Application method of full-automatic intelligent noodle machine processing robot

An application method, fully automatic technology, applied in the direction of dough sheeting machine/rolling machine/rolling pin, structural components of mixing/kneading machinery, dough forming and cutting equipment, etc., can solve diners' bad dining experience, noodle The taste cannot be maintained, the chewiness cannot be guaranteed, etc., to achieve the effect suitable for promotion, high degree of equipment automation, and suitable for small commercial use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] Embodiment: The principle of the application method of the fully automatic intelligent noodle machine processing robot in this embodiment is to mix flour and water in proportion, and then mix them evenly to form a small-particle flour dough, and then combine the small-particle flour The dough is extruded to form noodles, and finally the noodles are cut to form noodles.

[0018] The application method in this embodiment is implemented by the following equipment:

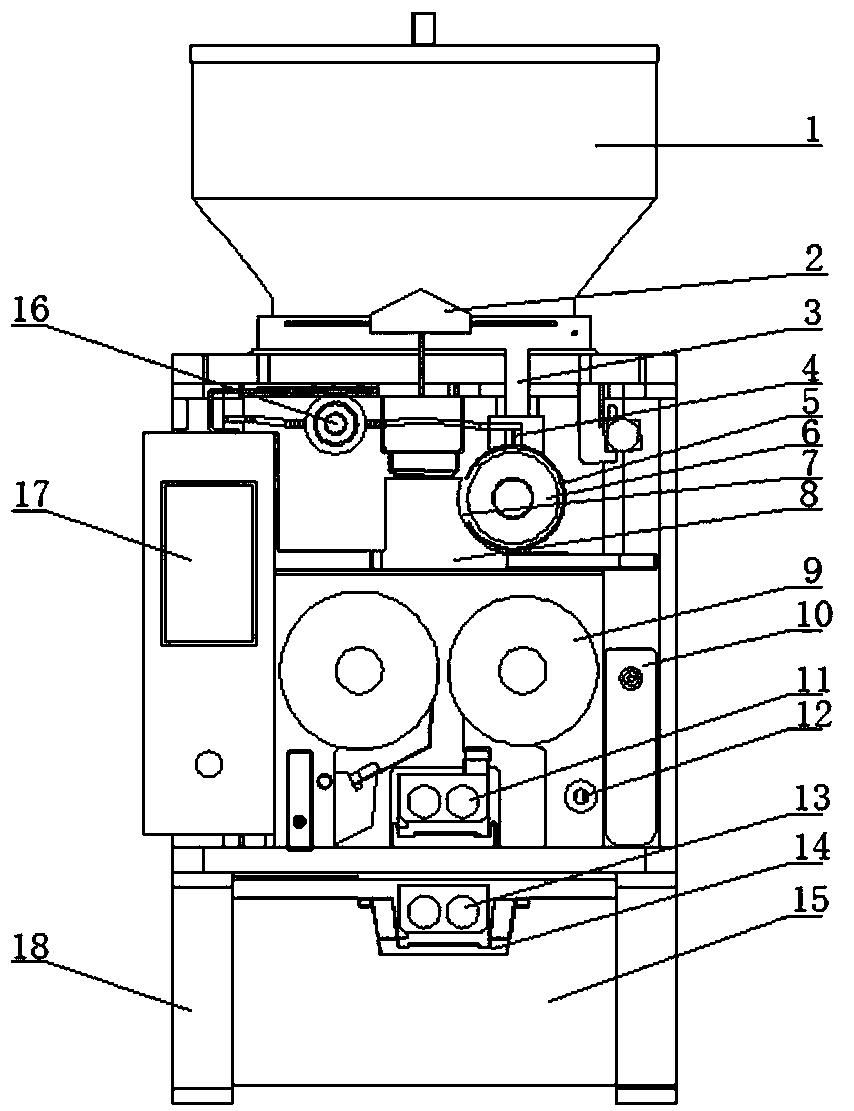

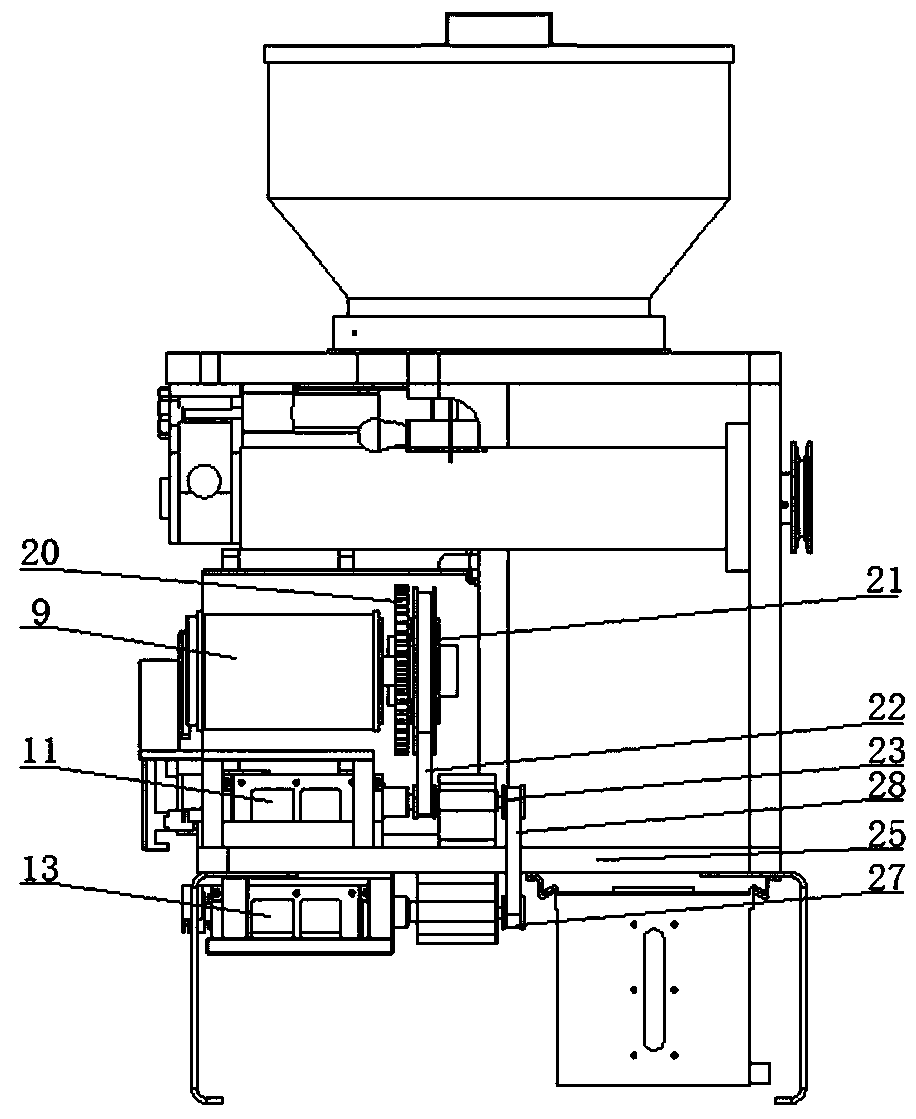

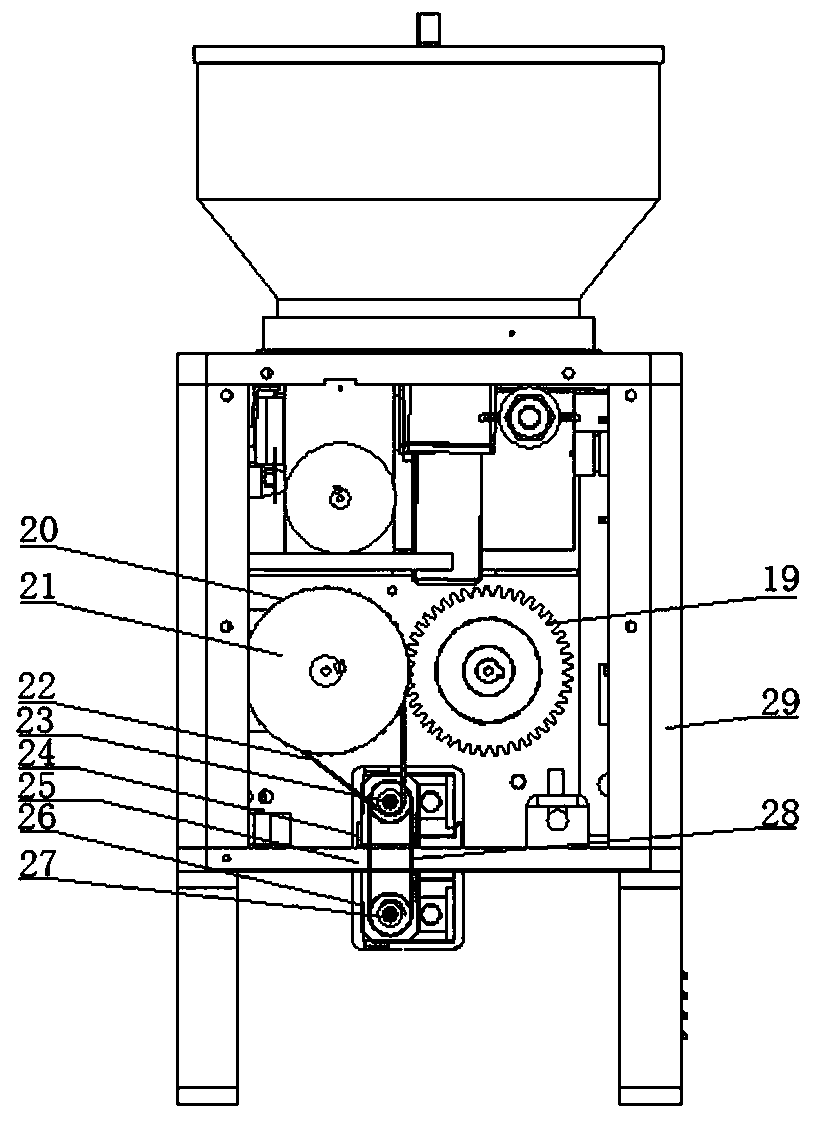

[0019] Such as figure 1 with image 3 As shown, the processing robot in this embodiment includes a frame 29. A mixing drum 5 is arranged in the middle and upper part of the frame 29. The mixing drum 5 is provided with a mixing screw 6 inside. The mixing screw 6 can be connected to the mixing drum through an external power source. 5 internal rotation. The internal space of the barrel of the mixing drum 5 serves as a mixing space for flour and water.

[0020] Such as figure 1 with image 3 As shown, a flour feeding de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com