Quality detection and classification device used for hardware shaft sleeves

A sorting device and detection device technology, which is applied in the field of hardware accessories processing, can solve problems such as confusion of finished product quality, influence on the overall quality of finished hardware shaft sleeves, and hazards, and achieve the effects of novel structure, lower specific gravity, and higher pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

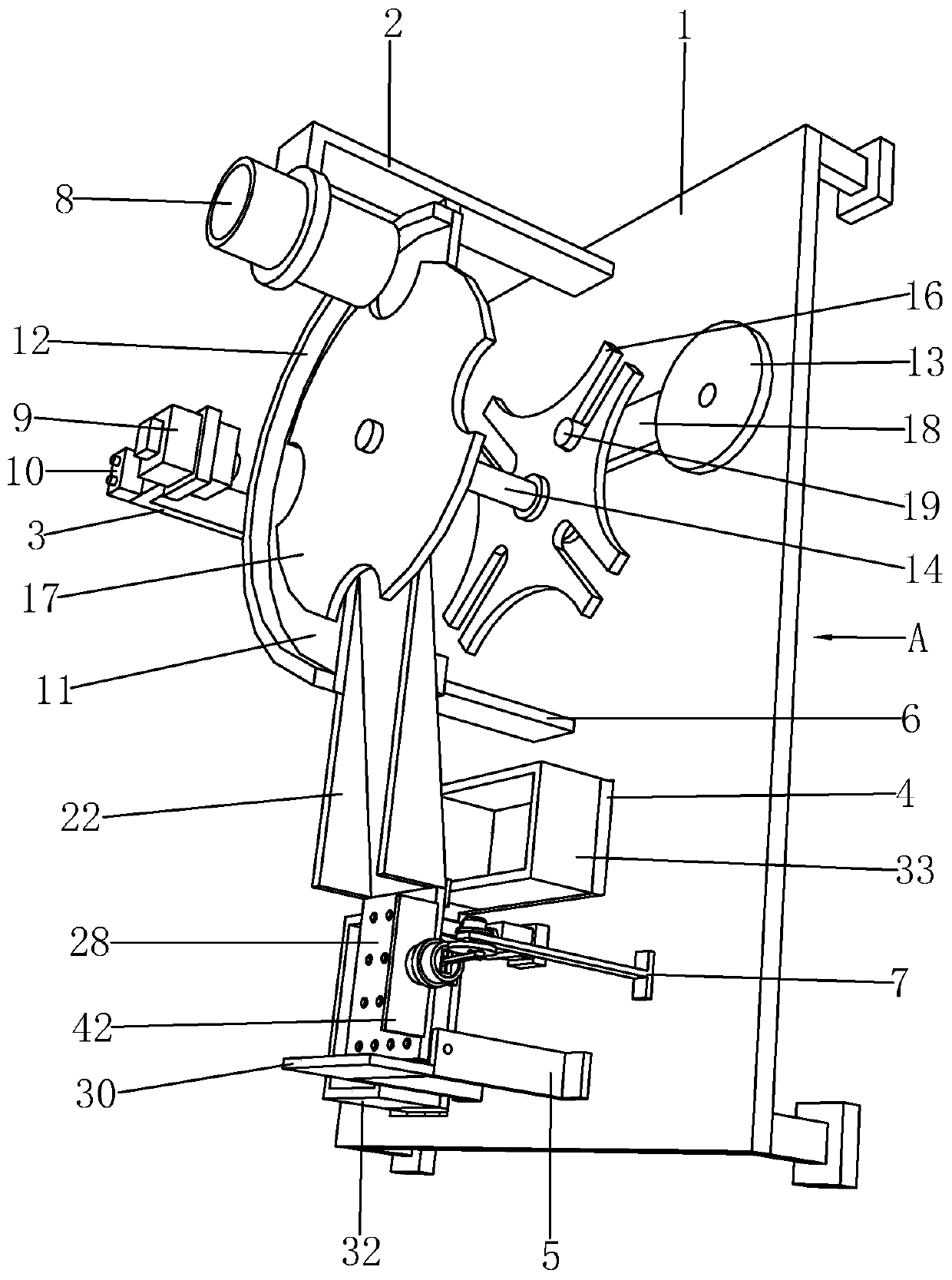

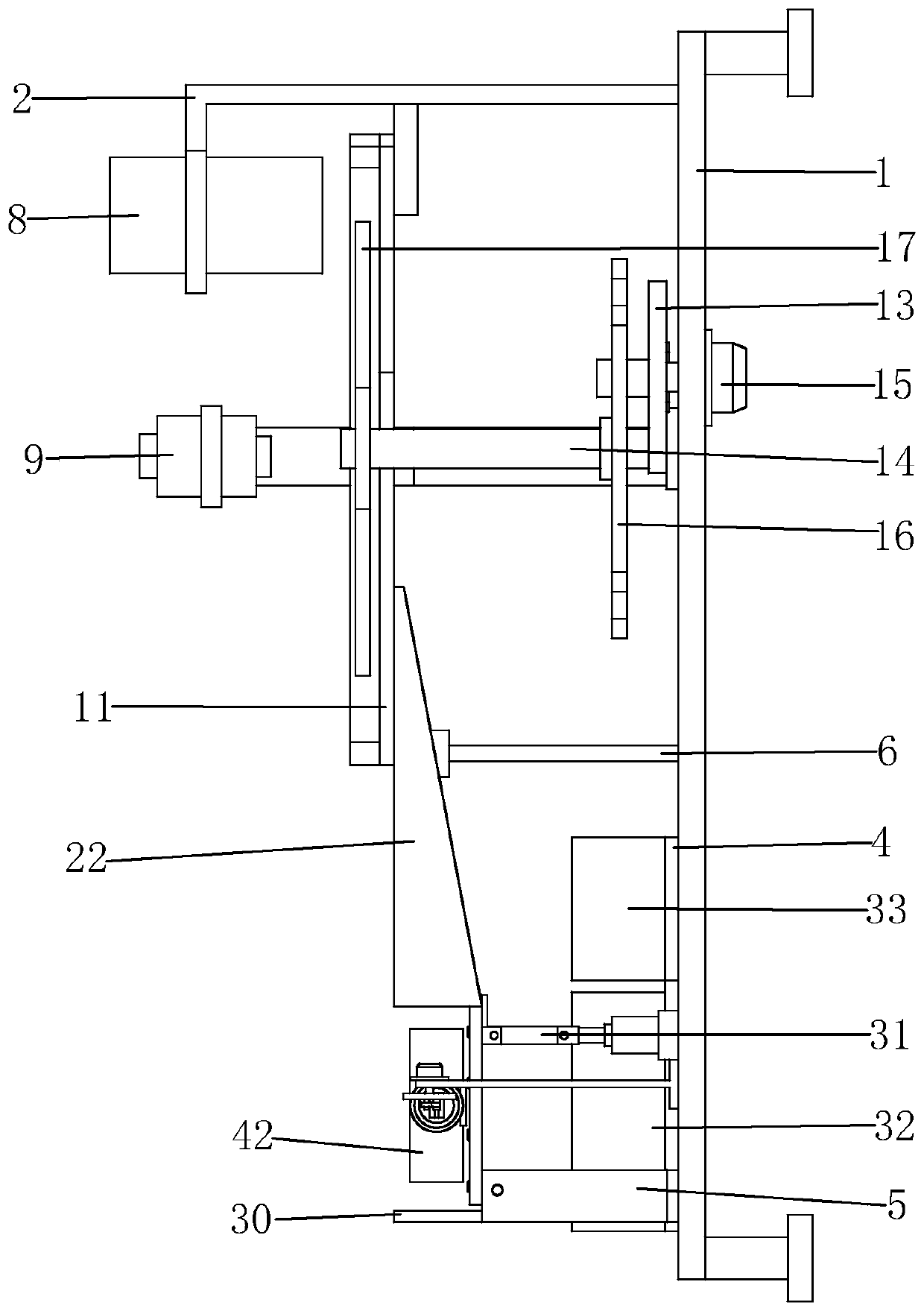

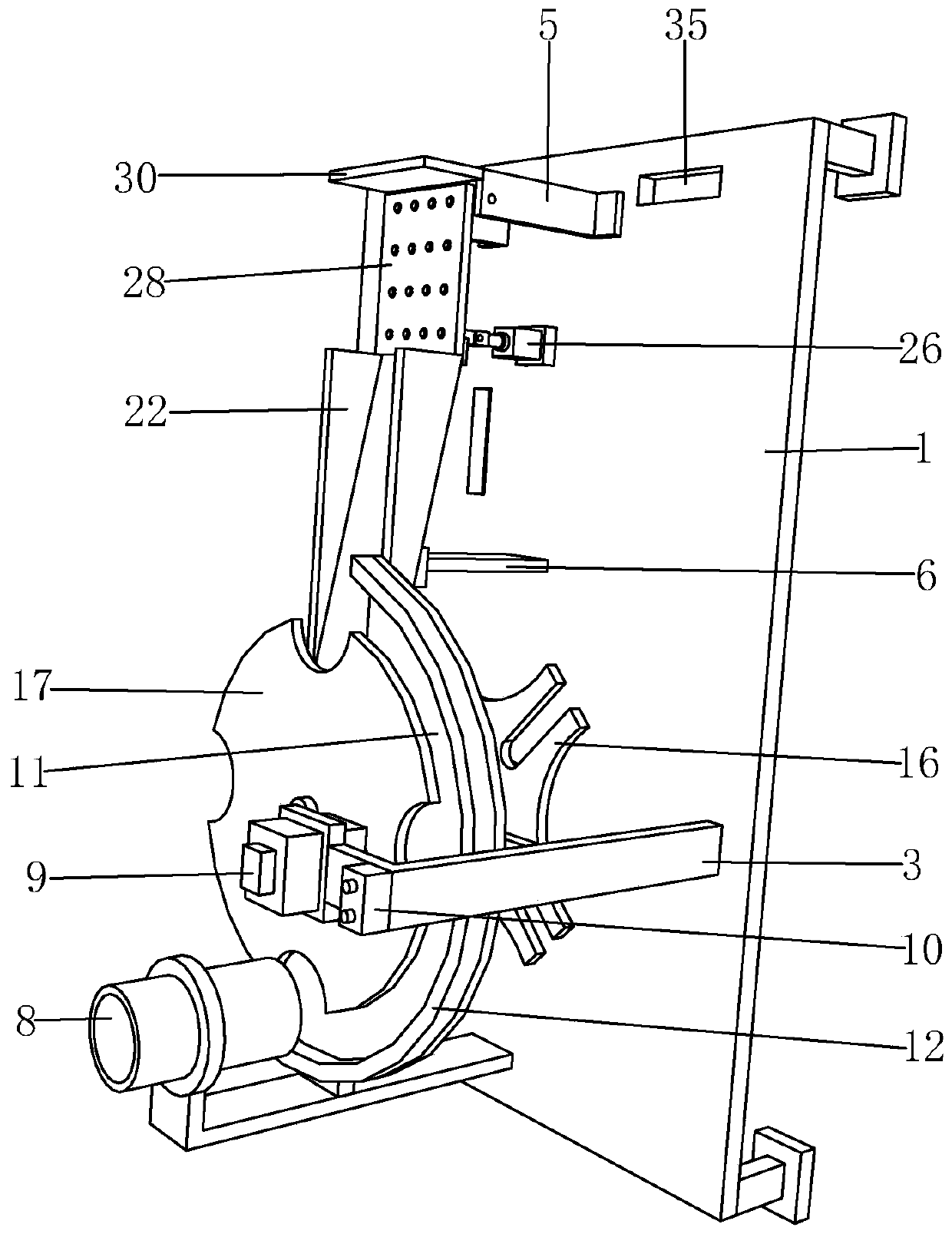

[0029] like Figure 1 to Figure 8As shown, it is a kind of quality inspection and classification device for metal shaft sleeves of the present invention, including a frame 1, and the frame 1 is respectively provided with a fixed bracket 2, a mounting bracket 3, an L-shaped receiving plate 4, a support plate 5, Bracket 6, pushing mechanism and stand 7, fixed bracket 2 is provided with feeding tube 8, and feeding tube 8 is open-ended at both ends, and detection device 9 and controller 10 are respectively provided on mounting bracket 3, and detection device 9 Electrically connected to the controller 10, the detection device 9 is used to detect the quality status of the hardware shaft sleeve. The detection device 9 belongs to the prior art, and will not be described in detail here. The controller 10 adopts a programmable logic controller 10, which has higher computing power Speed, ultra-small size, more reliable industrial anti-jamming design, PID function and high cost performanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com