Hydraulic drive device

A driving device, hydraulic technology, applied in the direction of machines/engines, rotary piston engines, rotary or oscillating piston engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below through specific examples.

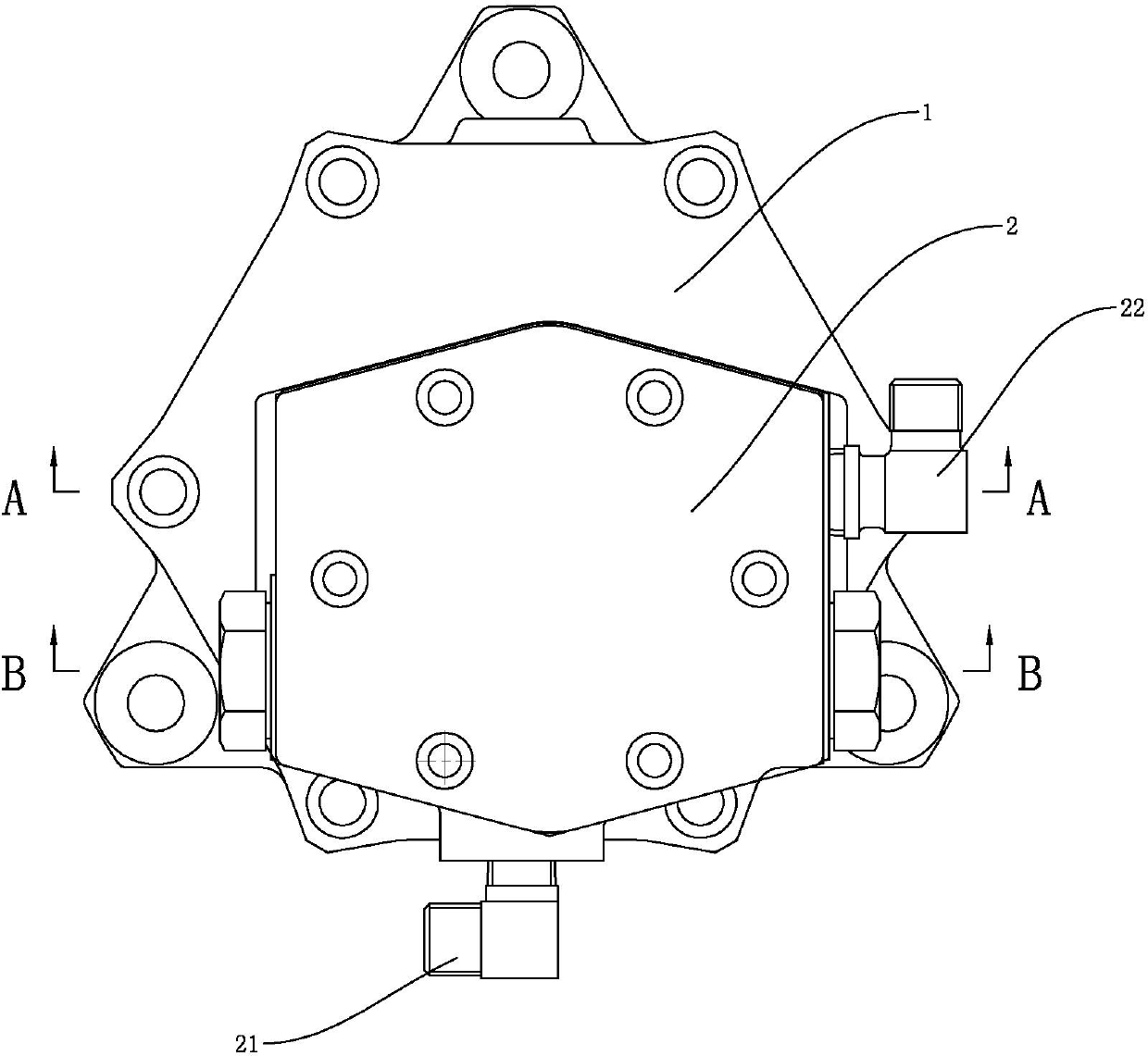

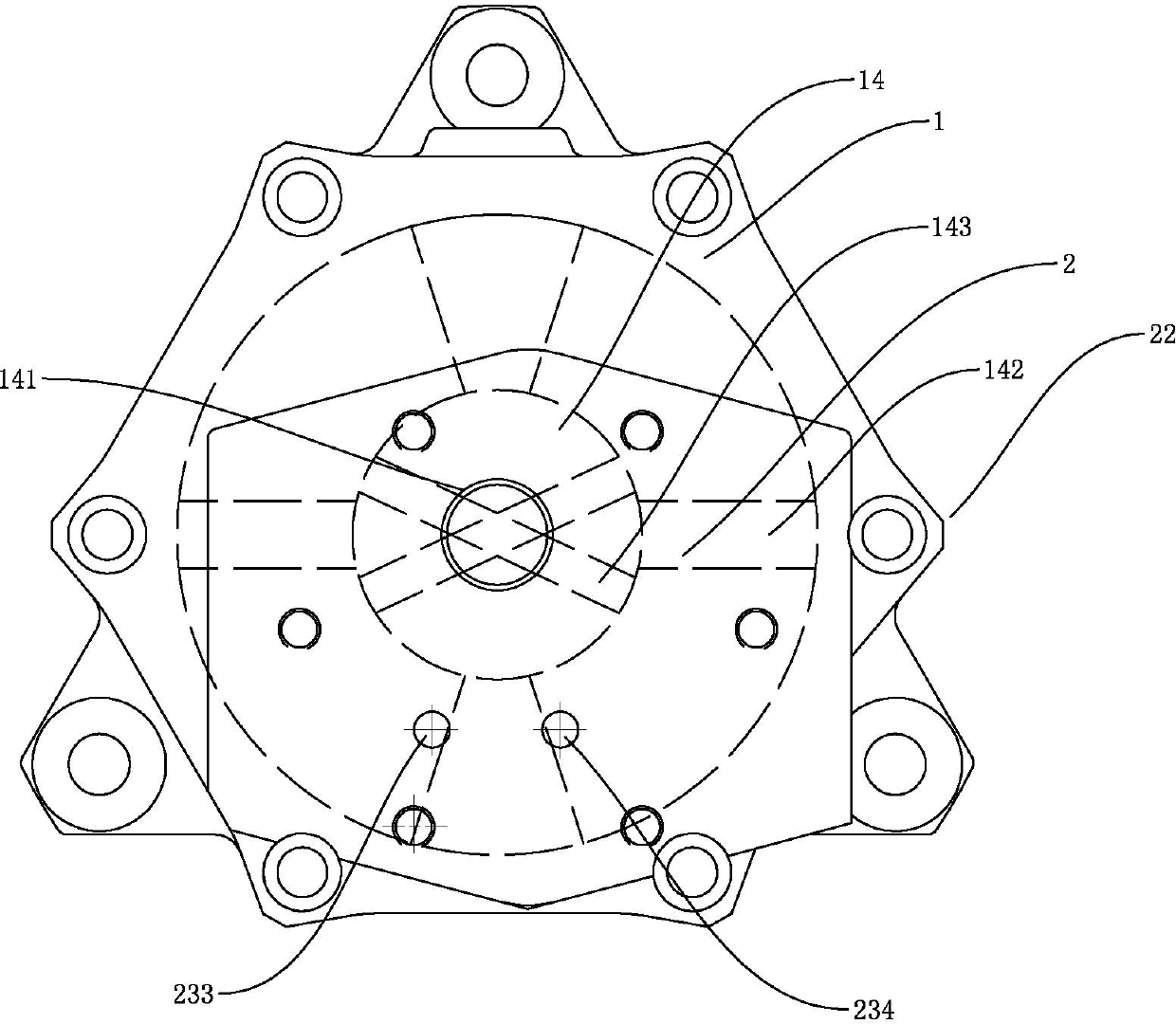

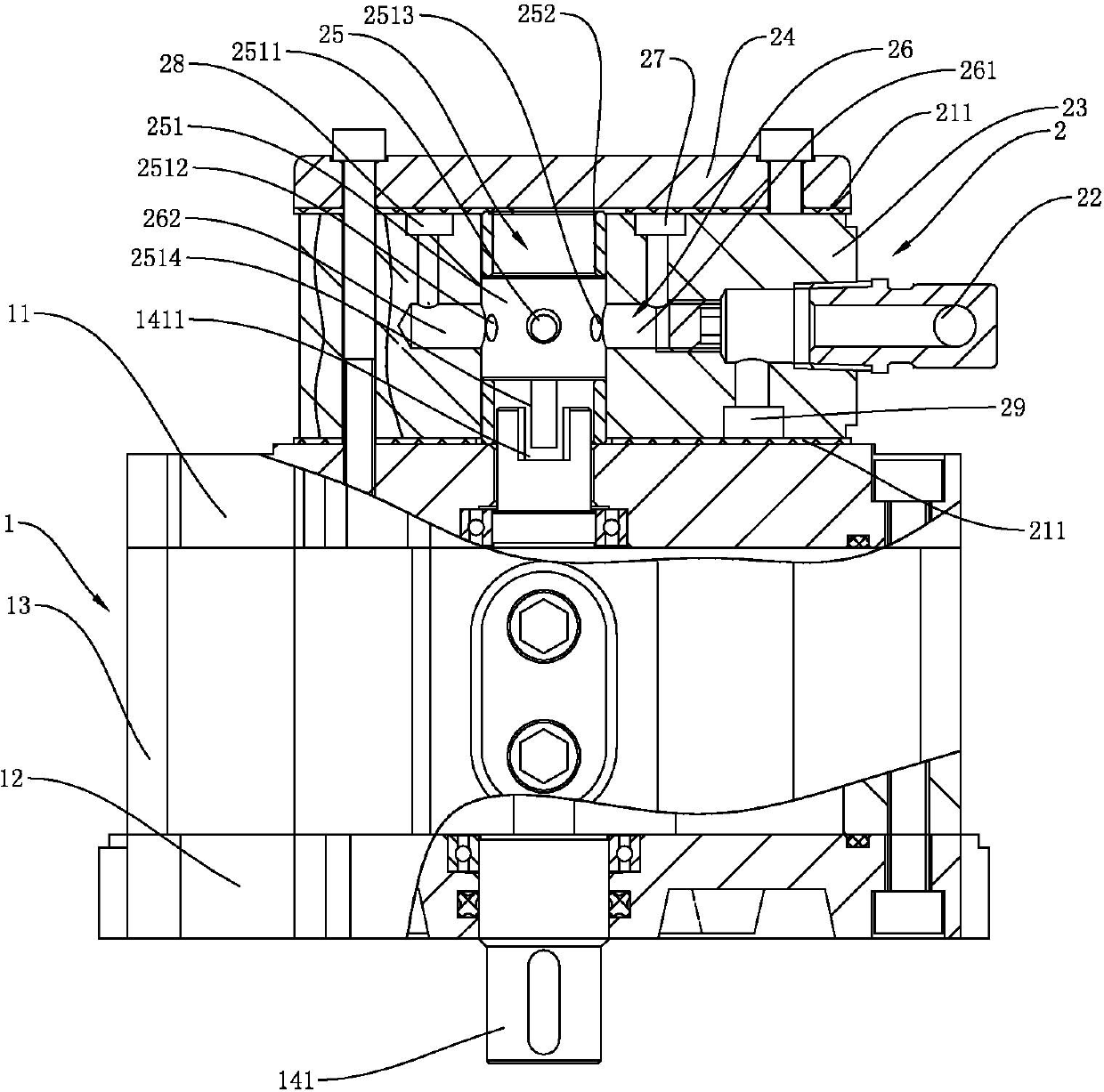

[0028] A hydraulic drive such as Figure 1 to Figure 13 As shown, it includes a hydraulic motor 1, the hydraulic motor 1 includes a stator 13 and a rotor 14 arranged in the stator 13, the upper end and the lower end of the stator 13 respectively fix the motor upper cover 11 and the motor lower cover 12, the stator 13 The rotor 14 is fixed between the motor upper cover 11 and the motor lower cover 12 by bolts, and the rotor 14 is rotatably installed in the stator 13 through a bearing and is sealed and matched by a sealing ring. The stator 13 is provided with two symmetrical liquid baffles 135, and the rotor 14 is provided with two symmetrical vanes 142. The two liquid baffles 135 and the two vanes 142 divide the cavity in the stator 13 into four liquid storage chambers. ,Such as Figure 4 As shown, they are respectively called the first liquid storage chamber 131, the second li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com