Support regulating block used for large special-shaped member installation combined type support system

A special-shaped component and support system technology, applied in the field of support and adjustment blocks, can solve the problems of insufficient safety guarantee for installation workers, difficult welding operation, poor installation accuracy, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

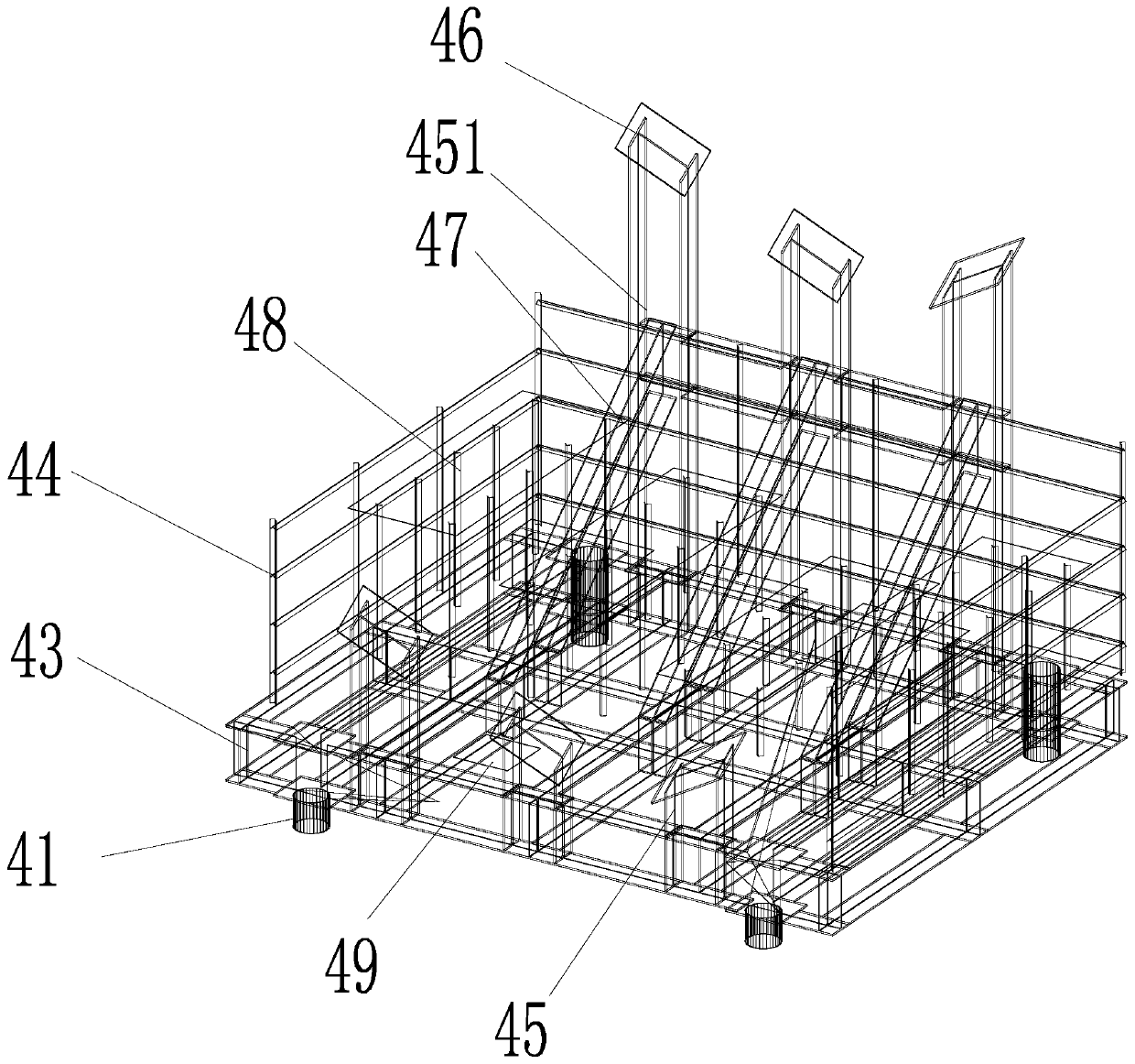

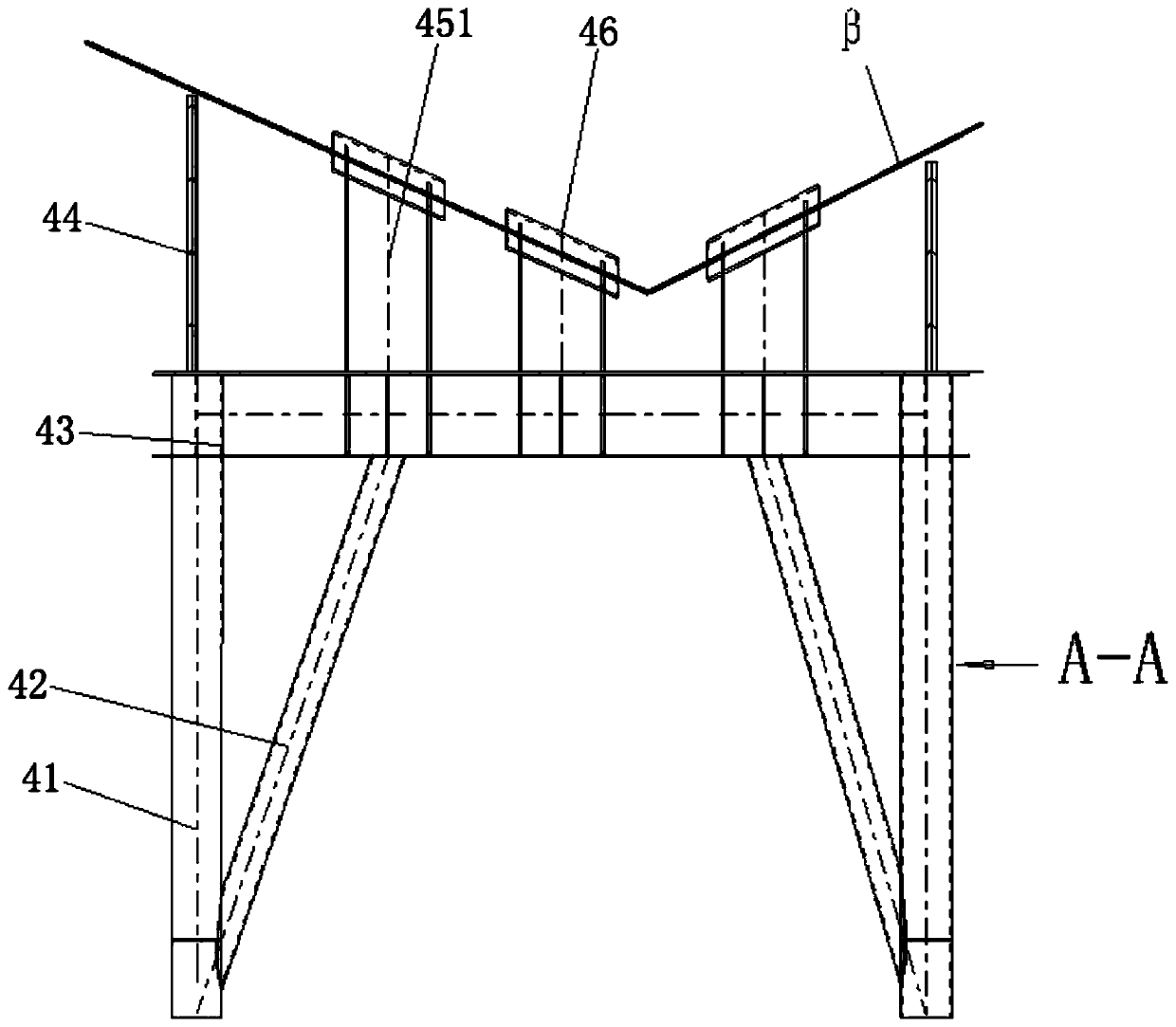

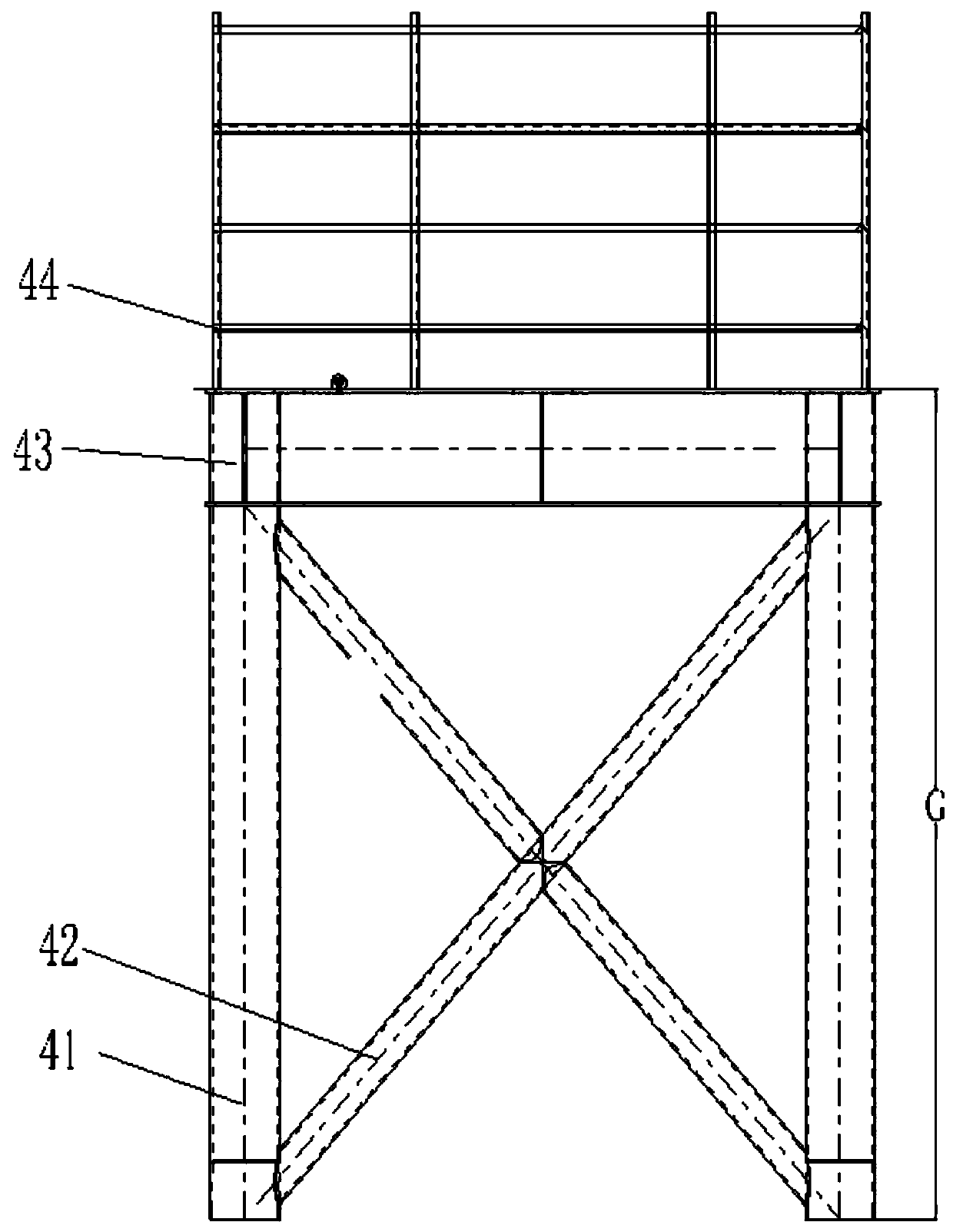

[0029] Such as Figure 1-5 As shown, the support adjustment block used in the combined support system for the installation of large special-shaped components provided by the present invention has a simple structure, scientific and reasonable design, and is easy to use, which can effectively improve the installation accuracy of large special-shaped components and ensure the safety of installation workers. At the same time, it can also reduce the difficulty of welding operation. The present invention includes a support adjustment platform 43 installed horizontally on the top of the large special-shaped component installation combined support system 5, and four support adjustment block main pipes 41, and the four support adjustment block main pipes 41 are respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com