Reverse pressure seepage treatment method for concrete faced dam on narrow river valley in rainy area during construction period

A treatment method and technology of face dams, applied in barrages, dams, barrages, etc., can solve the problems of many construction steps, high requirements, and difficult observation, and achieve the effects of speeding up construction progress, ensuring reliability, and ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the scope of protection of the present invention is not limited to the following Described embodiment.

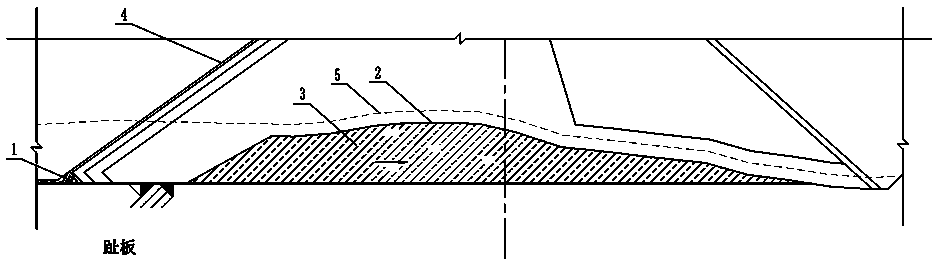

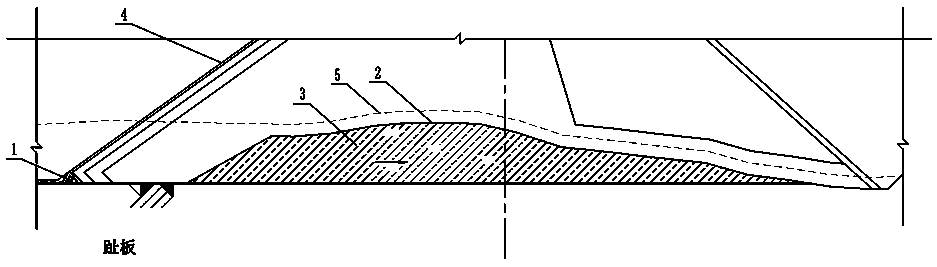

[0028] The reverse osmotic pressure treatment method of the face dam construction period on the narrow valley in the rainy area of the present invention is to combine the drainage and osmometer embedding requirements during the construction period on the bedrock 2 surface downstream of the toe plate 1 of the face rockfill dam. , excavate a drainage channel with a certain flow capacity along the cross-section of the bedrock 2 and backfill it with drainage material 3, such as figure 1 As shown; during the construction period, it is used as a discharge channel for c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com