Cloth feeding mechanism of embroidery machine and embroidery machine

A technology of cloth feeding mechanism and embroidery machine, which is applied to the mechanism of embroidery machines, embroidery machines, textiles and papermaking, etc. It can solve the problems of cloth wrinkles, unfavorable embroidery machine embroidery, and the inability of effective smoothing and equalization of cloth, and achieve the goal of increasing tension. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

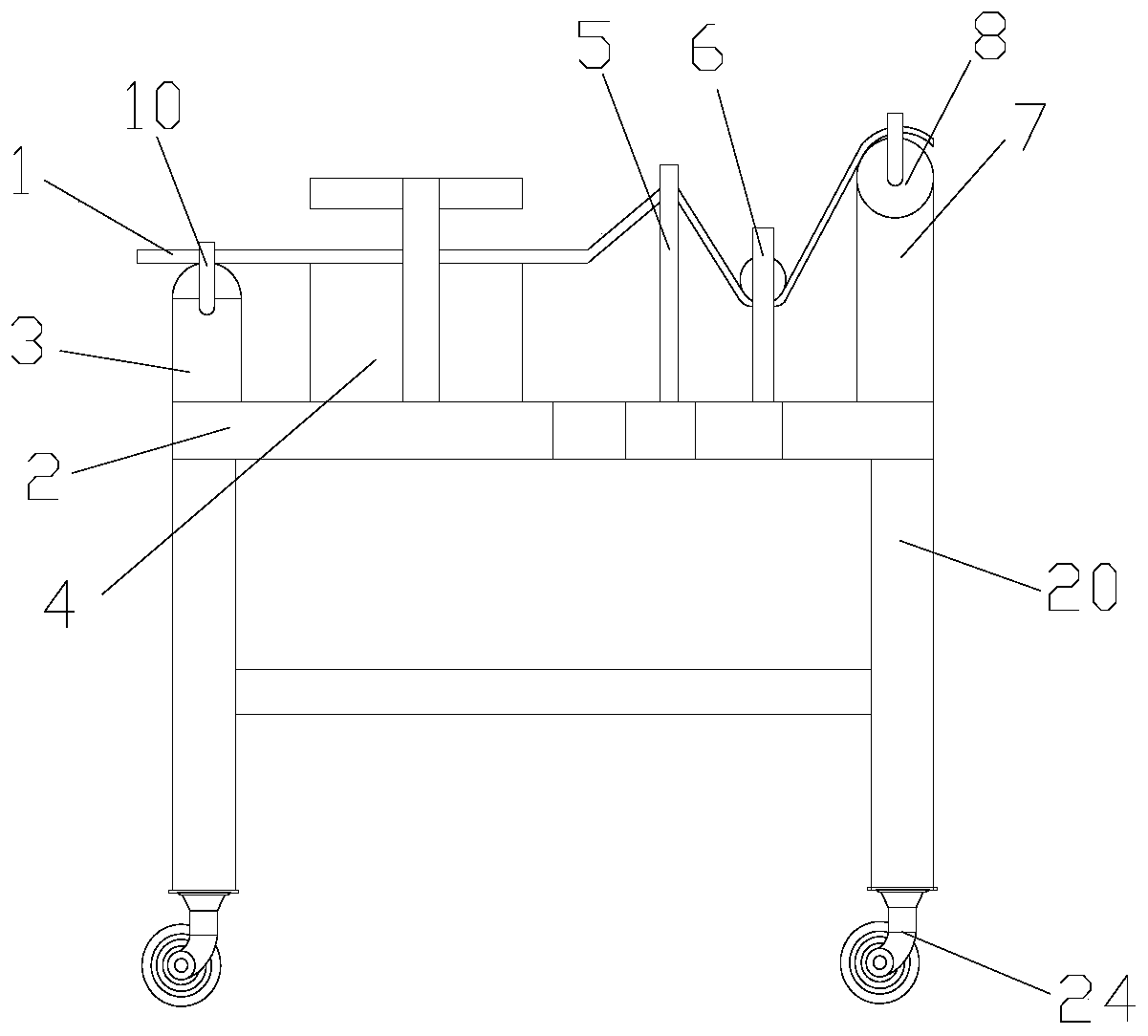

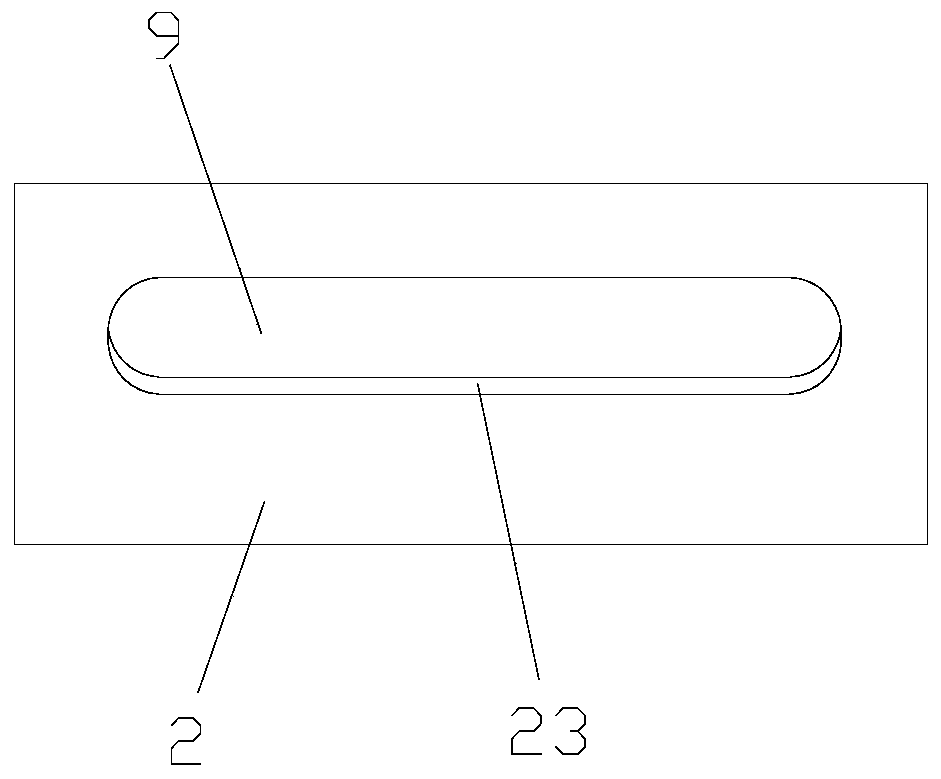

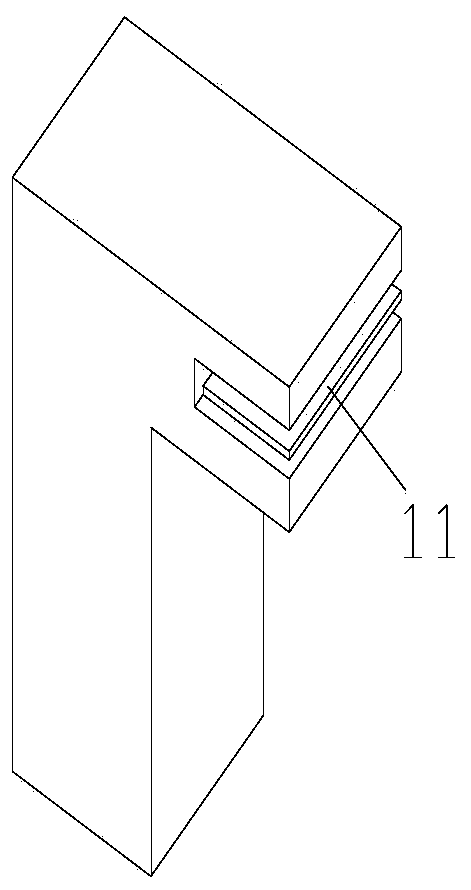

[0027] like Figure 1-3As shown, a cloth feeding mechanism of an embroidery machine includes a support plate 2 on which a first fixed column 3, a smoothing box 4, a support plate 5, a second fixed column 6 and a third fixed column are arranged. 7. The first fixed column 3, the second fixed column 6 and the third fixed column 7 are respectively located on both sides of the support plate 2, and the first fixed column 3, the second fixed column 6 and the third fixed column 7 are all in the form of Symmetrically distributed, the first fixed column 3, the second fixed column 6 and the third fixed column 7 are fixedly connected to the support plate 2, the first fixed column 3, the second fixed column 6 and the third fixed column 7 A paper roll 8 is arranged between them, and the first fixed column 3, the second fixed column 6 and the third fixed column 7 are all rotatably connected with the paper roll 8 on each of them, and the support plate 2 is provided with a cloth 1 Paired thro...

Embodiment 2

[0030] like Figure 1-6 As shown, a cloth feeding mechanism of an embroidery machine includes a support plate 2 on which a first fixed column 3, a smoothing box 4, a support plate 5, a second fixed column 6 and a third fixed column are arranged. 7. The first fixed column 3, the second fixed column 6 and the third fixed column 7 are respectively located on both sides of the support plate 2, and the first fixed column 3, the second fixed column 6 and the third fixed column 7 are all in the form of Symmetrically distributed, the first fixed column 3, the second fixed column 6 and the third fixed column 7 are fixedly connected to the support plate 2, the first fixed column 3, the second fixed column 6 and the third fixed column 7 A paper roll 8 is arranged between them, and the first fixed column 3, the second fixed column 6 and the third fixed column 7 are all rotatably connected with the paper roll 8 on each of them, and the support plate 2 is provided with a cloth 1 Paired thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com