Sealing structure and sealing method of plastic template

A technology of plastic formwork and sealing structure, applied in the field of sealing device of building formwork, can solve problems such as chromatic aberration, and achieve the effects of convenient construction and use, easy cleaning, and reduction of water loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1, a sealing structure of a plastic template.

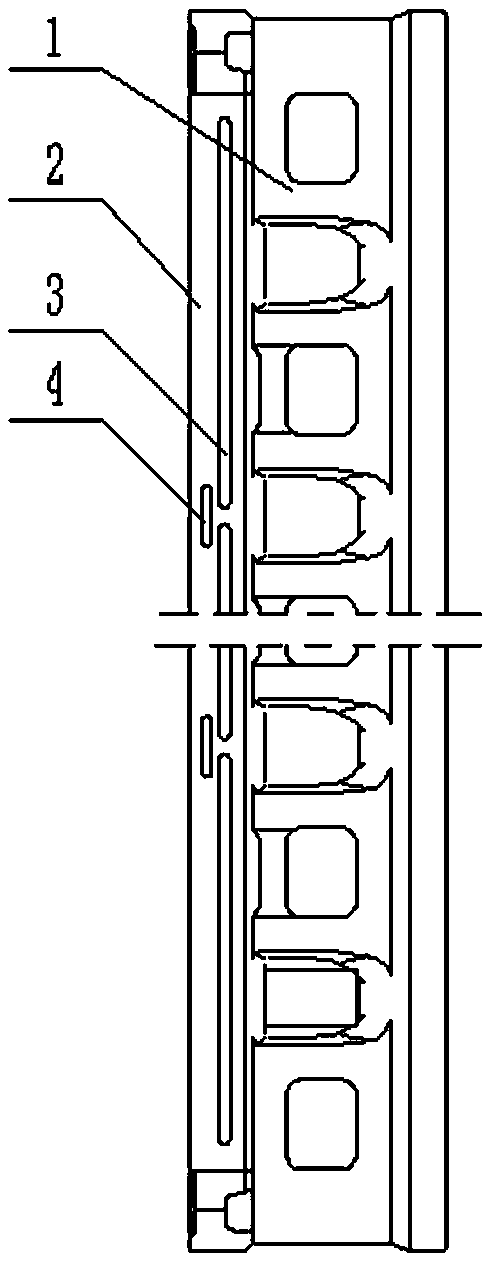

[0027] like figure 1 As shown, the plastic template includes a panel and a frame 1 arranged around the back of the panel. The frame 1 has two opposite side edges, and one side edge 2 is close to the panel.

[0028] On the side edge 2 of the frame 1 next to the panel, there are several elongated long U-shaped grooves 3 with a U-shaped cross section. The length direction of these long U-shaped grooves 3 is along the side edge 2 of the frame 1, and The long U-shaped grooves 3 are parallel to the bottom of the frame 1, and the long U-shaped grooves 3 form a discontinuous intermittent arrangement. The length of the long U-shaped groove 3 is generally set at 50 mm to 100 mm. When the concrete is poured later, under the action of the vertical vibrating force, the moisture flowing into the long U-shaped groove 3 can be retained in the groove. If the length of the long U-shaped groove 3 is set too long, the water will...

Embodiment 2

[0033] Embodiment 2, a sealing method of a plastic template.

[0034] combine figure 1 , the sealing method of plastic formwork provided by the present invention, comprises the steps:

[0035] a. On the side edge 2 of the frame 1 close to the panel of the plastic formwork, open several long U-shaped grooves 3 with a U-shaped cross-section, and connect two adjacent long grooves 3 on the side edge 2 of the frame 1 close to the panel. The discontinuous parts between the U-shaped grooves 3 are opposite to each other, and a long U-shaped short U-shaped groove 4 with a U-shaped cross section is set up. The length of the short U-shaped groove 4 is greater than the discontinuity between the two long U-shaped grooves 3 opposite to it. The length of the position, the short U-shaped groove 4 is far away from the distance of the plastic formwork panel, and the distance of the U-shaped groove 3 is far away from the plastic formwork panel.

[0036] For the relevant introduction of the lon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com