Bus duct structure

A technology of busway and dovetail groove, which is applied in the direction of cooling busbar device and fully enclosed busbar device, which can solve the problems of inconvenient use, small heat dissipation area of conductor and shell, and unfavorable heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The busway structure of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

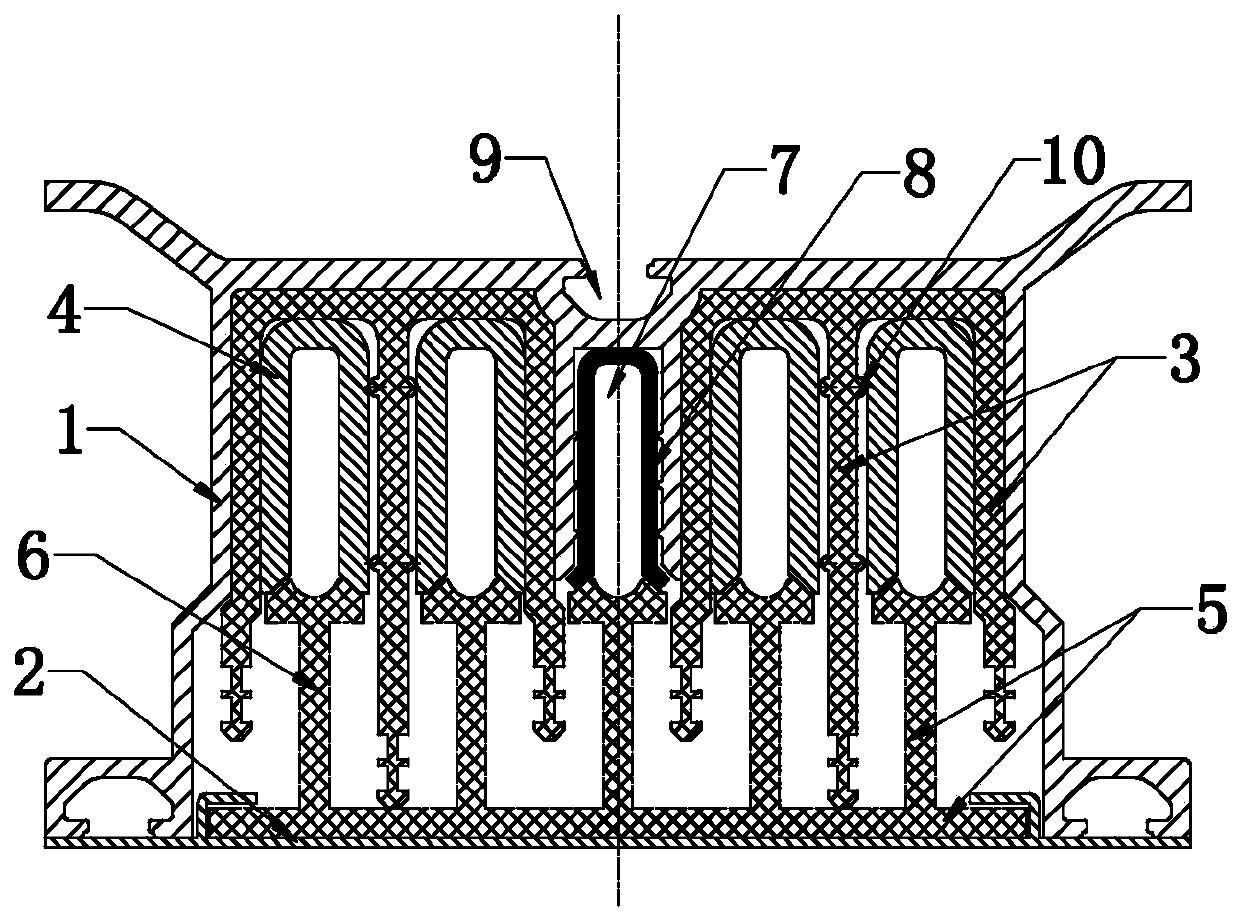

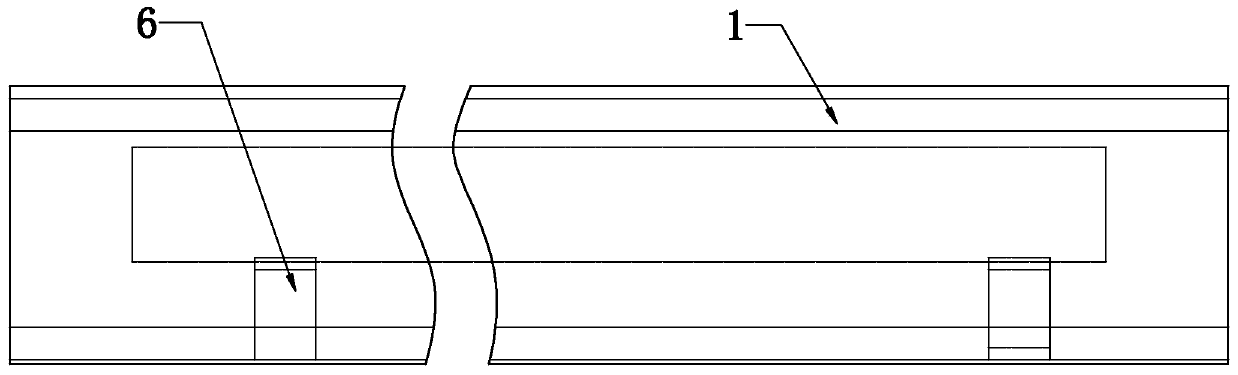

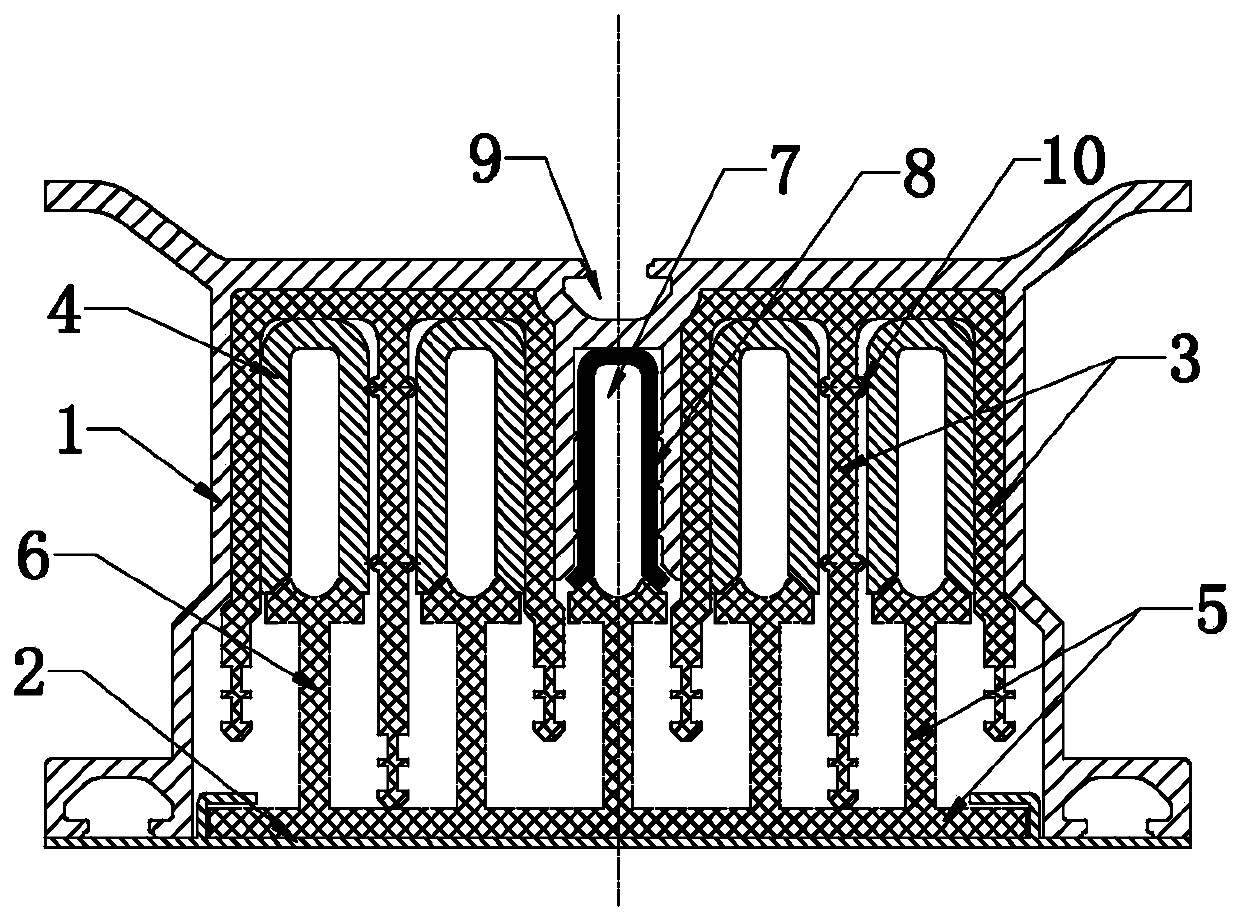

[0015] As shown in the figure, the busway structure of the present invention includes a shell 1 with an opening at the bottom and a cover plate 2 installed at the bottom opening of the shell, that is to say, the shell is composed of a frame surrounded by two sides and a top surface, The middle part of the housing 1 has a U-shaped slot 7 formed by two plates extending from the top to the bottom of the cavity. A grounding conductor 8 is placed in the U-shaped slot 7. The U-shaped slot 7 separates the inner cavity of the housing 1 from the The middle part is divided into two placement cavities on the left and right, and an m-shaped insulator 3 is placed in the left and right cavities, and each insulator 3 forms two U-shaped placement grooves for U-shaped conductors 4 respectively. The conductor 4 is separated from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com