Wing spar aligning tooling and aligning method

A technology of wing spar and tooling, which is applied in the field of aligning tooling for automatic hole-making of wing spar, can solve the problems that the hole-making accuracy cannot meet the production requirements, and cannot accurately measure the length error of the wing spar, so as to realize the automatic hole-making operation and improve the The effect of hole making accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

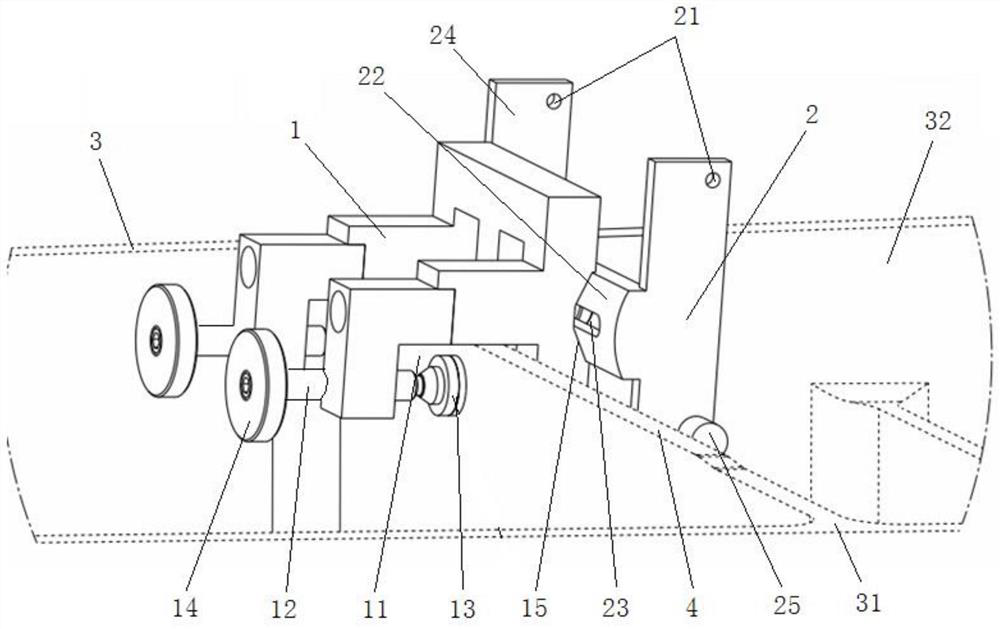

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

[0022] Such as figure 1 As shown, the spar alignment tooling of the present invention includes a vertical rib positioning block 1 and a sliding positioning block 2, and the vertical rib positioning block 1 is provided with a locking bayonet that can be stuck on the vertical rib 4 of the spar 3 , the sliding positioning block 2 is slidingly connected with the vertical rib positioning block 1, and the sliding direction is consistent with the width direction of the vertical rib 4. One end of the sliding positioning block 2 is provided with an offset reference hole 21, and the offset reference hole 21 exceeds The spar end face 31 and its axis are perpendicular to the spar cap inner surface 32 .

[0023] The invention utilizes the internal structure of the spar-rib position and vertical ribs to provide a reference for the hole-making equipment. The vertical rib 4 of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com