Annular food steamer

A steamer and ring-shaped technology, which is applied to inserts, lids of cooking utensils, etc., can solve the problem of food being difficult to cook quickly, and achieve the effects of saving time, improving utilization, and saving time and energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Further describe the present invention below in conjunction with accompanying drawing.

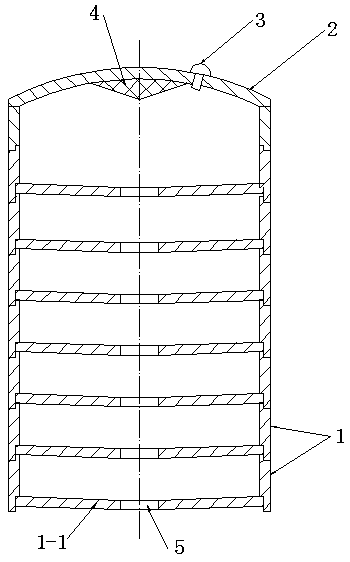

[0009] Such as figure 1 As shown, the annular steamer includes a multilayer steamer body 1 and a heat preservation cover 2. The steamer body is composed of an annular side wall and a steamer bottom 1-1 as a whole. The structure of the multilayer steamer body 1 is the same, and the steamer bottom 1-1 is conical. shape, the steamer bottom 1-1 is provided with a water vapor permeation hole 5 at the middle position; an exhaust valve 3 is installed on the heat preservation cover 2, and the middle position of the inner wall surface of the heat preservation cover 2 (by bonding or screw connection) way) is fixed with a conical top cover 4, the small end of the conical top cover 4 is downward; after the multi-layer steamer body 1 is stacked, the multi-layer water vapor passes through the holes 5 to form a water vapor ascending channel, and the conical top cover 4 The water vapor is condense...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com