Two-shaft wedge-shaped structure based on flexible screen inward folding and rotating

A flexible screen and rotating mechanism technology, applied in the direction of instruments, identification devices, etc., can solve problems with high requirements, and achieve the effect of reasonable structure design and simple and convenient modeling design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

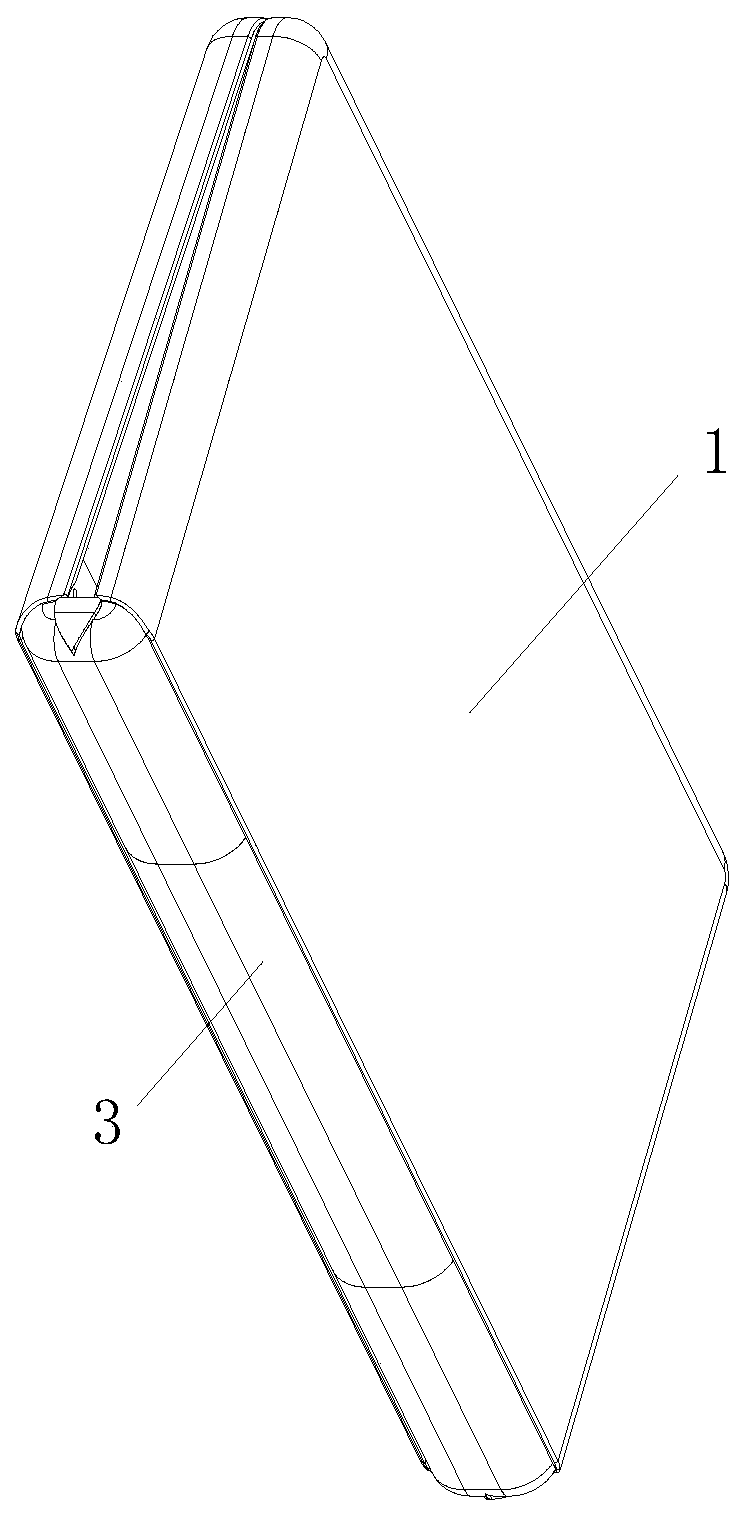

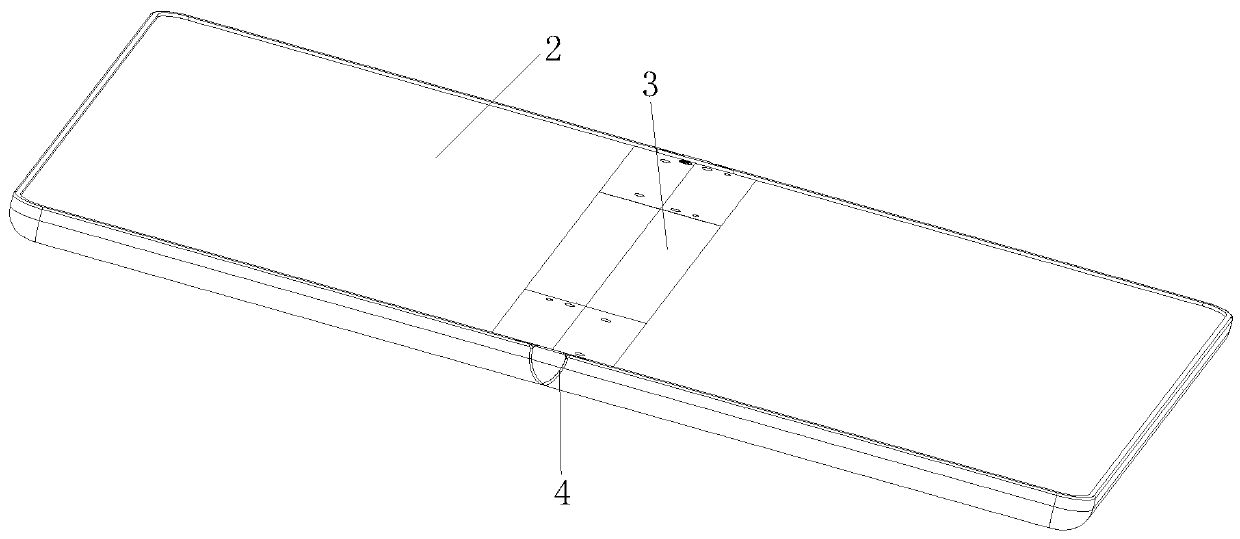

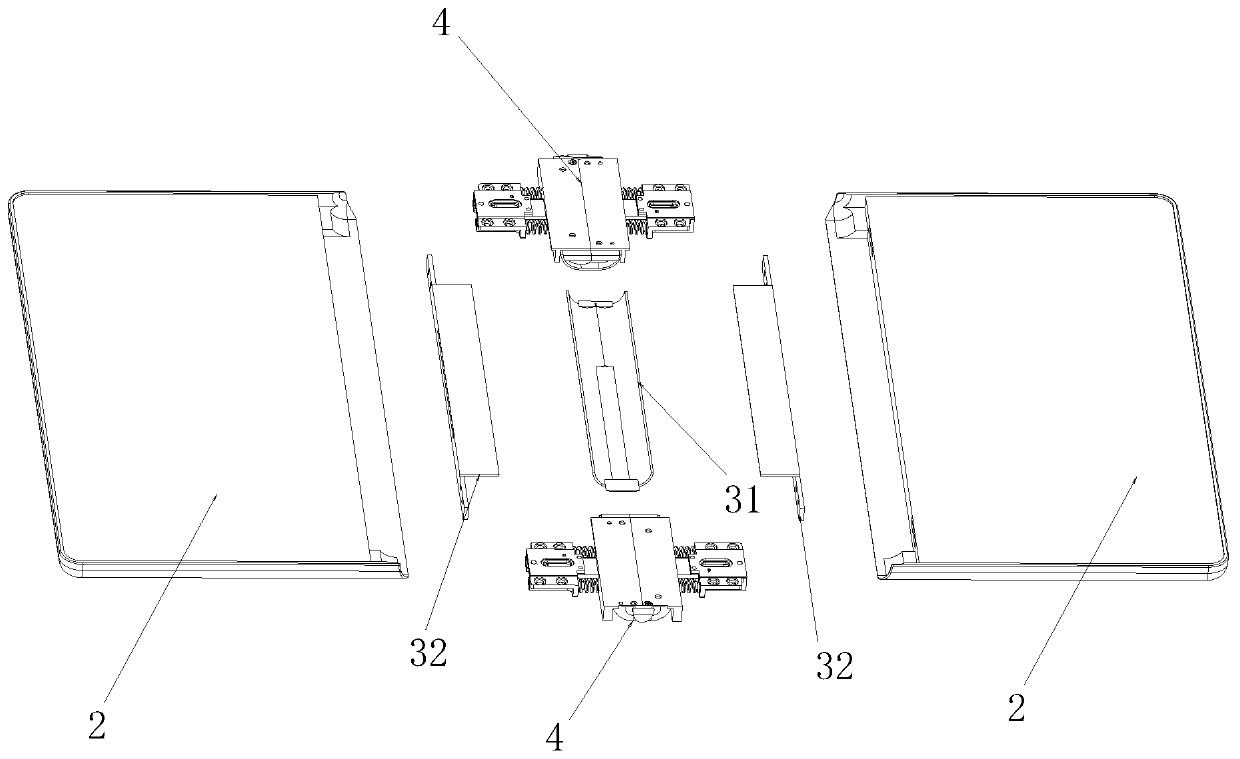

[0027] Such as Figure 1-9 As shown, a two-axis wedge structure based on the inward folding of the flexible screen disclosed in this embodiment includes a structural main body 1, and the structural main body 1 is composed of a casing 2, a packaging body 3 and two sides connecting the casing 2 Rotating shaft 4 is made up of, and described rotating shaft 4 comprises bilaterally symmetrical compensating mechanism 5 and middle rotating mechanism 6, and described rotating mechanism 6 is made up of multiple groups of movable blocks 7 and the rotating unit 8 that is arranged in described movable block 7, and described rotating The unit 8 is composed of a stuck point shaft 9, a gear shaft 10, a stuck point spring 11 and a round body 12. The stuck point spring 11 and the stuck point shaft 10 are combined to complete the stuck point stop at 0 degrees and 180 degrees, and generate For damping and torsion, the round body 12 is combined with the gear shaft 10 to complete synchronous rotati...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap