Carton conveying scheduling system and carton conveying system

A scheduling system and carton technology, applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc., can solve the problems of reducing production efficiency, increasing employee fatigue, manual secondary handling, etc., to improve operating efficiency and relieve employee fatigue intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

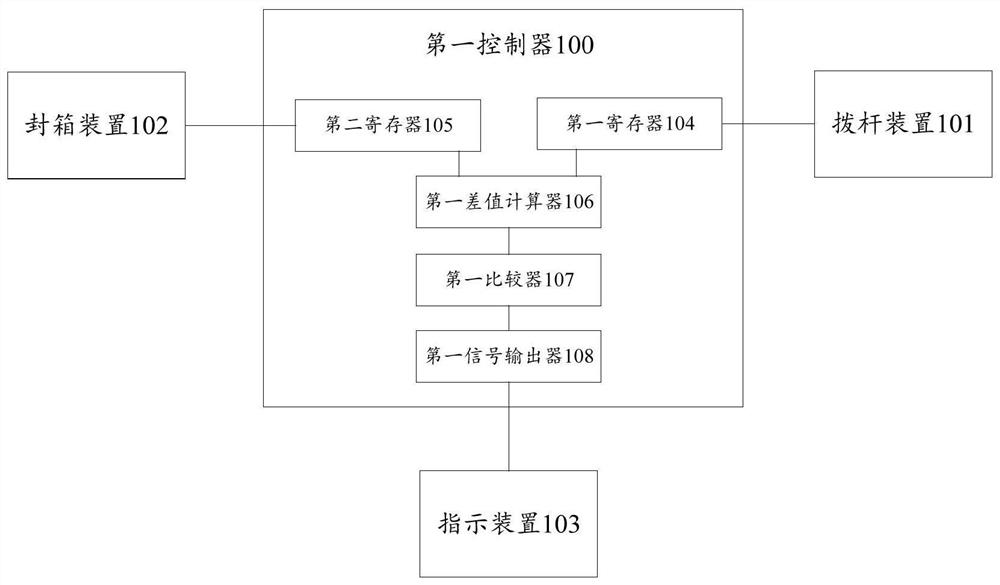

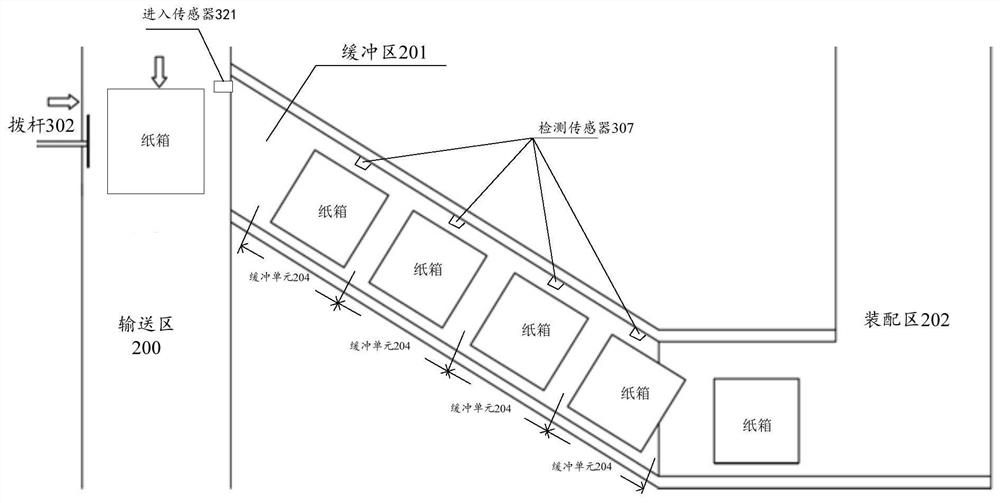

[0032] The embodiment of the present invention provides a carton conveying scheduling system. The carton conveying scheduling system is applied to the carton conveying line. The carton conveying line includes a conveying area, a buffer zone and an assembly area. The entrance of the buffer zone is connected to the conveying zone. The exit position connects with the assembly area, specifically, figure 1It shows a schematic structural diagram of a carton conveying scheduling system, which includes: a first controller 100, and a lever device 101, a sealing device 102 and an indicating device 103 connected in communication with the first controller; , the lever device is installed in the conveying area opposite to the entrance position of the buffer zone, and the sealing device is installed in the assembly area; the first controller 100 includes: a first register 104, which is used to record the lever action of the lever device 101, and obtain The first numerical value; The second ...

Embodiment 2

[0057] The embodiment of the present invention also provides a carton conveying system, the carton conveying system is configured with the above-mentioned carton conveying scheduling system, the carton conveying system includes other mechanical components or electronic components such as conveyor belts in addition to the above-mentioned carton conveying scheduling system , the implementation manner of the specific system may refer to related technical implementations, which will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com