A segregation behavior prediction method for a bloom convex roller under continuous casting heavy pressure

A prediction method and technology for blooms, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as quantitative prediction methods rarely reported, and there is no introduction to the quantitative prediction of bloom segregation behavior, so as to enrich the process theory. effect of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Example 1: Prediction of macro-segregation behavior during bloom reduction process:

[0053] Combined with the actual production process of the bloom continuous casting machine on site, the macro segregation of the convex roll reduction process is simulated and predicted, which is mainly divided into the following steps:

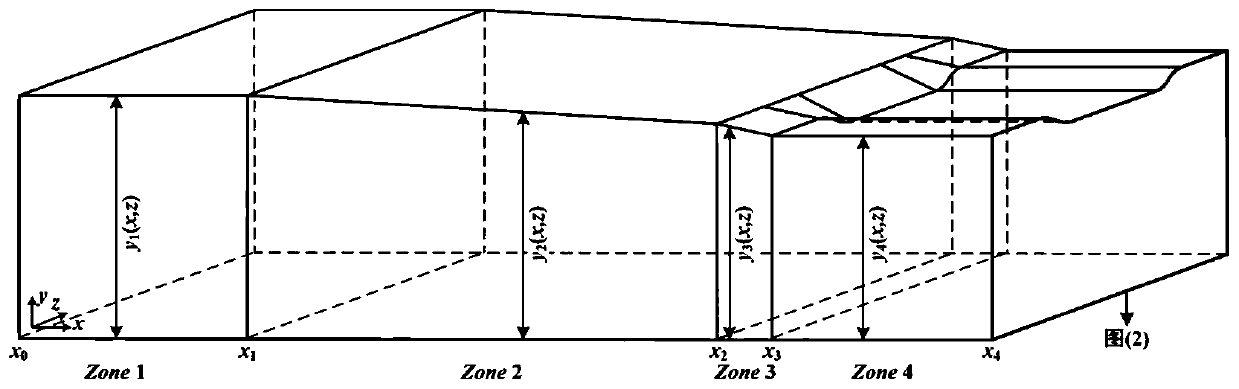

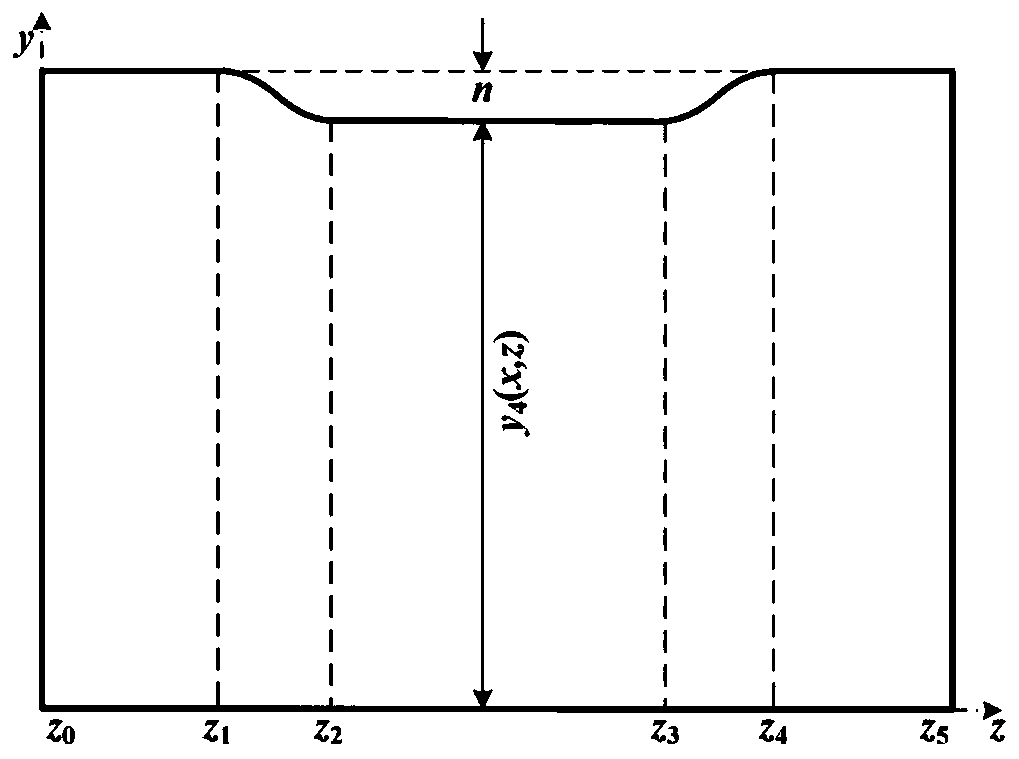

[0054] Step 1: Accurate description of billet shell morphology during continuous casting of blooms

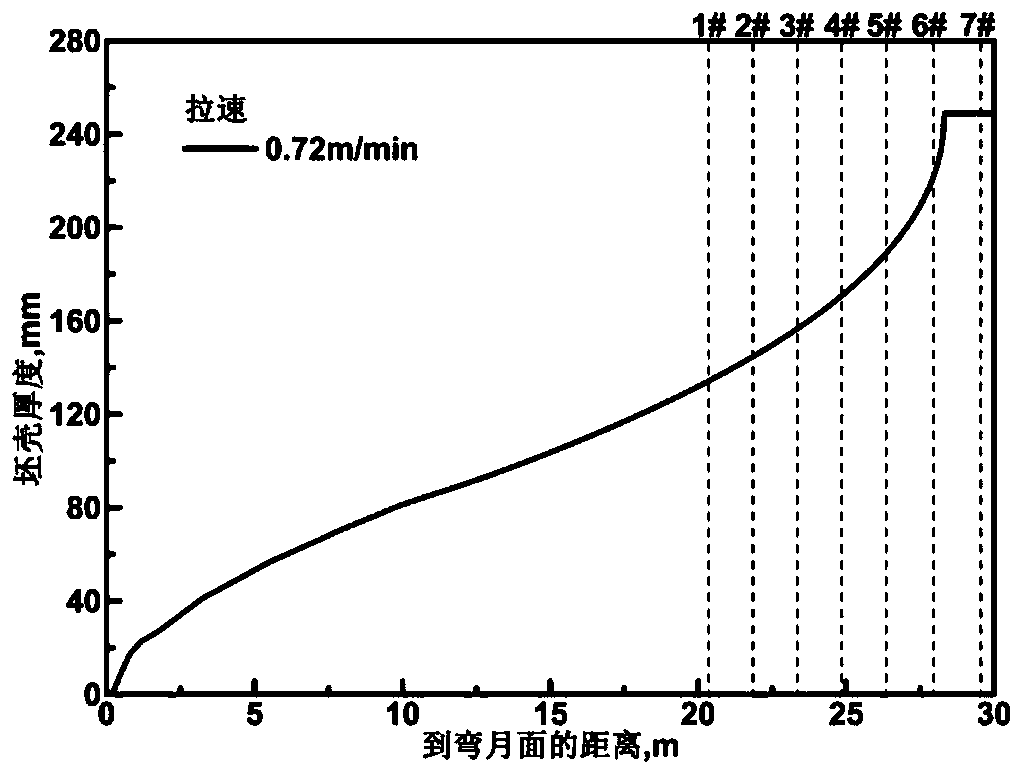

[0055] figure 1 The three-dimensional geometric model of the heavy reduction process of the convex roll of the bloom established for this example. In this example, the thickness of the bloom is 280mm, and the width is 380mm. The bloom in the geometric model is divided into hexahedron meshes, and the mesh size is 5mm. 2 , the number of grids is 3,400,000. The convex roller under heavy pressure at the end of solidification of the bloom is installed on the 6# tension leveler, which is located at a position 27.95m away from the crystallizer. Combined w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com