Detection equipment for detecting performance of stove

A technology for testing equipment and cooking utensils, which is applied in the field of cooking utensils, can solve problems such as inaccurate travel of temperature sensors, affect inspection efficiency, and hidden dangers of hand burns, and achieve the effects of improving safety in use, reducing manufacturing costs, and eliminating hidden dangers of hand burns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

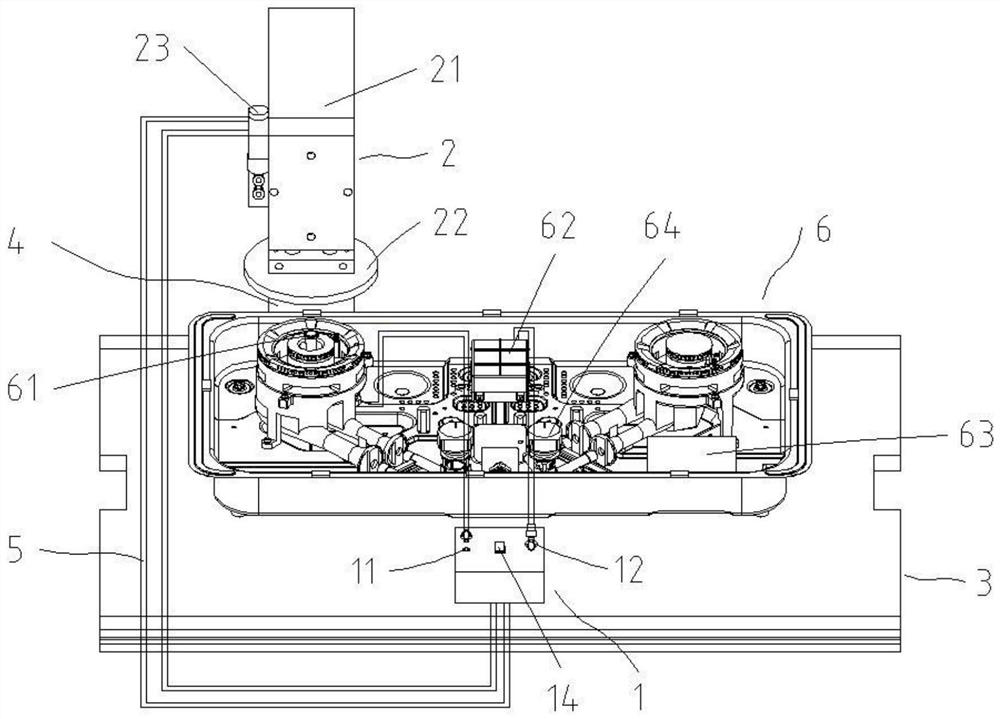

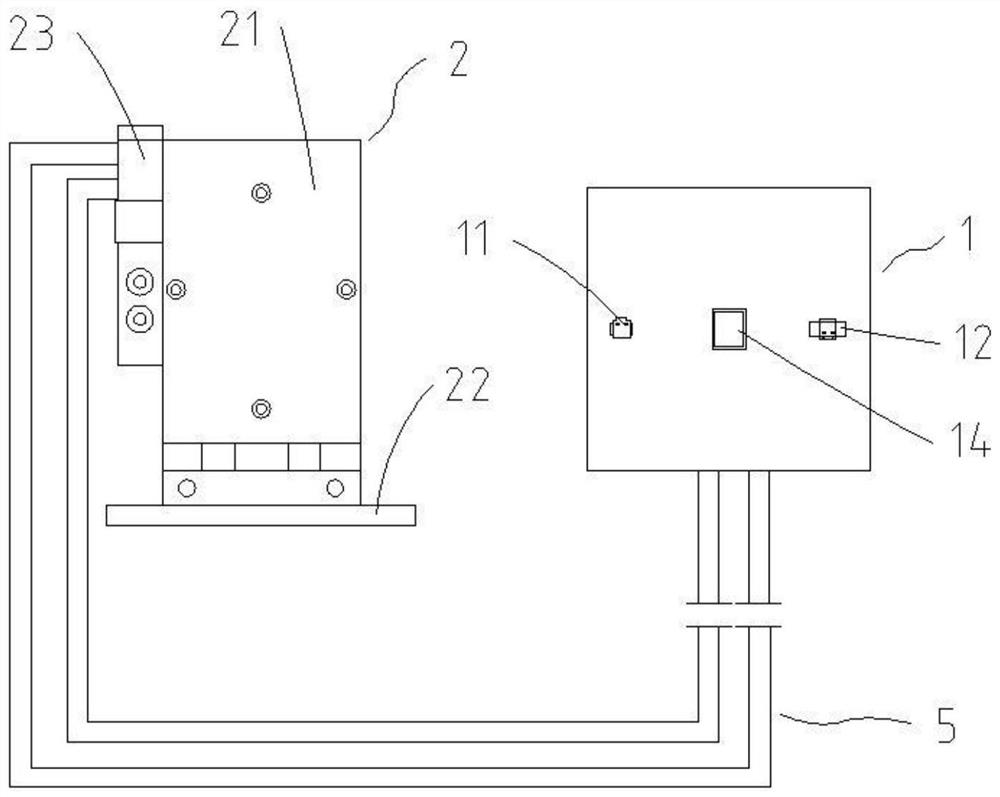

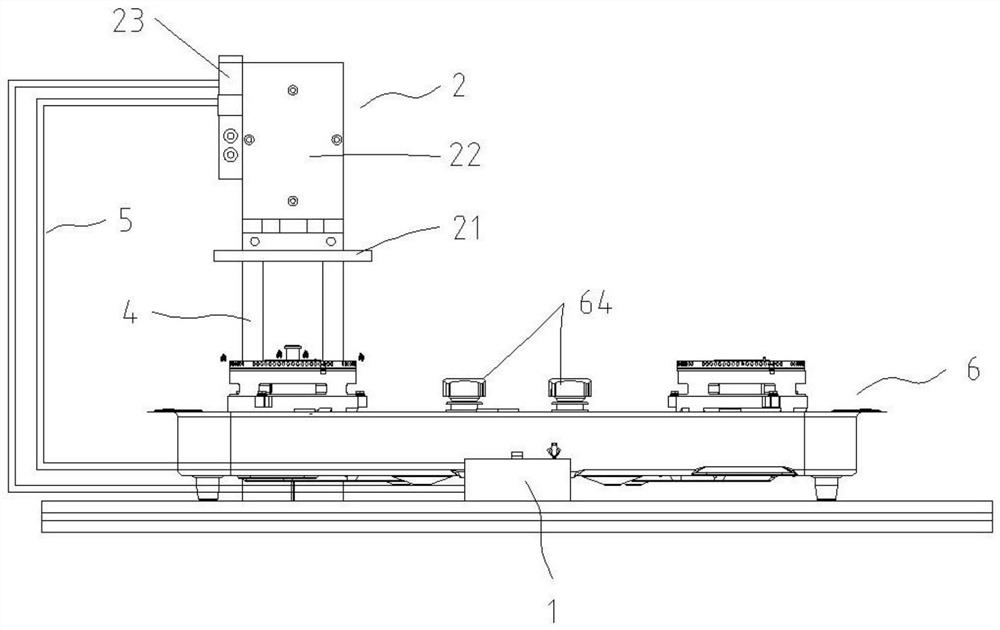

[0028] see Figure 1-6 , this embodiment provides a detection device for detecting the performance of a cooker, including a rheostat box assembly 1 and a pot simulation assembly 2 for pressing the temperature sensor of the cooker, wherein the rheostat box assembly 1 is provided with a temperature sensor terminal 11, The pulse igniter connection terminal 12 and switch 14, the temperature sensor connection terminal 11 is used to electrically connect the temperature sensor 61 of the cooker 6 through the wire 5, the pulse igniter connection terminal 12 is used for the pulse igniter of the cooker 6 through the wire 5 62 is electrically connected, and the pulse igniter 62 and the temperature sensor 61 are respectively connected to the power supply 63 of the cooker 6 . One end of the switch 14 is connected to the terminal 12 of the pulse igniter, and the other end is selectively connected to the pot simulation component 2 through the electric wire 5 . see Figure 6 , when the switc...

Embodiment 2

[0045] refer to Figure 7 , the difference between this embodiment and Embodiment 1 is that the temperature sensor simulator 13 is omitted, and the switch 14 is selectively connected to the electric converter 23, that is, the switch 14 has no rated resistance gear, but it has at least one There is no rated resistance file, and other parts are the same as in Embodiment 1.

[0046] It can be seen that by omitting the temperature sensor simulator 13, the structure and circuit diagram of the entire detection device are simplified, which is beneficial to reduce the manufacturing cost of the detection device.

Embodiment 3

[0048] The difference between this embodiment and Embodiment 1 is that the temperature sensor simulator 13, production line, detection module and assembly line board 3 are omitted, the rheostat box assembly 1 is installed on the preset installation station, and the pot simulation assembly 2 passes The installation bracket 4 is installed on the preset installation station, and the end of the switch 14 away from the pulse igniter terminal 12 is selectively connected to the electric converter 23, and other parts are the same as in the first embodiment.

[0049] It can be seen that by omitting the temperature sensor simulator 13, the production line, the detection module and the assembly line board 3, the structure and circuit diagram of the entire detection equipment are simplified, making the detection equipment suitable for laboratory use, and more convenient to move the detection equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com