A device and method for mass flow measurement of a fixed conductance element based on dynamic differential pressure decay

A mass flow and measuring device technology, applied in the field of measurement, can solve problems such as difficult precise control and slow piston movement, and achieve the effects of easy processing, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

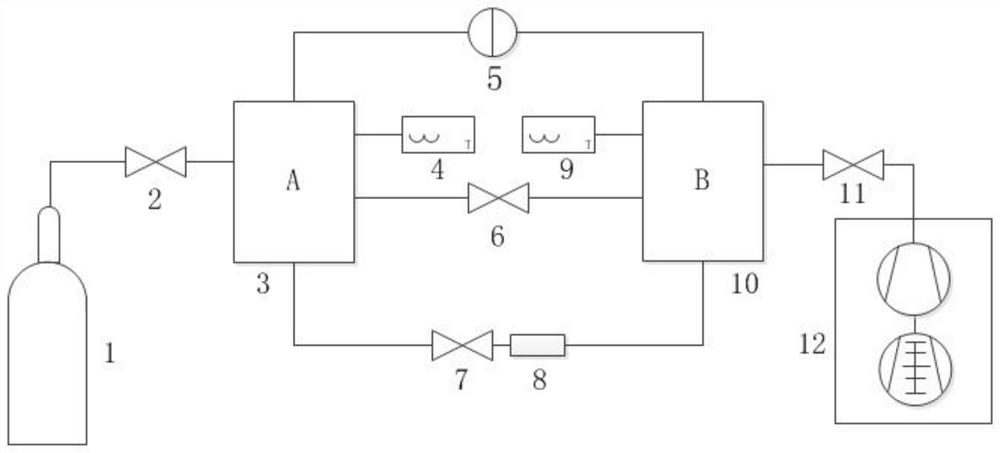

[0045] Such as figure 1 As shown, the mass flow measurement device and method of the present invention based on dynamic differential pressure attenuation with a fixed flow conductance element include an inflator 1, a first valve 2, a container A3, a first thermometer 4, a differential pressure transmitter 5, and a second valve 6. The third valve 7, the AAO fixed conductance element 8, the second thermometer 9, the container B10, the fourth valve 11, and the vacuum pump group 12.

[0046] The container A3 is connected with the inflatable device 1 through the first valve 2, the first thermometer 4 is installed on the container A, the container A3 is connected with the container B10 through the second valve 6, and the high pressure end of the AAO fixed flow conduction element 8 is connected with the third valve 7 , the low pressure end of AAO fixed flow conduction element 7 is connected with container B10, the second thermometer 9 is installed on container B10, container B10 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com