A wave cutting and extrusion hole fine strength integrated processing method

A processing method and a wave-like technology, applied in the fields of hole making, hole strengthening, and mechanical processing, can solve problems such as high operating costs, increase hole surface roughness, and reduce processing efficiency, so as to improve surface microhardness and fatigue life , Reduce the surface roughness of the hole, improve the effect of the surface strength of the hole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] To better explain the present invention, it will be described in detail by the

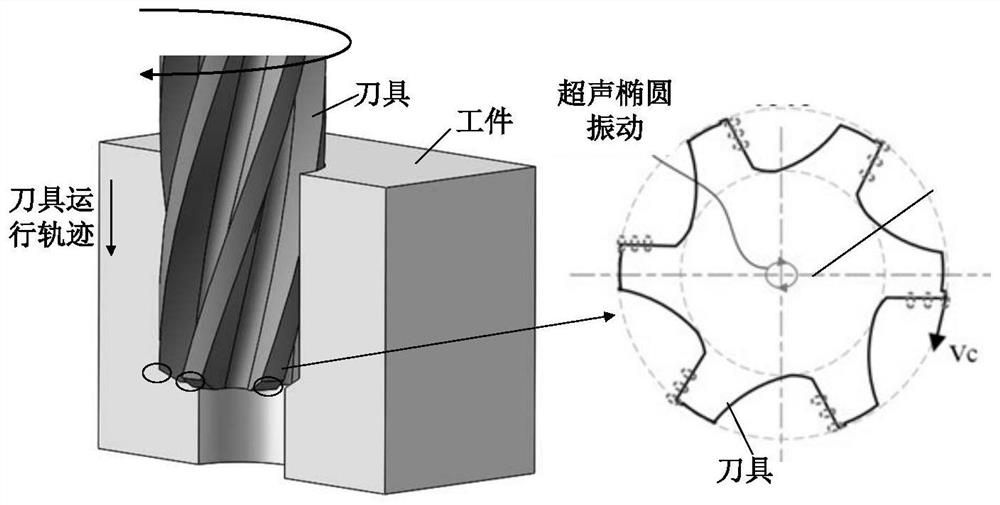

[0043] In this embodiment, a fluctuation-type cutting hole is provided, including: configuring the machine tool according to the strategy of the preset manufacturing, the machine tool, the machine tool integration is controlled in accordance with the strategy.

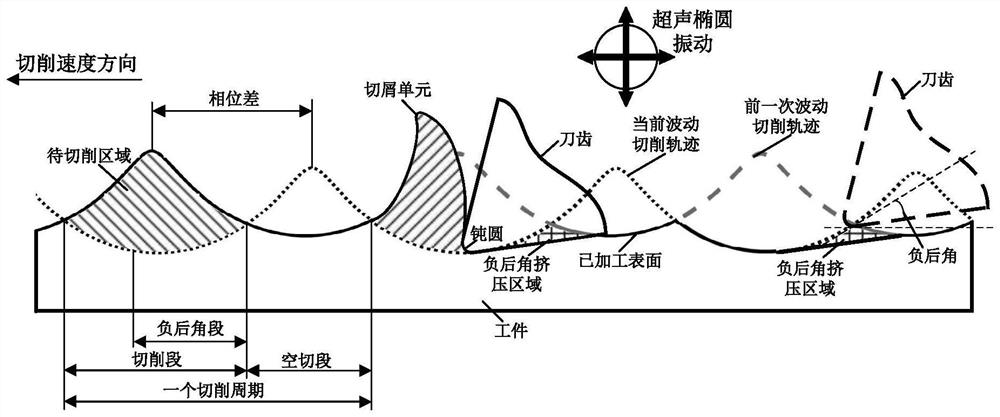

[0044] Further, during the manufacturing hole, a cutting operation of the tool is realized by means of ultrasonic elliptical vibration, and the side blade surface of the tool is caused by a negative angular region to impact the hole surface of the processed portion of the well.

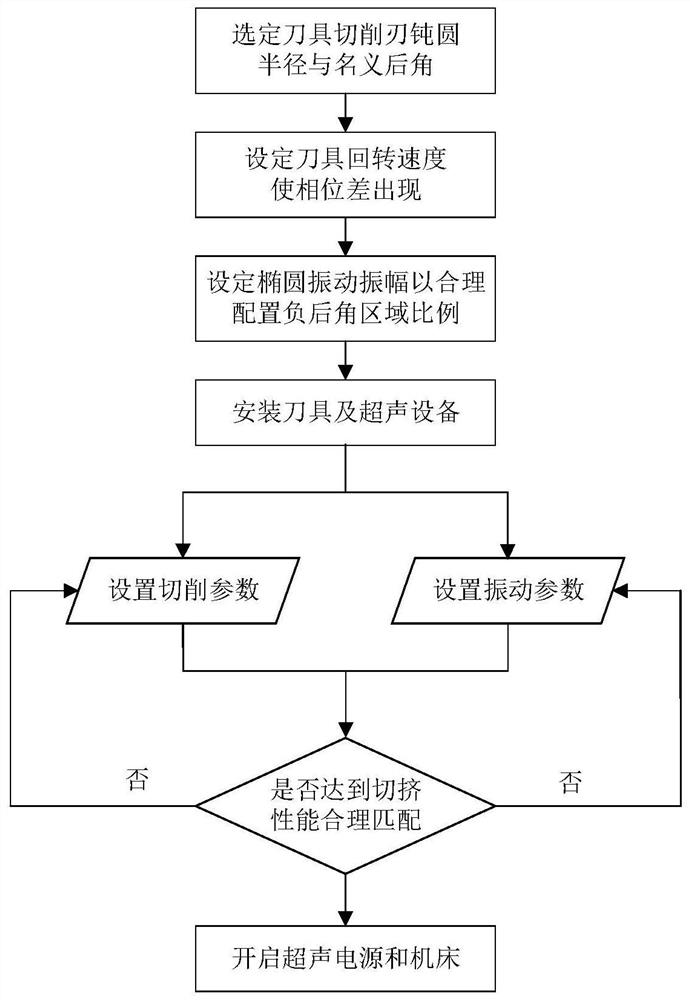

[0045] The strategy of manufacturing the intensive hole includes: a phase difference for improving the cutting force to improve the cutting force to increase the processing accuracy, for making the side blade of the cutter after the side blade of the tool after the knife is elliptical vibration Amplitude,

[0046] According to the name of the tool, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com