Cupulate foundation integral mould subsection casting one-step integral forming structure and forming method

A technology of cup-shaped foundation and segmented pouring, which is applied in the direction of basic structure engineering and construction, can solve the problems of long construction time, offset of cup core position, and large labor-hour consumption, so as to shorten the construction period and avoid position deviation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

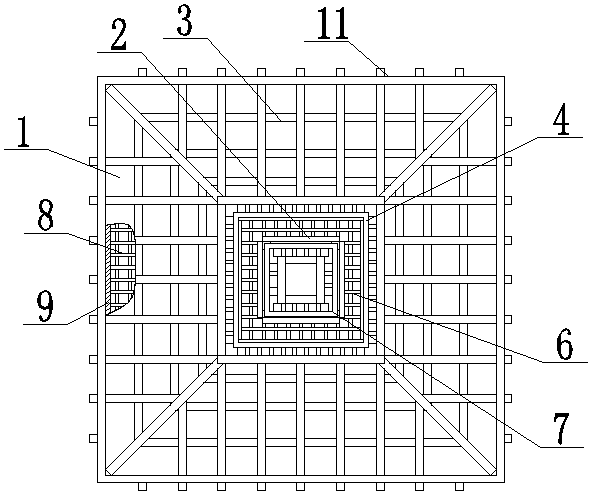

[0041] A cup-shaped basic integral mold segmented pouring one-time integral forming structure, its composition includes: a basic frame, an inner mold assembly 7 and an outer mold assembly 10, and the basic frame includes bottom bars laid on the foundation cushion 18 8 and the cup core frame 2 fixed on the base cushion, the cup core frame external fixed steel bracket 6, the outer mold assembly is composed of the bottom formwork 9 fixed on the top of the chassis, the slope formwork 1 and the outer template 4 fixed on the outside of the steel bracket, and the inner mold assembly is fixed inside the cup core frame.

Embodiment 2

[0043] According to the cup-shaped basic integral mold described in Embodiment 1, the integral molding structure is poured in sections, and a fixed frame 3 is fixed outside the outer mold assembly and inside the inner mold assembly.

Embodiment 3

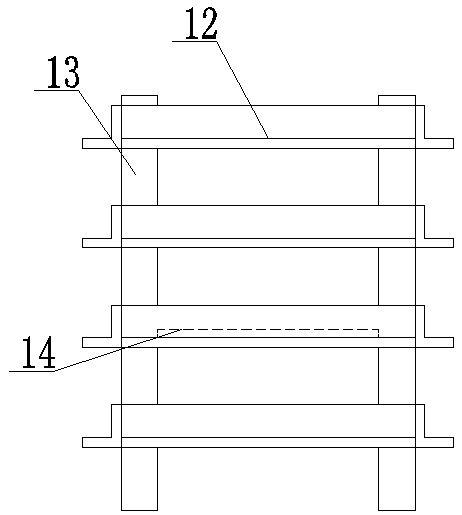

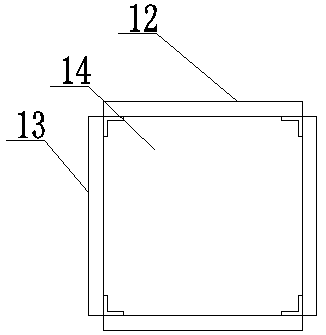

[0045] According to the cup-shaped foundation integral mold described in Embodiment 1, the one-time integral forming structure is poured in sections, the cup core frame includes four vertically arranged main frames 13, and a set of top-to-bottom The auxiliary frame 12 is arranged, and the cup core bottom mold steel plate 14 is fixed inside the main frame.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com