Device capable of simultaneously carrying out axial loading detection on multiple pairs of bearings

An axial loading and bearing technology, applied in measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve problems such as single function, bearing vibration, component failure, etc., to achieve a wide range of applications and improve efficiency , the effect of convenient replacement and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

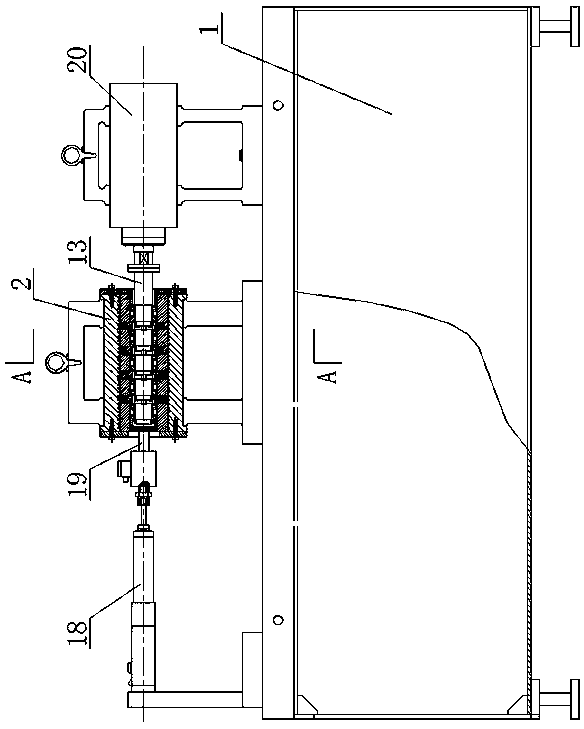

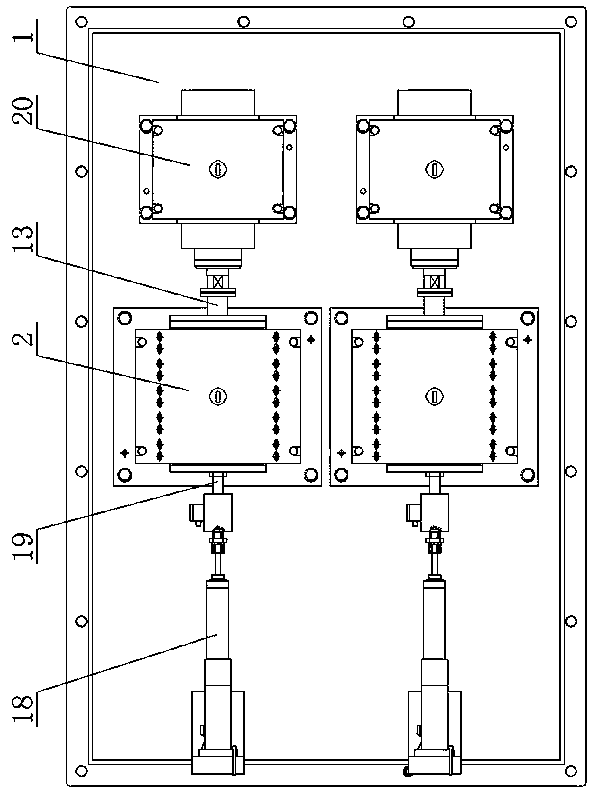

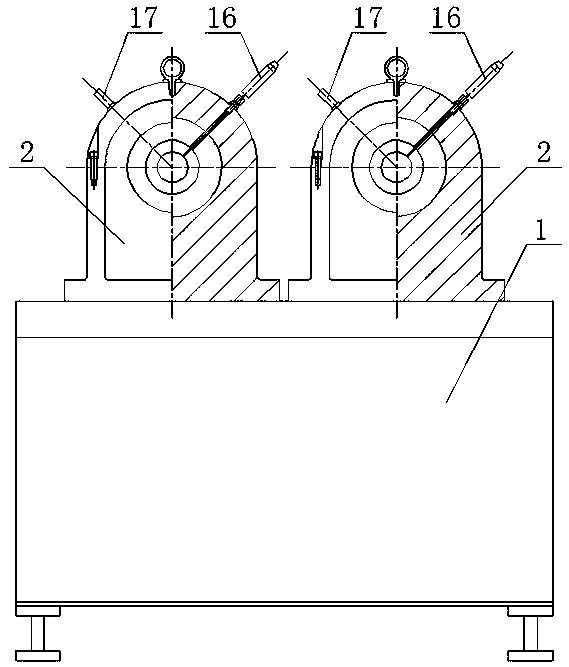

[0021] see Figure 1 to Figure 3 , a device capable of simultaneously testing multiple pairs of bearings for axial loading, including a base 1, on which is provided test components for installing multiple pairs of test bearings 3, and for simultaneously applying axial loads to multiple pairs of test bearings 3 The loading part, and the driving part for driving multiple pairs of test bearings 3 to rotate synchronously, the test part includes a housing 2 for installing multiple pairs of test bearings 3, and the loading part includes a servo electric cylinder 18 arranged on one side of the housing 2 , the servo electric cylinder 18 pushes the extruding rod 19 to load the housing 2 so as to apply an axial load to the pairs of test bearings 3, and the driving part includes an electric spindle 20 arranged on the other side of the housing 2 to drive the rotation of the multiple pairs of test bearings 3 A plurality of temperature sensors 16 for detecting the temperature of each test b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com