A milling tool for flange bearing parts

A flange bearing and tooling technology, which is applied to metal processing equipment, metal processing machinery parts, supports, etc., can solve the problems of difficult positioning and clamping methods, low efficiency, poor drilling quality of parts, and achieve positioning Fixing is convenient and efficient, avoiding damage and ensuring the quality of milling processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

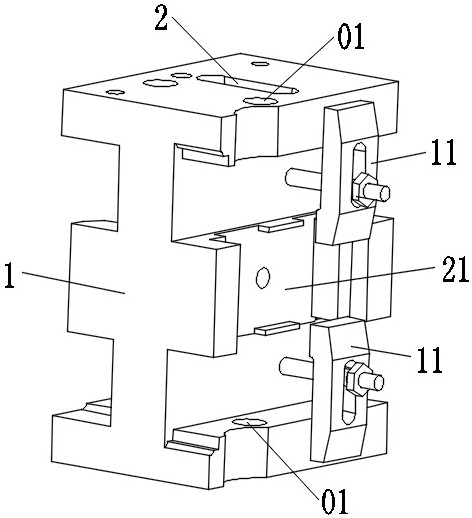

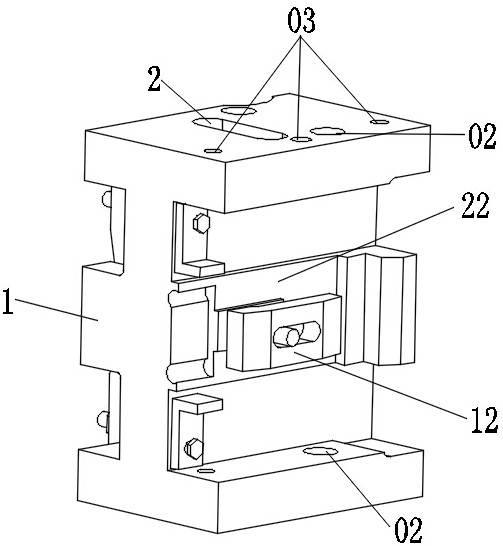

[0037] A kind of milling tool for the flange bearing parts of this embodiment, such as figure 1 with figure 2 As shown, it includes an I-shaped tooling base 1 with a pressing part 2 on one side, the upper and lower ends of the front of the tooling base 1 are symmetrically provided with first main body positioning holes 01, and the front of the tooling base 1 is provided with a first The positioning part 21, the upper and lower sides of the first positioning part 21 are symmetrically provided with the first clamping part 11; the upper and lower ends of the back of the tooling base 1 are symmetrically provided with the second main body positioning hole 02, and the tooling base 1 is provided with a second positioning part 22 on the back, and the second clamping part 12 is provided on the second positioning part 22; the upper end of the back of the tooling base 1 is also provided with a number of drill guide holes 03.

[0038] The overall structure of the tooling base 1 is I-sha...

Embodiment 2

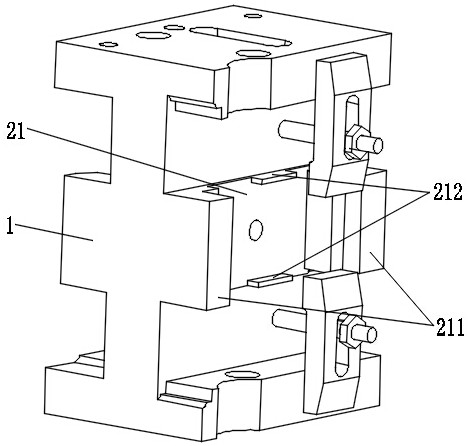

[0043] This embodiment is further optimized on the basis of embodiment 1, such as image 3 As shown, it also includes a first auxiliary support part 211 and a tool positioning part 212, the first auxiliary support part 211 is arranged on the left and right ends of the first positioning part 21, and the tool positioning part 212 is symmetrically arranged on the first positioning part 21 upper and lower sides.

[0044] The first positioning part 21 performs positioning and fixing on the flange bearing part on the plane, and the left and right ends of the first positioning part 21 respectively correspond to the left positioning surface and the right positioning surface of the flange bearing part and are provided with a first auxiliary support part 211 , that is, through the matching and bonding of the first auxiliary support parts 211 at the left and right ends and the positioning surfaces on the left and right sides of the flange bearing part, the quick positioning and fixing of...

Embodiment 3

[0047] This embodiment is further optimized on the basis of above-mentioned embodiment 1 or 2, such as Figure 4 As shown, a second auxiliary support portion 221 is also included, and the second auxiliary support portion 221 is disposed at the left end or the right end of the second positioning portion 22 .

[0048] The second auxiliary support part 221 is arranged on the left end or the right end of the second positioning part 22, and the second auxiliary support part 221 is arranged on the positioning surface of the left side or the right side of the corresponding flange bearing part, through the second auxiliary support part 221 and the convex The matching and fitting between the positioning surfaces on the left or right side of the flange bearing part can realize the quick positioning of the flange bearing part in the left and right directions on the back of the tooling base 1 .

[0049] Other parts of this embodiment are the same as those of Embodiment 1 or 2 above, so de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com