Packaging method of fiber Bragg grating strain sensor

A strain sensor, fiber optic Bragg technology, applied in the direction of optical devices, instruments, measuring devices, etc., can solve the problem of non-sensitive key structural strain measurement without effective measurement methods, and achieve the effect of effective, reliable and accurate testing means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

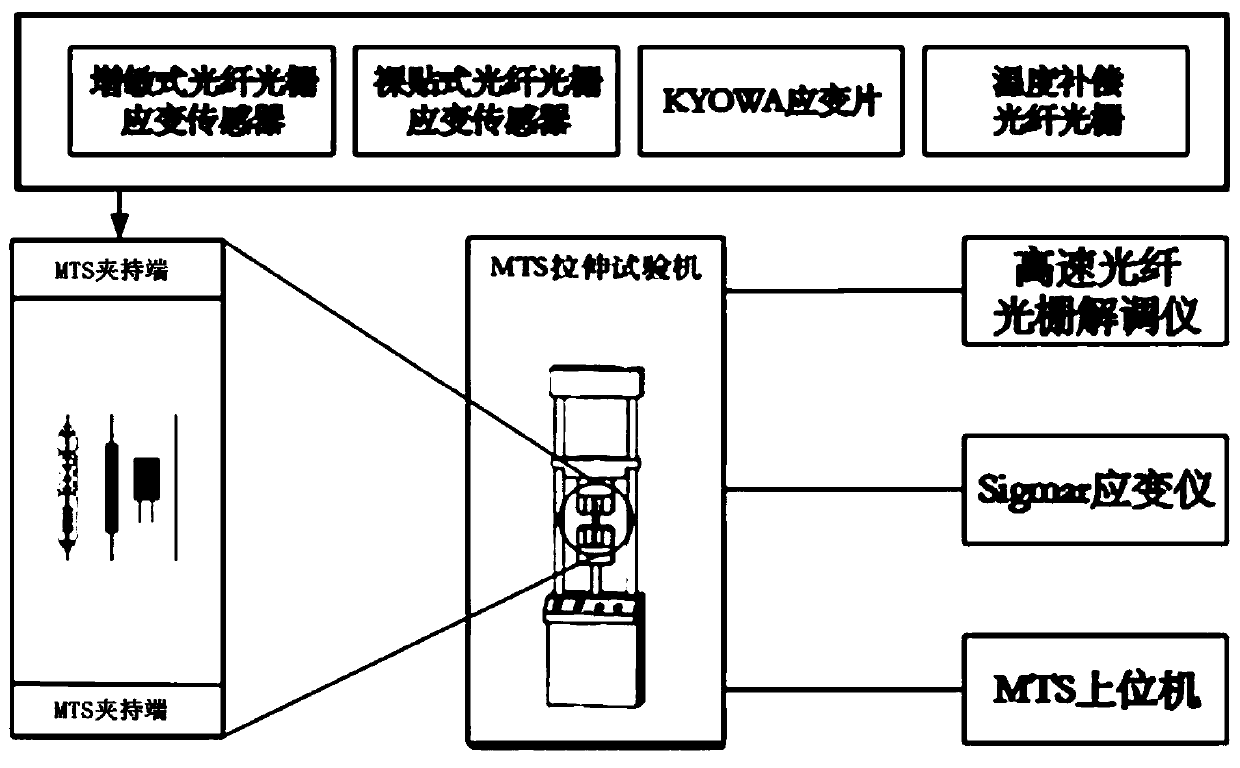

[0024] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

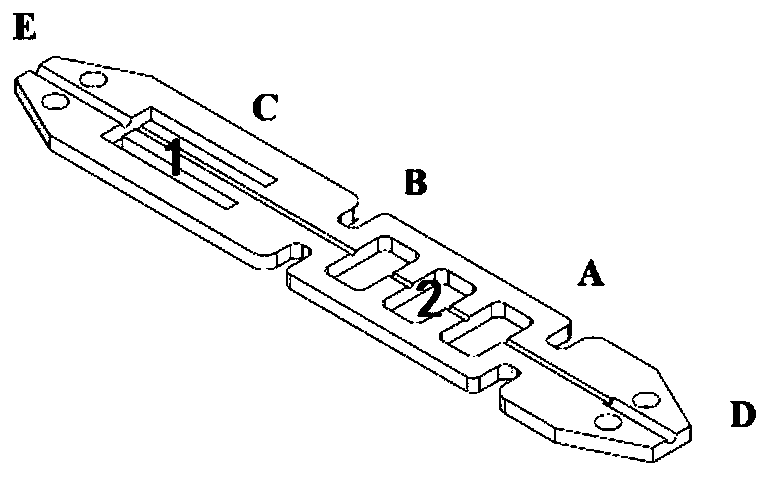

[0025] Such as Figure 1-4 Shown, a kind of optical fiber Bragg grating strain sensor, comprises the following steps: 1) before packing of grating optical fiber strain sensor, carry out mechanical simulation analysis to described grating optical fiber strain sensor;

[0026] Such as figure 1 The structure of the fiber grating strain sensor is shown. Such as image 3 As shown, the mechanical simulation analysis, the steps are as follows, 11 use the finite element analysis method to mesh the sensor; 12 simulate the tensile test loading process to fix one end of the sensor substrate, and apply tension to the other end to stretch, so as to simulate the current The force state of the sensor when the surface of the measured object attached to the sensor is stretched.

[0027] A finite element analysis is perfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com