Hand mold overturning posture control mechanism

A posture control and hand model technology, applied in the direction of conveyor objects, furnaces, lighting and heating equipment, etc., can solve inconvenience and other problems, achieve the effect of easy adjustment, reduce manufacturing cost, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

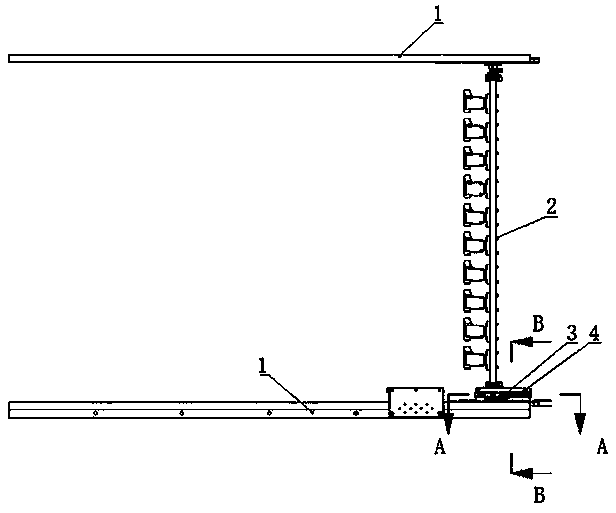

[0019] The hand mold turning posture control mechanism of the present invention is set on an automated dipping glove production line, such as figure 1 As shown, the automated dipping glove production line has a pair of chain conveyor lines 1, the pair of chain conveyor lines 1 passing through a dipping station; the production line also includes a number of mold bars 2, which are arranged on the pair of chain conveyors through a rotatable structure A clutch 3 is installed between the conveying lines 1 and on a rotatable structure.

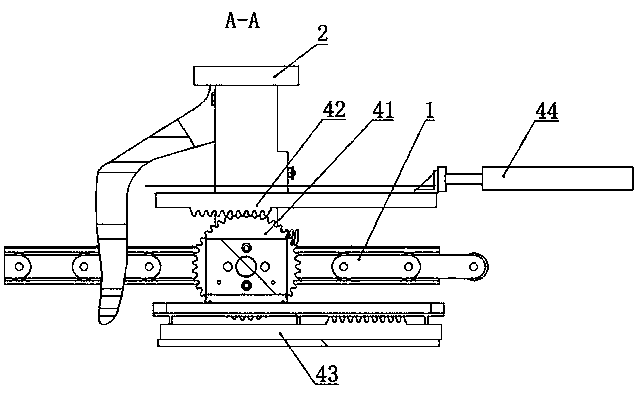

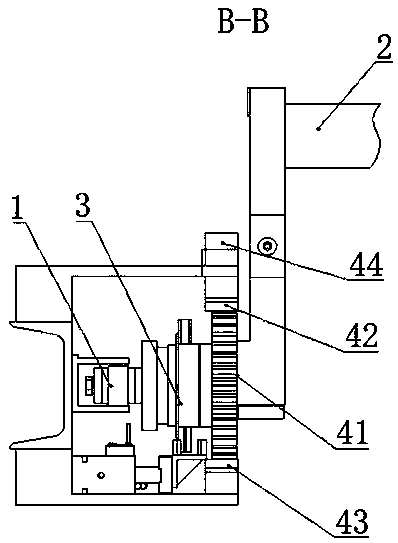

[0020] Such as figure 2 , 3 As shown, the turning drive mechanism 4 includes

[0021] Gear 41, gear 41 is installed between each mold rod 2 and clutch 3;

[0022] The rack group is installed on the dipping station and can mesh with the gear; the rack group includes

[0023] At least one upper rack 42 arranged on the dipping station, the upper rack 42 is arranged horizontally with the tooth surface facing down, and the extending direction of the upper rack ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com