A photovoltaic module and a manufacturing method thereof

A photovoltaic module and manufacturing method technology, applied in photovoltaic power generation, photovoltaic modules, electrical components, etc., can solve problems such as lowering the energy conversion efficiency of photovoltaic modules, low energy conversion efficiency of photovoltaic modules, and rising operating temperature of photovoltaic modules, and achieves a simple structure , easy installation, avoid the effect of temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

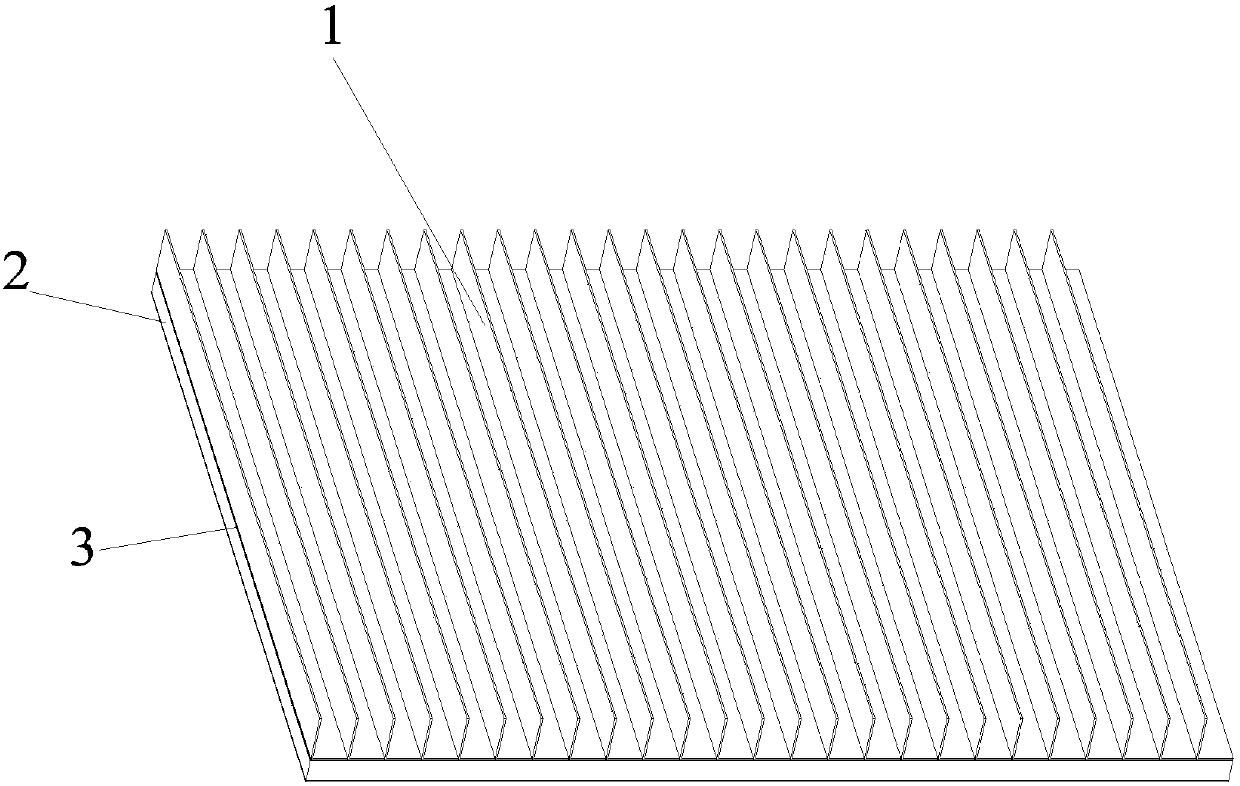

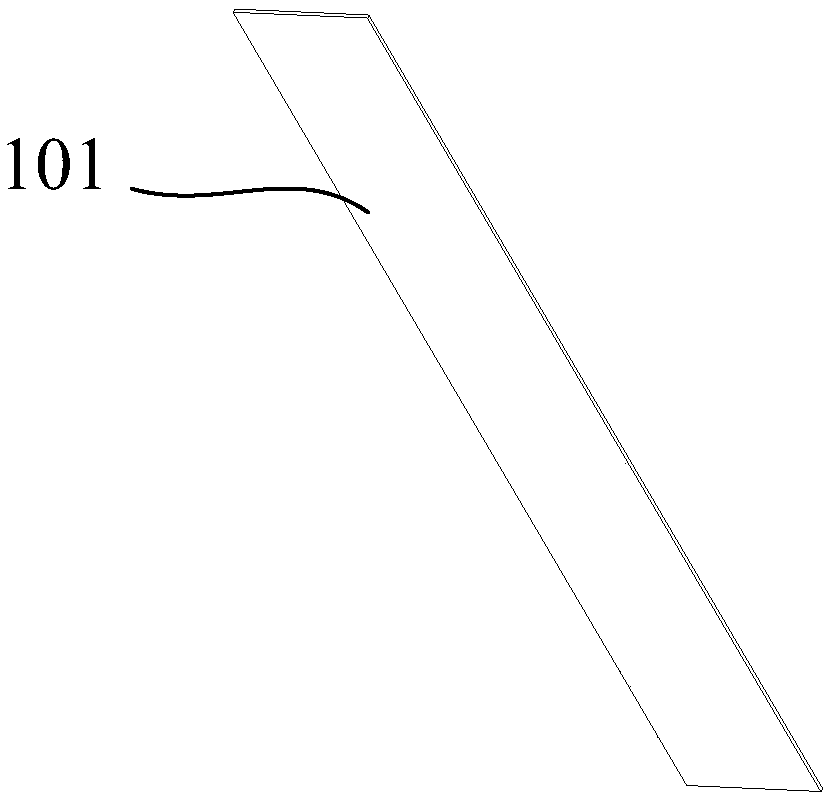

[0047] Please refer to Figure 1 to Figure 5 , in this embodiment, the photovoltaic module is specifically rectangular, and the heat dissipation fins 1 are processed with a metal slab 101 with a thinner thickness and excellent thermal conductivity. The material of the metal slab 101 is aluminum and its alloys, copper and its alloys. The shape of the fins 1 is elongated, and multiple heat dissipation fins 1 are arranged side by side on the back of the photovoltaic module body 2 , and the heat dissipation fins 1 are parallel to a pair of sides of the photovoltaic module.

[0048] In order to improve the heat dissipation effect as much as possible, the bonding part 12 of the heat dissipation fin 1 in this embodiment completely covers the back of the photovoltaic module body 2, which can ensure that the heat dissipation fin 1 can dissipate the heat from the back of the photovoltaic module body 2 as much as possible. spread out as figure 1 with Figure 4 shown in .

[0049] The ...

Embodiment 2

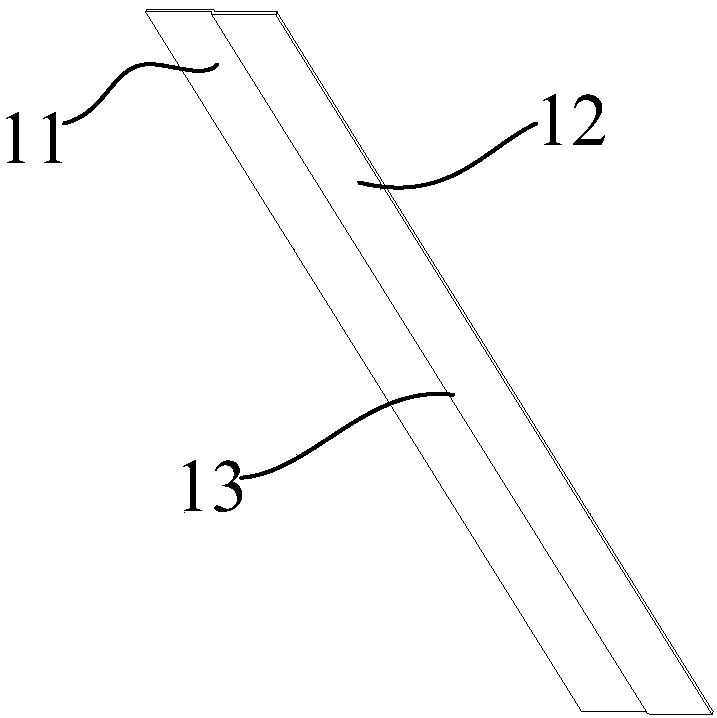

[0064] Please refer to Figure 6 to Figure 11 , in this embodiment, the photovoltaic module is specifically rectangular, and the heat dissipation fin 1 is processed with a metal slab 101 with a thinner thickness and excellent thermal conductivity. The material of the metal slab 101 is aluminum and its alloys, copper and its alloys, such as Figure 7 As shown in , the processed metal slab 101 forms a fin array, and the fin array includes a plurality of heat dissipation fins 1, any heat dissipation fin 1 includes a bonding part 12 and a bent heat dissipation part 11, and the bonding The part 12 is attached to the back of the photovoltaic module body 2 , and the bent heat dissipation part 11 is bent toward the side away from the back of the photovoltaic module body 2 .

[0065] In order to improve the heat dissipation effect as much as possible, the bonding part 12 of the heat dissipation fin 1 in this embodiment completely covers the back of the photovoltaic module body 2, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com