Snow removal rolling brush assembly

A technology of roller brush and assembly, applied in snow surface cleaning, construction, cleaning methods, etc., can solve the problems of large vibration and abnormal noise of snow removal roller brush, time-consuming and laborious installation and disassembly, shortening the use time of roller brush, etc. Good stability, reduced labor intensity, and high efficiency of snow removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

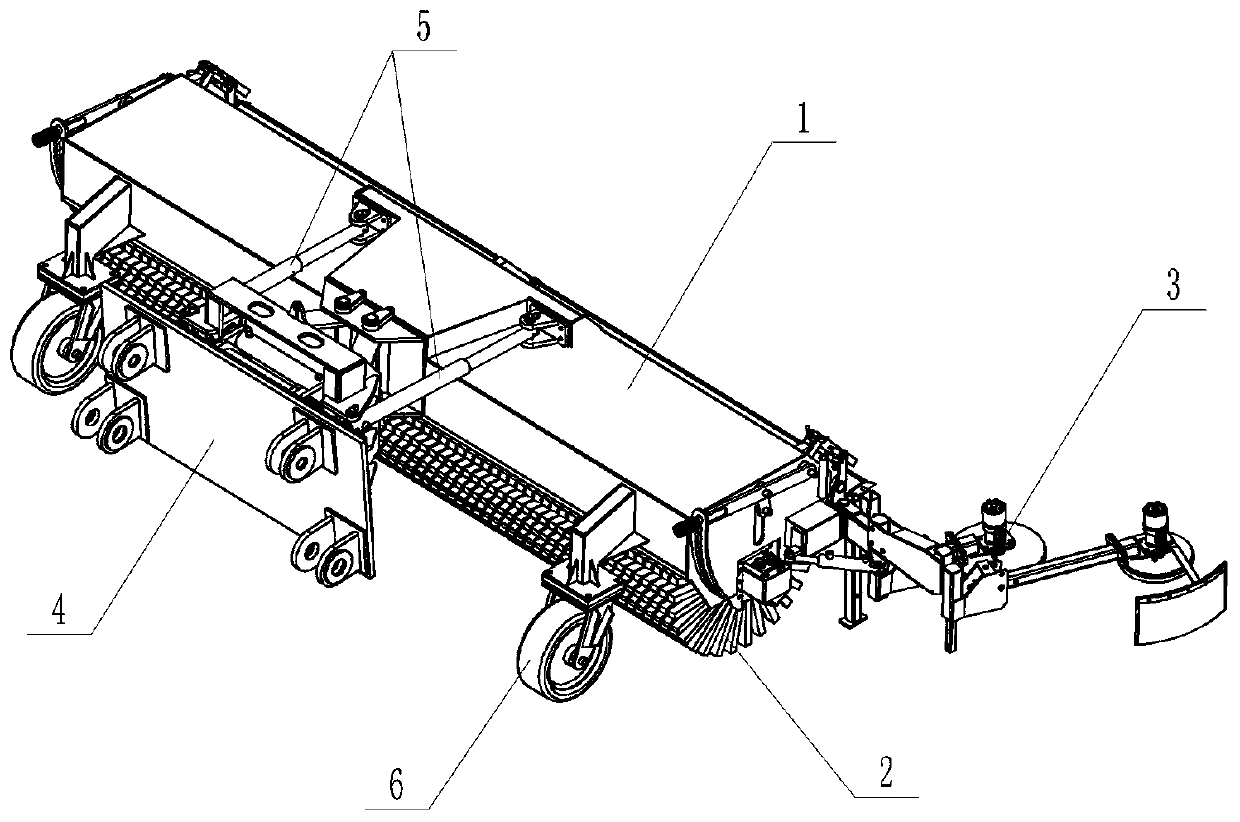

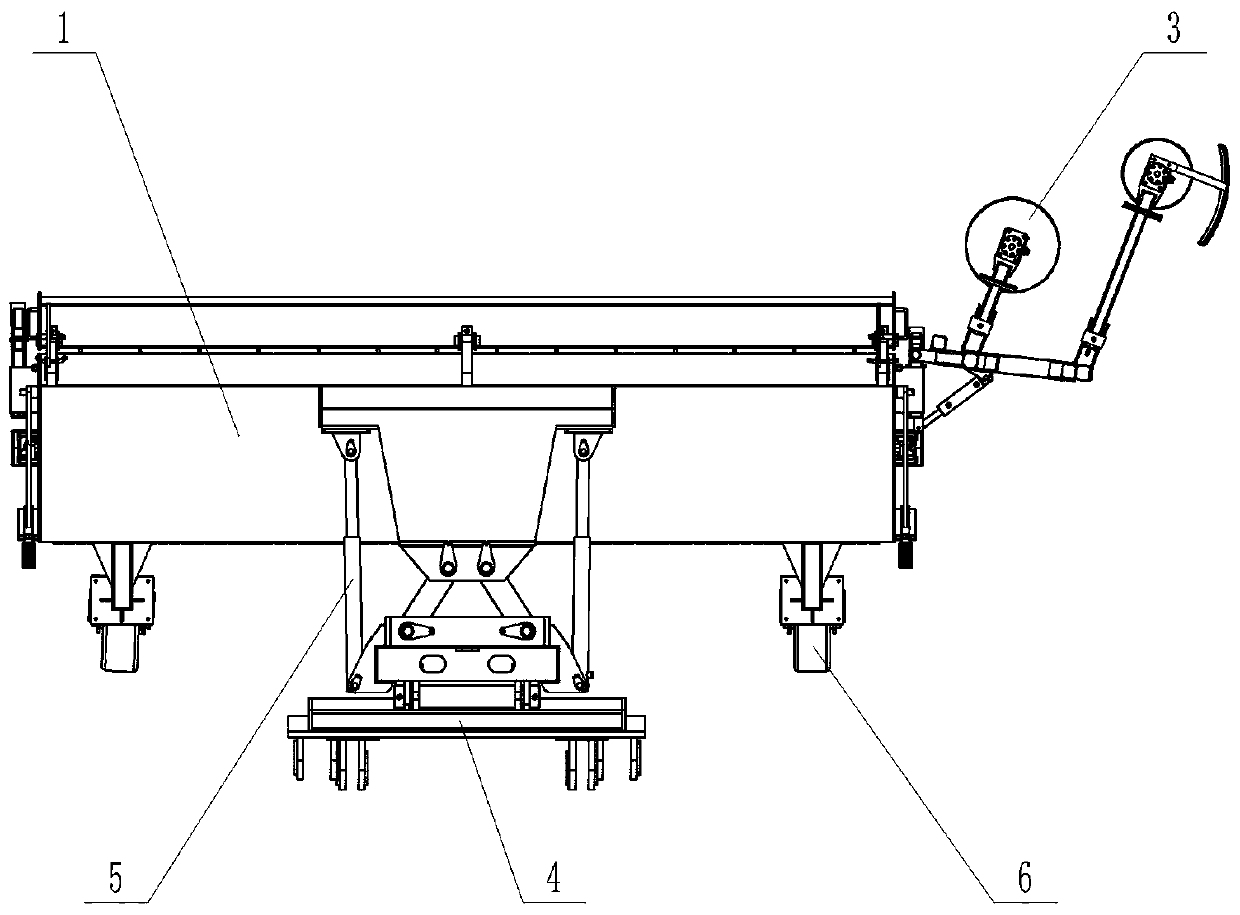

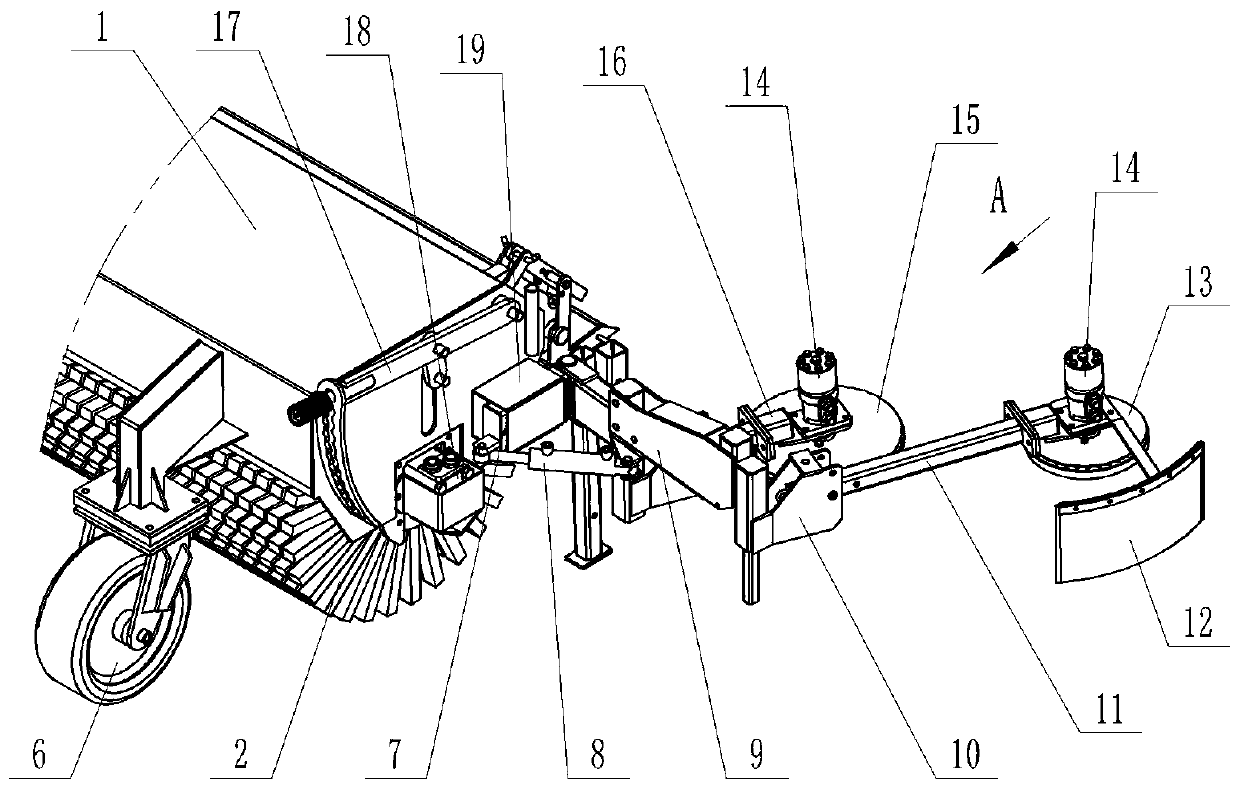

[0037] according to Figure 1-19 The specific structure of the present invention will be described in detail. The snow removal roller brush assembly includes a roller brush support cover 1, and a snow removal roller brush 2 is rotated in the roller brush support cover 1; The two ends of the side are respectively provided with telescopic legs 22. The snow-removing roller brush 2 includes a roller brush rotating shaft 26 in the middle, on which several groups of roller brush blades 27 arranged continuously in the axial direction are arranged. The snow removal roller brush 2 is rotationally connected with the both sides of the roller brush support cover 1 through the roller brush rotating shaft 26, and the two ends of the roller brush rotating shaft 26 of the snow removing roller brush 2 are respectively provided with a roller brush driving motor 18. The outside of the roller brush drive motor 18 is provided with a roller brush motor seat 23, and the shell of the roller brush m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com