Grinding blank, method for producing same, and method for producing diamond grinding blank

A manufacturing method and diamond technology, applied to the blank for grinding and its manufacture, and the field of diamond grinding blank manufacturing, which can solve problems such as short circuit, magnetic head function failure, etc., reduce defective rate, reduce roughness, and improve cracking phenomenon Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

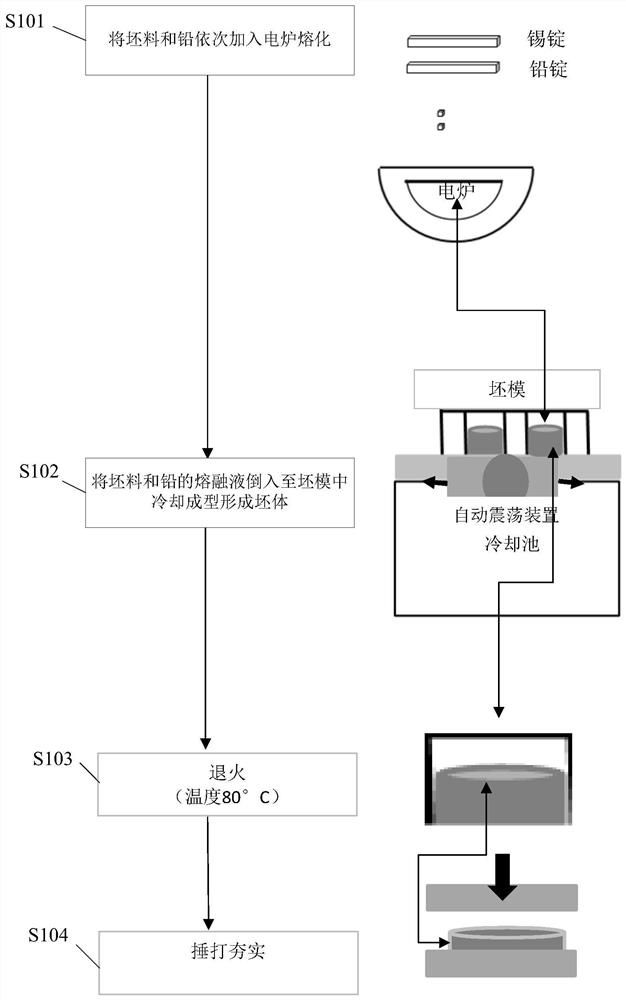

Method used

Image

Examples

Embodiment Construction

[0025] Several different preferred embodiments of the present invention will now be described with reference to the accompanying drawings, wherein like reference numerals in different drawings represent like parts. As mentioned above, the essence of the present invention is to provide a blank for grinding, a diamond grinding blank, which can enhance the diamond particles embedded in it more firmly, and the cracking of the blank during the grinding process is improved, thereby reducing the abrasiveness of the abrasive. defective rate.

[0026] In the present invention, the grinding blank is especially suitable for the grinding process in the manufacturing process of the magnetic head, for example, grinding the elongated bar with a plurality of magnetic head bodies. As an improvement, lead is added to the blank, the content of lead is less than 1% of the total mass of the blank, and the performance of the blank can be greatly improved with the optimized content ratio.

[0027] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com