Intelligent full-automatic multi-functional hardware stripping machine

A fully automatic and multi-functional technology, applied in the field of hardware strippers, can solve the problems of excessive production costs, waste of labor, and easy occurrence of injury accidents, so as to reduce maintenance and use costs, enhance ventilation effects, and achieve the effect of natural heat dissipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

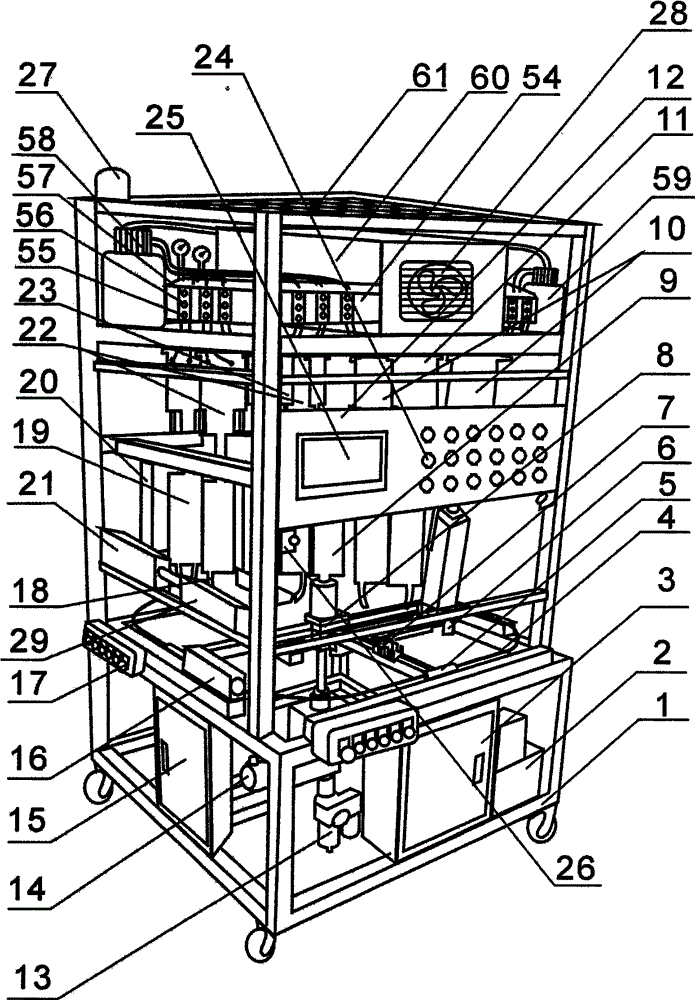

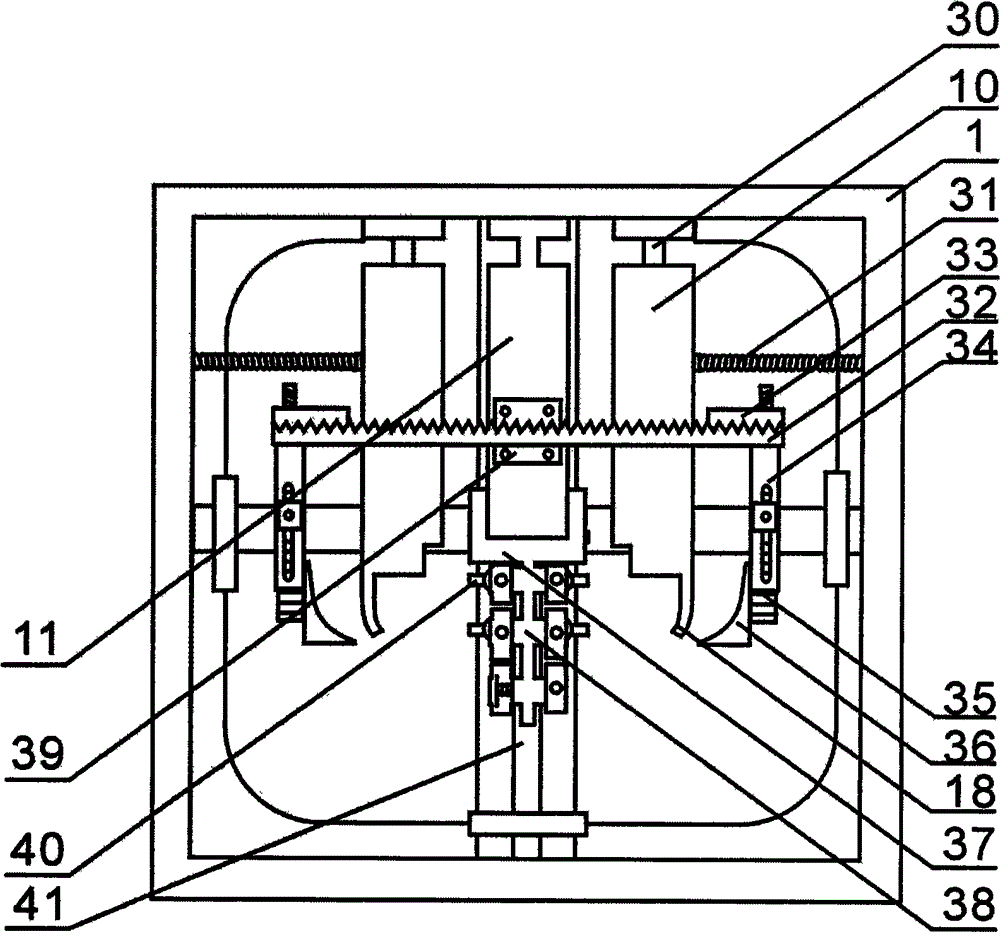

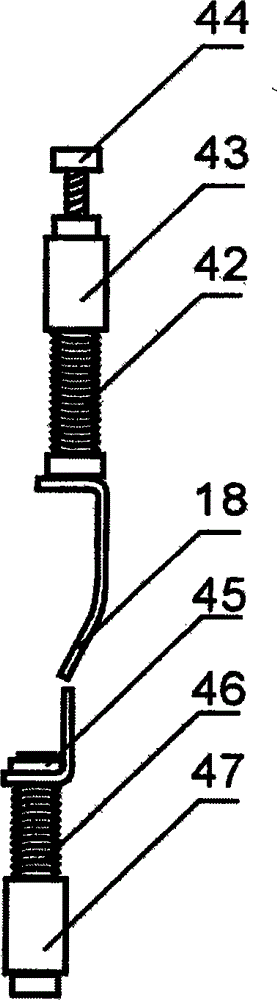

[0035] Such as figure 1 As shown, the intelligent full-automatic multi-functional hardware stripping machine described in the embodiment of the present invention includes a frame 1, an automatic lubricating oil supply device 2, a hydraulic manipulator 6 for edge cutting, a pneumatic fastening manipulator 16, and a manipulator 18 for pressing products, The rack 1 is divided into four layers from bottom to top. First, for the bottom layer:

[0036]An automatic lubricating oil supply device 2 is fixedly installed at the bottom of the frame 1 so as to automatically supply lubricating oil to each part of the machine on time to prevent the machine from being damaged by friction during long-term operation. The tool box 3 of the tool, correspondingly, is located at the other side of the bottom of the frame 1 and fixedly installs the scrap box 15 and an air pump 13 is added inside the frame between the scrap box 15 and the tool box 3, which is located at the center of the bottom of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com