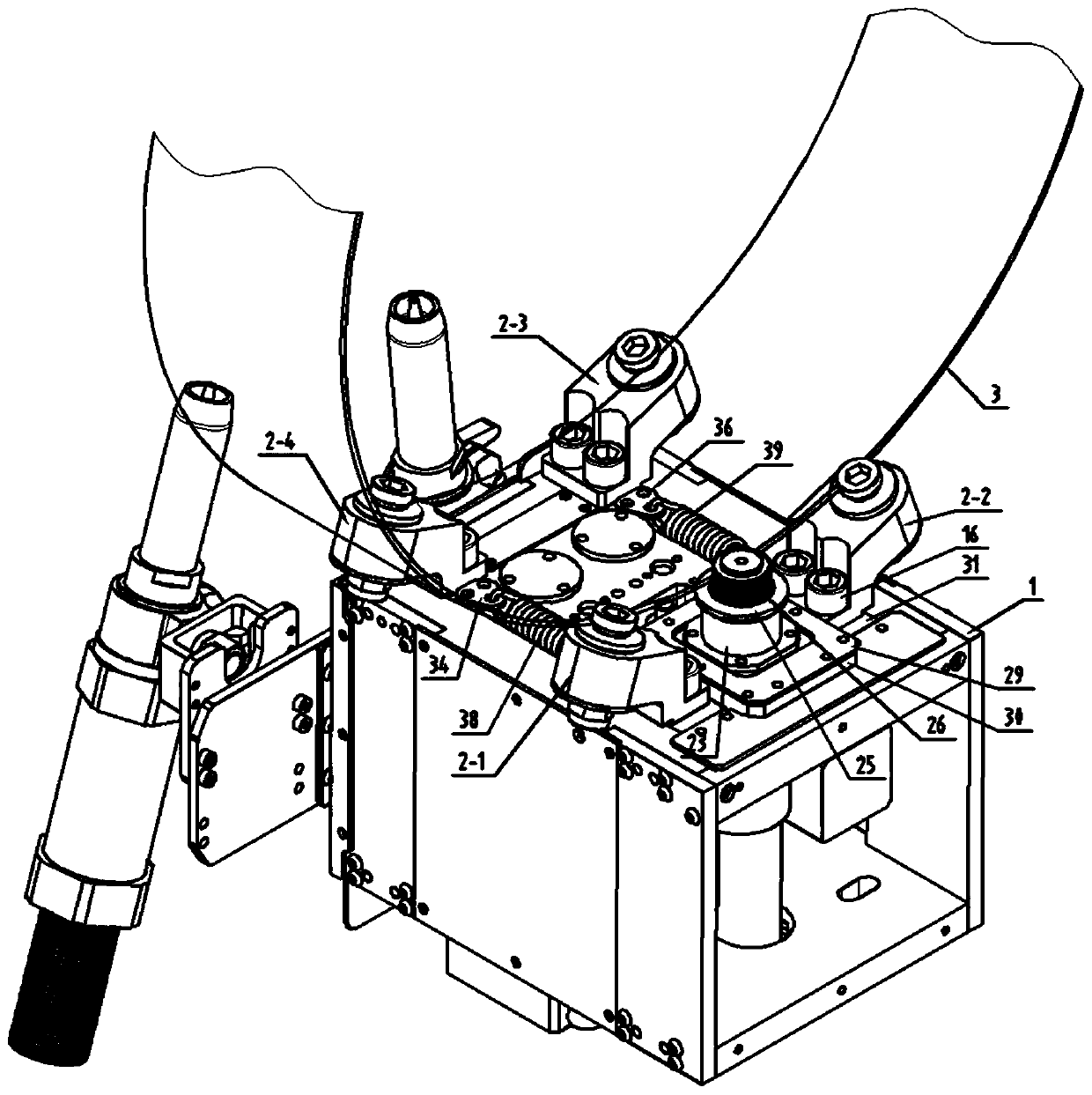

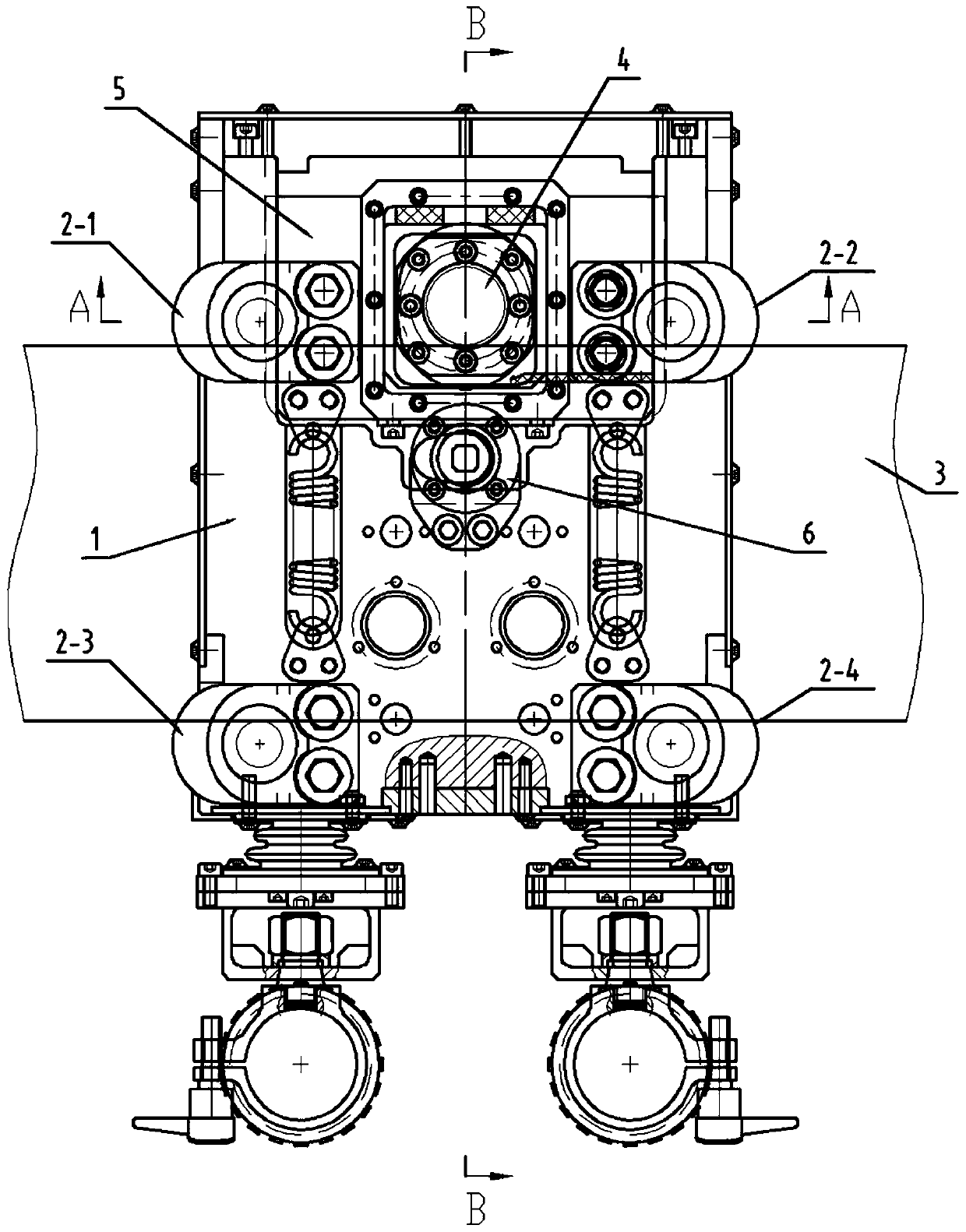

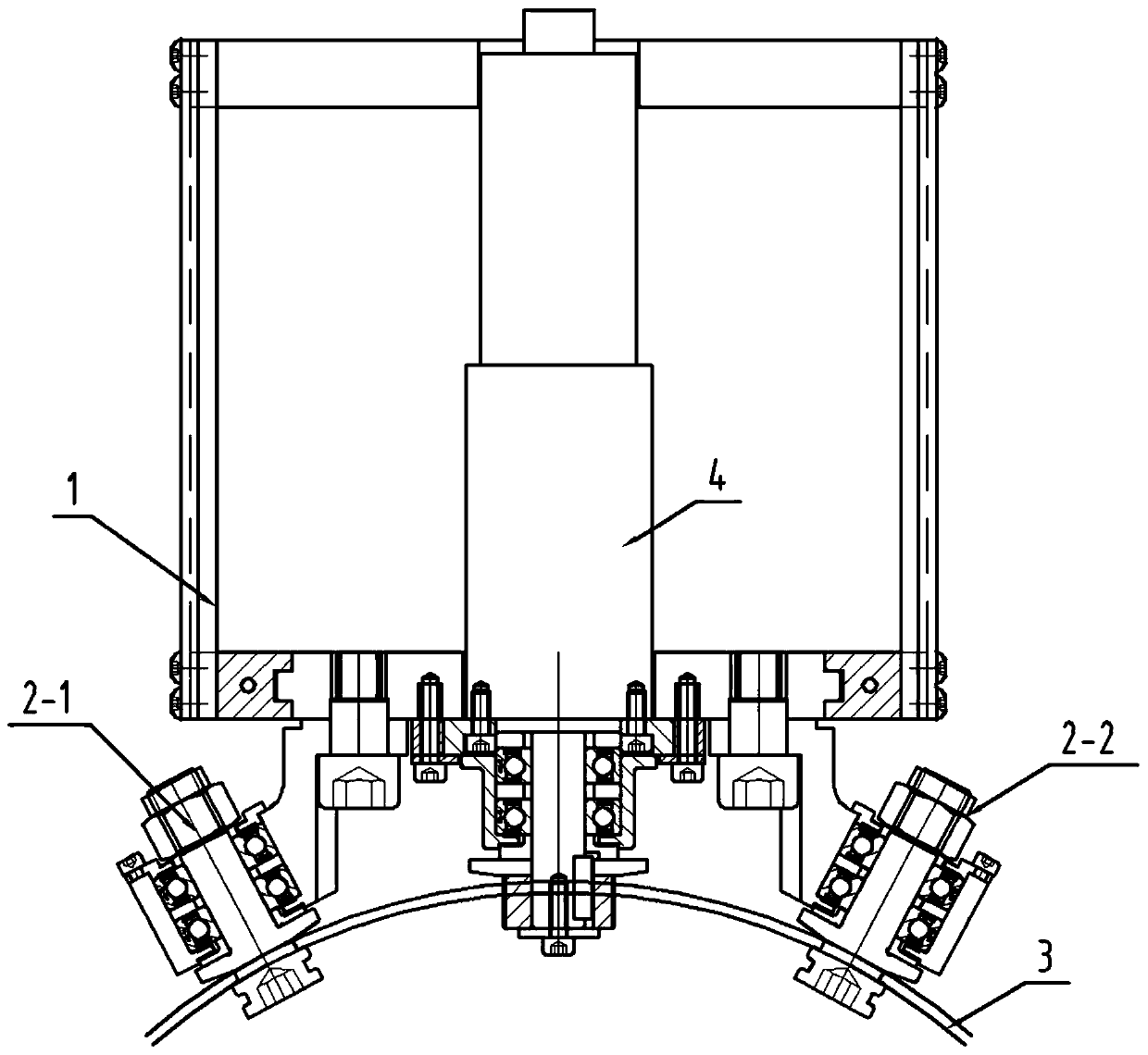

[0066] In order to further explain the technical means and effects adopted by the present invention to achieve the intended purpose of the invention, in conjunction with the accompanying drawings and preferred embodiments, the traveling mechanism of a side-drive full-position automatic welding trolley for pipelines proposed according to the present invention is described below. Specific embodiments, structures, features and effects thereof are described in detail below.

[0067] The main structure of the present invention consists of a follower assembly 2 and a double floating locking structure 4 . The double-floating locking structure makes the follower assembly close to the track 3 and has a pressing force on the track 3, so that the welding trolley is driven to walk along the track 3 by friction. Alternatively, the double-floating locking structure uses the gears to mesh with the track 3 to drive the welding trolley to walk along the track 3, and the curvature of the follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com