Intelligent operation control system of bridge crane

An overhead crane, operation control technology, applied in transportation and packaging, load hanging components, safety devices, etc., can solve problems such as reducing work efficiency, affecting safe operation, load swinging, etc., achieving a wide range of applications, eliminating swinging Phenomenon, simple effect of design scheme

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

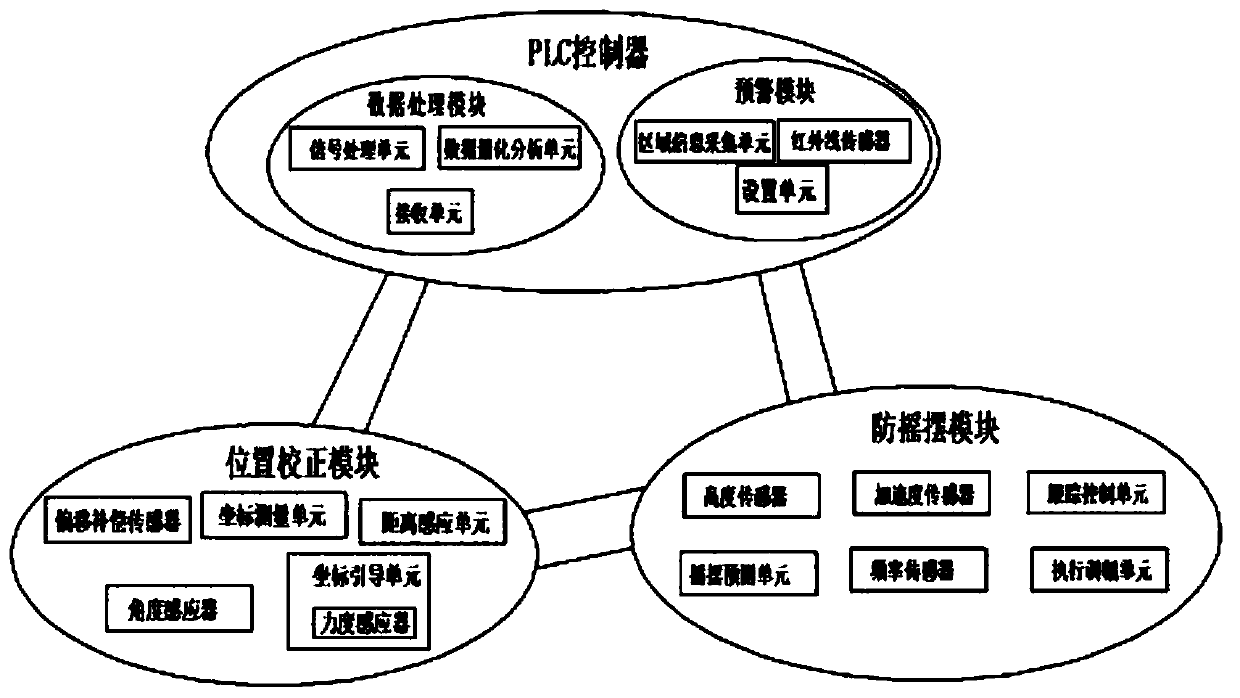

[0031] Such as figure 1 , 2 As shown, the technical solution of the present invention is an intelligent operation control system of a bridge crane, which mainly includes a position correction module, an anti-sway module, a data processing module, and a PLC controller;

[0032] Position correction includes a coordinate measurement unit, a distance sensing sensor, an offset compensation sensor, an angle sensor, and a coordinate guidance unit; the coordinate measurement unit is used to establish coordinates to mark the position of the object; the distance sensing sensor is used to set the distance coordinates of the moving position of the object The distance is measured; the offset compensation unit is used to offset the offset from the actual coordinates; the angle sensor is used to measure the oblique angle of the object on the crane coordinates; the coordinate guidance unit includes pulse code signals and activity types for Send a pulse coded signal to the object to determine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com