Lap joint type ejector cooling structure

A cooling structure and tile-type technology, applied in the direction of machines/engines, jet propulsion devices, etc., to achieve the effect of protecting against damage and avoiding high temperature thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, the present invention is described in detail as follows:

[0025] 1. The overall structure:

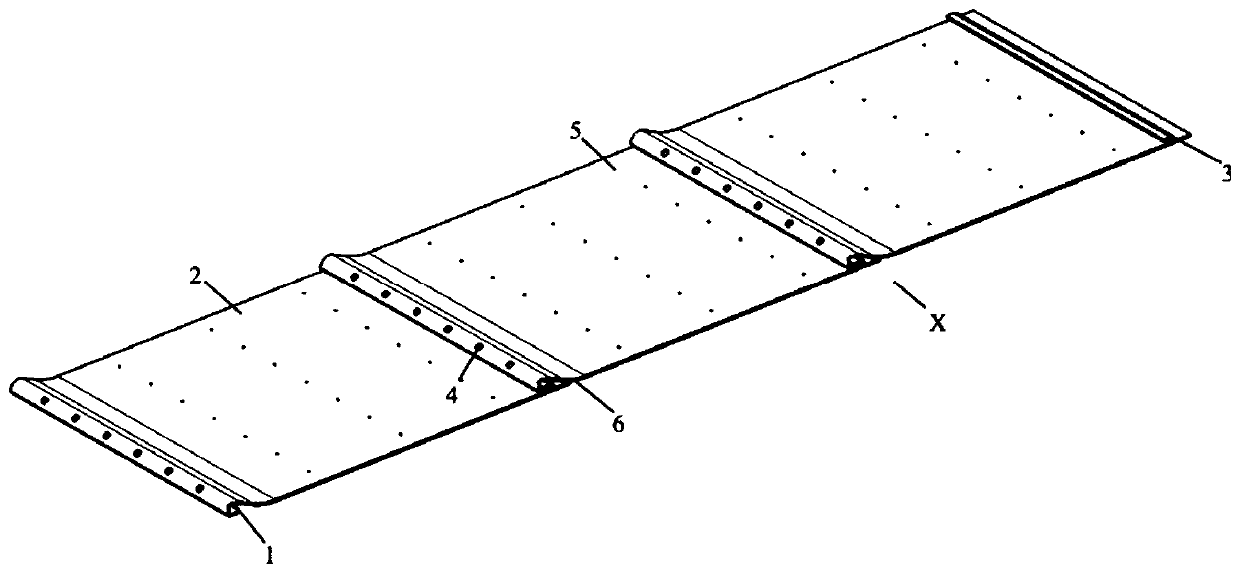

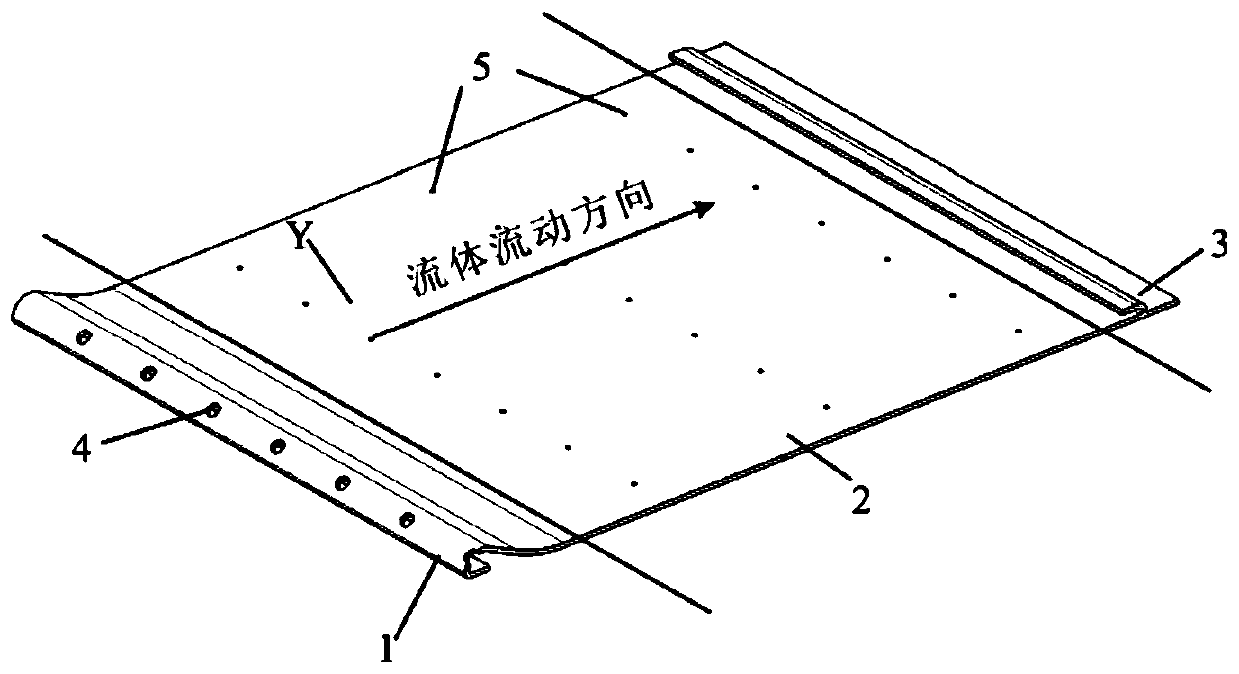

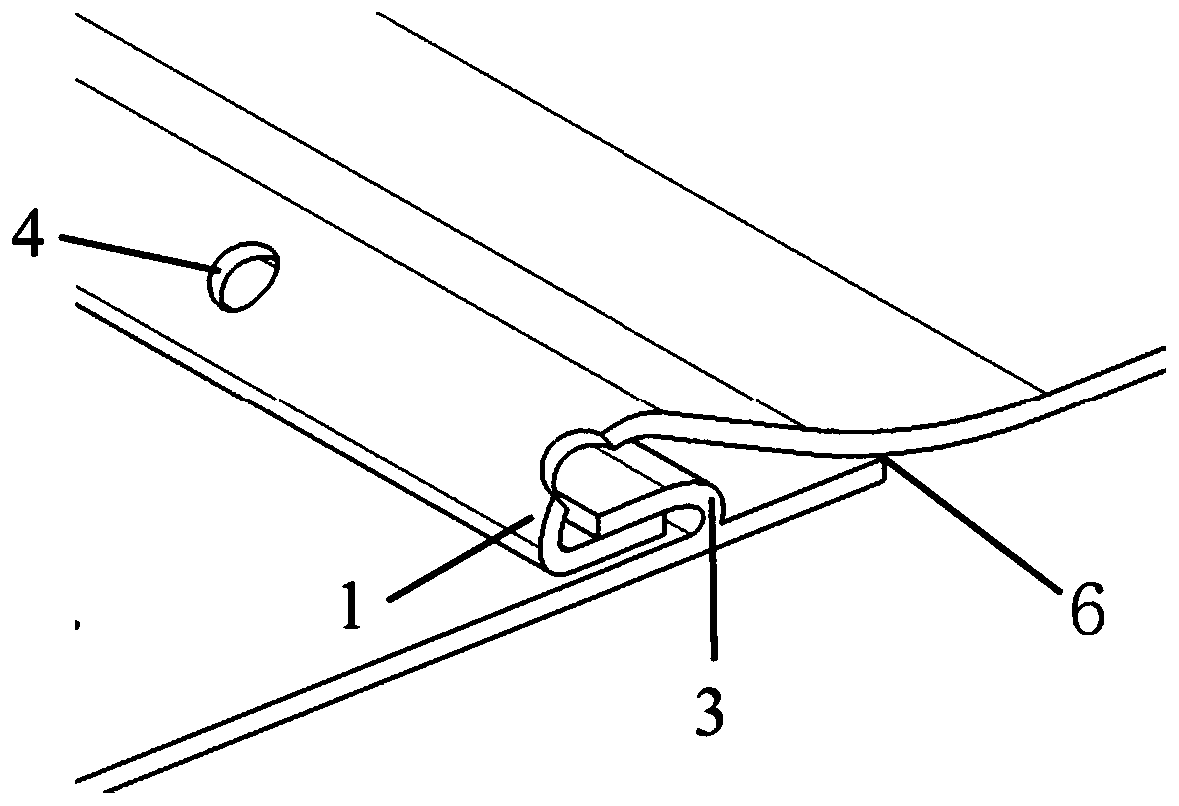

[0026] The schematic diagram of the overall structure of the lap joint ejection cooling structure of the present invention is as follows: figure 1 As shown, the cooling structure adopts the idea of segmented design, and is composed of cooling structural units through tile lap joints, such as figure 2 shown. The cooling structural unit is an improvement on the longitudinal corrugated heat shield, including an upper overlapping area 1, a flat plate area 2, and a lower overlapping area 3; the upper overlapping area 1 is corrugated-like, and the transverse The cross section is in the shape of a hook, and the end of the hook is straight, and there is an impact air film hole 4 on it; the lower lap area 3 is in the shape of a buckle, and the cross section along the airflow direction is in the shape of a hook, and the end of the curv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com