Machine room fault detection alarm robot

A technology of fault detection and robotics, applied in the direction of manipulators, manufacturing tools, etc., can solve the problems of shortening the service life of the chip, cost, high temperature problems of the chip cannot be detected in time, and achieve the effect of ensuring the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific embodiments. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

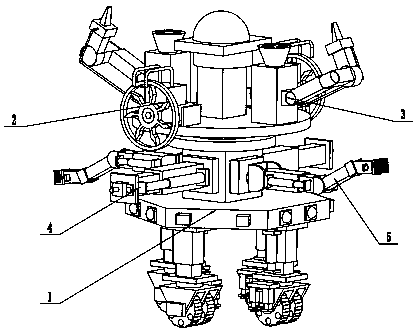

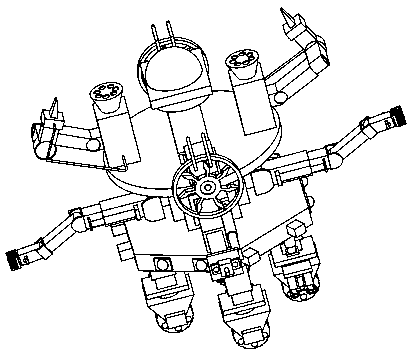

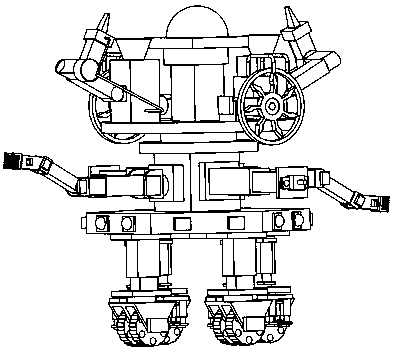

[0023] Example figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 As shown, a machine room fault detection and alarm robot includes a base walking part 1, a cooling part 2, a fire fighting part 3, an infrared detection part 4, and a grabbing part 5, and is characterized in that the second support of the cooling part 2 201 is fixedly installed on the upper end surface of the circular large plate 117 of the base walking part 1; the bottom end surface of the dry powder box 301 of the fire fighting part 3 is fixedly connected with the upper end surface of the circular large plate 117 of the walking part 1; the first support of the inf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com