Novel sequential switching waveguide switch

A waveguide switch and sequential technology, applied to waveguide devices, electrical components, circuits, etc., can solve the problems of lower product reliability, many control modules, and complex structures, so as to reduce the number of parts, improve reliability, and reduce complexity. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in conjunction with accompanying drawing.

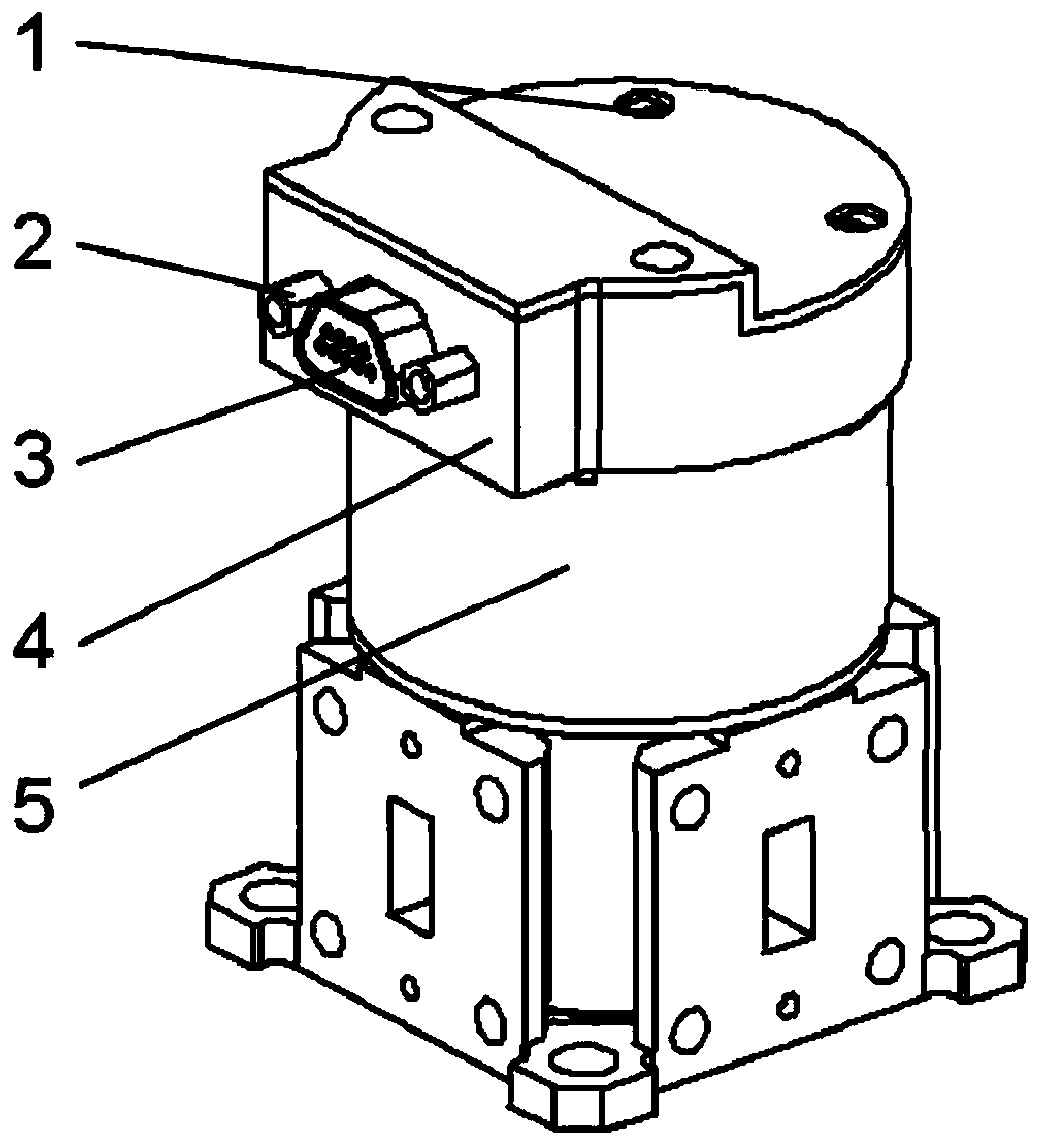

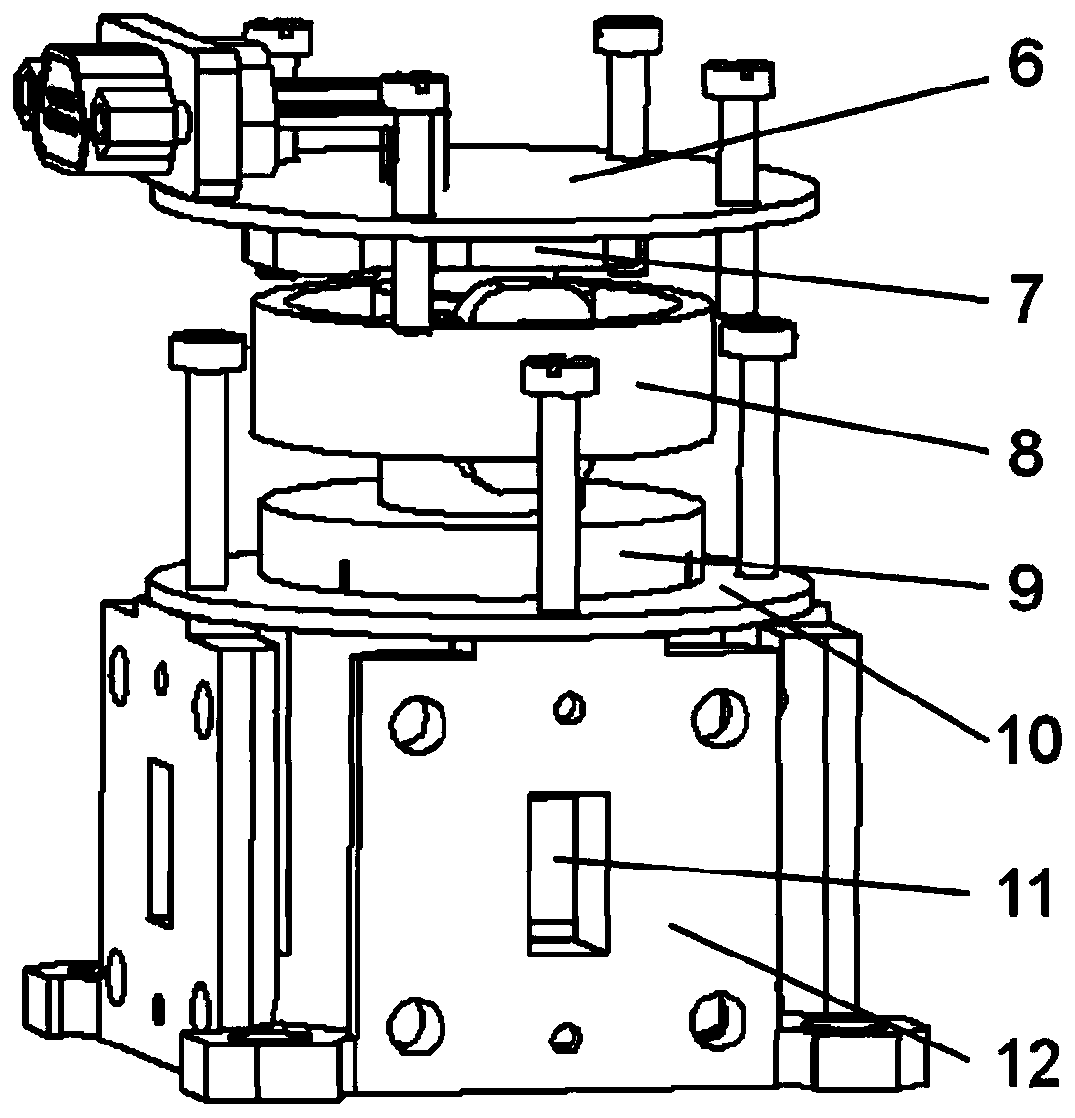

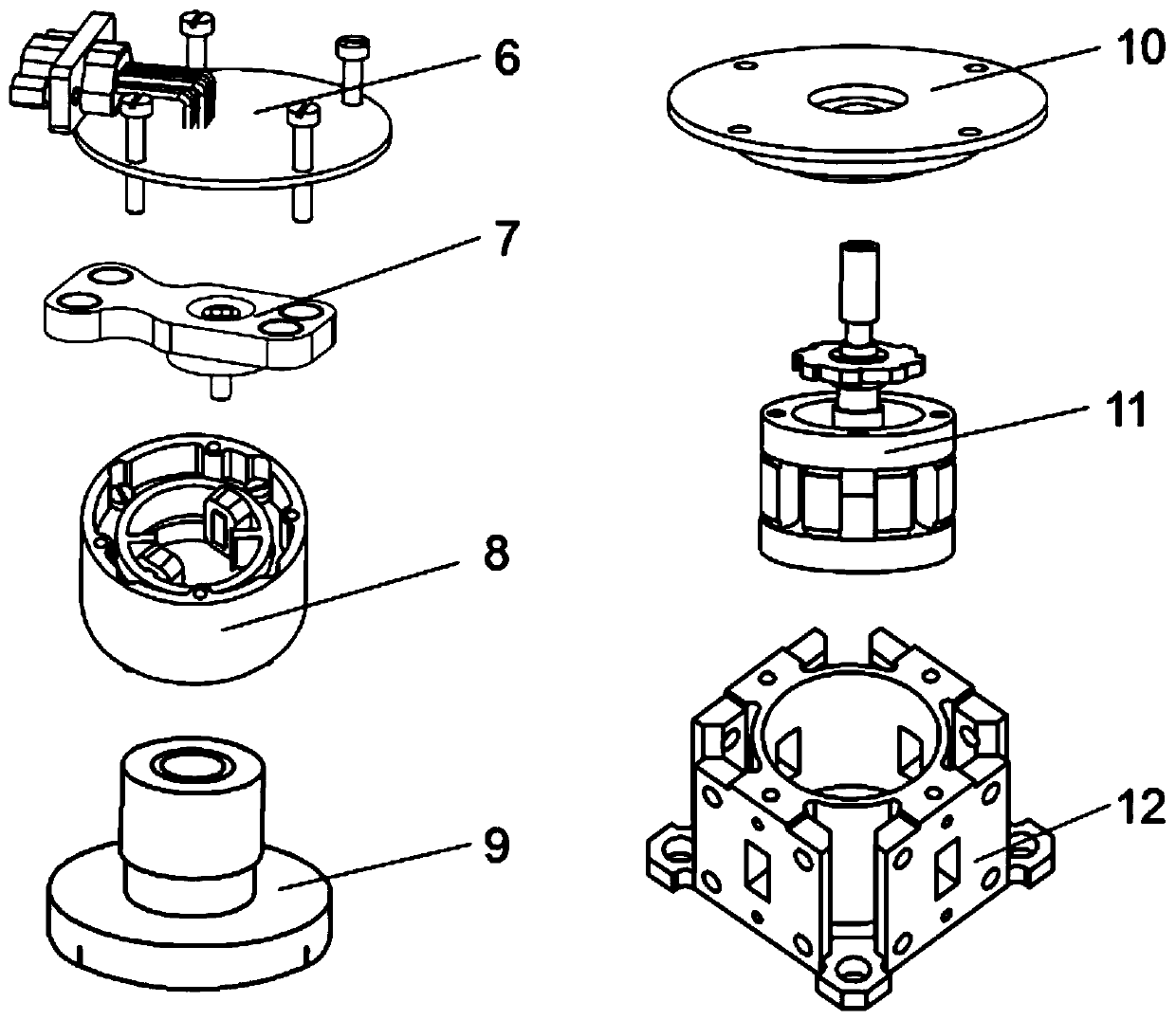

[0033] like figure 1 , figure 2 , image 3 As shown, the present invention sequentially switches the waveguide switch, including the upper casing 4, the circuit board group 6, the position feedback assembly 7, the drive stator group 8, the rotor group 9, the bearing seat assembly 10, the guide rotor group 11 and the guide stator group 12. The upper housing 4 is fixed above the middle housing 5 by mounting screws 1; the circuit board group 6 is located above the position feedback assembly 7, and the D-Sub connector 3 is fastened to the upper housing 4 by fastening screws 2; the drive stator group 8 It is fixed above the rotor group 9; the bearing block assembly 10 is fixed together with the guiding stator group 11; the guiding rotor group 11 is assembled in the guiding stator group 12.

[0034] like Figure 4 As shown, the circuit board group 6 is installed in the upper casing 2 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com