Condensed dinaphthalene-based micromolecular functional material and preparation method and application thereof

A technology of functional materials and small molecules, used in semiconductor/solid-state device manufacturing, photovoltaic power generation, instruments, etc., can solve the problems of low electron mobility and energy conversion rate, complex processing technology, weak processing performance and light absorption performance, etc. The effect of high electron mobility, overcoming complex processing technology, and good energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

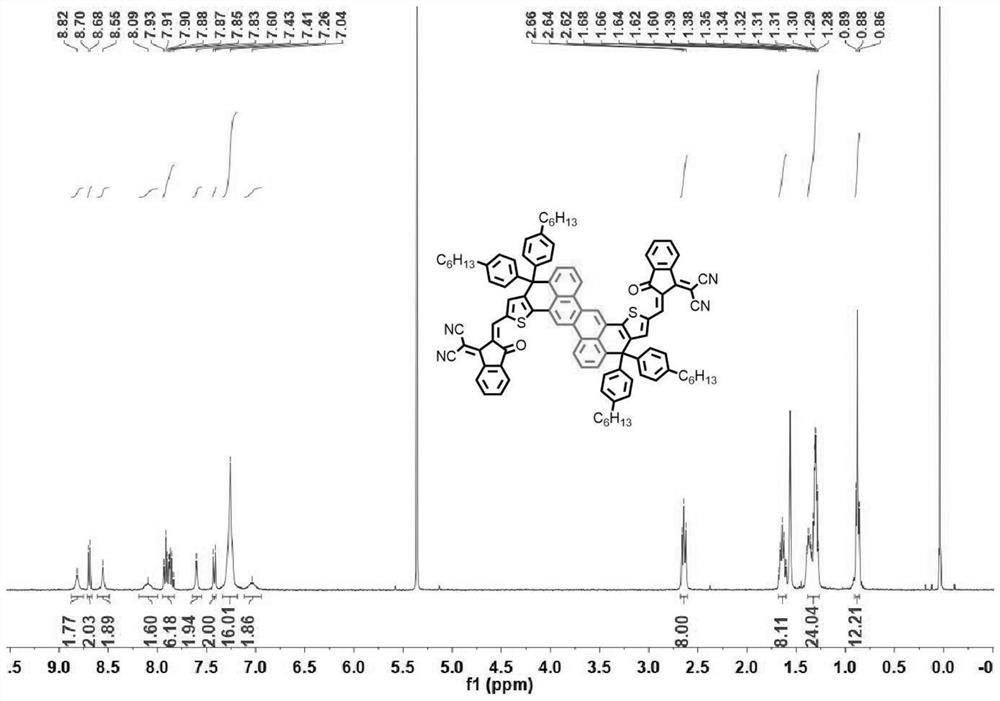

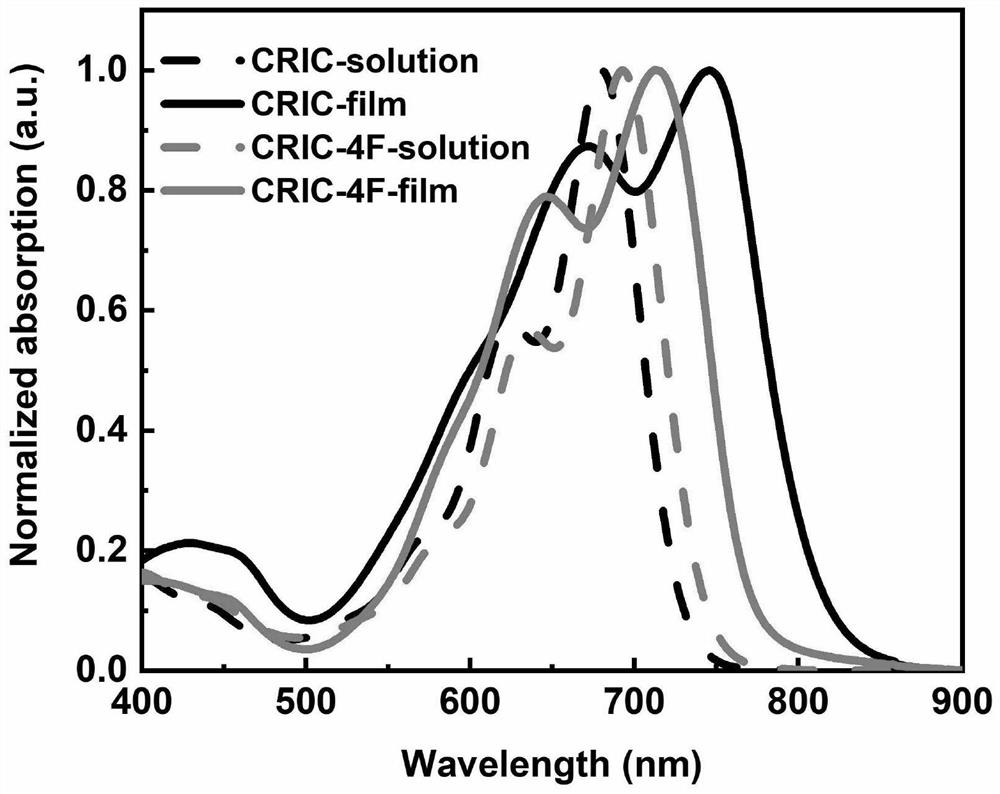

[0033] Such as figure 1 and image 3 : For the small molecule functional material CRIC based on condensed dinaphthalene, the structural formula is:

[0034]

[0035] Concrete synthetic steps are as follows:

[0036]

[0037] (1), under nitrogen protection, compound A1 (0.96g, 2mmol), bromothiophene ester compound (1.4g, 6mmol) and Pd(PPh3) 4 (50mg, 0.04mmol) were added in 25mL of anhydrous toluene, And add 8mL of ethanol and potassium carbonate (1M, 3mL), and then the reaction was heated to reflux at 110°C for 24h. After the reaction was cooled to room temperature, it was poured into ethanol to precipitate, filtered, and dried to obtain compound A2 (0.89g, 81%) ;

[0038] (2), under nitrogen protection and -78 ° C, p-hexylbromobenzene (1.2g, 5mmol) was dissolved in 20mL of anhydrous THF, then n-BuLi (2mL, 5mmol) was added dropwise, and stirred for 1 Then, compound A2 (0.44g, 0.82mmol) was added dropwise into the system, the reaction was moved to room temperature, sti...

Embodiment 2

[0042] As shown in Table 1: Polycarbonate (PCZ-300) is dissolved in THF to form a film-forming agent solution with a mass concentration of 10%; take 500 grams of 10% PCZ-300 solution, add 5 grams of CRIC, fully stir and dissolve with THF, and form Coating solution: apply the coating solution on the surface of the aluminum base of φ24*L250mm by dip coating, and dry it for 2 hours to obtain a single-layer organic photosensitive drum with a photosensitive layer thickness of 15 μm.

Embodiment 3

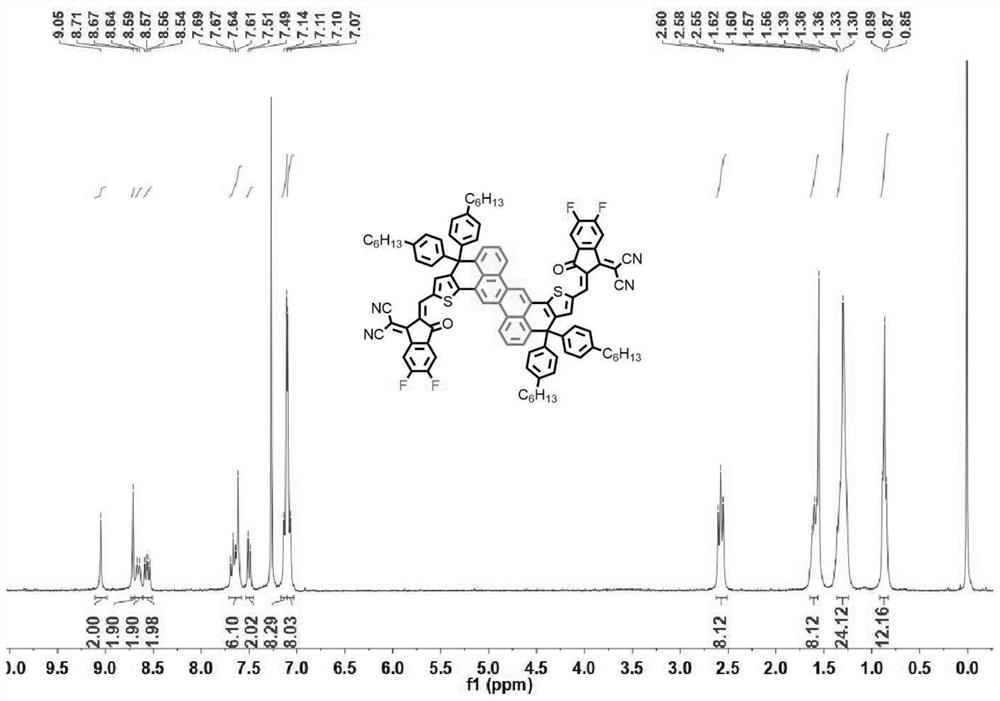

[0044] Such as figure 1 and image 3 : For the small molecule functional material CRIC-4F based on condensed dinaphthalene, the structural formula is:

[0045]

[0046] Concrete synthetic steps are as follows:

[0047] Under nitrogen protection, compound A1 (0.96g, 2mmol), bromothiophene ester compound (1.4g, 6mmol) and Pd(PPh3)4 (50mg, 0.04mmol) were added to 25mL of anhydrous toluene, and 8mL of ethanol was added and potassium carbonate (1M, 3mL). Then the reaction was heated to reflux at 110° C. for 24 h, and the reaction was cooled to room temperature, poured into ethanol for precipitation, filtered, and dried to obtain compound A2 (0.89 g, 81%);

[0048] (2), under nitrogen protection and -78 ° C, p-hexylbromobenzene (1.2g, 5mmol) was dissolved in 20mL of anhydrous THF, then n-BuLi (2mL, 5mmol) was added dropwise, and stirred for 1 Then, compound A2 (0.44g, 0.82mmol) was added dropwise into the system, the reaction was moved to room temperature, stirred overnight, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com