Wide-range fixed safety belt suspension device

A suspension device and seat belt technology, which is applied to seat belts, life-saving equipment, etc., can solve the problems that the lift car cannot be approached, cannot be welded and fixed, and the cost of the lift car is high, so as to ensure the reliability and stability of the fixation and improve the Operation convenience, the effect of ensuring personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

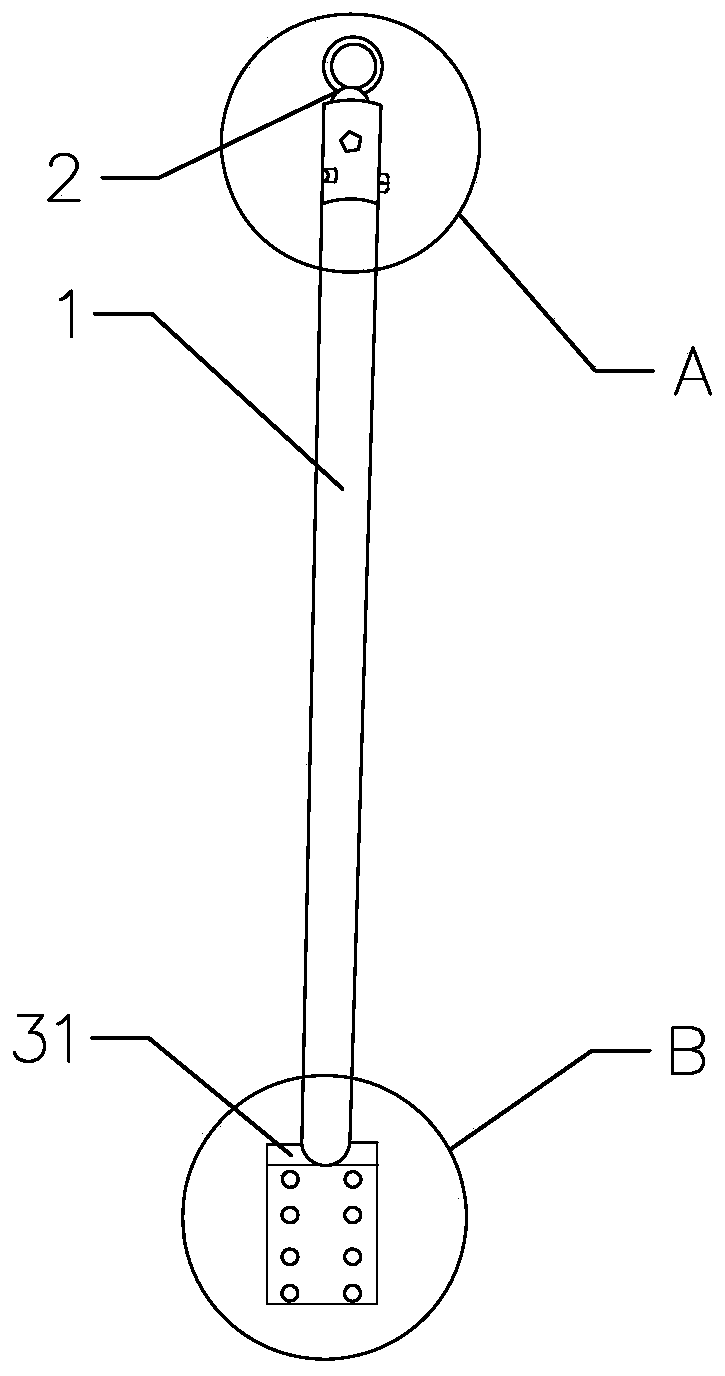

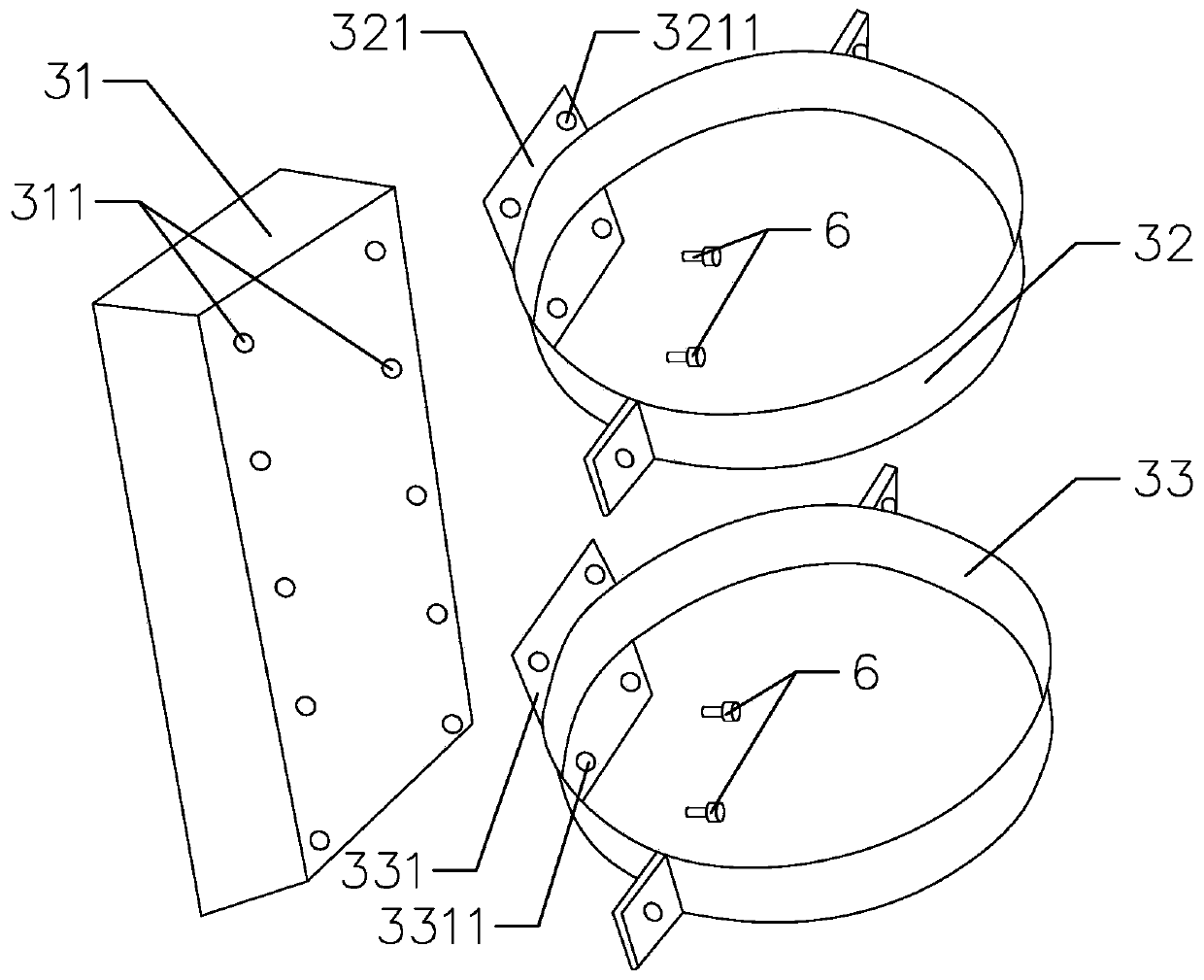

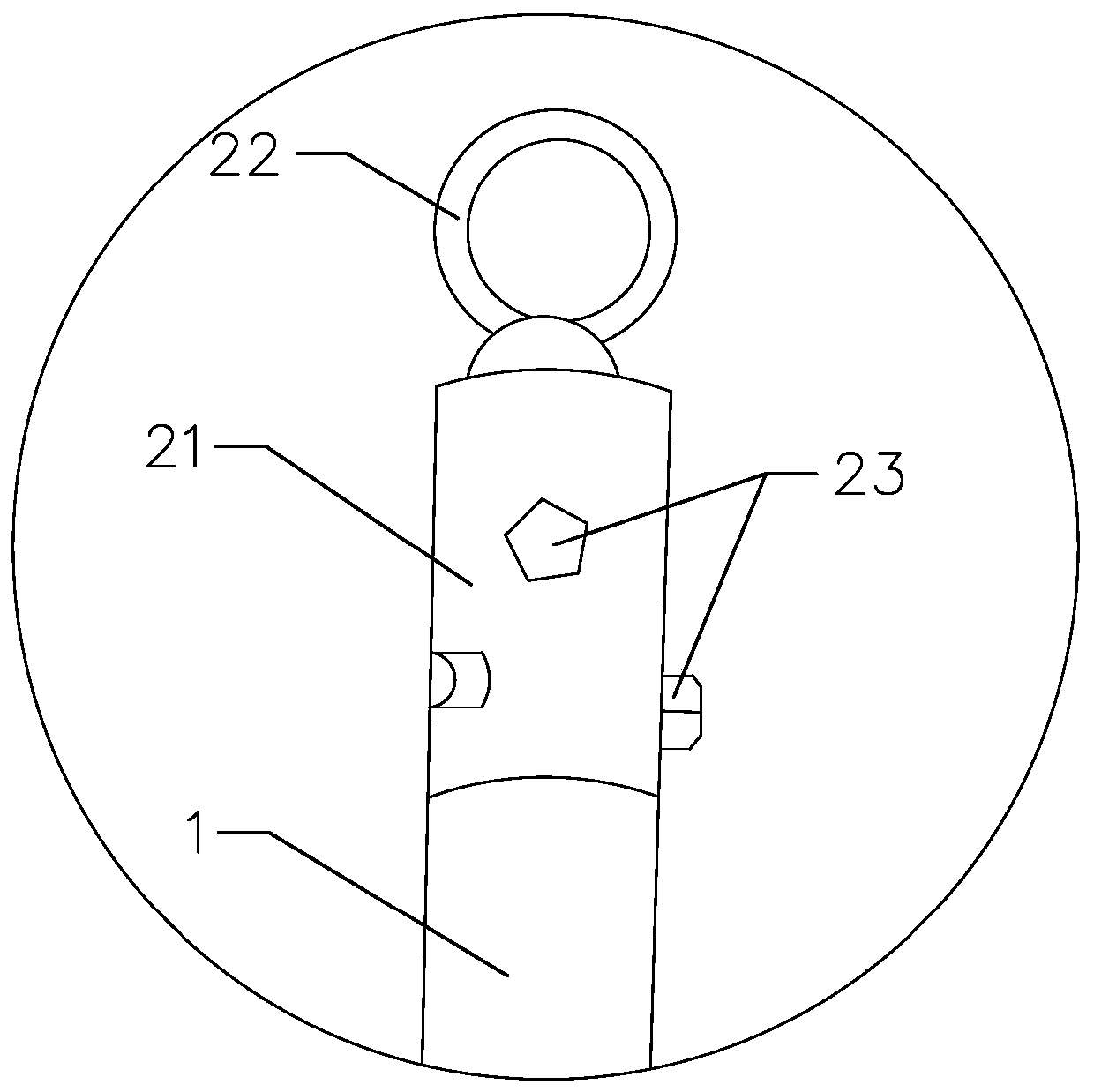

[0032] like Figures 1 to 4 As shown, the present invention provides a widely applicable fixed safety belt suspension device, comprising a riser 1, a safety belt hanging ring 2 and a fixed structure, the safety belt hanging ring 2 is located at the top of the riser 1, and the fixed structure is located at the vertical The bottom end of the pipe 1 and the riser 1 are fixed together with the electrical equipment through a fixed structure, and a safety belt suspension device is provided to ensure the personal safety of the maintenance personnel when repairing the equipment.

[0033]In this embodiment, the fixed structure and the standpipe 1 are detachably fixed together, so that the fixed structure and the standpipe can be detachable, so that when maintaining different electrical equipment, different fixing structures can be selected to match with the standpipe, so as to achieve maintenance efficiency. Purpose, and the fixing structure specifically includes a utility pole fixing ...

Embodiment 2

[0038] The difference between this embodiment and the first embodiment lies in that the structures of the upper hoop and the lower hoop are different.

[0039] In this example, if Figures 5 to 6 As shown, the upper hoop 32 includes a first upper hoop piece 322 and a second upper hoop piece 323, and the first upper hoop piece 322 and the second upper hoop piece 323 are connected by first bolts 324 and encircled to form the The upper hoop 32, the first upper hoop piece 322 and the second upper hoop piece 323 are all provided with an upper adjustment hole 325, and the upper adjustment hole 325 is provided with a plurality, and the first bolt 324 passes through different upper adjustment holes 325 By changing the enclosing inner diameter of the upper hoop 32, the upper hoop can be applied to utility poles of different sizes, which greatly improves the applicability of the fixed safety belt suspension device, that is, the fixed safety belt suspension device is widely applicable. ...

Embodiment 3

[0045] The difference between this embodiment and the first embodiment is that the riser is a telescopic riser.

[0046] In this example, if Figure 7 As shown, the standpipe 1 includes an inner standpipe 11 and an outer standpipe 12. The inner standpipe 11 is sleeved in the outer standpipe 12 and can be telescopically arranged along the axial direction of the outer standpipe 12, so that the overall length of the standpipe can be adjusted if necessary. At the same time, the overall length of the standpipe can be adjusted by adjusting the inner standpipe and the outer standpipe, so that it can be well adapted to different working conditions during operation, without replacing the entire standpipe, which greatly improves the work of maintenance personnel efficiency, and the safety belt hanging ring 2 is detachably connected to the top of the inner riser 11 through a fastening structure, so that the safety belt hanging ring 2 and the inner riser 11 are detachably connected, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com