Glove stacking mechanism for full-automatic glove screening and packing machine

A fully automatic packaging machine technology, applied in the field of glove palletizing mechanism, can solve the problems of increasing the input cost of enterprise human resources, affecting the progress of the enterprise's production operation, increasing the labor intensity of workers, etc., and achieves the reduction of labor input cost, simple structure, and improved The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Specific embodiments of the present invention will be described below.

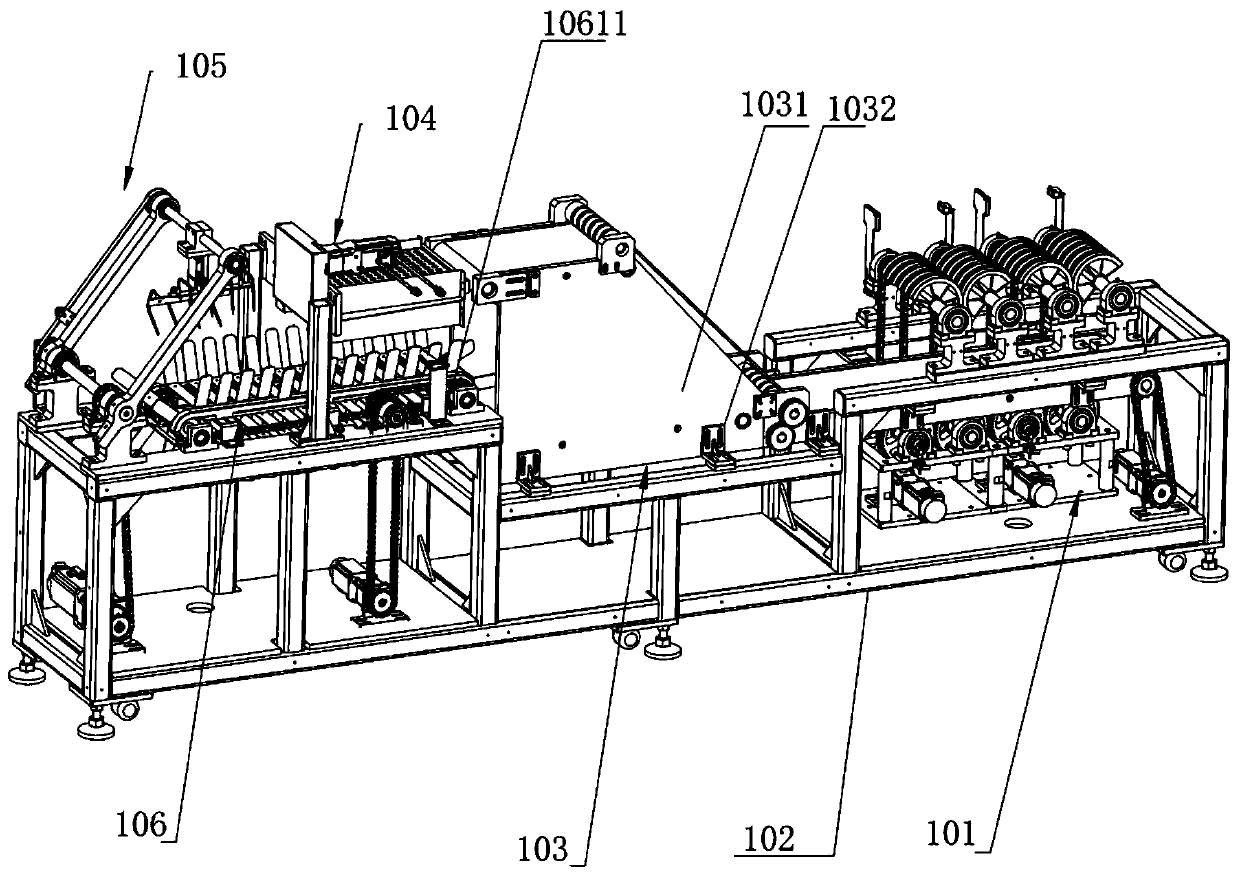

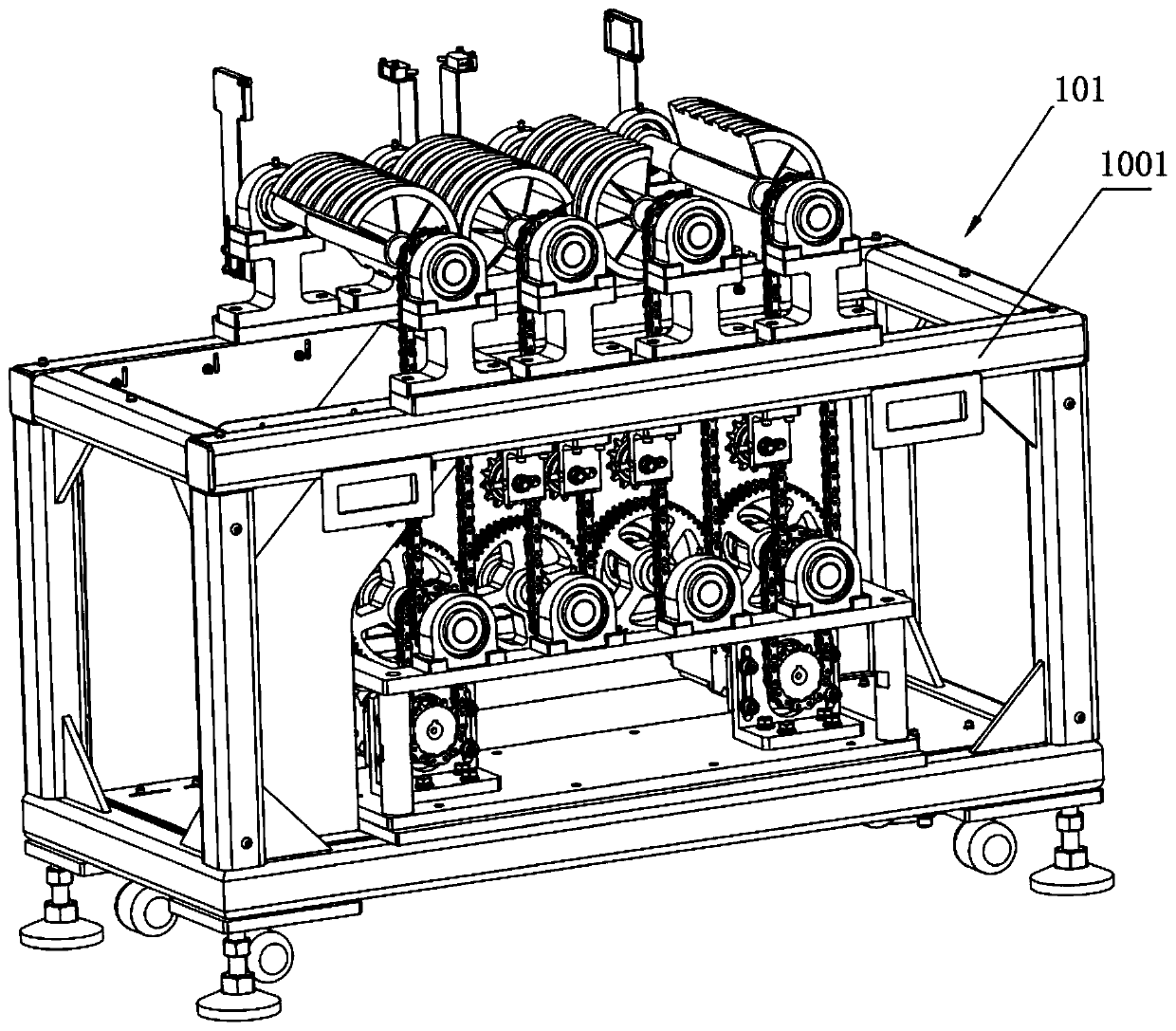

[0041] like figure 1 As shown, the glove palletizing mechanism of the automatic glove screening and packaging machine includes a first frame 102, on which a good product peeling mechanism 101 for peeling good glove products and a glove conveyor belt for conveying good glove products are arranged in sequence. 103. The glove counting and turning mechanism 104 for stacking and counting good glove products, the glove grasping and conveying mechanism 105 for handling good glove products, and the gloves for moving good gloves from the glove counting and turning mechanism 104 to the glove grasping and conveying mechanism 105 The glove palletizing conveyor belt 106, the rotating end of the glove counting and turning mechanism 104 is located above the glove grabbing and transporting mechanism 105.

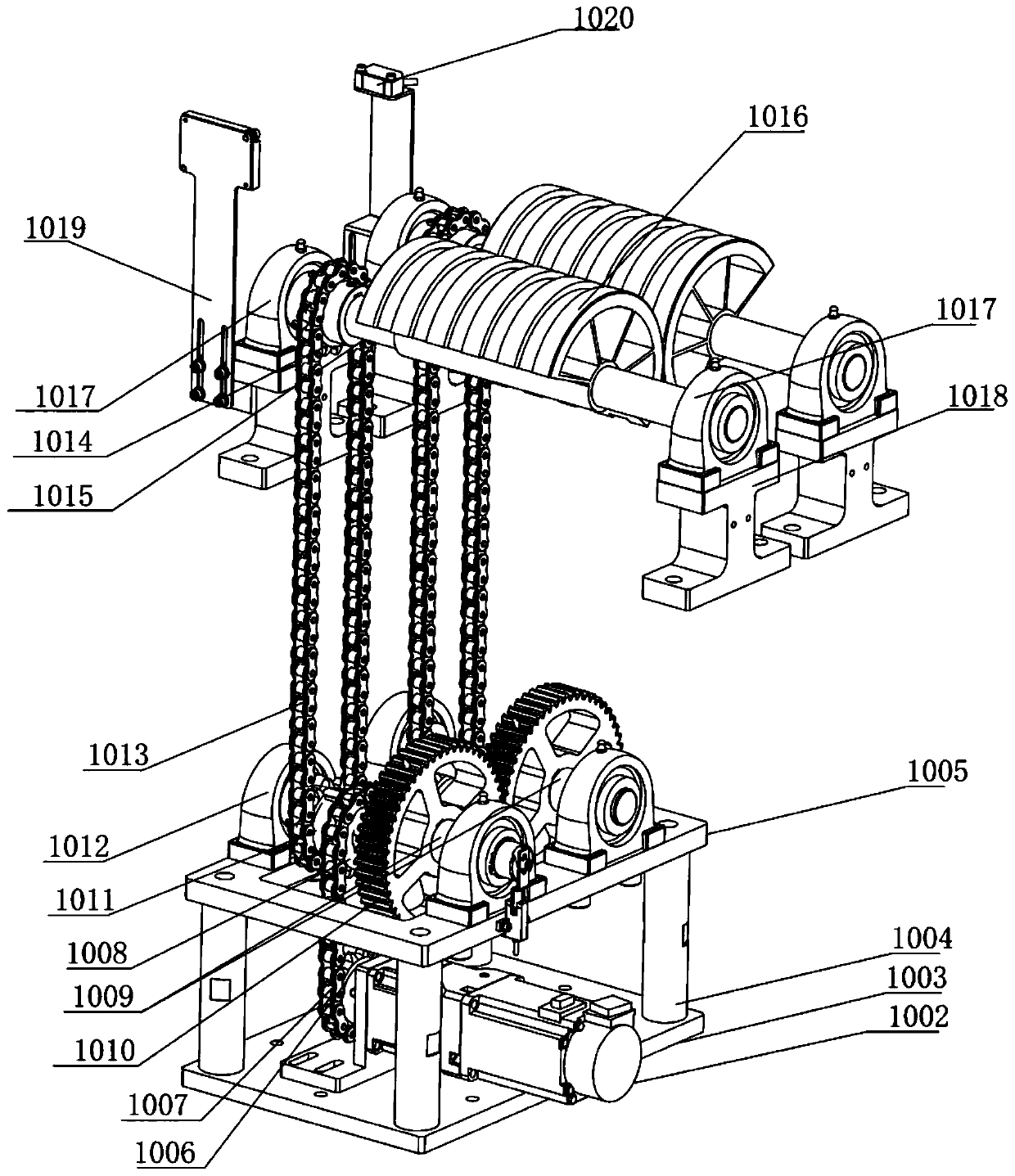

[0042] The specific structure of good product stripping mechanism 101 is as follows:

[0043] It includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com