Circular saw web heat treatment inter-process plug-in mounting and ferrying device and method

A circular saw blade and inter-process technology, which is applied in the field of fork mounting and ferry device between heat treatment processes of circular saw blades, can solve problems such as low fork mounting and ferry efficiency, and achieve the effect of saving labor costs and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

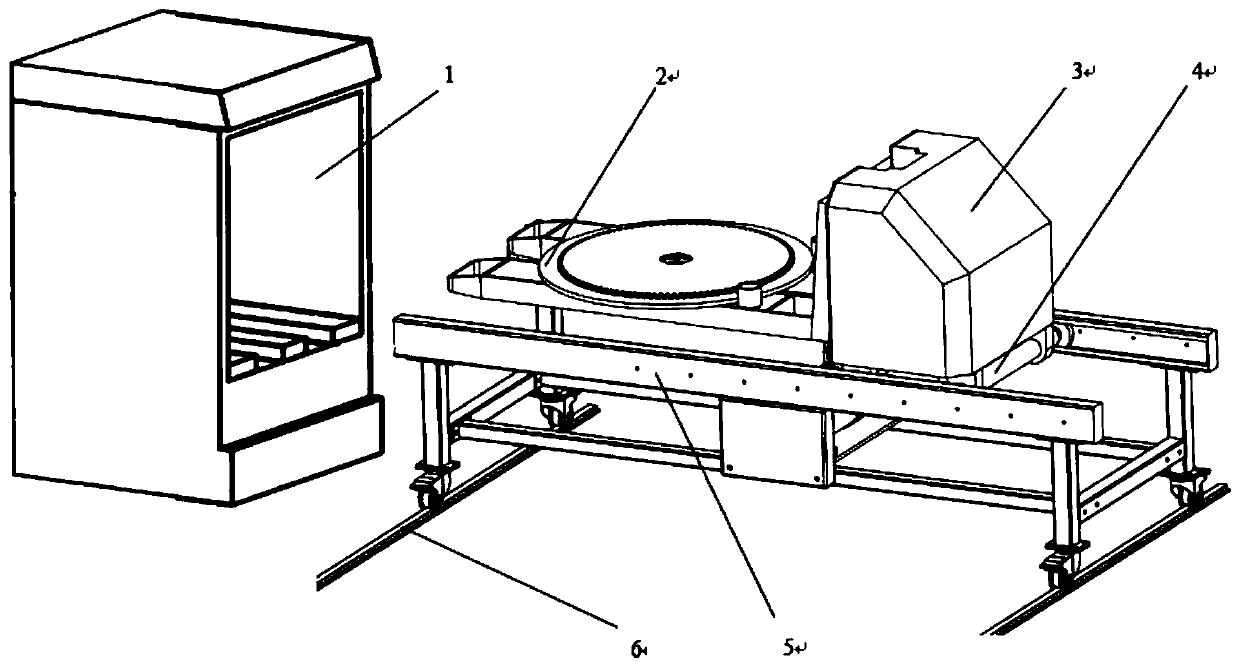

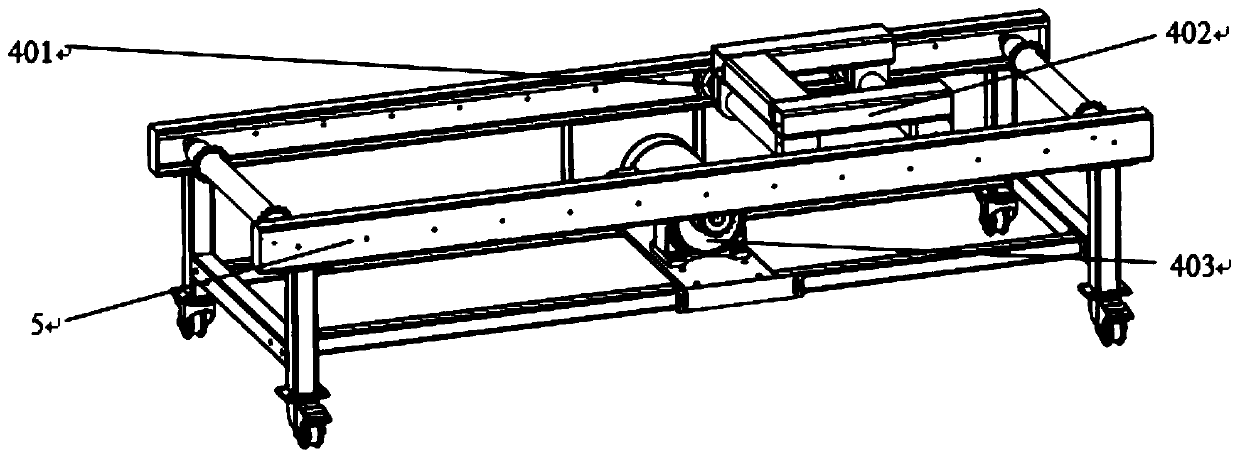

[0031] Such as figure 1 As shown, the present invention as a whole includes a heat treatment furnace 1, a tray 2, a lifting device 3, a feeding device 4, a workbench 5 and a ferry slide 6; the workbench 5 is placed on the ferry slide 6 through the lower pulley And can move back and forth on the ferry guide rail 6, the pulley below the workbench 5 is provided with a self-locking device, the described feeding device 4 is placed on the workbench 5 and the connection mode with the workbench 5 is a movable connection, The lifting device 3 is fixed on the feeding device 4 , the tray 2 is placed on the lifting device 3 , and the workbench 5 is placed directly in front of the heat treatment furnace 1 .

[0032] The pallet 2 is used to lift and carry the heat-treated workpieces participating in the transportation, so the pallet 2 can be a circular, rectangular or any other disc-shaped piece that can complete the lifting action and achieve the lifting effect.

[0033] The workbench 5 i...

Embodiment 2

[0049] The difference between Embodiment 2 and Embodiment 1 is that the driving mode of the feeding device 4 is hydraulic drive, and the specific driving mode of the hydraulic drive is that the output end of the hydraulic cylinder is connected to a fixed piece with a relatively constant position. The movement can drive the support frame 402 connected to the main body of the hydraulic cylinder to move.

[0050] Implementing this embodiment has the following benefits compared to the prior art:

[0051] The feeding device adopts hydraulic drive mode, which can provide greater torque and more precise movement distance control.

Embodiment 3

[0053] Embodiment 3 discloses a method for forking and ferrying workpieces between heat treatment processes using circular saw blades, including the following steps:

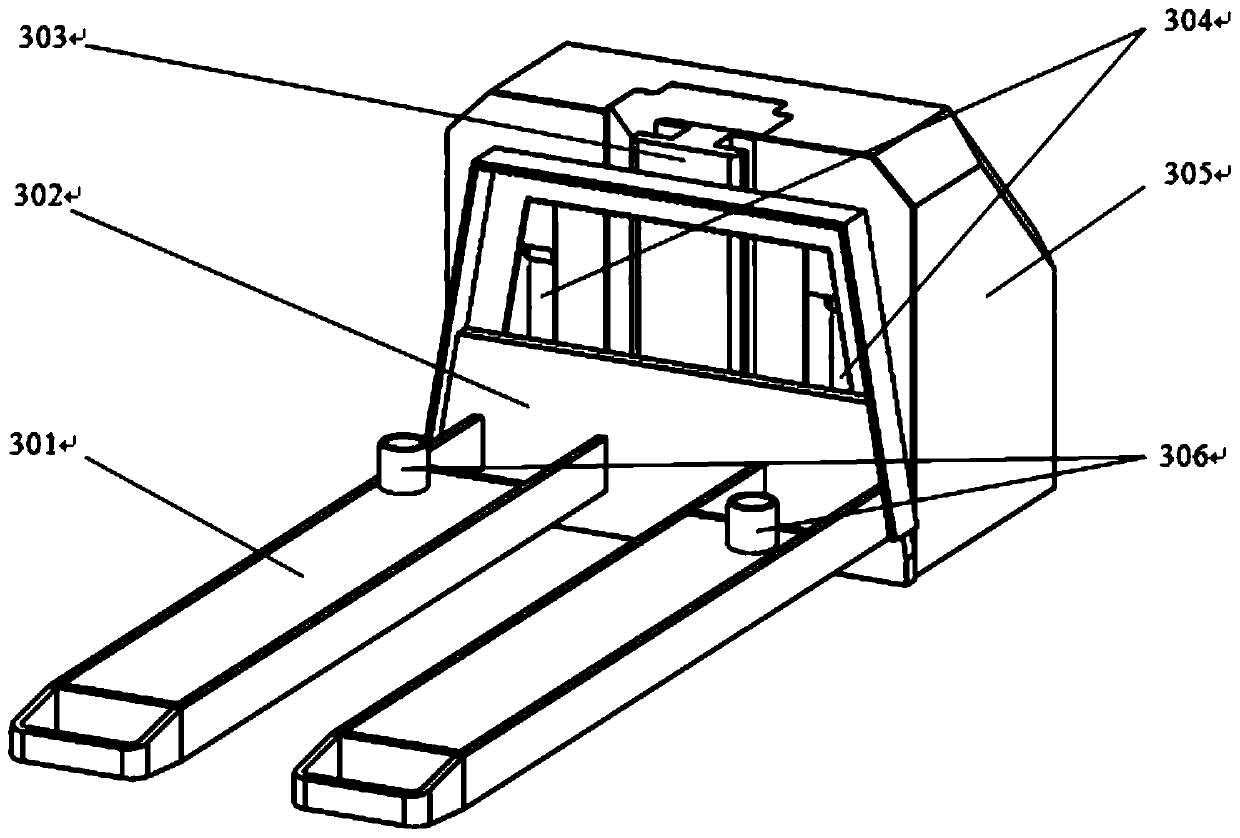

[0054] - When the circular saw blade is placed on the pallet 2, the workbench 5 of the fork loading and ferry device in the heat treatment process of the circular saw blade moves along the ferry guide rail 6 to the front of the heat treatment furnace 1 and is fixed with a self-locking device, and the lifting device The hydraulic cylinder 304 in 3 functions to lift the main body 301 of the fork frame along the guide rail 303 and lift up the pallet 2, and the power source 403 in the feeding device 4 provides power to make the support frame 402 drive the lifting device 3 along the guide rail Do feed motion.

[0055] - When the pallet fork frame main body 301 sends the circular saw blade into the heat treatment furnace 1 and cooperates with the matching fork groove 103, the hydraulic cylinder 304 in the lifting devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com