Plastic formwork with self-sealing structure and sealing method for plastic formwork

A technology of self-sealing structure and plastic formwork, applied in the field of plastic formwork and plastic formwork sealing, can solve the problems of chromatic aberration at the seam of water screen in formwork gap and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1, a plastic template with a self-sealing structure.

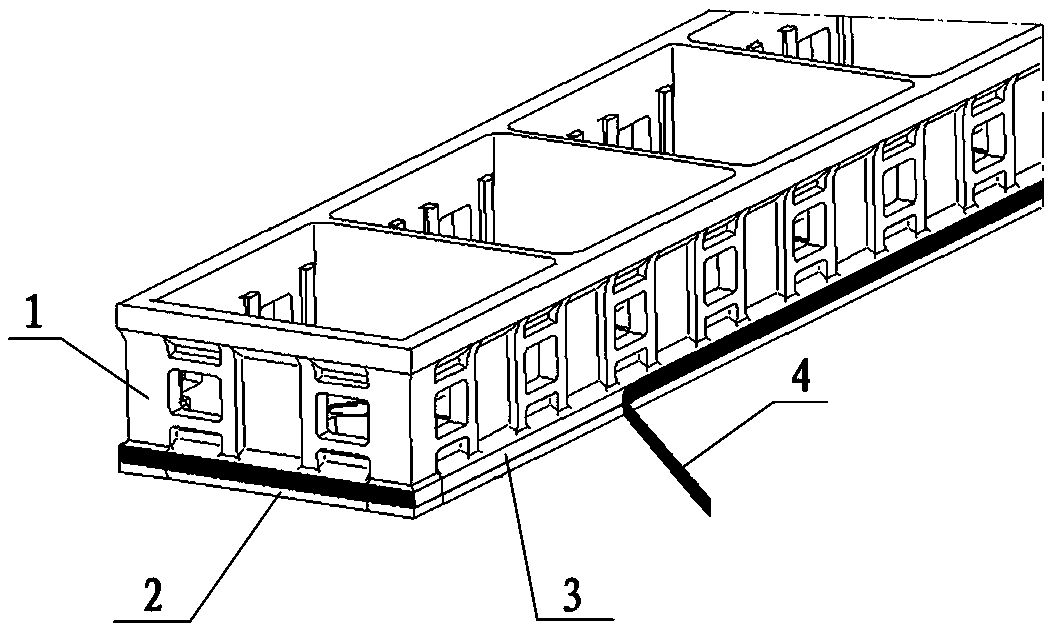

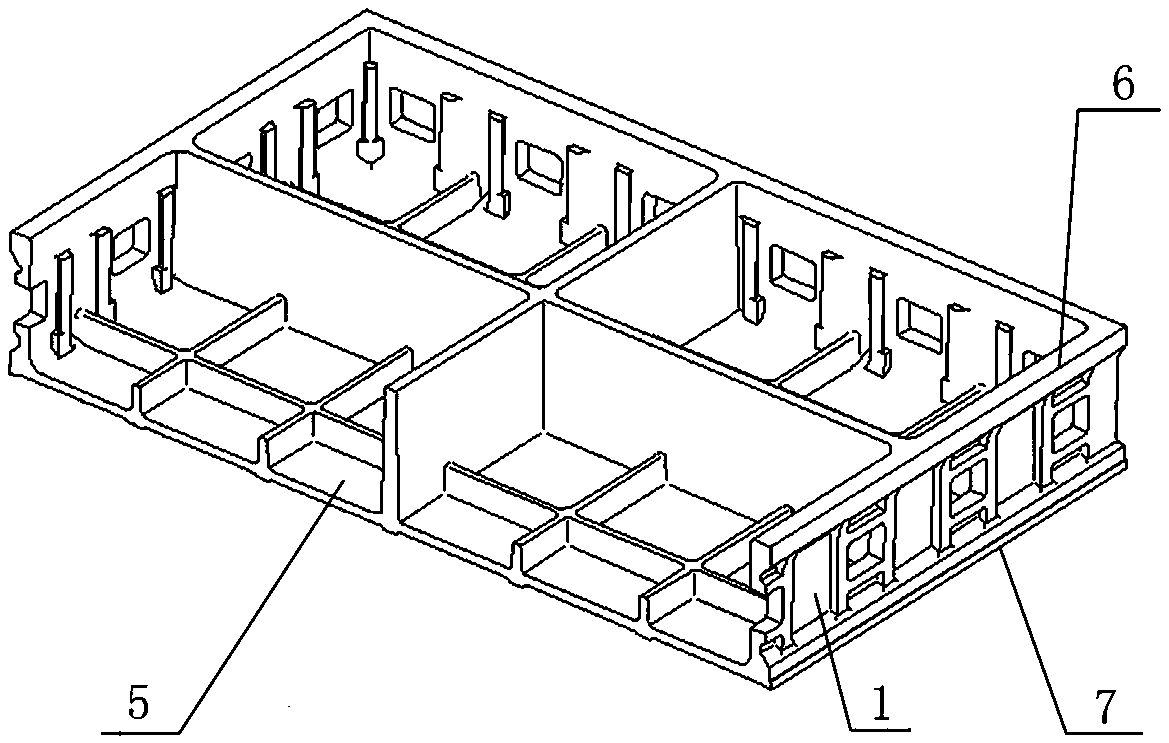

[0028] like figure 2 As shown, the existing plastic formwork generally includes a panel 5 and a frame 1 arranged around the back of the panel 5. The upper and lower ends of the frame 1 are respectively the upper edge 6 of the template and the lower edge 7 of the template, and the upper edge 6 of the template is away from the panel 5. One side edge, template lower edge 7 is the panel edge of this plastic formwork.

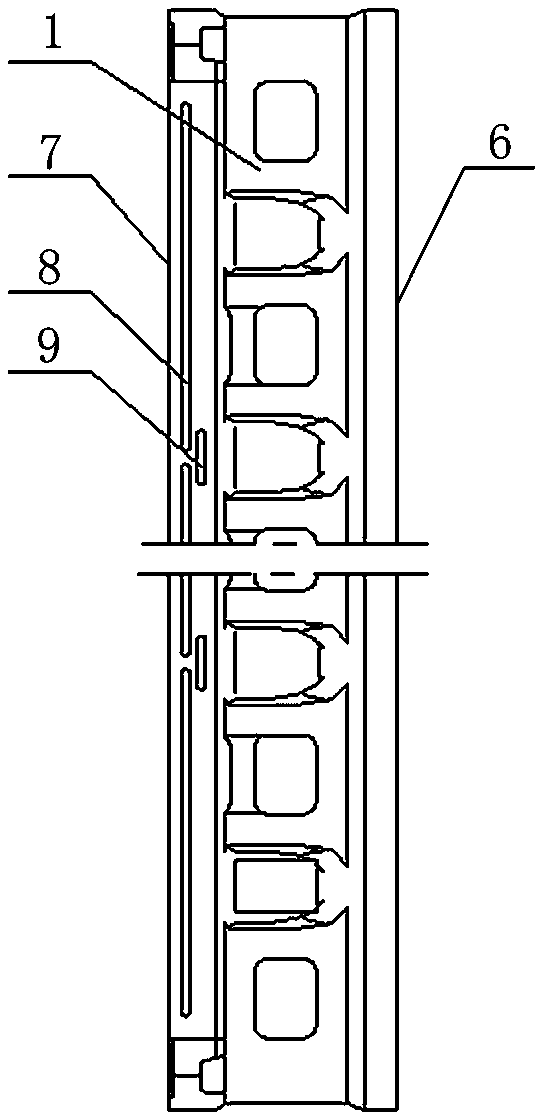

[0029] like image 3 As shown, the plastic formwork with self-sealing structure provided by this embodiment has a structure: on the outer wall of the frame 1, there are several long grooves 8 adjacent to and parallel to the lower edge 7 of the formwork, and these long grooves 8 are arranged In a straight line, and form a discontinuous intermittent arrangement. The length of the long slot 8 is generally set to be 50 mm to 100 mm. When concrete is poured later, under the action of the vertic...

Embodiment 2

[0036] Embodiment 2, a plastic template with a self-sealing structure.

[0037] like Figure 4 As shown, compared with Example 1, the short groove 9 is located below the discontinuous part between the two long grooves covered by it in this embodiment, that is, the distance between the short groove 9 and the lower edge 7 of the template is lower than that of the long groove 8 from the lower edge of the template. The distance along 7 is short, or in other words, the distance between the short groove 9 and the upper edge 6 of the template is farther than the distance between the long groove 8 and the upper edge 6 of the template. Other structures in this embodiment are the same as those in Embodiment 1.

Embodiment 3

[0038] Embodiment 3, a plastic template with a self-sealing structure.

[0039] The difference from Embodiment 1 and Embodiment 2 is that in this embodiment, two short grooves are arranged on the side of the discontinuity at the opposite ends of each two adjacent long grooves, and the two short grooves are respectively located on both sides of the corresponding discontinuity. , that is, the two short grooves are respectively located above and below the discontinuities they cover. Other structures in this embodiment are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com